Production schedule prediction method and system based on data mining

A technology of production schedule, forecasting method, applied in the field of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

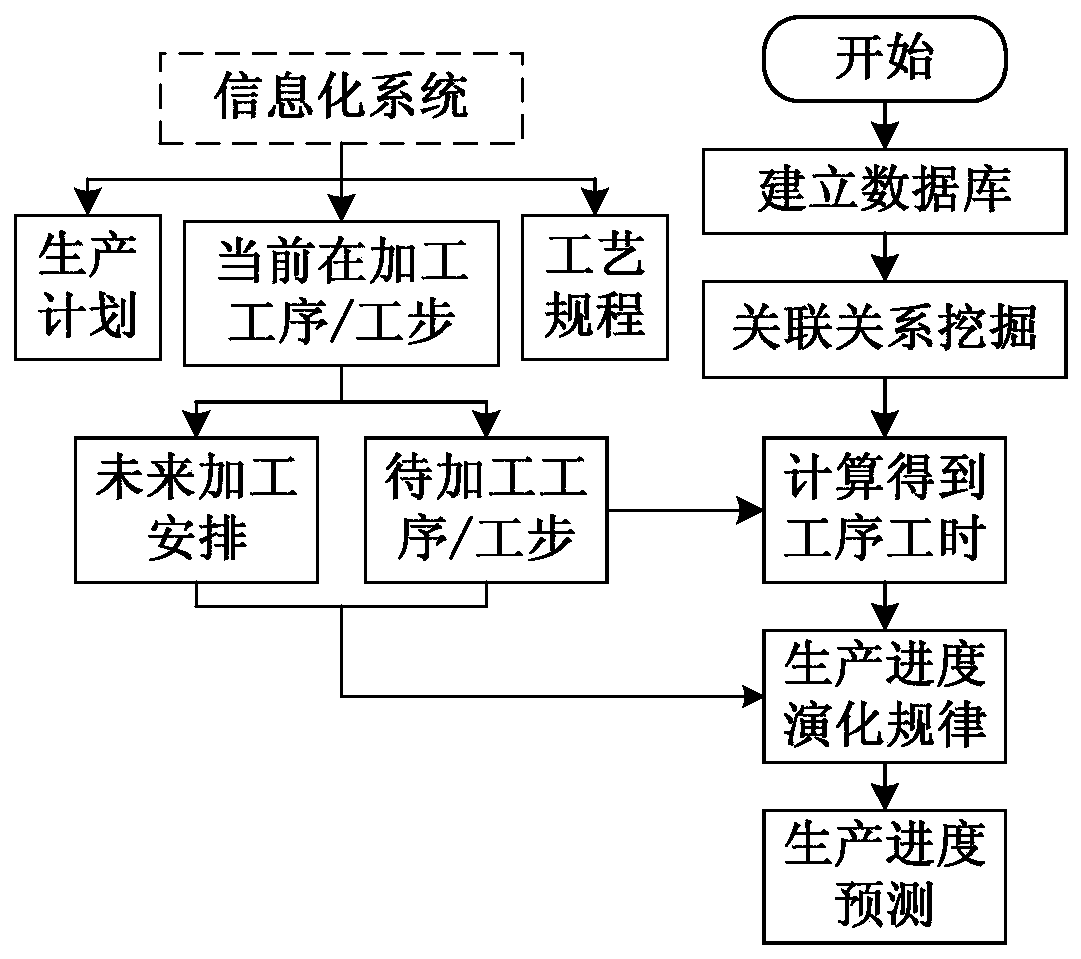

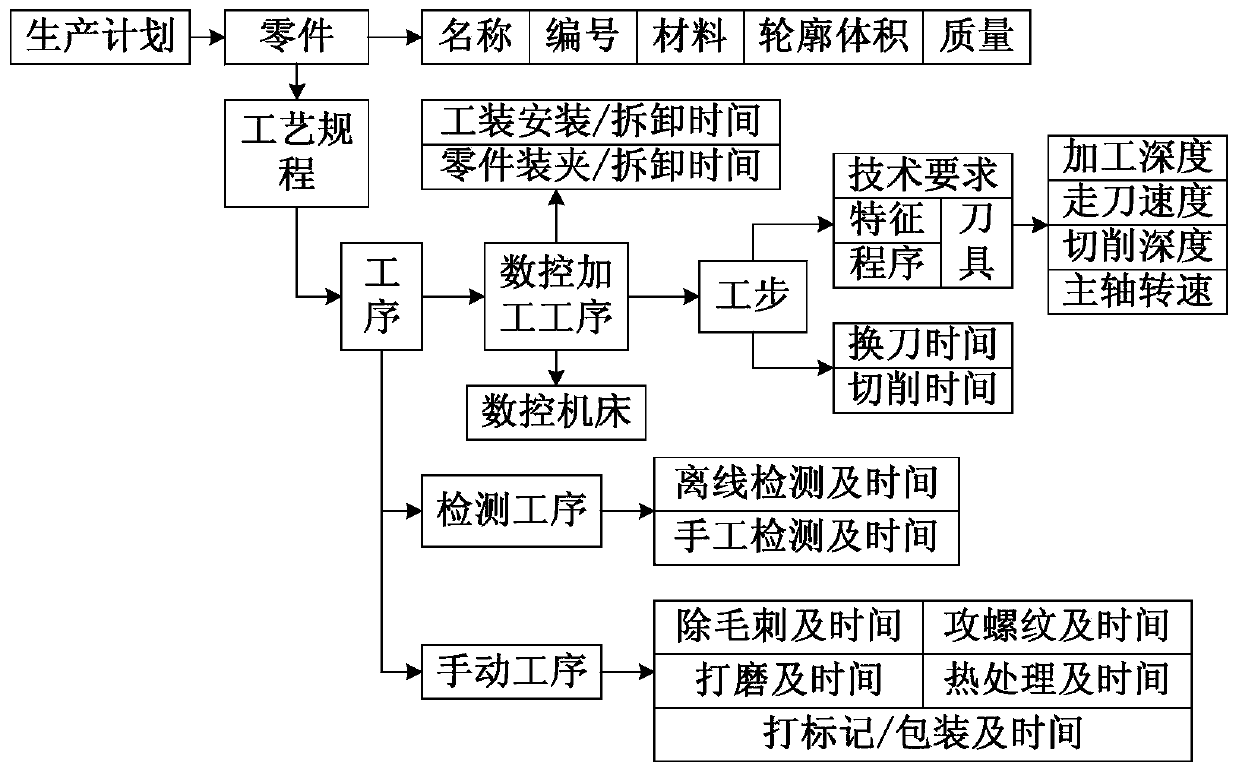

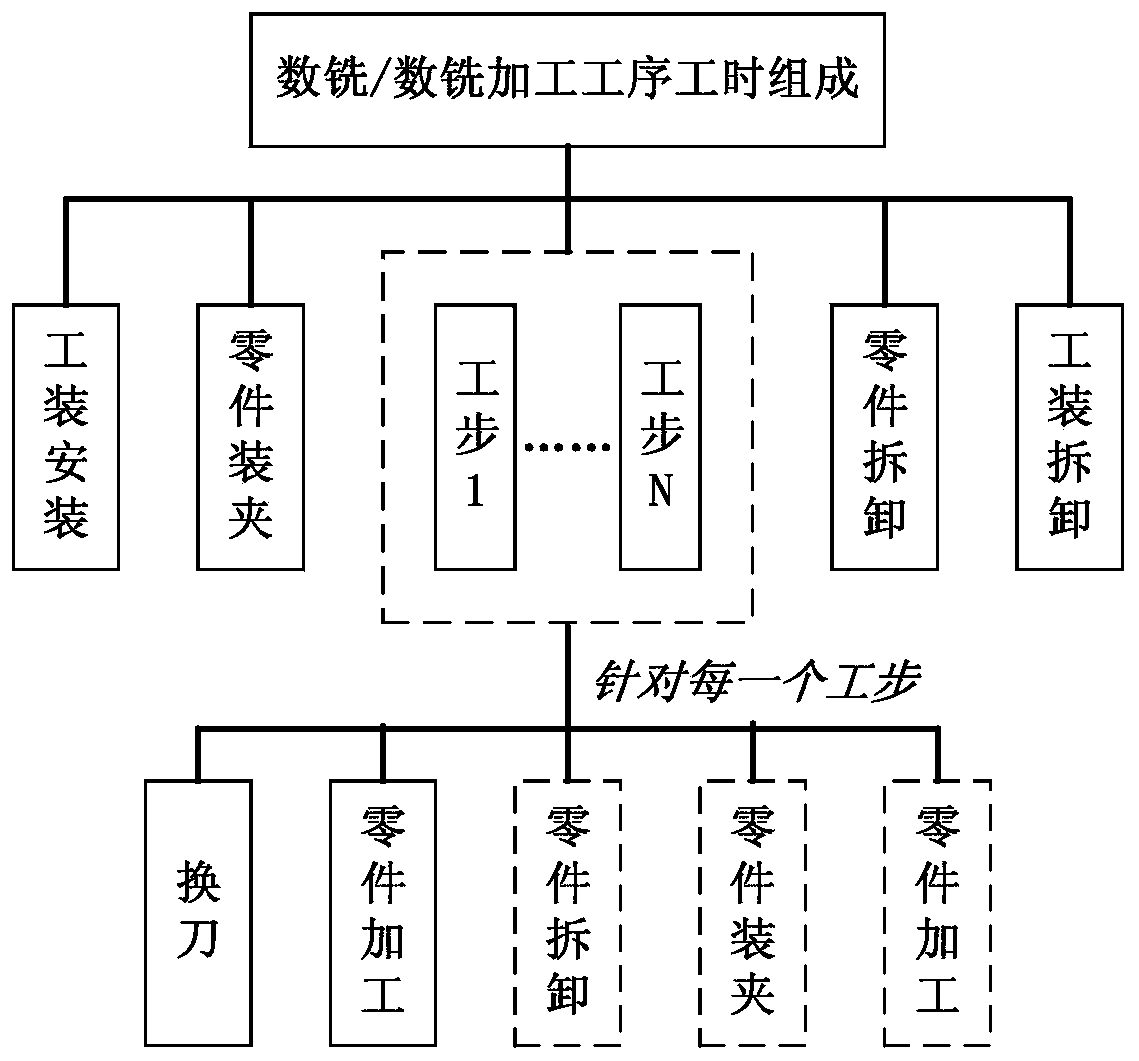

[0042] The production schedule forecast needs to be based on the machining time to predict the start and end processing time of each part in the machining workshop, and the machining time is currently mainly carried out through mathematical model methods, simulation methods, feature reasoning methods, and neural network methods. However, these methods are mainly for large-scale batch production, and cannot be applied to satellite products with multi-variety and small-batch characteristics. On the basis of fully referring to previous research results, the present invention proposes a satellite-oriented product-oriented machining workshop production progress prediction method based on data mining, obtains the relevant influencing factors of man-hour calculation through historical data mining, and integrates the current processing status of all parts in the workshop , to predict the production progress, and provide reference for the subsequent scientific formulation of production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com