Digital-bus-based bracket and tray assembly capable of supplying materials circularly

A digital bus and pallet technology, applied in the field of intelligent logistics and transportation equipment, can solve the problems of cycle lengthening, efficiency reduction, and time-consuming listing and dismantling, etc., to achieve high supply efficiency, ensure production progress, and realize the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

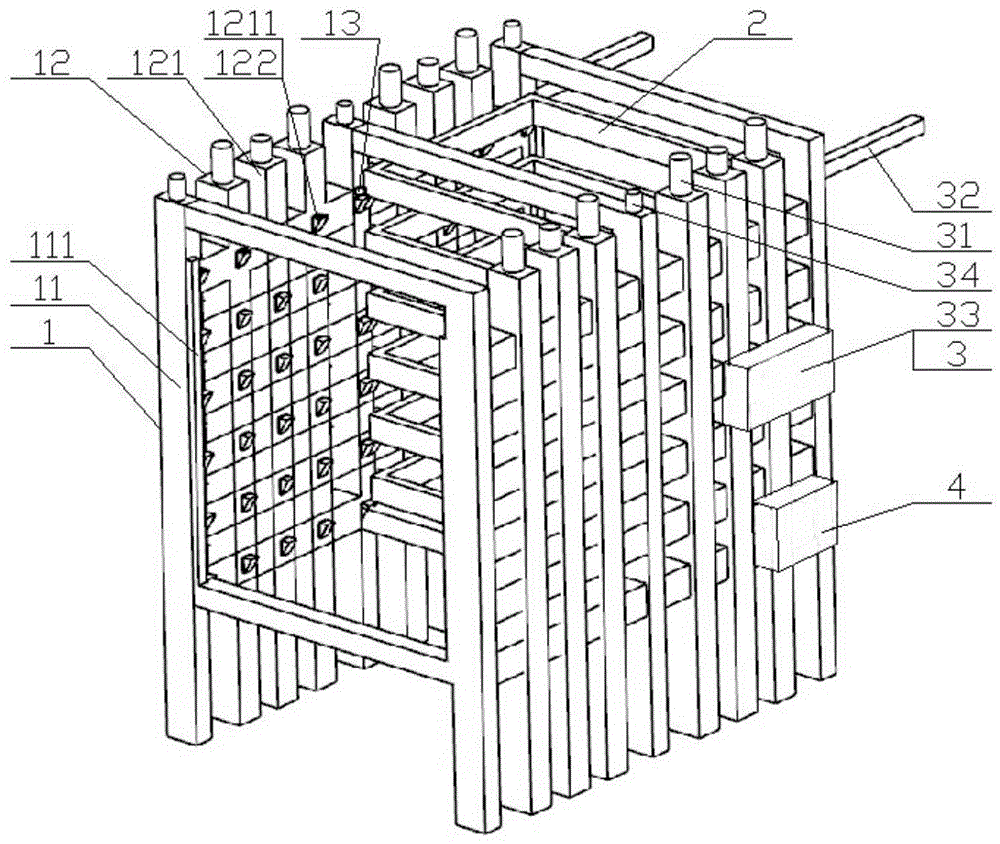

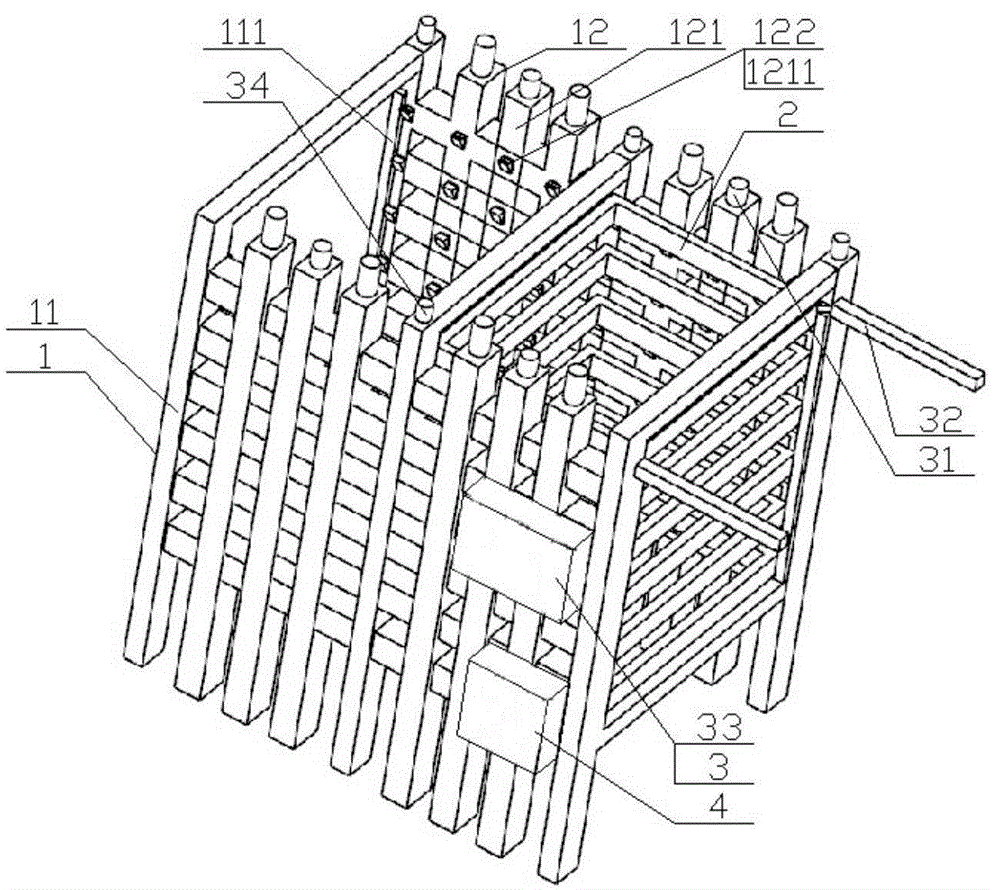

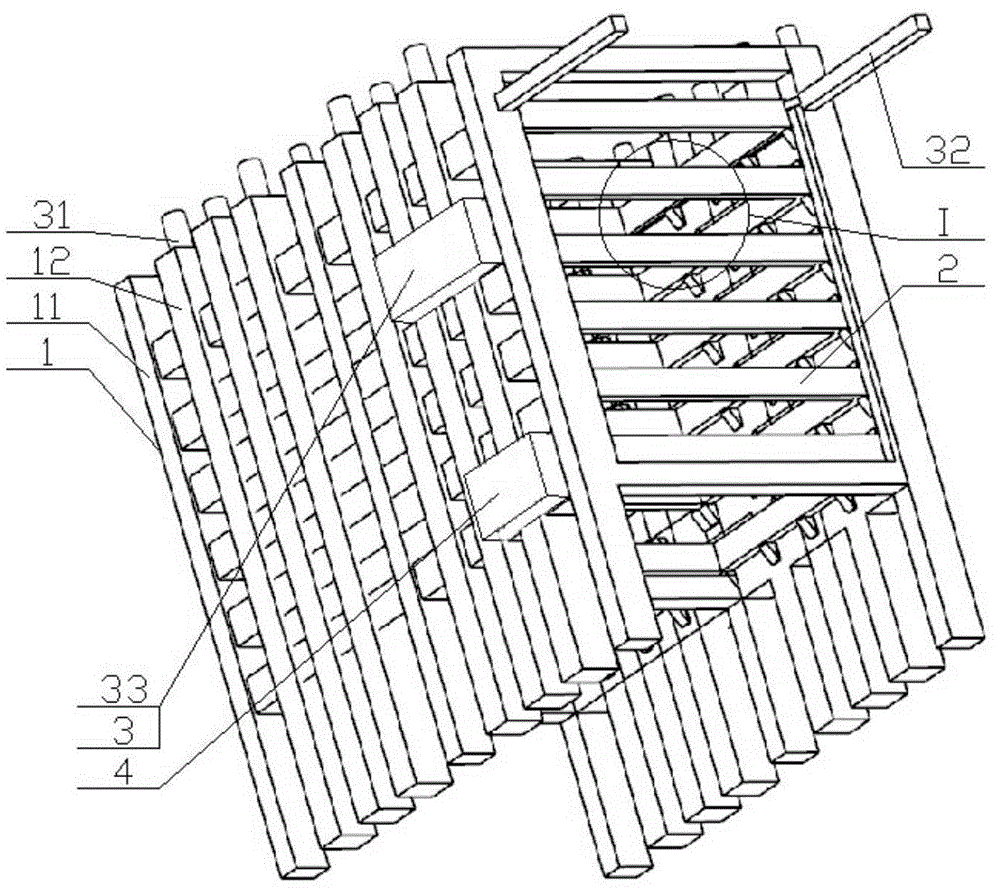

[0025] Below in conjunction with accompanying drawing, the present invention will be further described (for the ease of seeing figure explanation, Figure 1 to Figure 4 The bottom plate of the frame body 11 and the tray bottom plate of the tray 2 are not shown).

[0026] Such as Figure 1 to Figure 3 As shown, the bracket and tray of the circulation supply material based on the digital bus include a multi-layer bracket 1 , a tray 2 , a power unit 3 and an electric control unit 4 .

[0027] The multi-layer bracket 1 includes a frame body 11 and a tray support mechanism 12. The frame body 11 is a rectangular frame structure, and its interior is provided with two interconnected accommodation chambers along its length direction. The interior of the frame body 11 is along its length. Limiting plates 111 are provided at both ends of the length direction;

[0028] The tray support mechanism 12 is symmetrically arranged on the left and right along the length direction of the frame b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com