Air vane torsion lever processing technology

A processing technology and air rudder technology, applied in the field of mechanical processing science, can solve the problems of increasing the production cost of the manufacturer, low qualification rate, affecting the production progress and delivery nodes of the product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

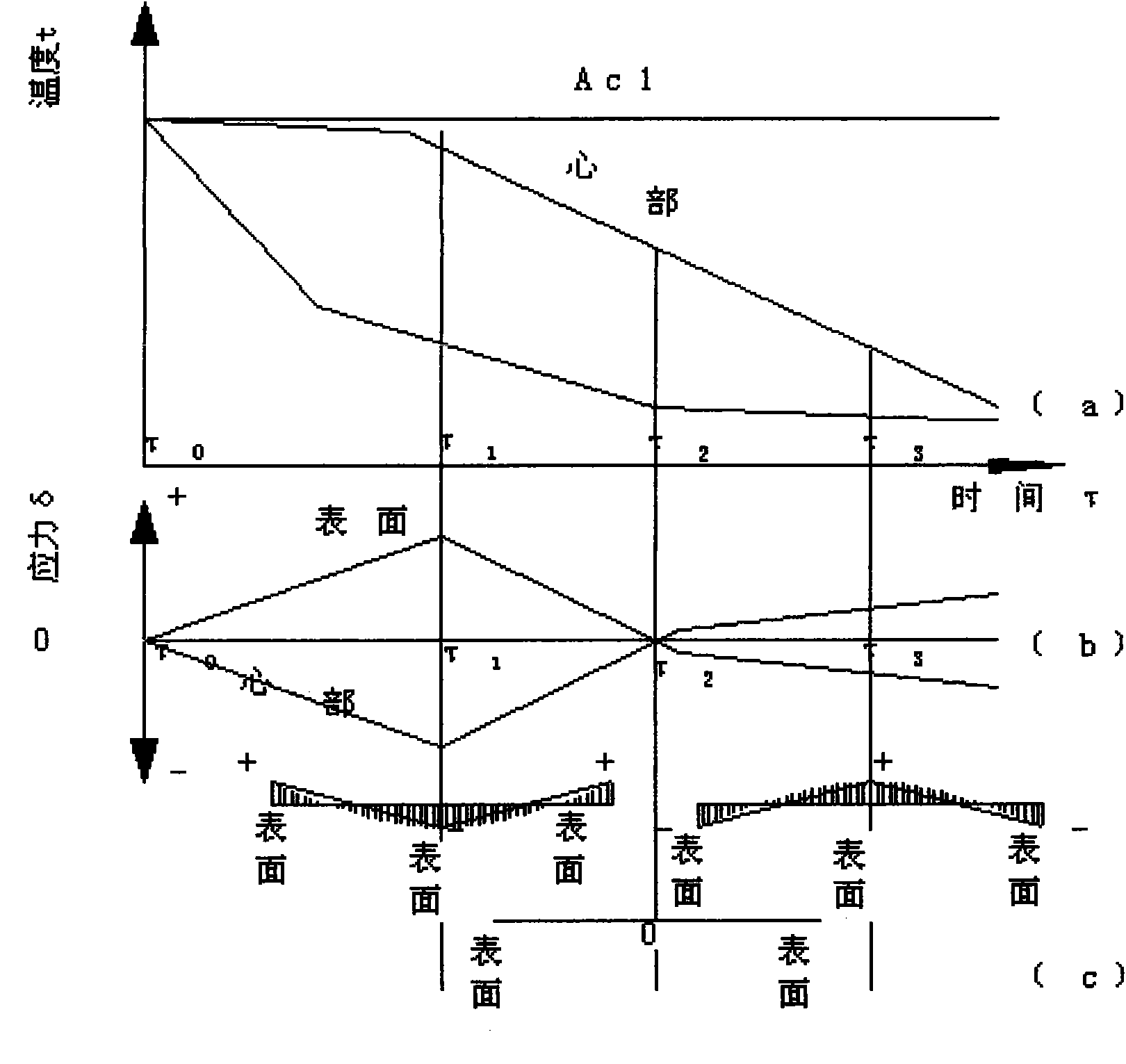

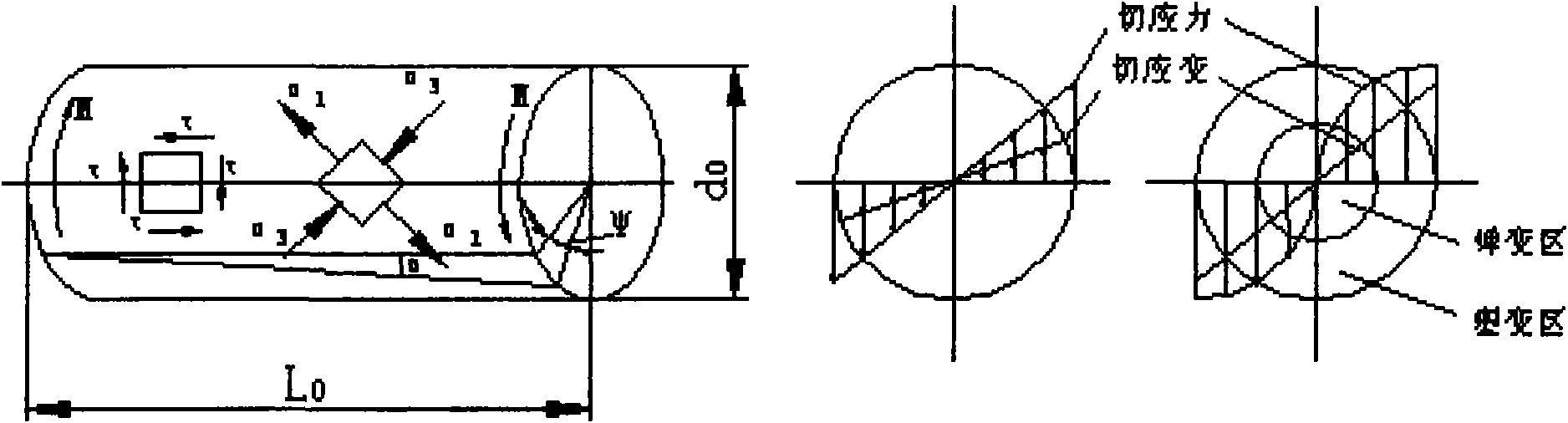

[0067] An air rudder torsion bar processing process, the production process of the torsion bar is: mechanical processing->heat treatment->heating and loading->magnetic particle inspection->wire cutting->mechanical processing->surface treatment->angle inspection->endurance test -> Angle inspection -> Delivery and storage; the working environment temperature of the processing is not lower than 25°C. In the heating and loading step, the torsion bar is twisted 90 degrees on the tooling and then fixed. The temperature of the workpiece entering the furnace must not exceed 30°C. Heating up; keep it at 110-120°C for 2-3 hours and then do not release it immediately. After the furnace drops to 25-30°C, unload the workpiece after the furnace is released to restore the torsion bar to its original shape, and then re-twist the torsion bar by 90 degrees to install and fix it. , enter the furnace and heat up to 110-120 ℃ for 1.5-2 hours, the product is not released immediately, after the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com