Activation furnace for producing and reproducing activation block absorbent charcoal

A technology for regeneration and activation of activated carbon, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as easy scattering, inconvenient use, and limited application range, so as to ensure production progress, improve effect, and ensure product activation quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

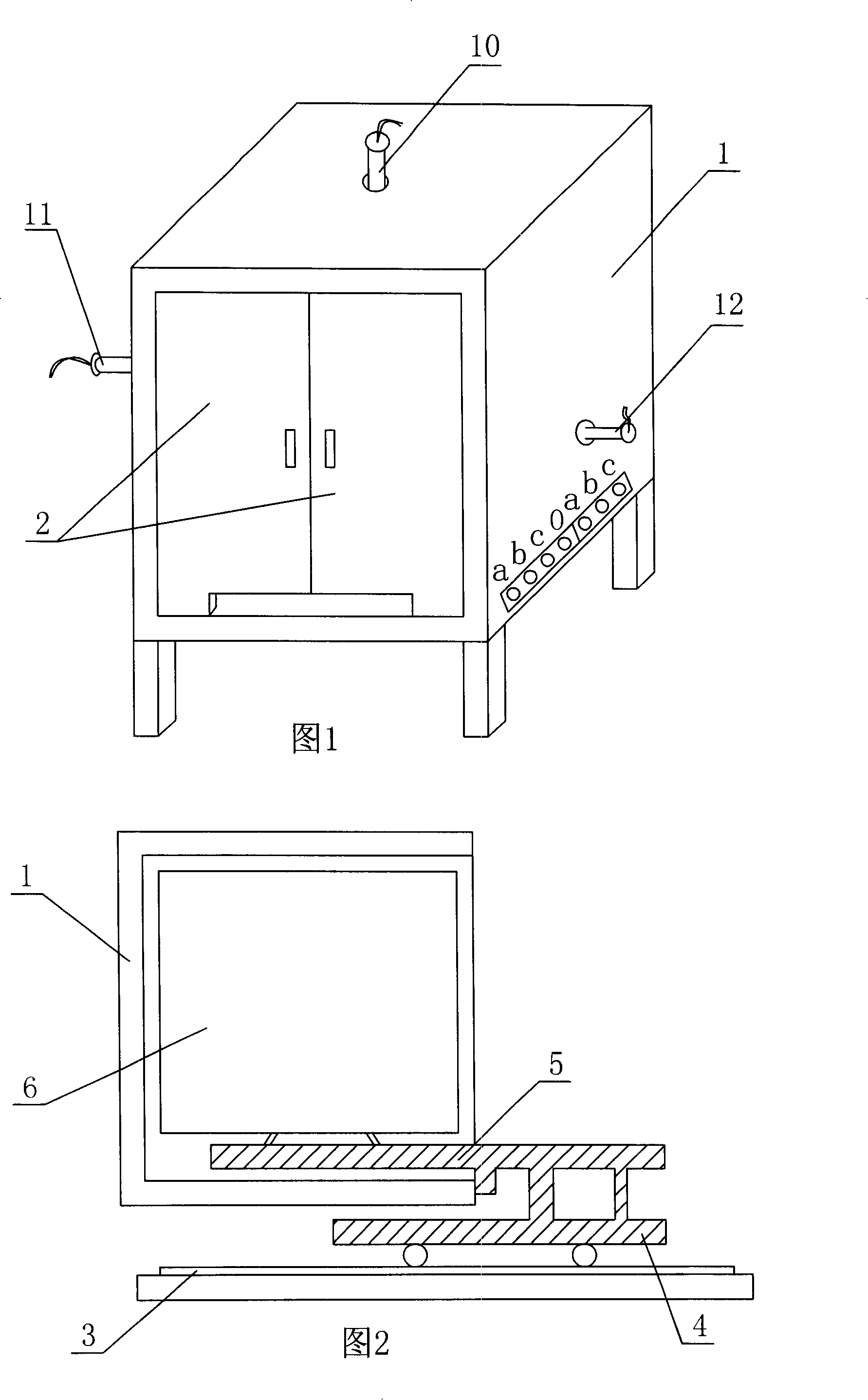

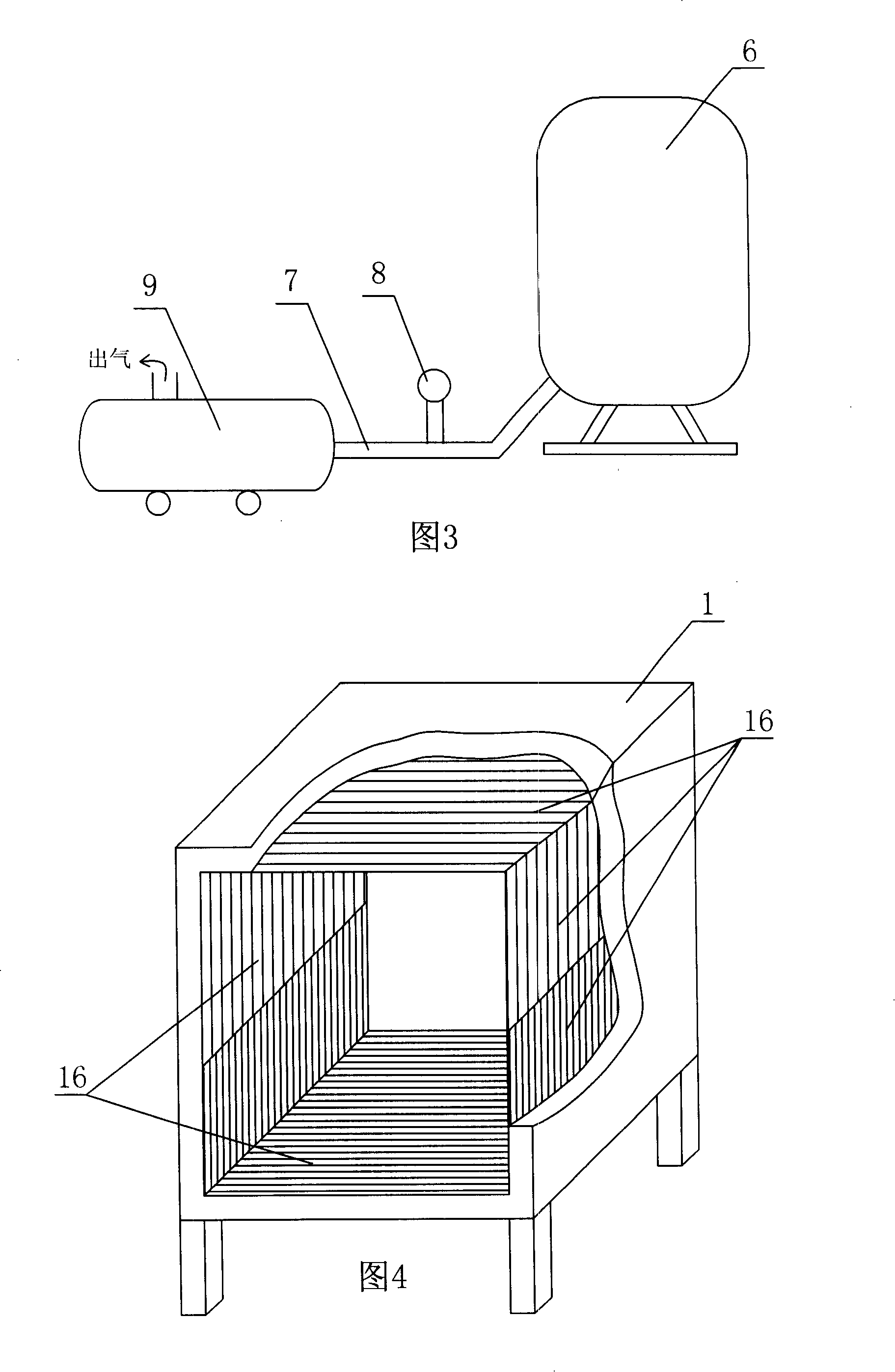

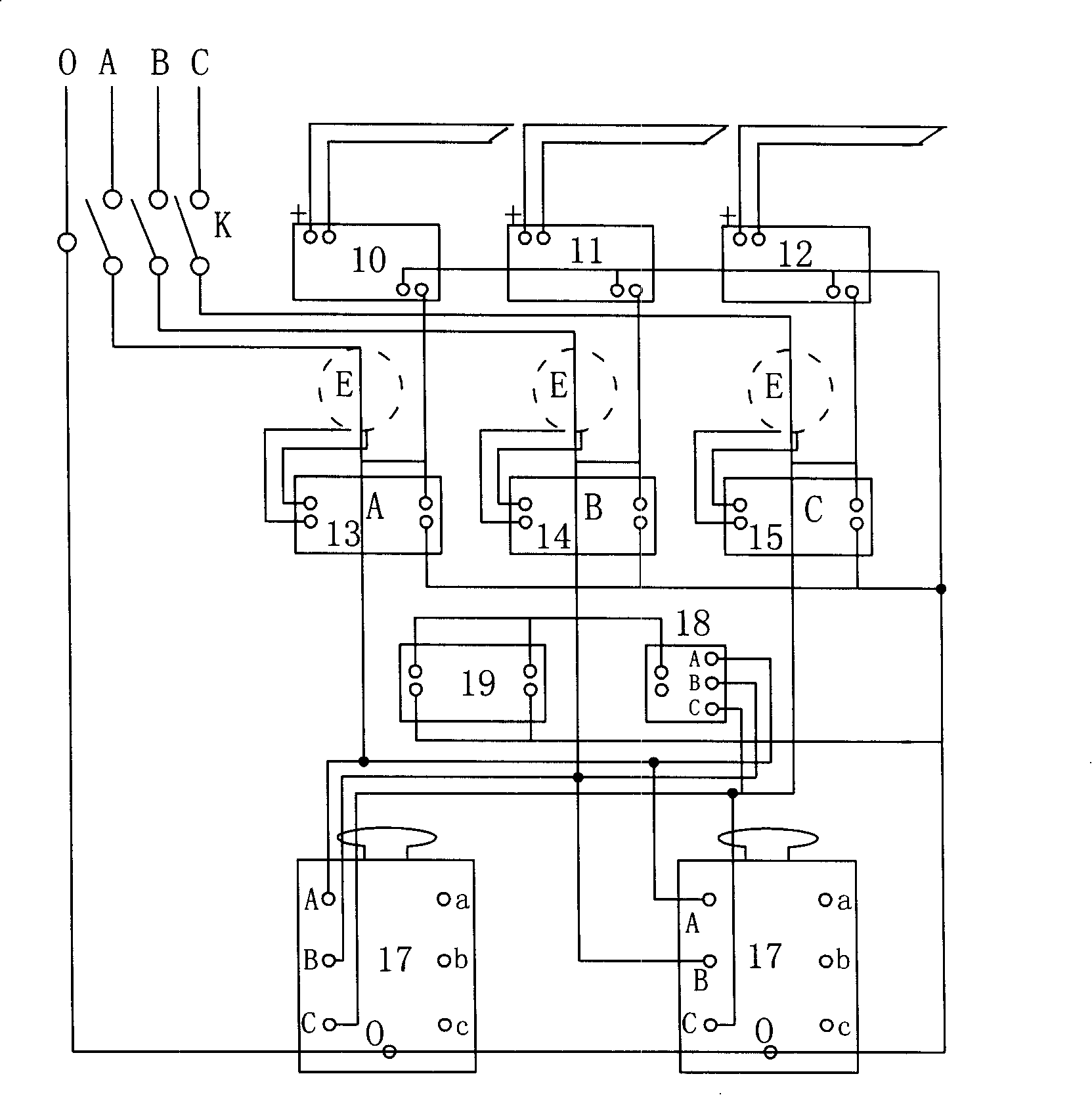

[0025] As shown in Figure 1, the activation furnace of the present invention has a closed furnace body 1 with a furnace door 2 at the front. The inner cavity volume of the furnace body 1 is greater than 1.5 cubic meters. , the outer surface of the brick is pasted with an asbestos insulation layer for heating and heat preservation; The upper bracket 5 is provided with a sealed metal (such as stainless steel) container 6 with a sealed door on the bracket 5, and the container is communicated with the suction port of the vacuum pump 9 outside the furnace body 1 and the vacuum gauge 8 through the connecting pipe 7 (see Fig. 3); As shown in Fig. 1, the temperature sensor 10,11,12 that measures the corresponding position temperature in the furnace body 1 top and one side upper part, the other side lower part is equipped with respectively, and its signal line is respectively the same as corresponding digital Temperature display 13, 14, 15 connections (see Figure 5 ), the top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com