Multi-aperture ceramic microbead grinding and machining device

A technology of ceramic microbeads and grinding processing, which is applied in the direction of grinding devices, grinding tools, grinding machine tools, etc., and can solve the problem of single operation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

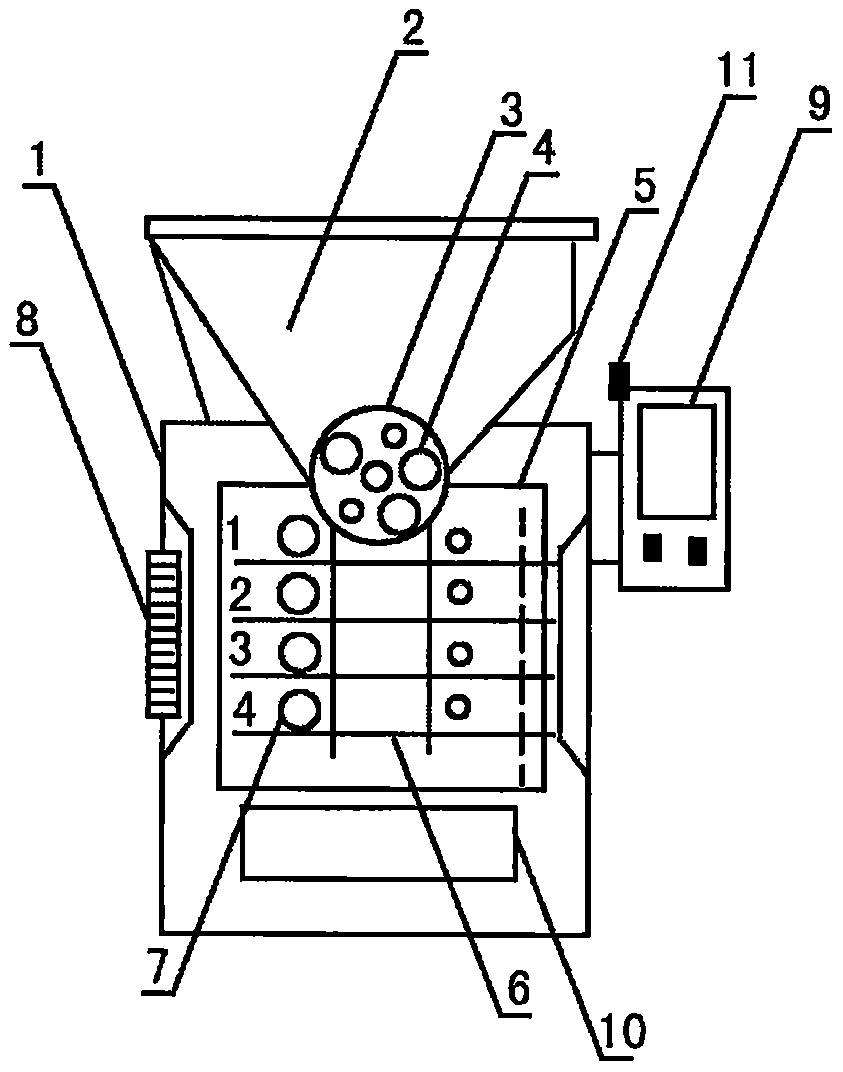

[0012] Embodiment: as shown in the accompanying drawing. A multi-aperture ceramic microbead grinding and processing device, comprising a body (1), a feed port (2), a rotating sieving disc (3), a multi-aperture hole structure (4), and a grinding ball The components are located in the middle and lower part of the body (1), including a cylindrical storage device (5), a multi-stage grinding frame (6), and a ball groove (7). The individual differences of the microbeads sort the apertures of the sieve disc (3) from small to large, and then fall into the corresponding ball groove (7) for multi-stage grinding processing, and are uniformly discharged from the discharge port (10).

[0013] A grinding and processing device for multi-aperture ceramic microbeads, provided with a prompting device (11), which sends a corresponding prompt when the ceramic microbeads fall into an inappropriate pore structure.

[0014] The utility model relates to a multi-aperture ceramic microbead grinding an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com