A method for controlling coaxiality between parts and components

A control method and coaxiality technology, applied in the control field of coaxiality between components, can solve the problems of poor product performance, product failure, poor rotation flexibility of components, etc., to achieve high tool durability and dimensional consistency Good, good rotation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for limiting the present invention.

[0038] Example. A method for controlling the coaxiality between parts and components, consisting of Figure 1-7 shown, including the following steps:

[0039] (1) Machining process:

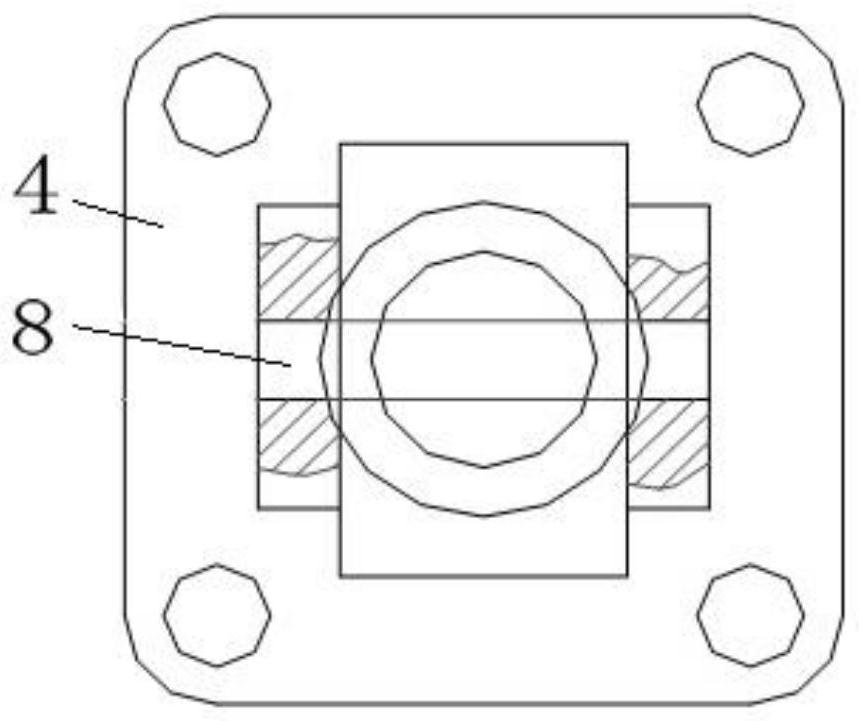

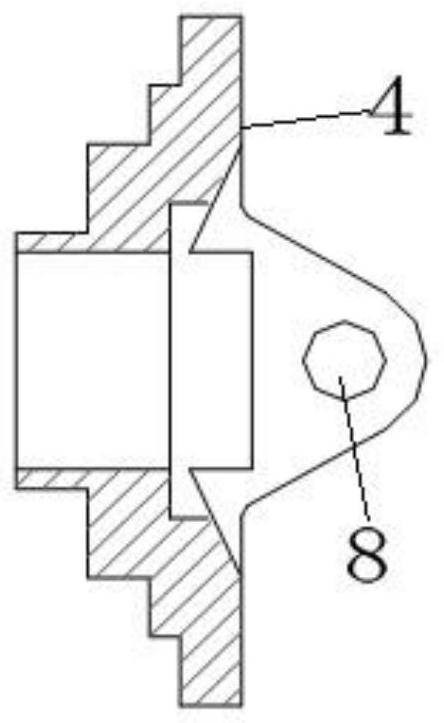

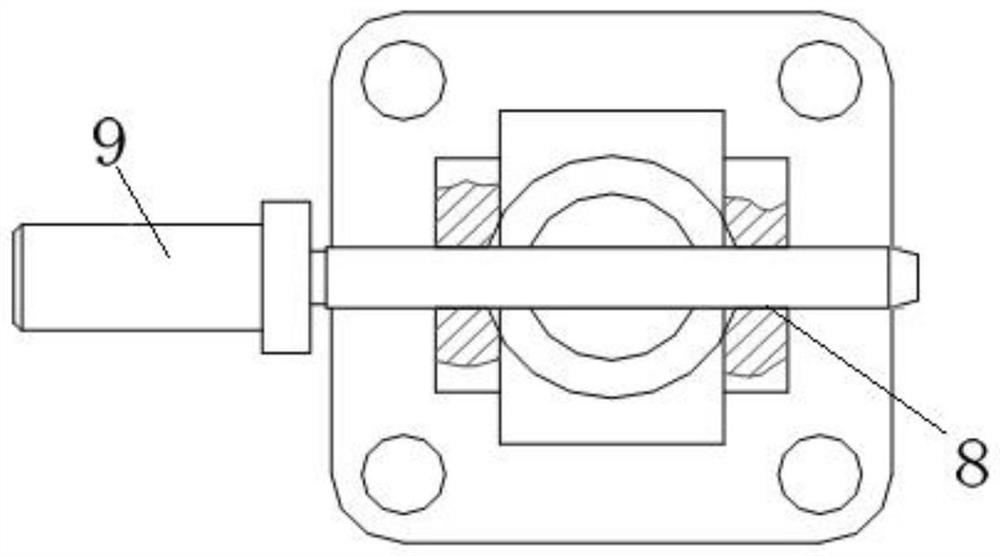

[0040] 1.1 Use the 2 ΦA holes 8 on the reamer bracket 4 of the long-bladed hard alloy reamer with end teeth;

[0041] 1.2 Use the extended grinding sleeve to grind the hole or the extended honing bar to honing the two ΦA holes 8 on the bracket 4;

[0042] 1.3 Use the first coaxiality mandrel 9 to measure the coaxiality between the two ΦA holes 8 on the bracket 4;

[0043] (2) Welding process:

[0044] 2.1 Put the open retaining ring 6 and the bearing 5 into the bearing hole of the rocker arm 1 to form a rocker arm assembly;

[0045] 2.2 Use the second coaxiality mandrel 10 to penetrate the rocker arm a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com