Machine tool special for riveting globe joint

A special machine tool and ball joint technology, applied in the field of ball joint riveting and pressing special machine tools, can solve the problems of low production efficiency, product rework and maintenance, ball joint too loose, etc., to save production costs, improve production efficiency, and eliminate the effects of rework.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

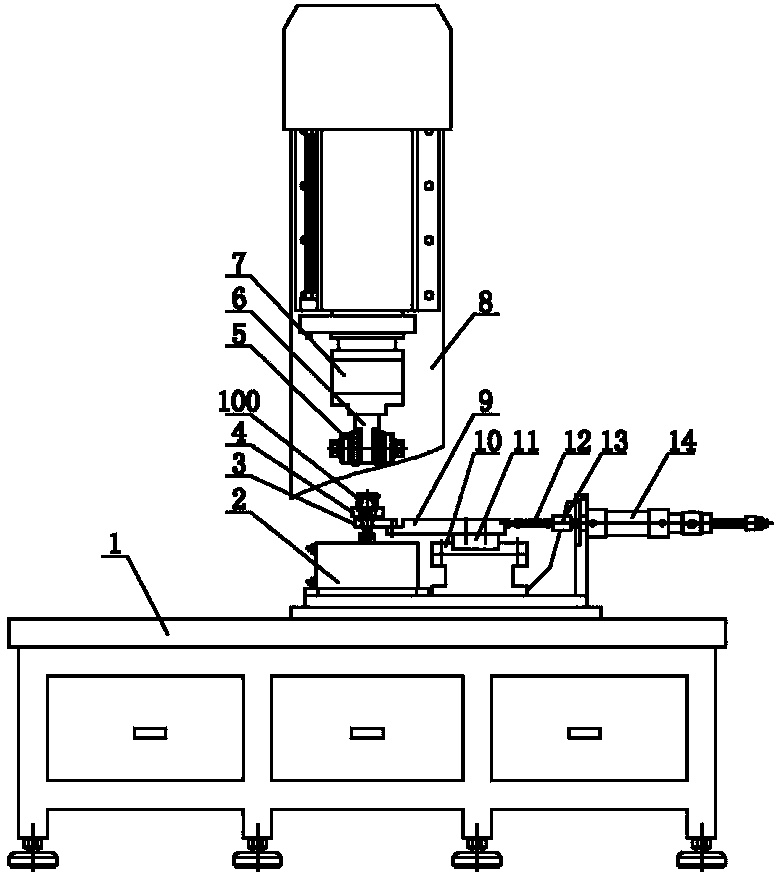

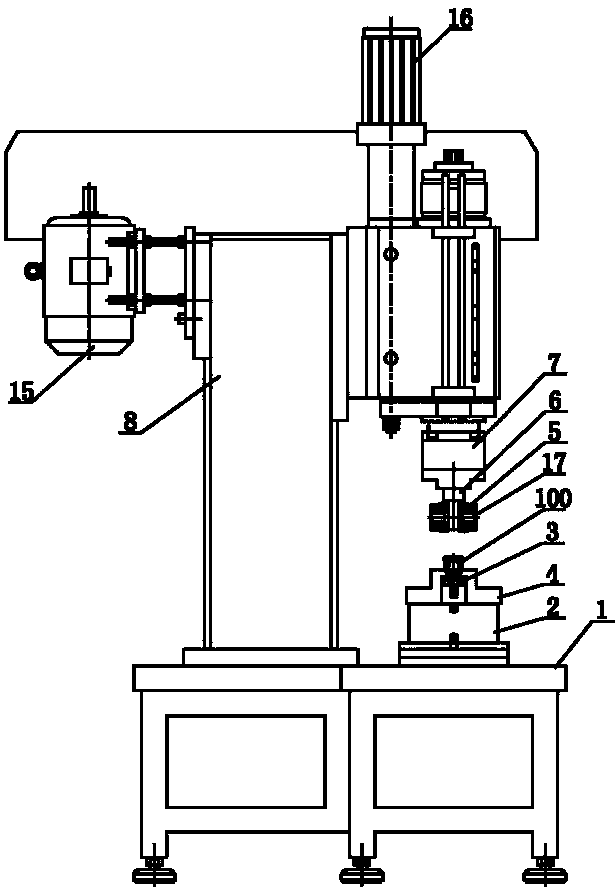

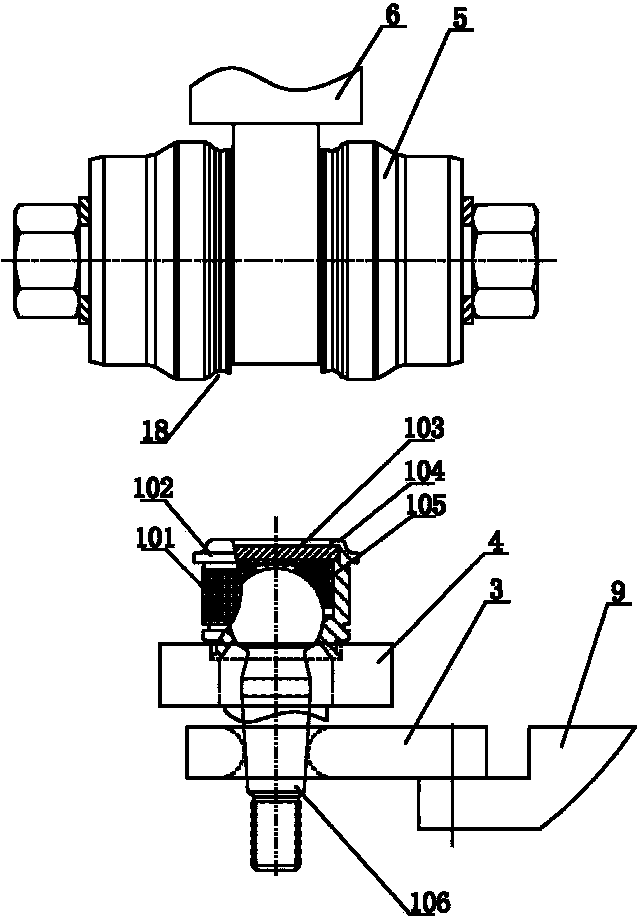

[0015] As shown in the figure, the ball joint riveting special machine tool of the present invention is used for the riveting assembly of ball joint products. The ball joint products include ball head rod 106, ball head seat 105, backing plate 103, shell 101 and upper cover 102, The ball head of the ball head rod 106, the ball head seat 105 and the backing plate 103 are located in the inner hole of the shell 101, the upper cover 102 is connected to the upper opening of the shell 101, and the upper cover 102 is riveted to form an upper cover riveting edge 104, and the upper cover is riveted Crimping 104 defines the head of ball head shaft 106 , head seat 105 and backing plate 103 within housing 101 . The special machine tool for ball joint riveting of the present invention includes installation 4, riveting head 5, power head 7, servo motor 16 and torque detection device, and the mounting seat 4 is arranged on the horizontal machine body 1 for ball joint workpiece 100. Installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com