Method for repairing DAD-40 conductive adhesive bonding product

A DAD-40, conductive adhesive technology, used in conductive adhesives, electrical components to assemble printed circuits, etc., can solve problems such as inability to guarantee product quality, scrap, and inability to disassemble and disassemble, to ensure delivery progress and huge economic benefits. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

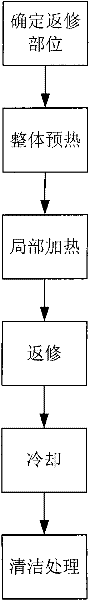

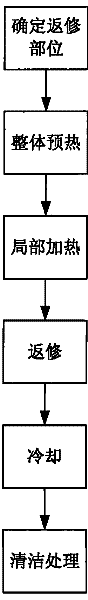

Image

Examples

Embodiment Construction

[0017] In order to ensure the smooth progress of the batch production of microwave products, improve the qualified rate of repair of DAD-40 conductive adhesive products, and combine the inherent characteristics of various product structures, it has become a production task to repair the common faults of conductive adhesive products. One of the bottlenecks to be completed on schedule is to conduct a technological exploration test to determine a safe and economical process that ensures that the repaired product will not be damaged for reference to similar products.

[0018] 1. Analysis

[0019] The parts where the product uses conductive adhesive are mainly the conductive bonding between the shell and the metal parts and the metal layer of the printed circuit board, as well as the point-solid bonding of the product debugging and adjustment parts. In view of the actual problem of a large number of scrapped products in the rework of conductive adhesive bonding products, combined w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com