Lithium battery feeding dust removal system and dust removal method

A dust removal system and lithium battery technology, applied in chemical instruments and methods, dissolution, mixers, etc., can solve problems affecting production progress, uneven feeding, easy congestion of raw materials, etc., to prevent congestion, improve uniformity, The effect of convenient mixing control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

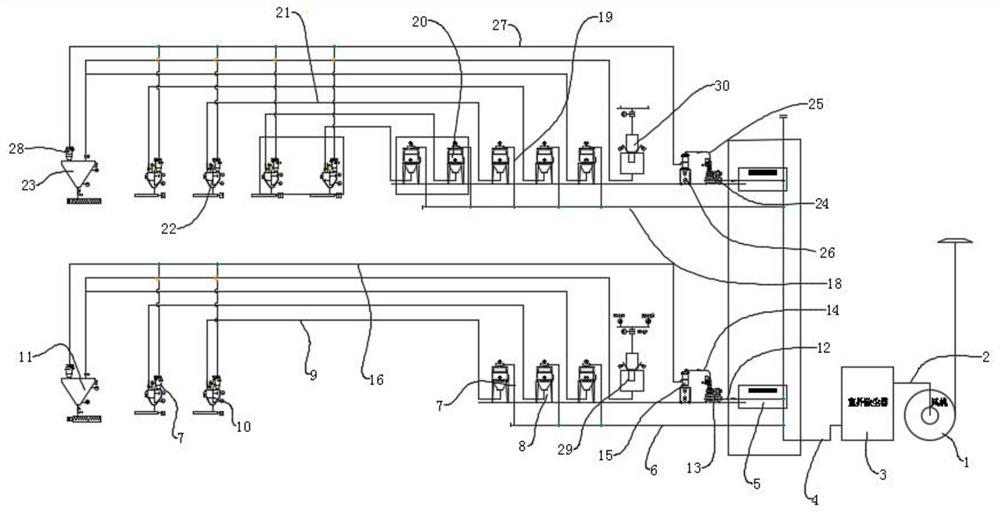

[0036] The present invention also provides a lithium battery feeding and dedusting method, comprising the following steps:

[0037] S1, start the fan 1, and the fan 1 blows the air flow into the outdoor dust collector 3 through the first air path 2;

[0038] S2. The airflow passing through the first airway 2 is blown into the second airway 4, and the airflow in the second airway 4 is dedusted by the external dust collector 5 of Party A, and then blown out after being pressurized by the first high-pressure fan 131, and then passed through the first online The filter 15 filters and blows the airflow into the first pressure controller 17 through the sixth branch 16, and uses the first pressure controller 17 to control the first metering bin 10 and the main material bin to be in negative pressure, so as to speed up the first metering bin. 10 and the material flow rate in the first main material silo 11;

[0039] S3. The airflow passing through the first airway 2 is blown into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com