Automatic detection device for material shortage of hopper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is further described in detail through specific implementation methods:

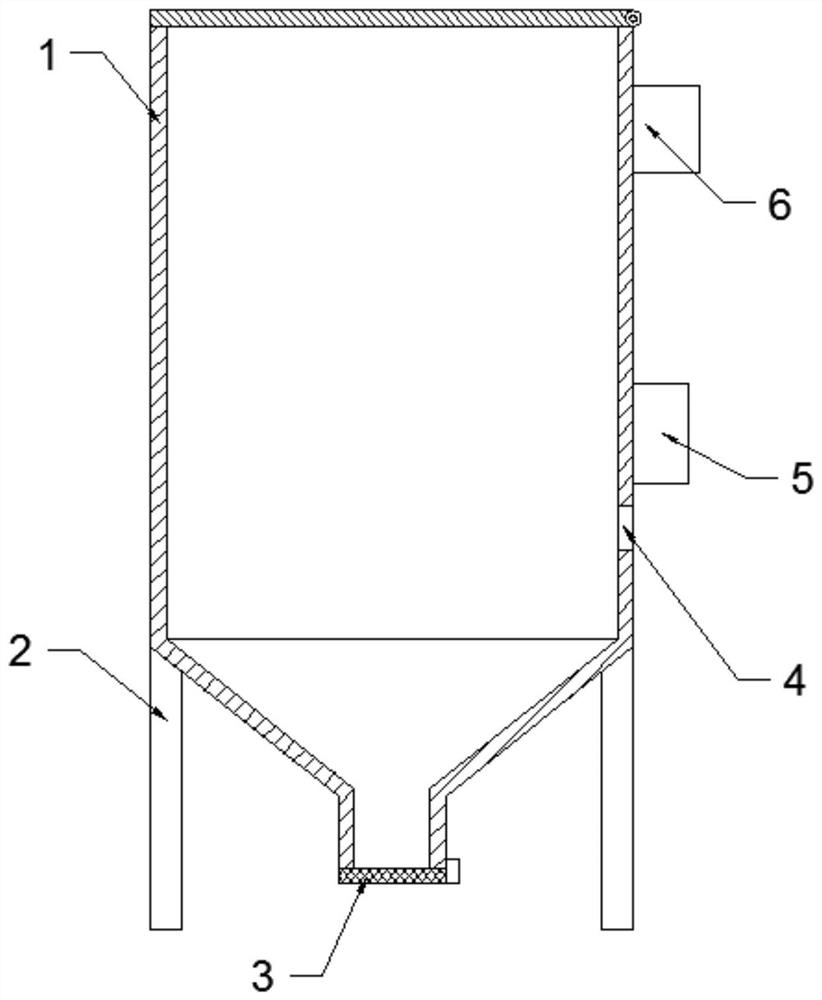

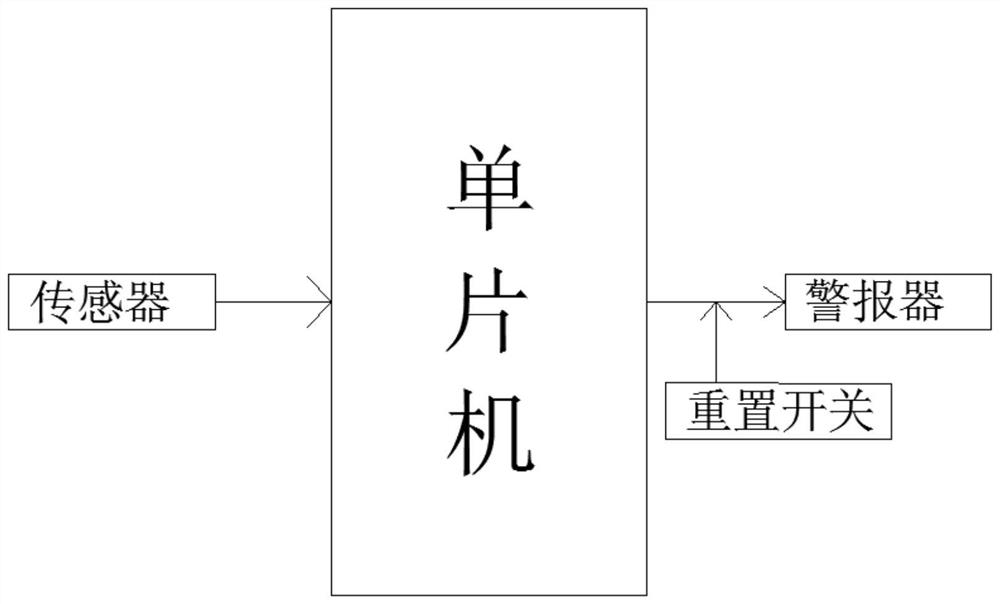

[0015] The reference numerals in the accompanying drawings of the description include: hopper 1 , fixed bracket 2 , solenoid valve 3 , sensor 4 , controller 5 , and alarm 6 .

[0016] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0017] An automatic alarm device for lack of material in a hopper, comprising a hopper 1 and an alarm system, the bottom of the hopper 1 is fixedly connected with a fixed bracket 2, the hopper 1 is provided with a detection hole, and the detection hole is 3 to 10 cm (preferably 5 cm) away from the bottom of the hopper 1, so that After the lack of raw materials in the hopper 1, the operator will have more reaction time for adding raw materials to the hopper 1), the bottom of the hopper 1 is provided with a solenoid valve 3, and the solenoid valve 3 is connected to the controller 5 for electrical signals. The alarm system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com