Roof heat preservation system structure

A thermal insulation system and thermal insulation layer technology, which is applied to roofs, roof coverings, building roofs, etc., can solve the problems of large workload, many construction steps, and accelerated aging of thermal insulation materials, so as to improve and reduce time cost and economic cost Material waste and labor loss, and the effect of improving fireproof and waterproof functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

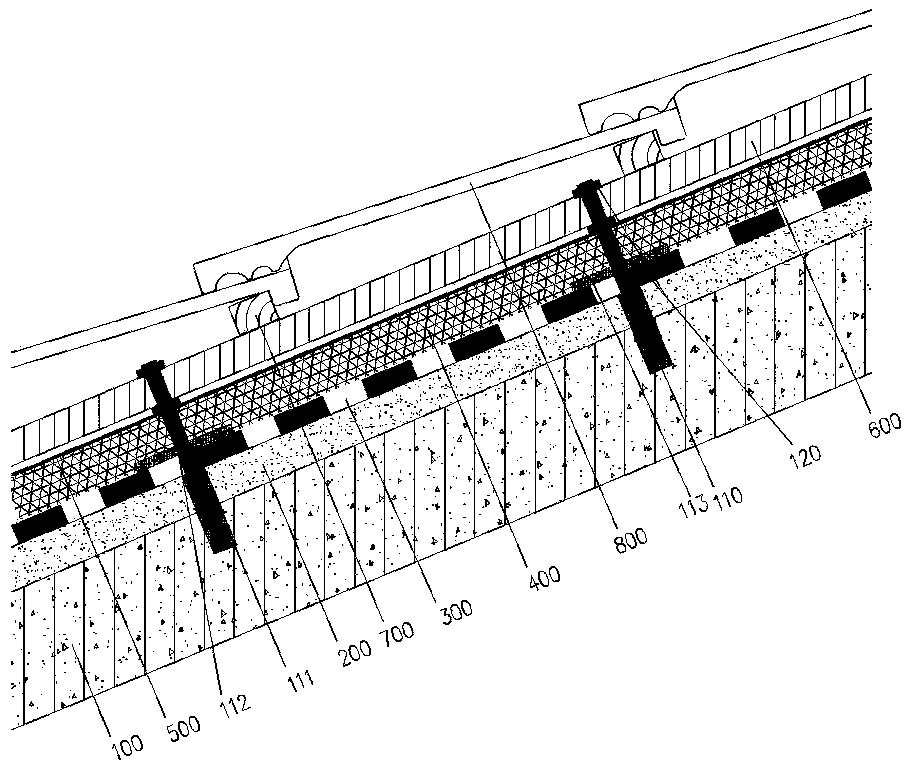

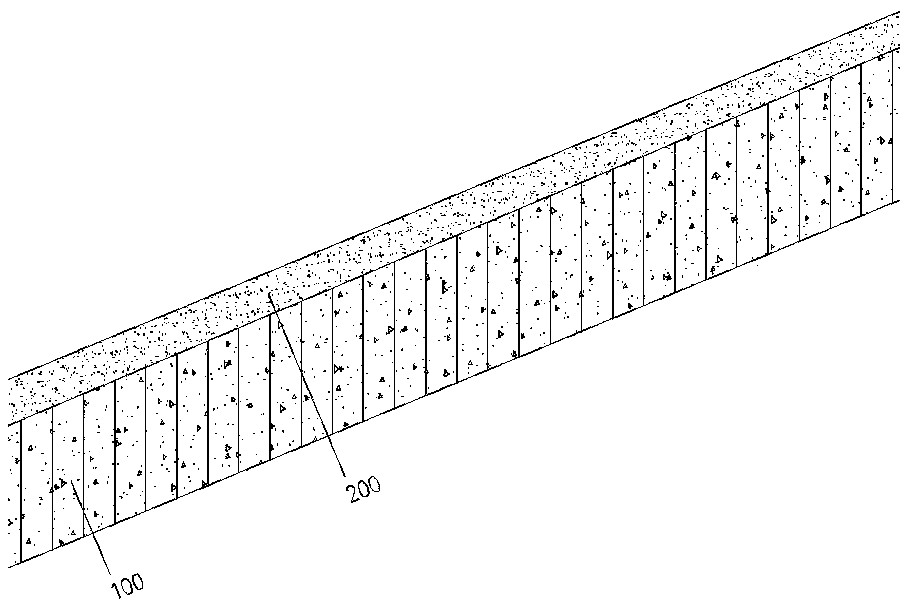

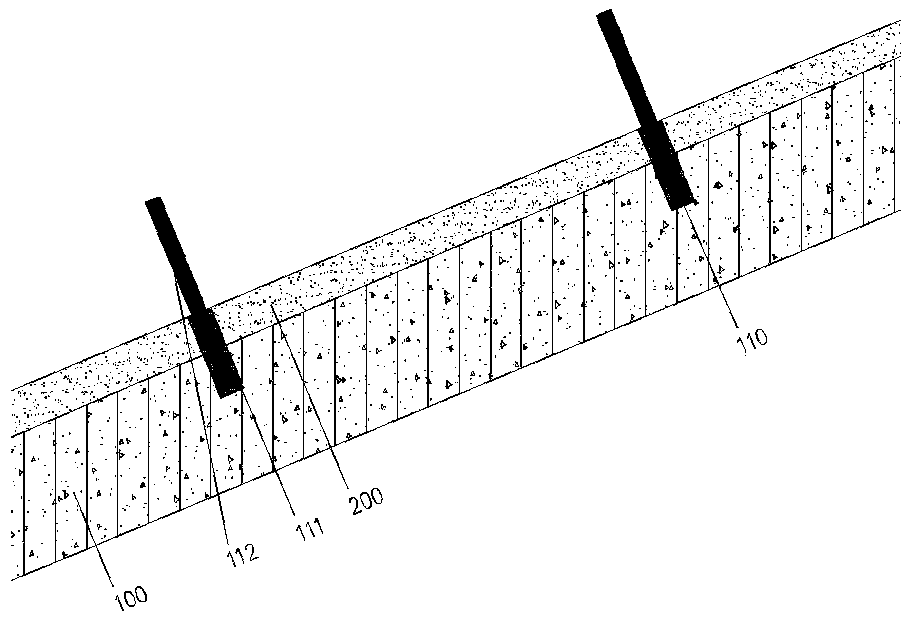

[0045] like figure 1 As shown, the roof insulation system structure of the present invention includes a reinforced concrete base layer 100 and a mortar leveling layer 200 laid on the reinforced concrete base layer 100. On the mortar leveling layer 200, a line planting bar 110, a waterproof layer 300, and a thermal insulation layer are sequentially arranged The layer 400, the protective layer 500 and the downstream strip 600, the tile hanging strip 700 is laid on the downstream strip 600, the roof tile 800 is hung on the hanging tile strip 700, and the downstream strip 600 is fixed on the protective layer 500 through the metal planting bar structure and leveled , the protective layer 500 is a mortar protective layer or a protective layer covered with an easy-to-roll material

[0046] like image 3 and Figure 7As shown, the metal planting bar structure includes a metal planting bar 110 and a fixing member 120. One end of the metal planting bar 110 is fixed on the reinforced c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com