Mounting method of embedded GRC boards

An installation method, mosaic technology, applied in the direction of architecture, building structure, etc., can solve the problem that it is difficult to ensure the effective connection between the GRC line and the supporting structure, the verticality of the pre-embedded steel bars and the distance from the side are difficult to ensure, and the cumulative error of the GRC panel installation is large. and other problems, to achieve the effect of simple structure, firm anchorage, and improved installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

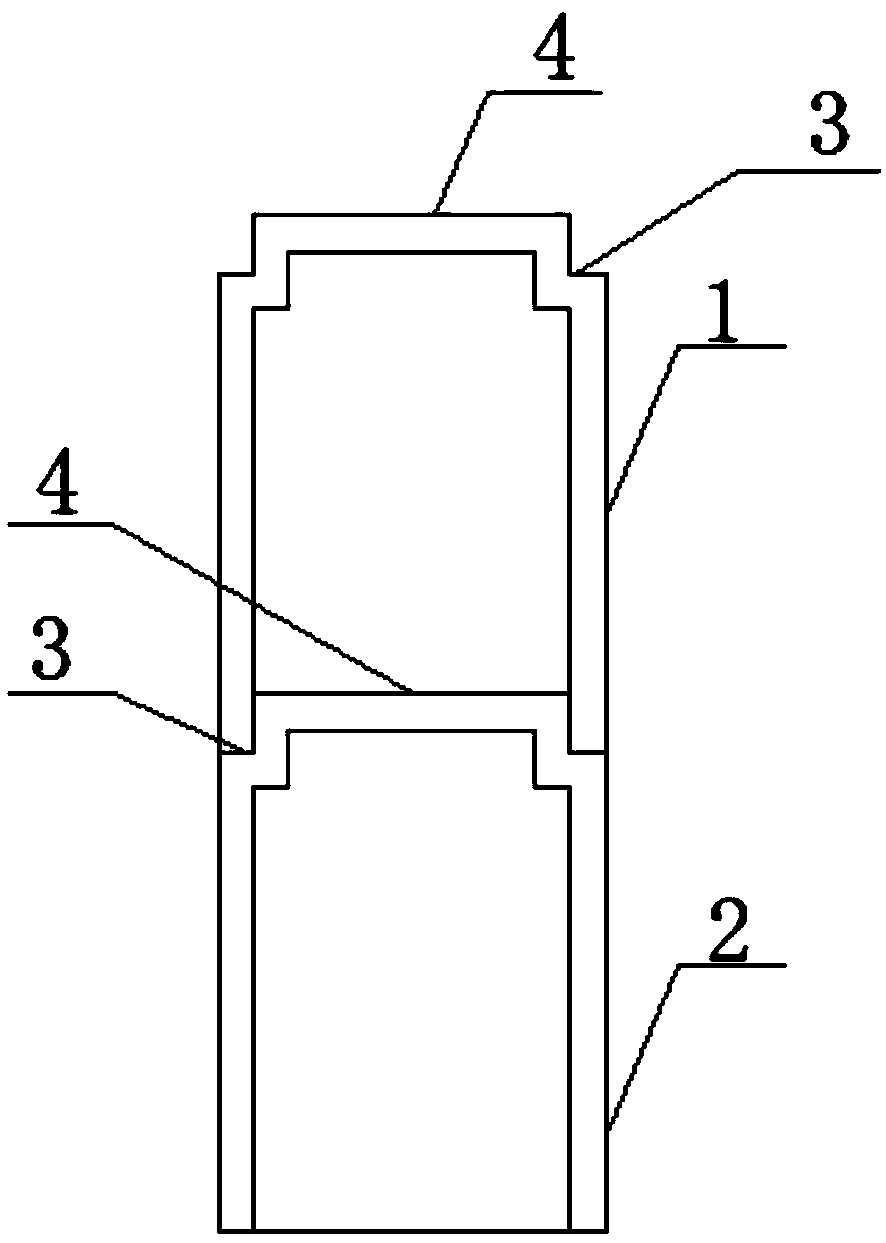

[0026] Concave-convex shapes are set at the joints of the two materials of the GRC line, so that the lower material can be completely embedded in the upper material.

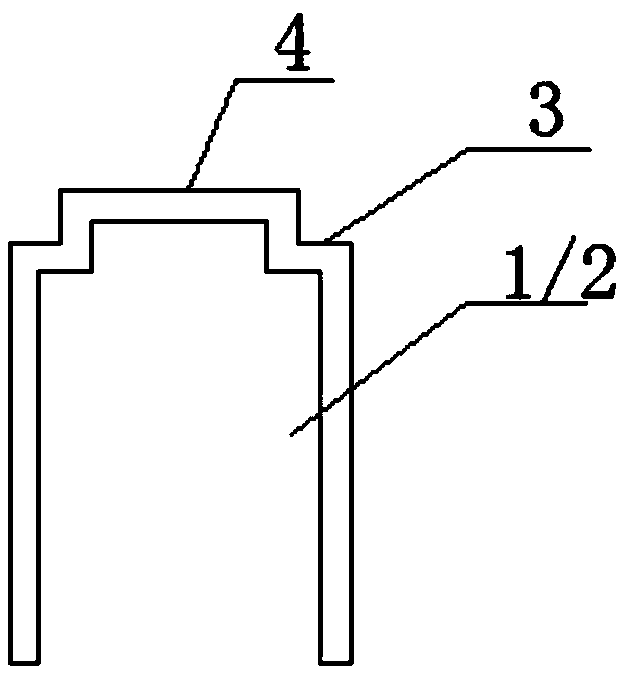

[0027] In the GRC concave-convex shape, the thickness of the left and right sides of the line is consistent with the thickness of the GRC surface layer, and the protruding part in the front is 3-5 cm

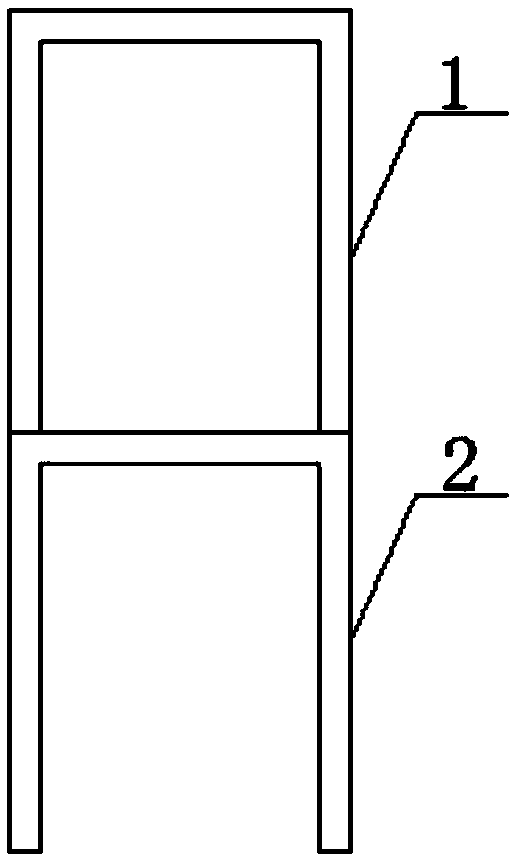

[0028] When the first GRC board 1 and the second GRC board 2 are produced, a concave part 3 on both sides and a convex part 4 on the upper side are respectively set on the material, so that the second GRC board 2 can be completely embedded in the first GRC board 1 .

[0029] In the concave parts 3 on both sides and the convex part 4 on the upper side, the thickness of the concave parts 3 on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com