Polyester fiber dyeing process dyestuff consumption supervision software product and software method

A technology of polyester fiber and software products, applied in the field of polyester fiber dyeing and chemical supervision, to avoid inventory backlog, reduce inventory capital occupation, and improve the automation level of production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

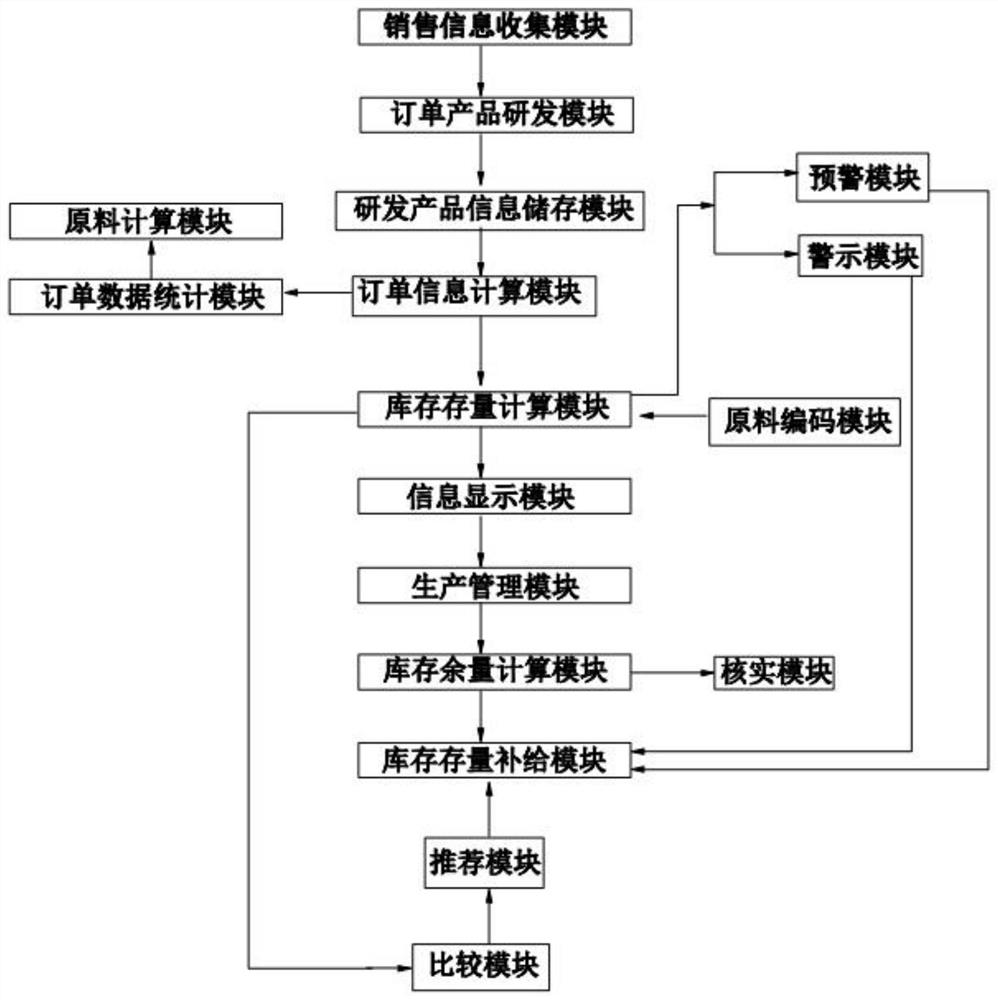

[0041] Such as figure 1 As shown, the polyester fiber dyeing process dyeing and chemical consumption supervision software products include,

[0042] Sales information collection module, input sales order information and store sales order sales information;

[0043] The order product research and development module analyzes the required polyester fiber types, specifications, and required dyeing materials according to the sales order products, and issues the research and development material acquisition information of the polyester fibers and dyeing materials required for research and development;

[0044] Research and develop the product information storage module, analyze the required polyester fiber type, specification, and required dyeing material type according to the sales order product, and store the polyester fiber type, specification,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com