Patents

Literature

96results about How to "Swing fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

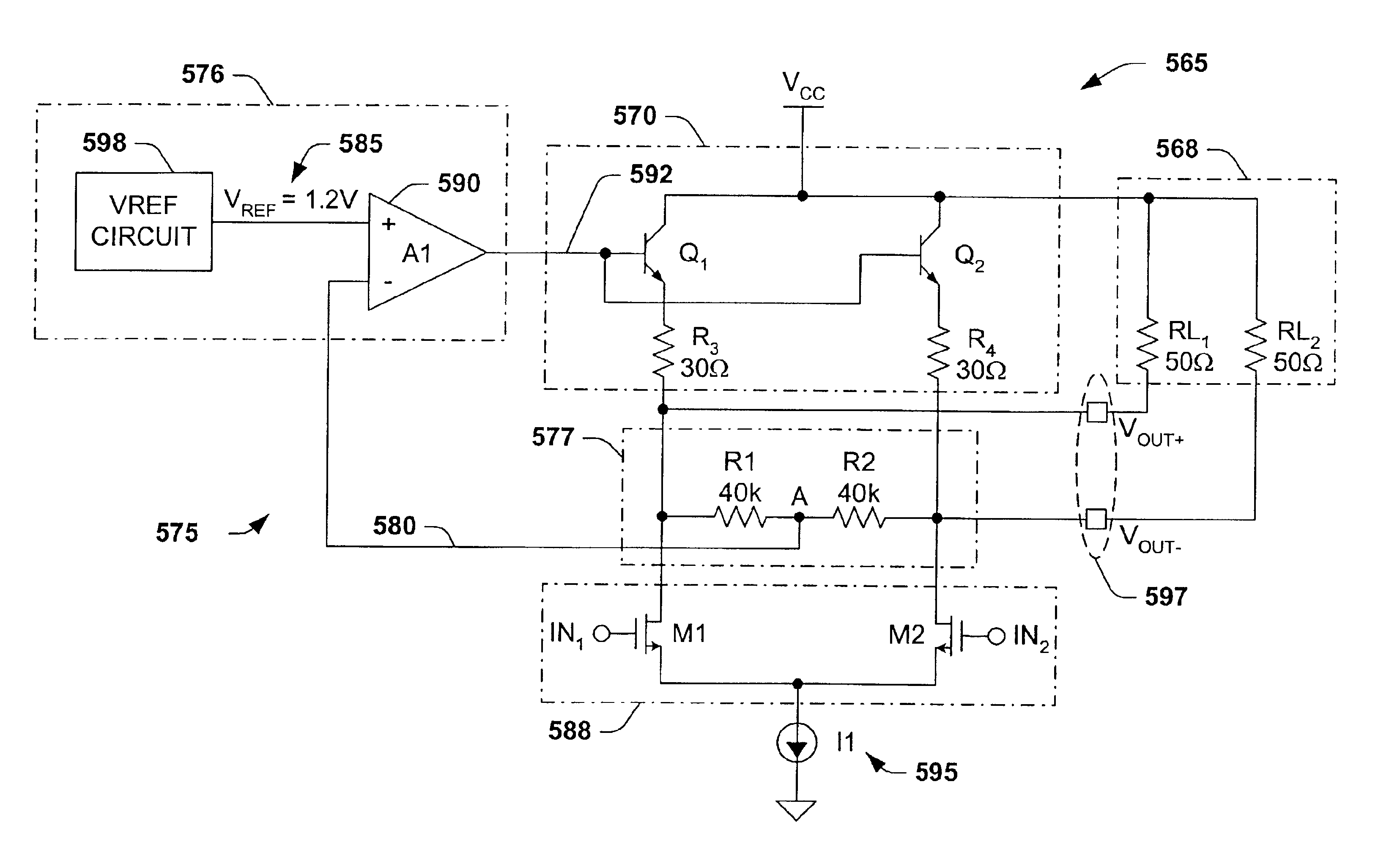

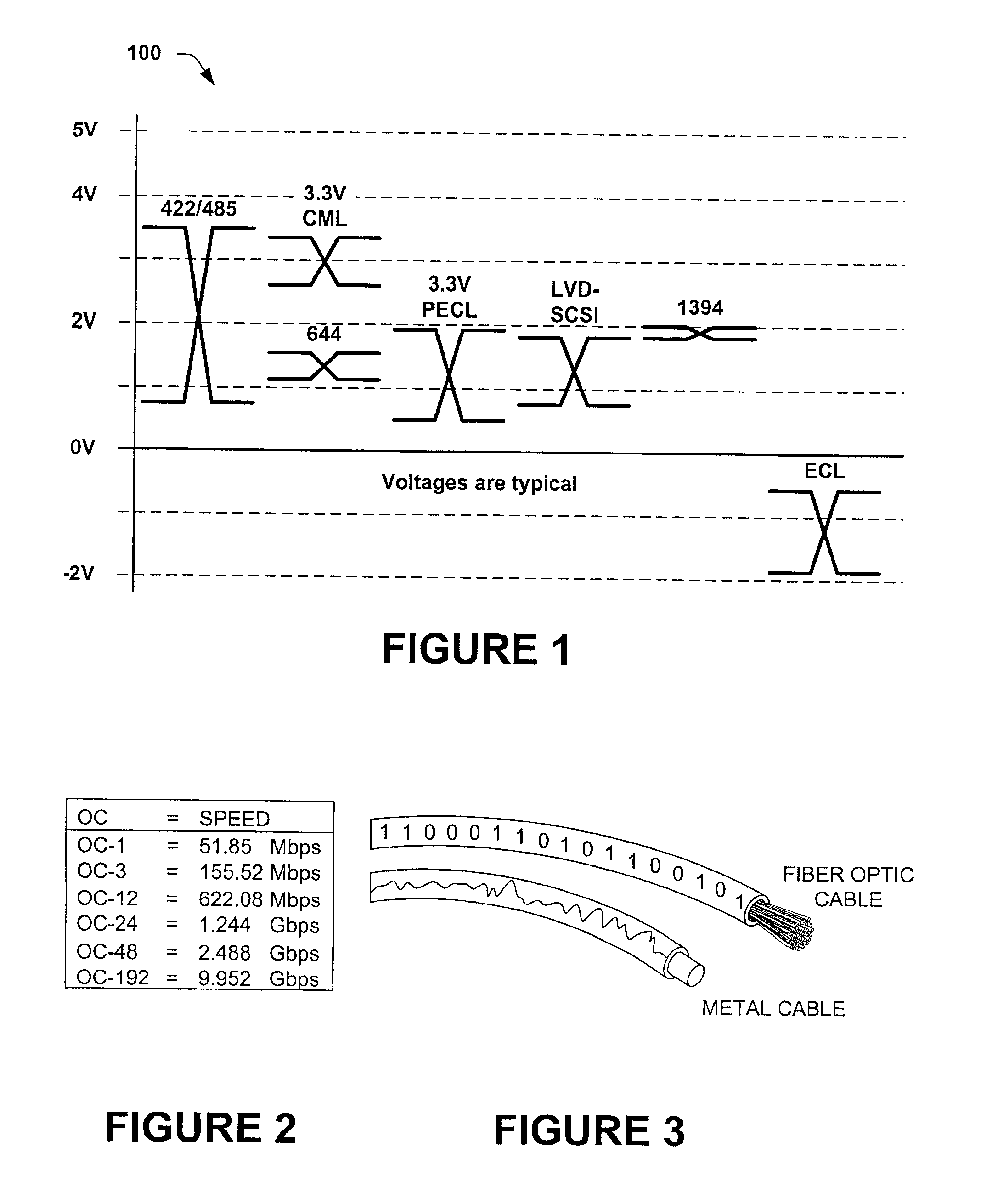

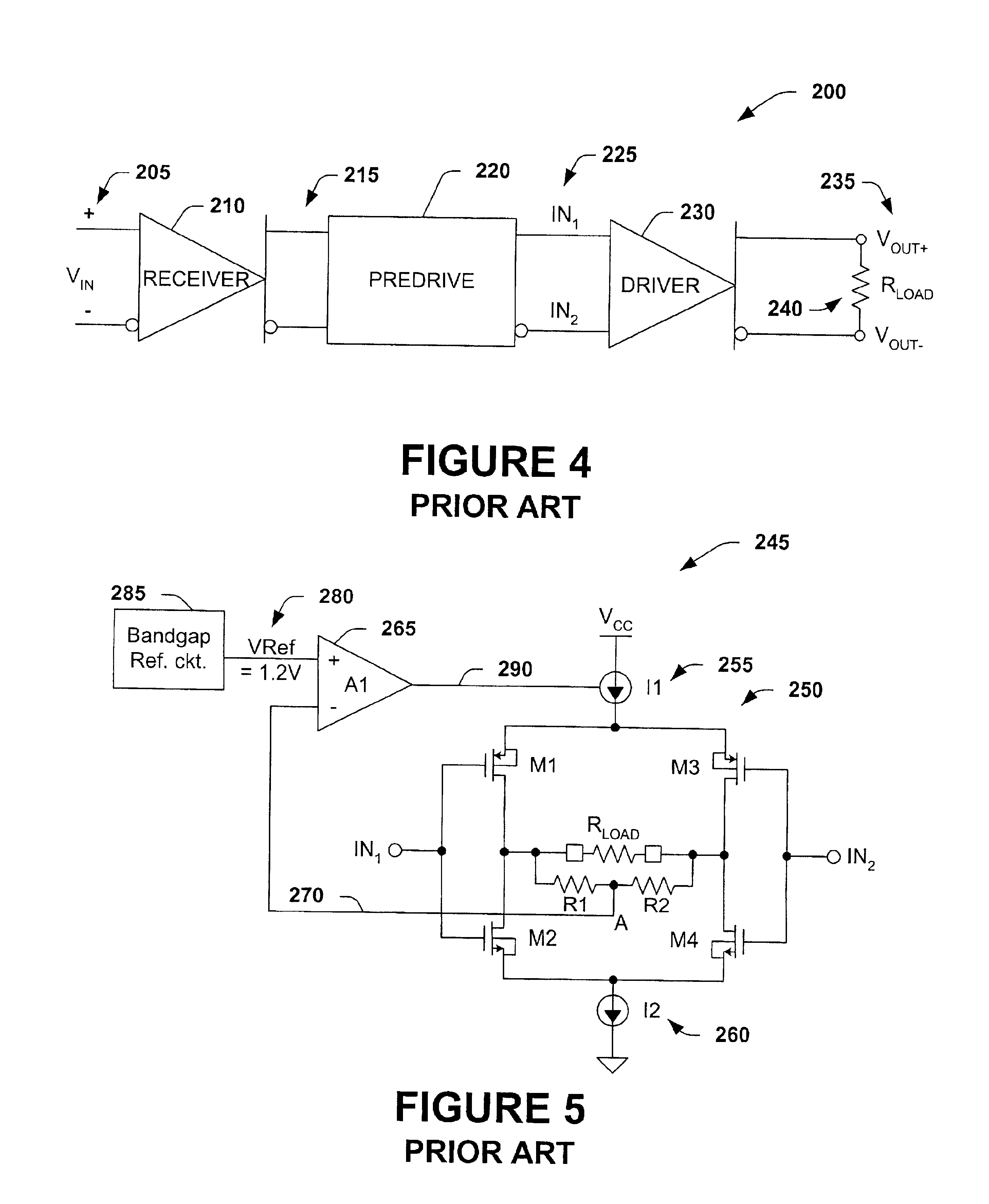

Interchangeable CML/LVDS data transmission circuit

InactiveUS6847232B2Easy to operateReduce input voltageLogic circuits coupling/interface using field-effect transistorsAmplifier with semiconductor-devices/discharge-tubesDriver circuitTransceiver

A system and method is described for a driver circuit used for high speed data transmission in LVDS and CML transceiver device applications. The transceivers are intended to receive a low voltage differential input signal and interchangeably drive a standard LVDS load with a TIA / EIA-644 compliant LVDS signal, and a standard CML load with a standard CML compatible signal. The driver circuit operates at speeds up to 1.36 Gbps, making it compatible with the OC-24 signaling rate for optical transmission. To accomplish this, the driver uses a mixed combination of voltage and current mode drive sections in the output circuit when coupled to LVDS loads, and when the driver is coupled to CML loads, operates purely in a current mode using only the current mode drive section. MOS transistors and a current source are used in the current mode switch portion to switch the drive with a constant current at the high speeds, and NPN transistors in the voltage mode output portion provide variable impedance for the output circuit. A common mode compensation circuit using a feedback voltage from the load generates a compensation signal for variable impedance control of the NPN transistors to yield a regulated voltage for the common mode dc voltage.

Owner:TEXAS INSTR INC

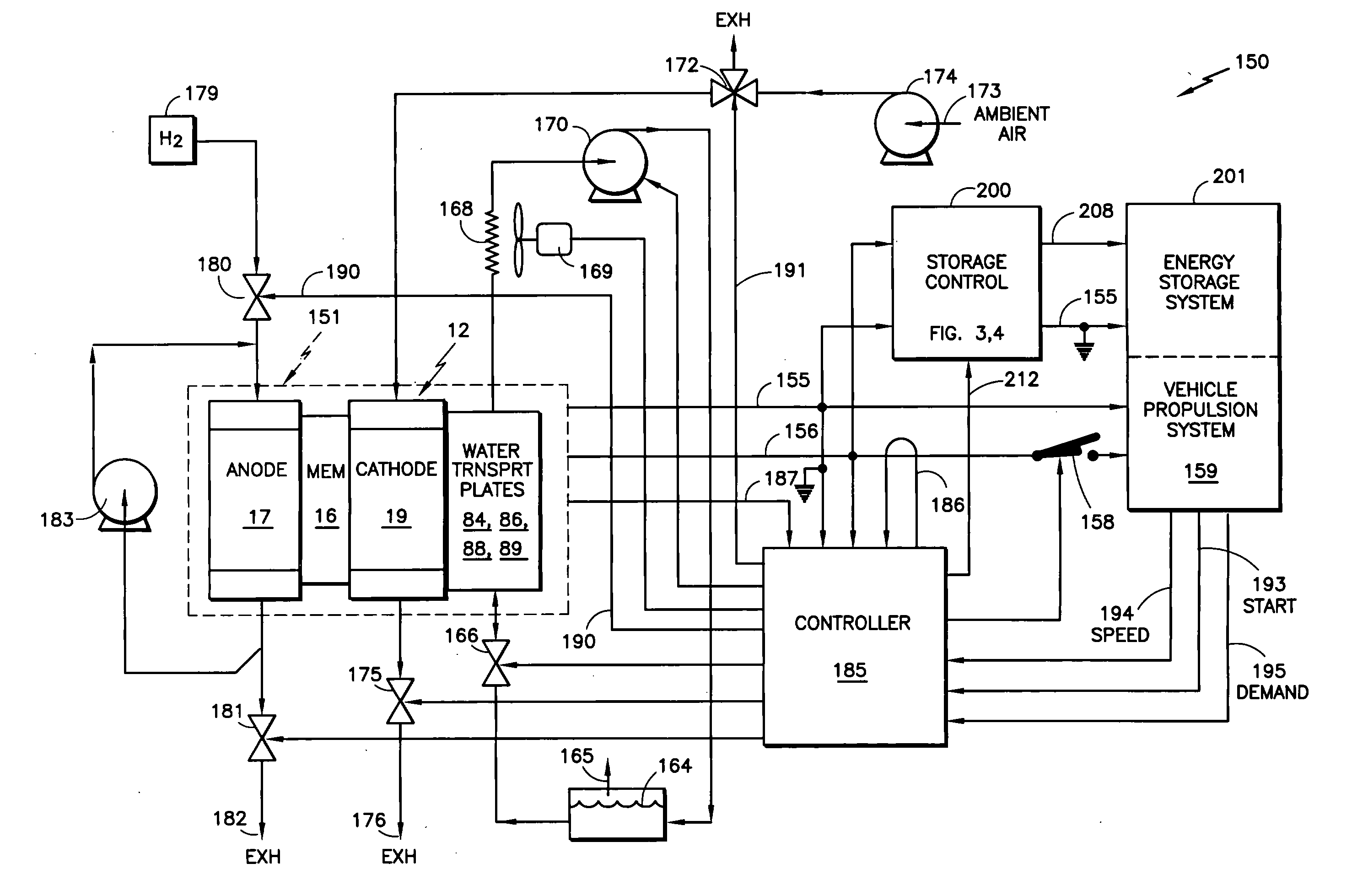

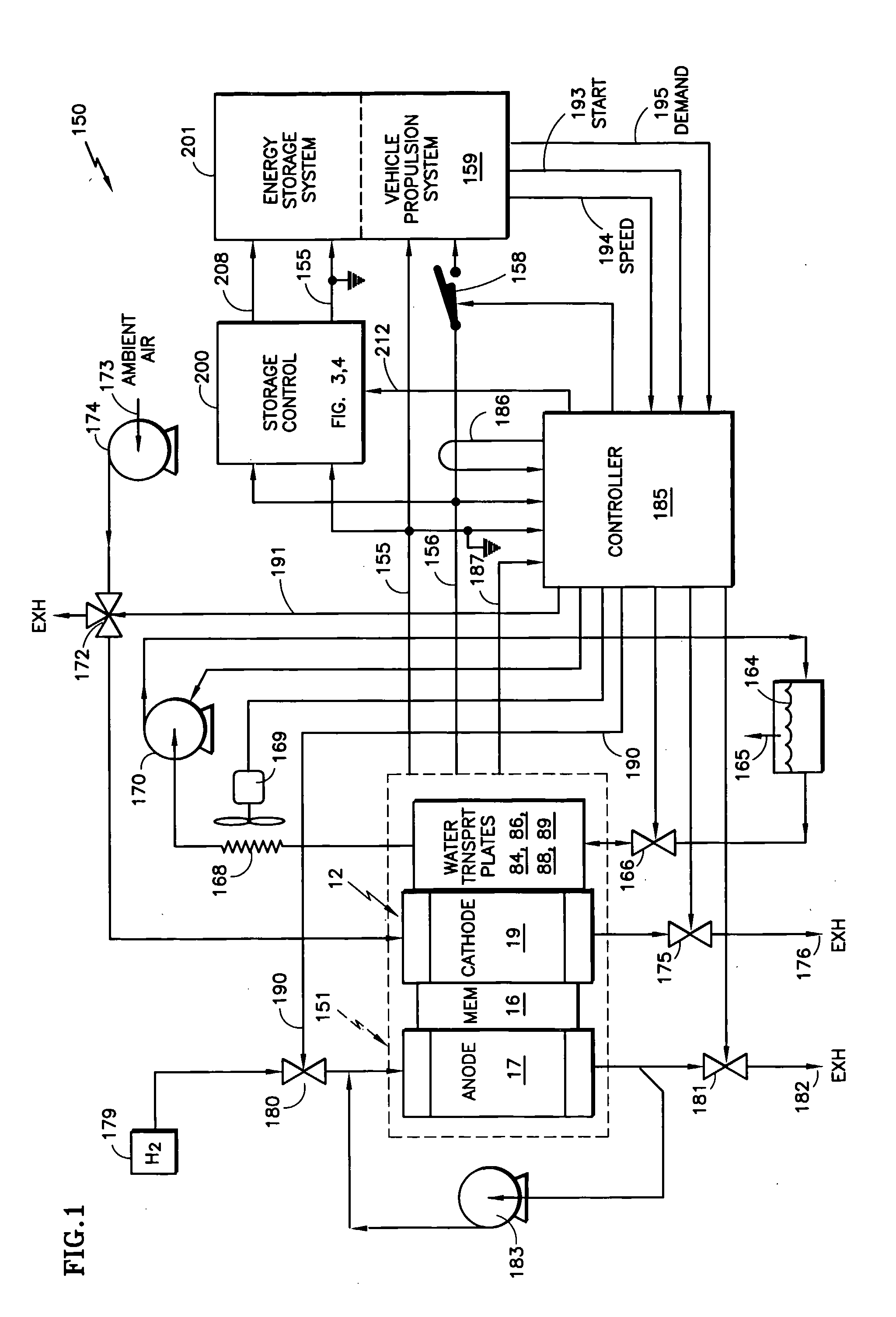

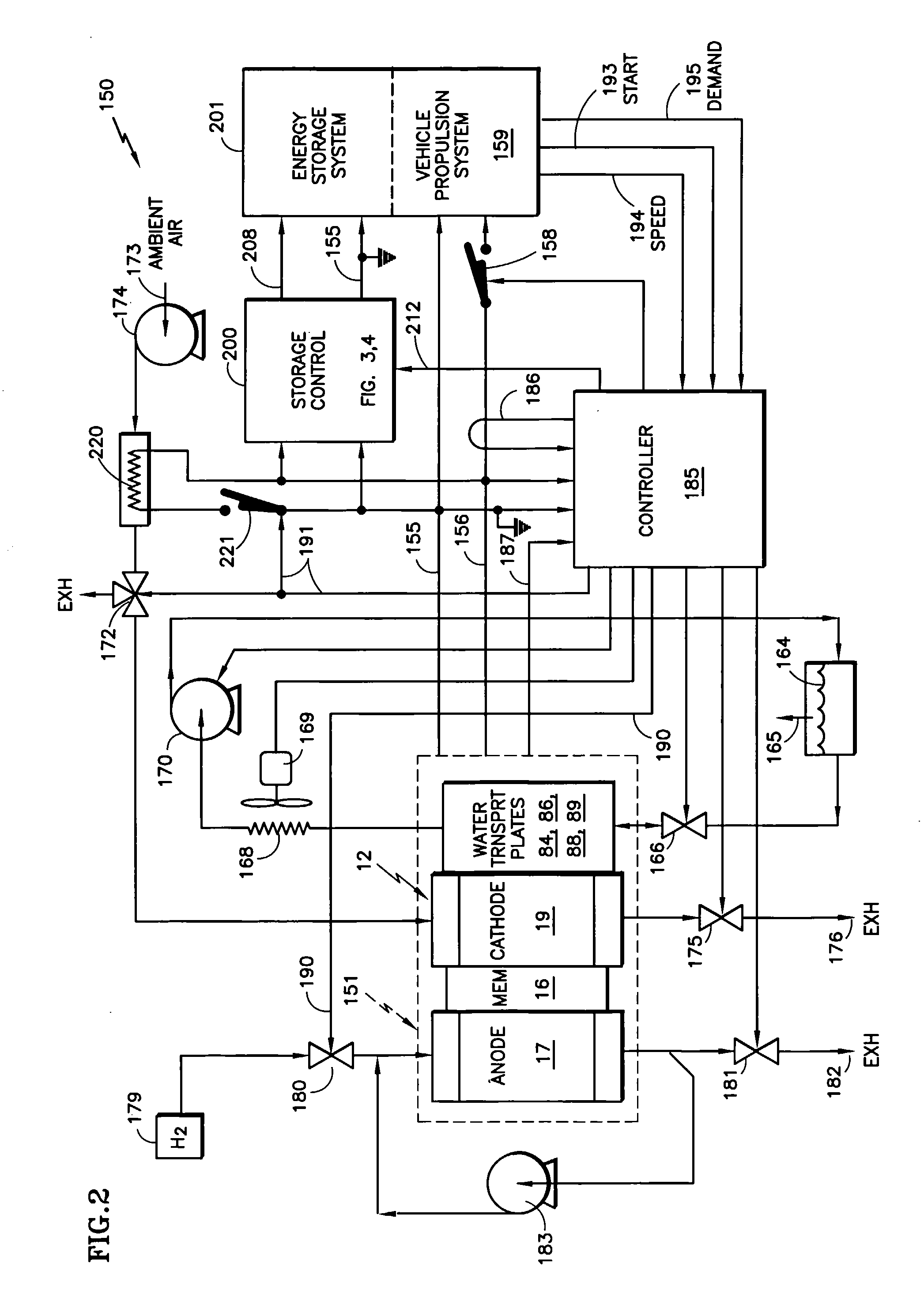

Fuel Cell Power Plant Diverting Air in Response to Low Demand

InactiveUS20090098427A1Reduce performance degradationImproved fuel cell power plantFuel cell auxillariesTransportation fuel cell technologyFuel cellsPower station

A fuel cell system, which may be powering a vehicle propulsion system (159), includes a fuel cell power plant having a stack (151) including a plurality of fuel cells (12), each having a cathode (19) and anode (17) separated by a membrane (16), and an air pump (174) connected to reactant air flow fields through a diverter valve (172). A controller (185) is responsive to normal and high demand to cause the diverter valve to allow air to flow from the pump to the reactant air flow fields, and is responsive to low demand to cause said diverter valve to divert air directly into ambient so that it does not reach the cathode, thereby to reduce open circuit voltage conditions that promote degradation of the cathode, and to prevent excessive performance decay. An auxiliary load (220) can be in the diverted air flow, either ahead of or after the diverter valve. Energy storage (200, 201) works with the vehicle propulsion system.

Owner:REISER CARL A

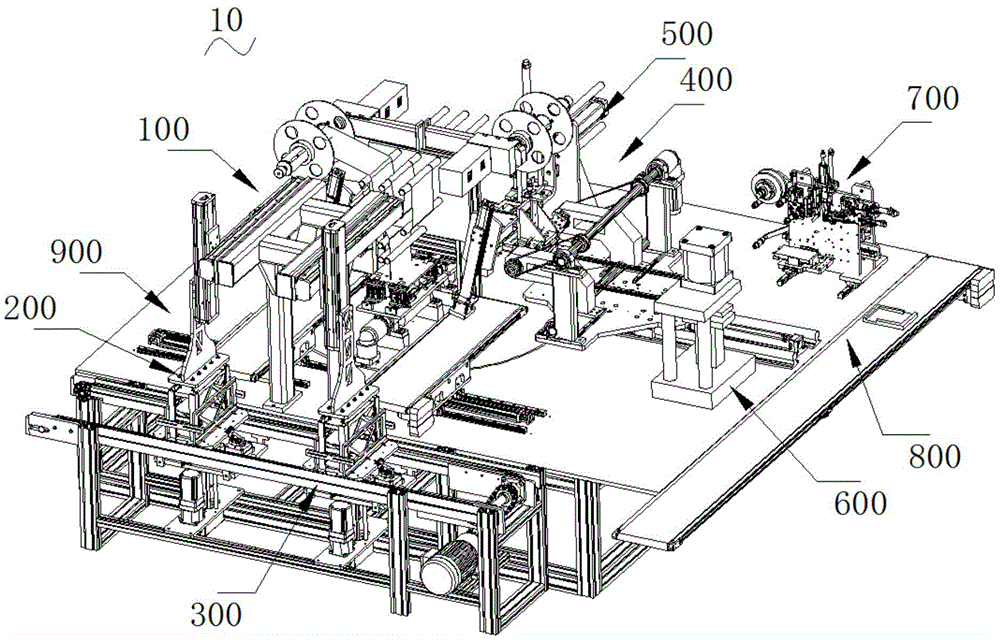

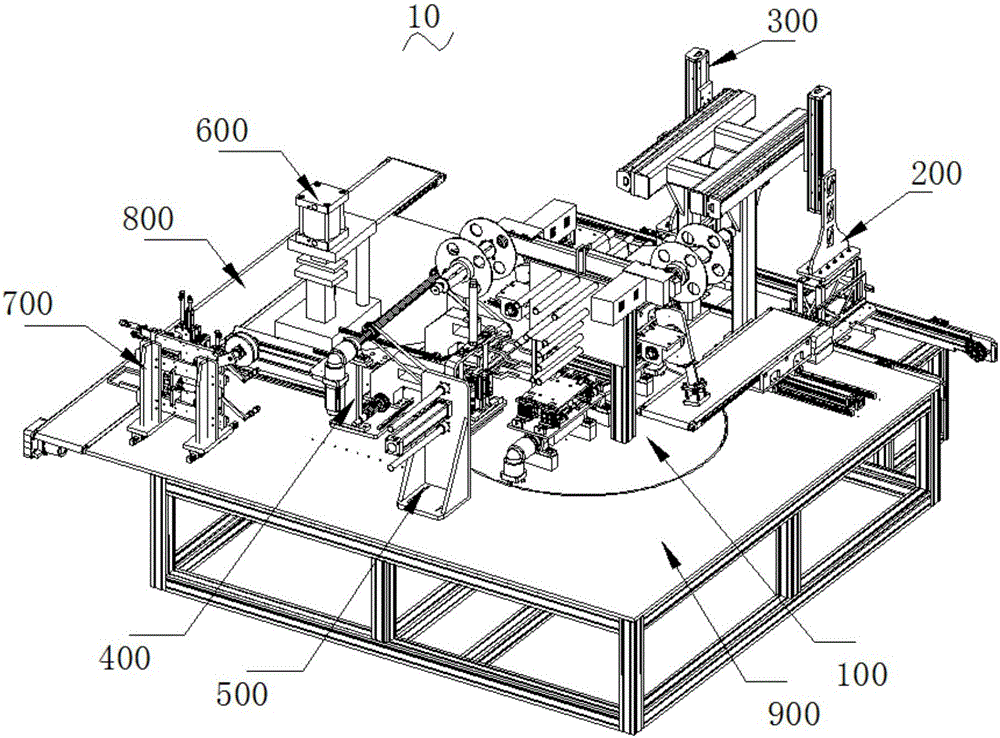

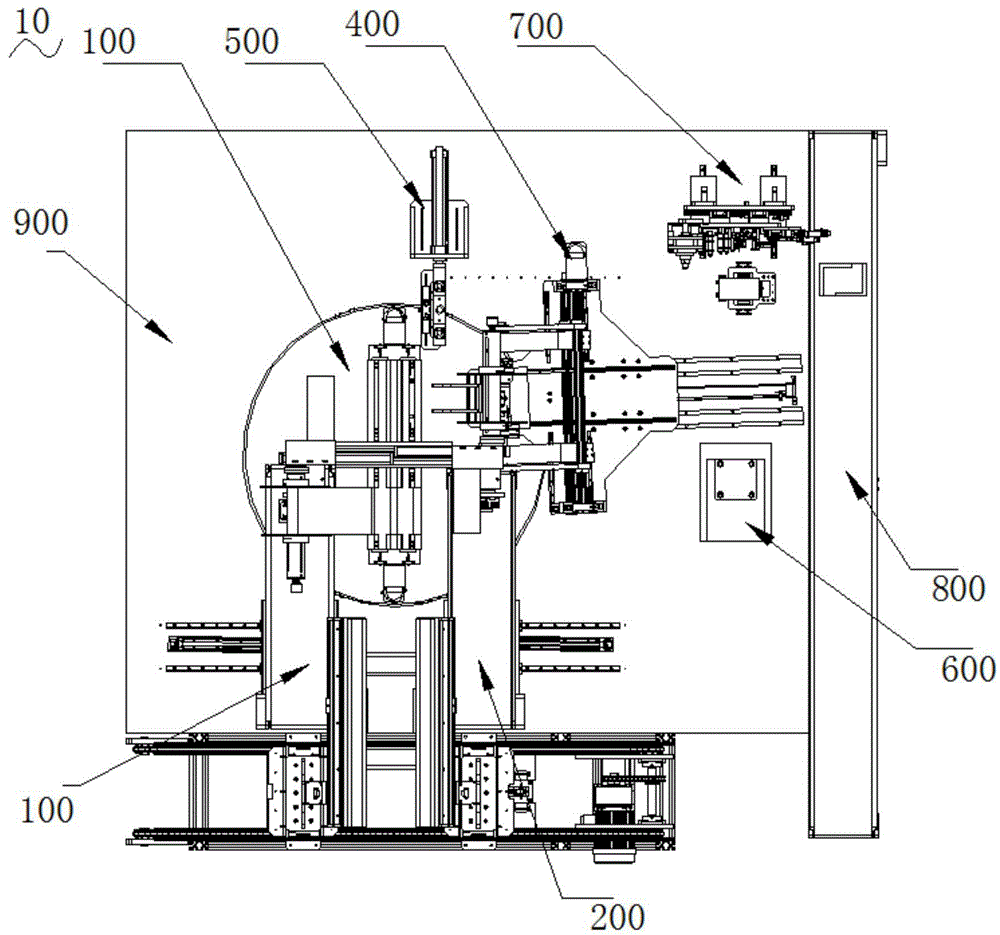

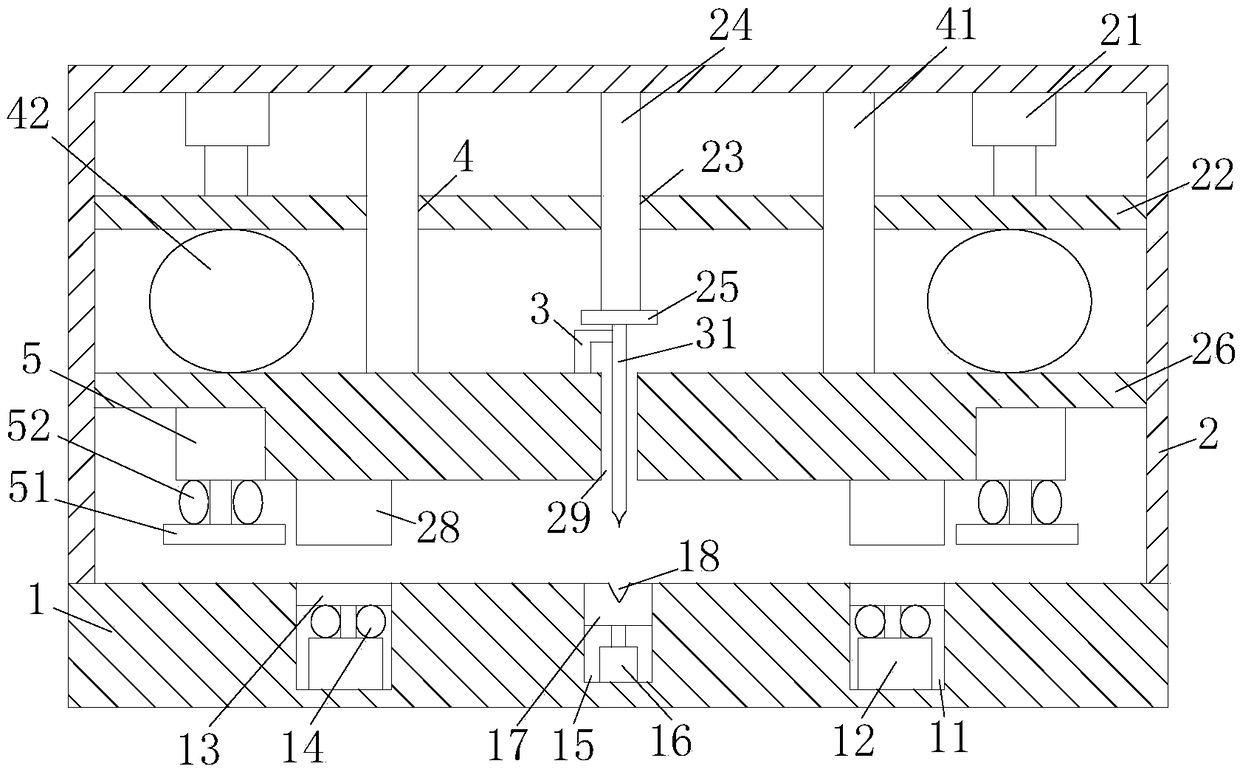

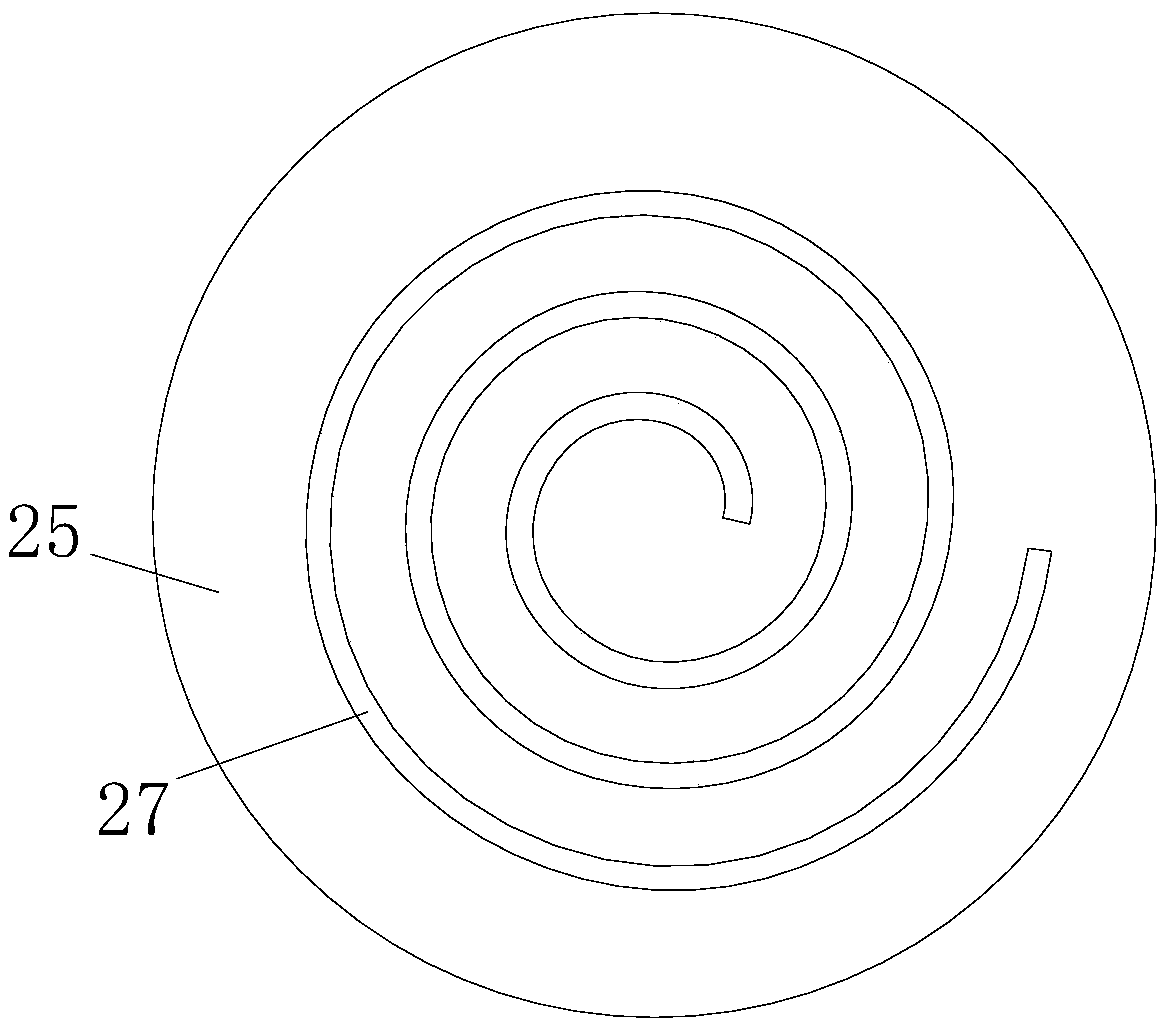

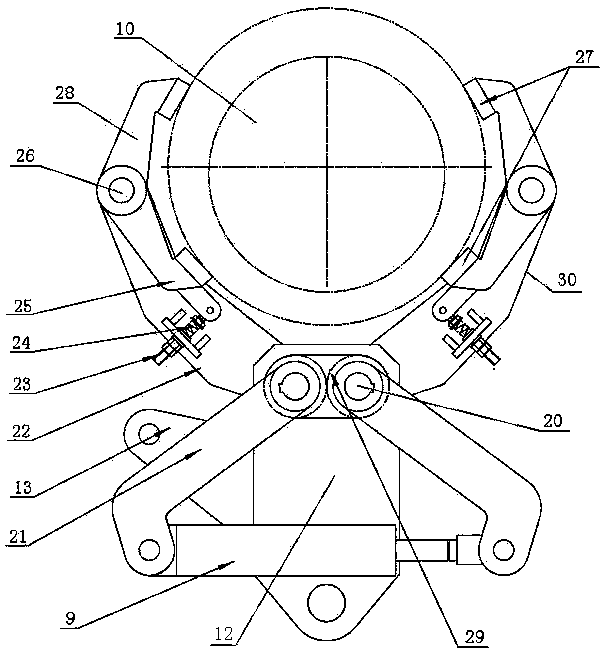

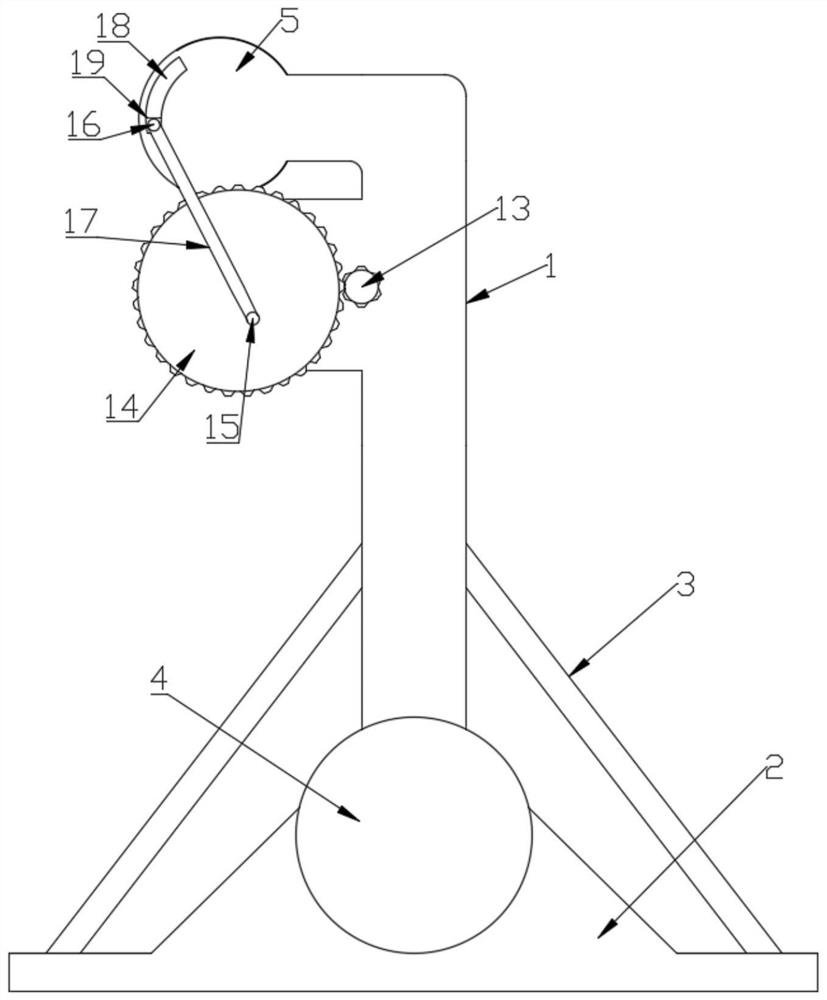

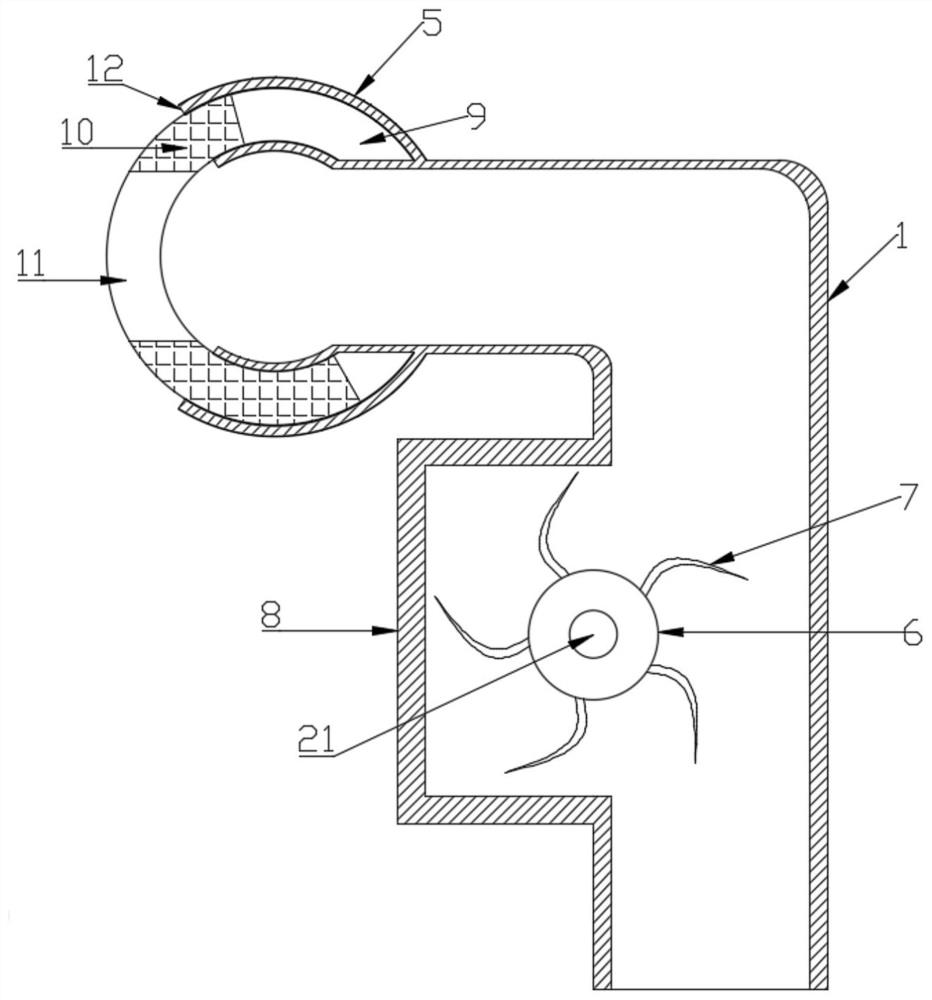

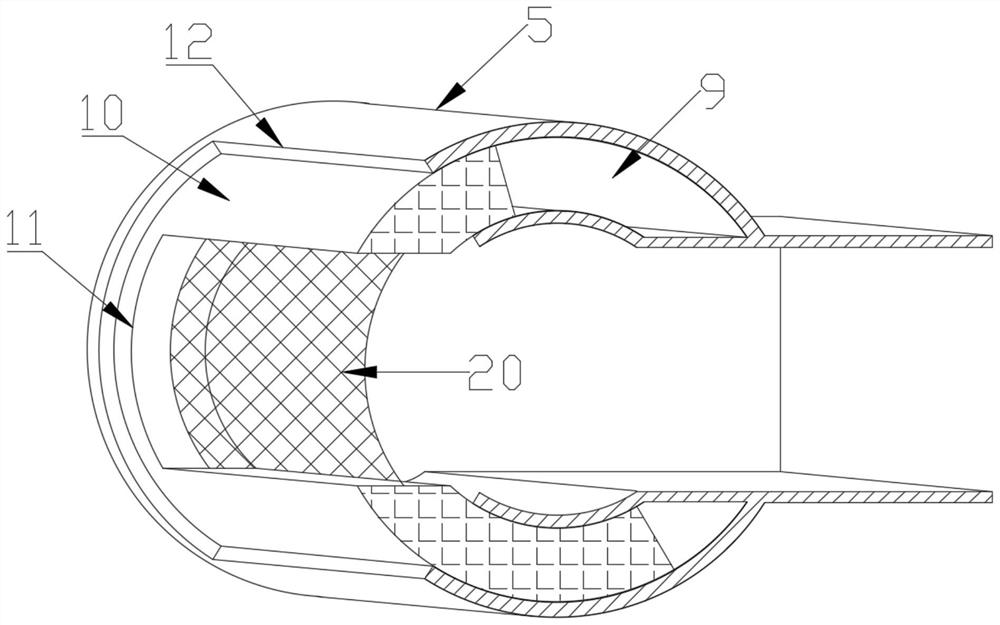

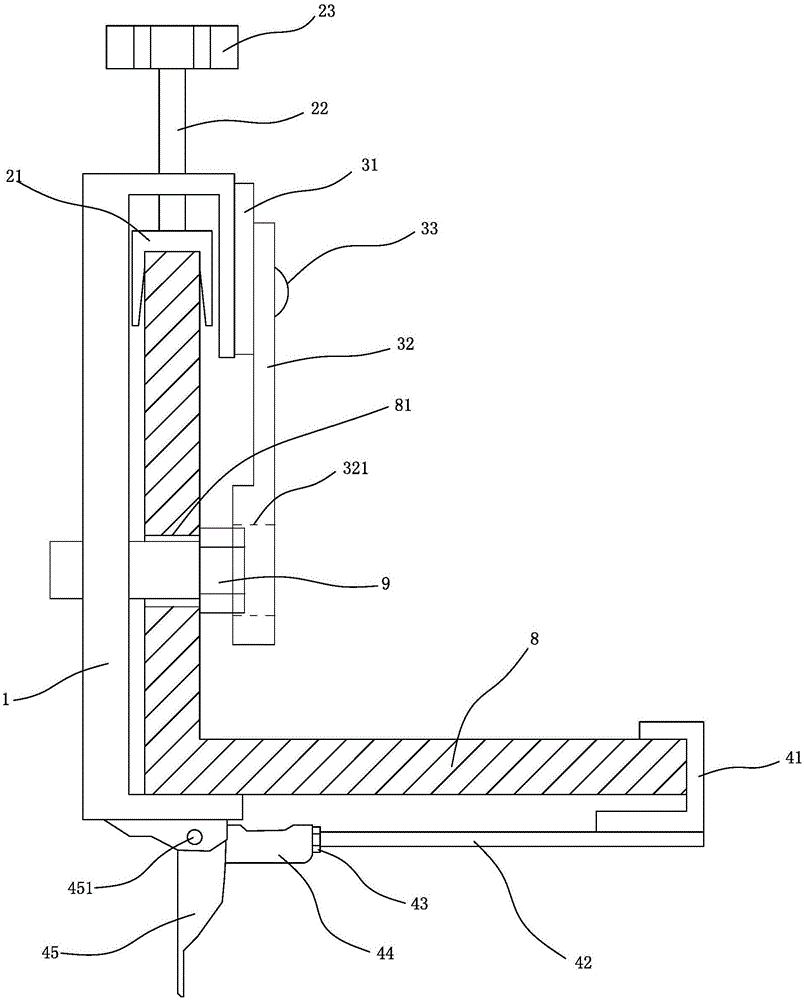

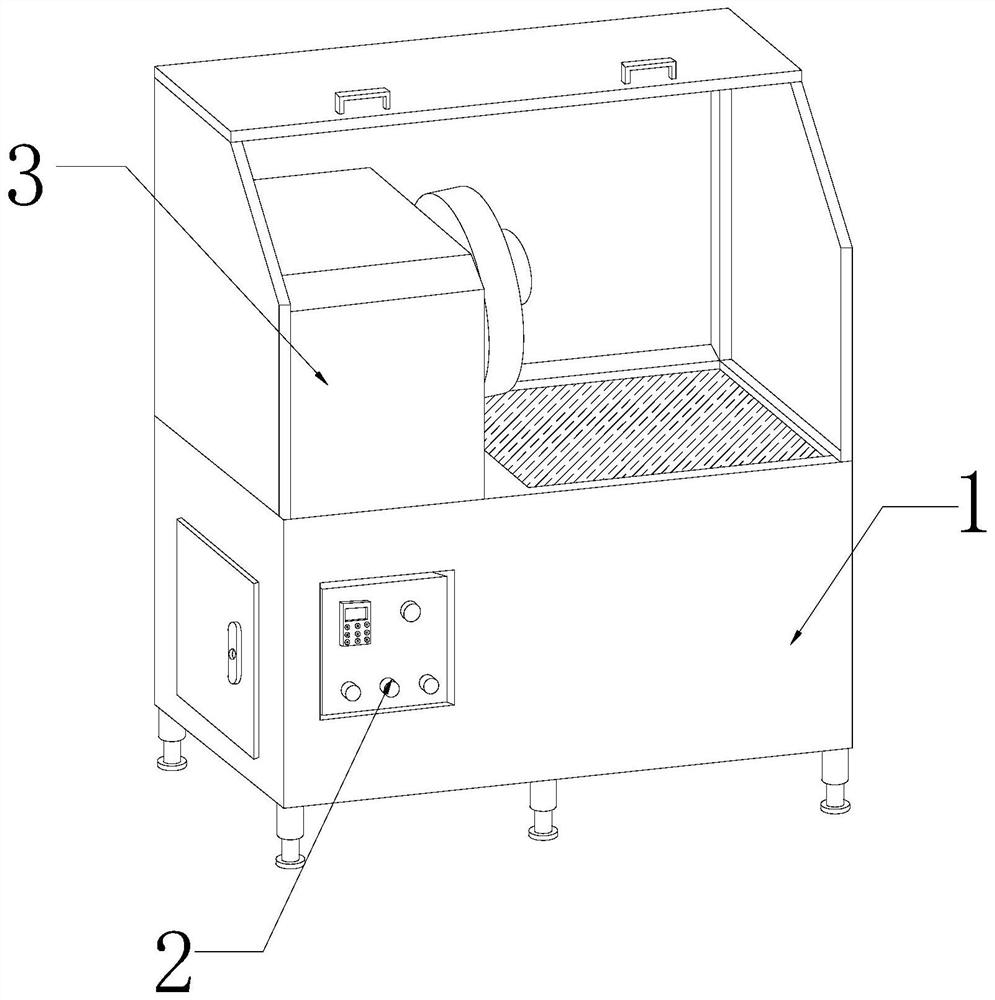

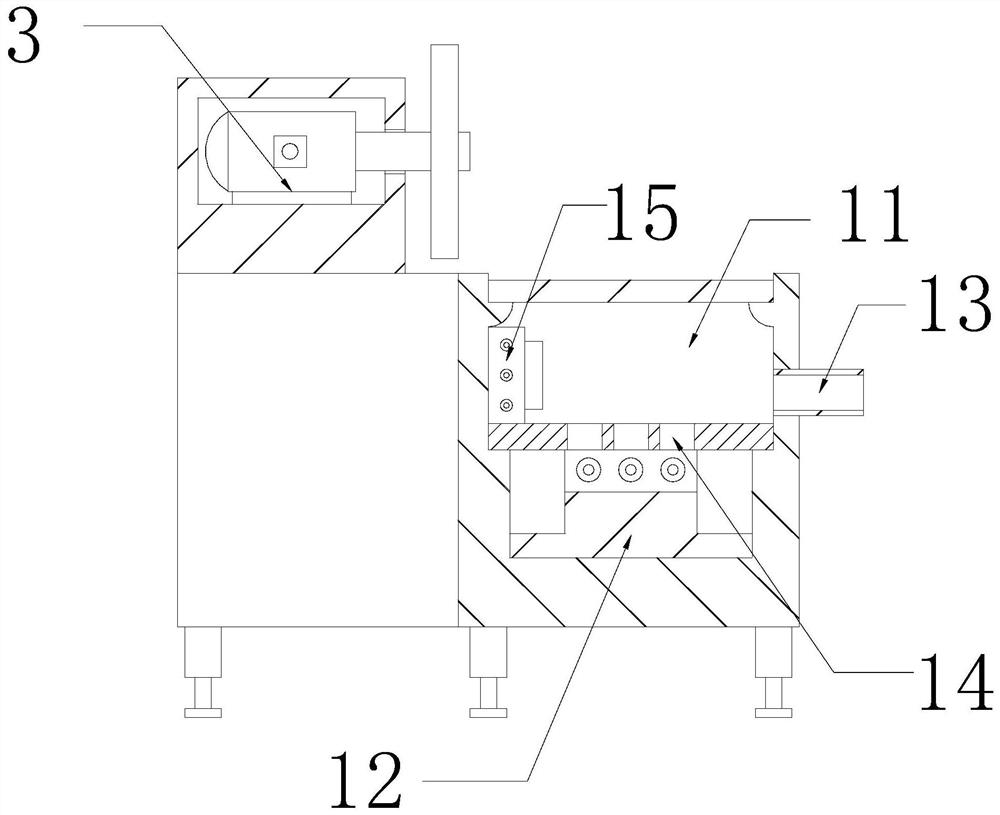

Integrated cell laminating machine and cell laminating method

ActiveCN106374144AHigh precisionImprove lamination qualityAssembling battery machinesFinal product manufactureVertical planeEngineering

The invention relates to the technical field of battery lamination, particularly to an integrated cell laminating machine and a cell laminating method. The integrated cell laminating machine comprises a laminating station, wherein the laminating station comprises a rotary plate, a rotary plate rotating apparatus arranged below the rotary plate for driving the rotary plate to rotate, and multiple laminating apparatuses uniformly arranged on the rotary plate for performing lamination; each laminating apparatus comprises a laminating rotary platform, a laminating power mechanism for driving the laminating rotary platform to swing in a vertical plane, and a first attraction mechanism and a second attraction mechanism which are symmetrically arranged on the two sides of the laminating rotary platform for attracting and driving a positive plate and a negative plate to swing in a vertical plane, and a diaphragm material-releasing mechanism mounted above the laminating rotary platform for supplying diaphragms, wherein each laminating power mechanism is positioned at the bottom of the corresponding laminating rotary platform; and the swinging track of the laminating rotary platform is externally tangent with the swinging track of the corresponding first attraction mechanism and second attraction mechanism. The integrated cell laminating machine has high laminating efficiency, high laminating precision and good laminating quality.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

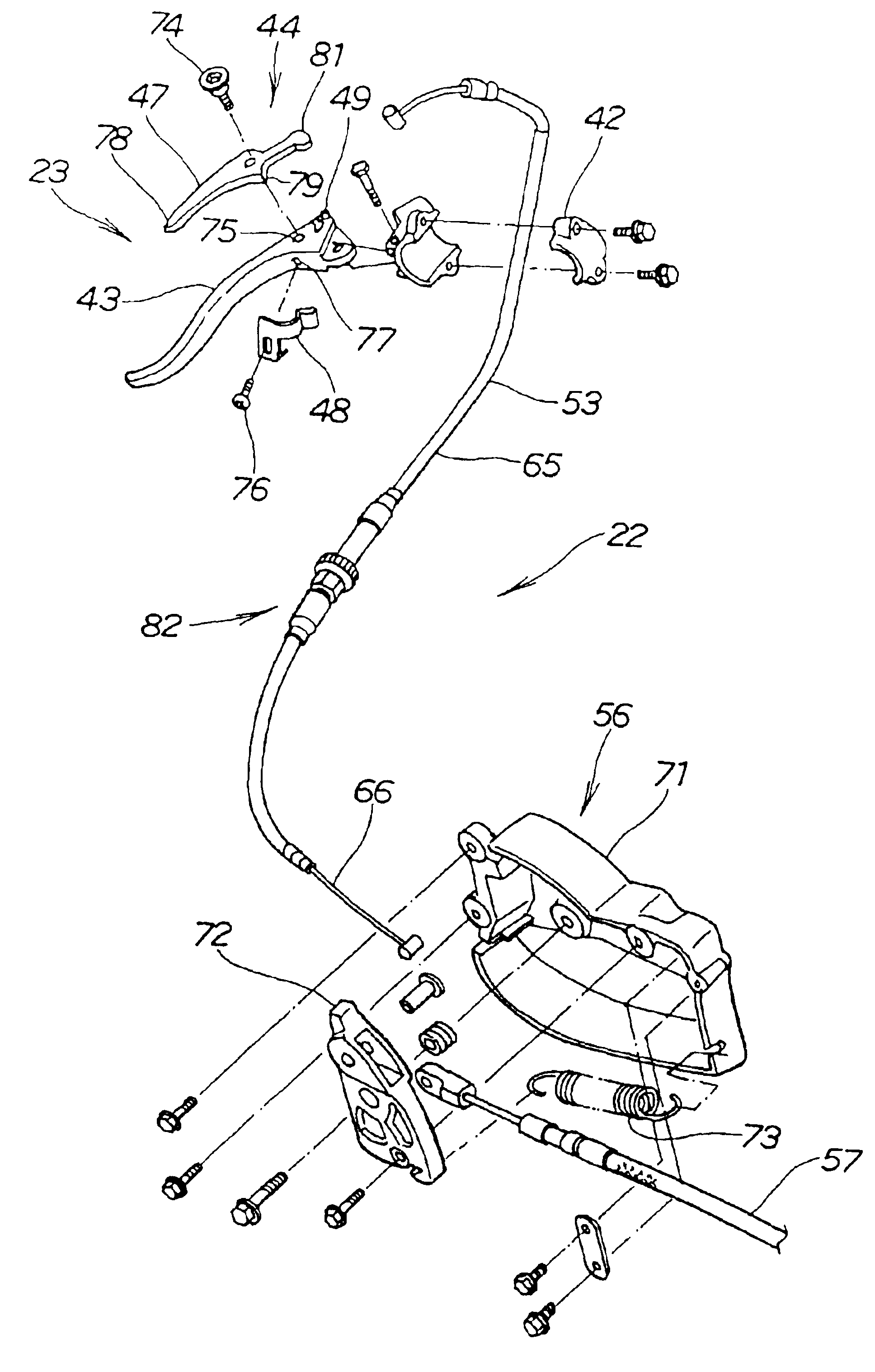

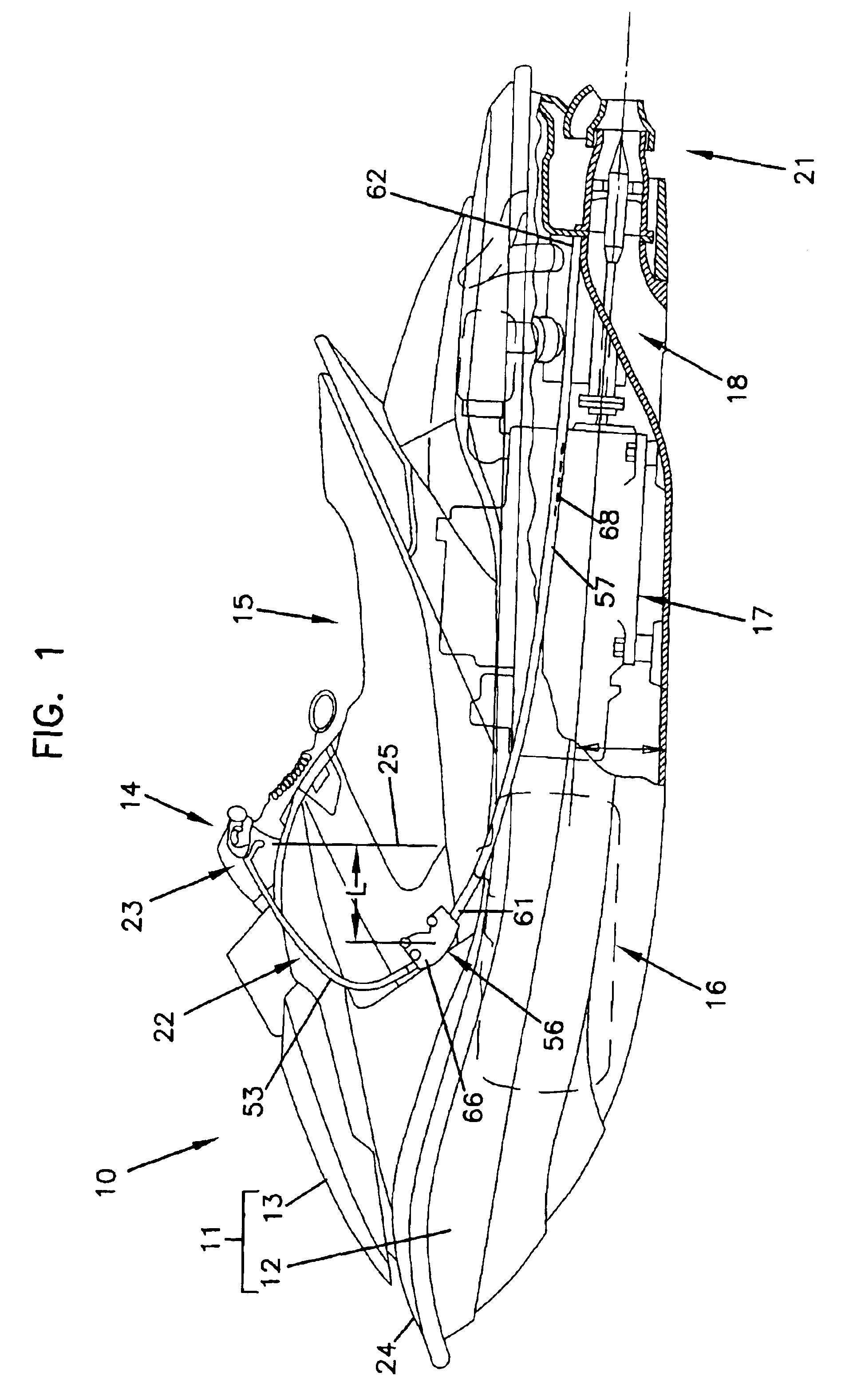

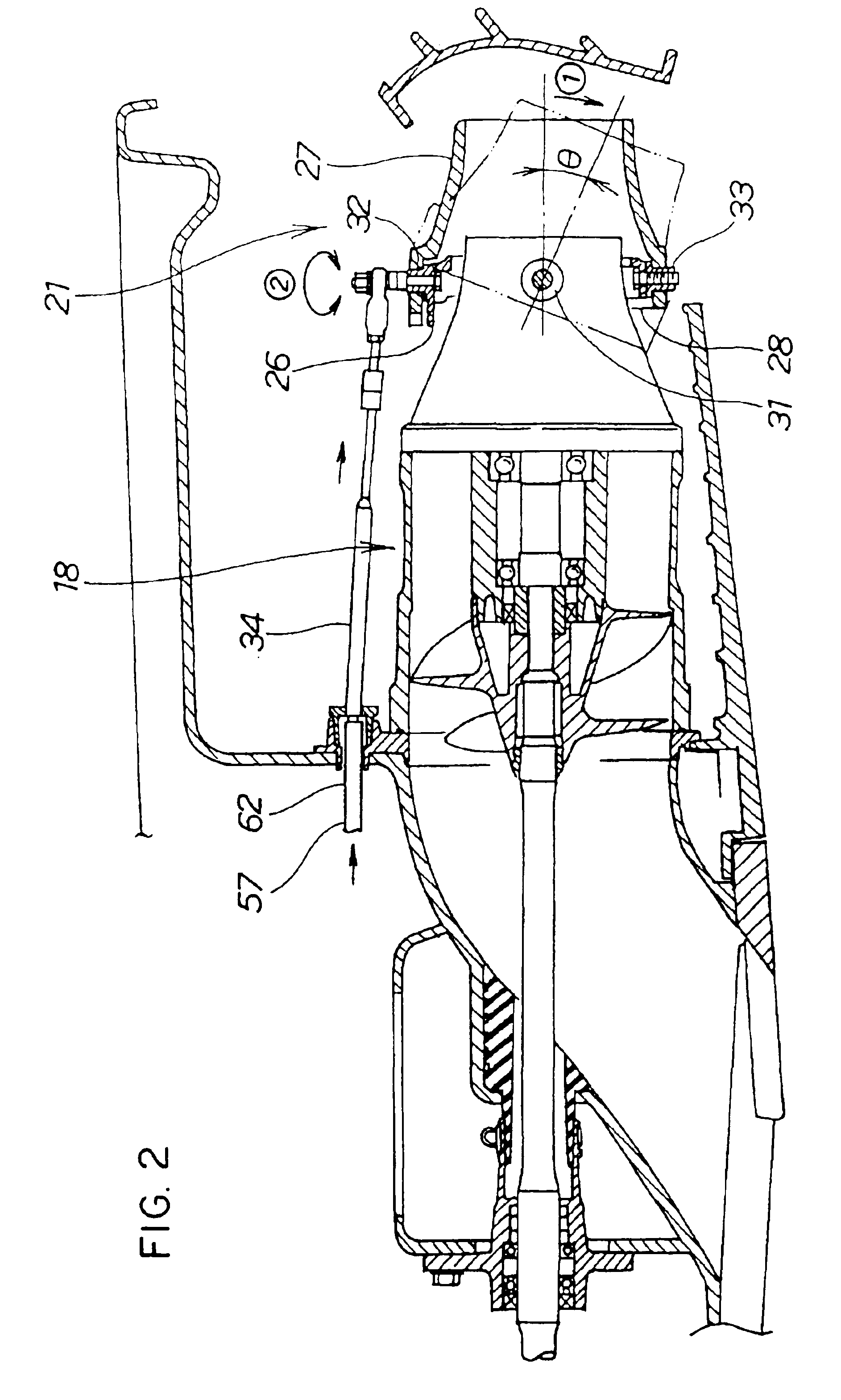

Trim operating lever device for personal watercraft

InactiveUS6875065B2“locking” effectImprove operating forceSteering by jetsPropulsive elementsWatercraftNozzle

A trim operating lever device is disclosed which can downwardly or vertically swing a nozzle capable of adjusting the jet direction of jet water. When the trim operating lever is gripped with a finger of the hand which is gripping the steering handle, a lever of the lever lock means can be substantially simultaneously operated with the finger, to effect locking. Therefore, the number of operations by the left hand necessary for swinging the nozzle is reduced. Also, because the trim operating lever makes it possible to enlarge the operating force, the nozzle can be swung quickly.

Owner:HONDA MOTOR CO LTD

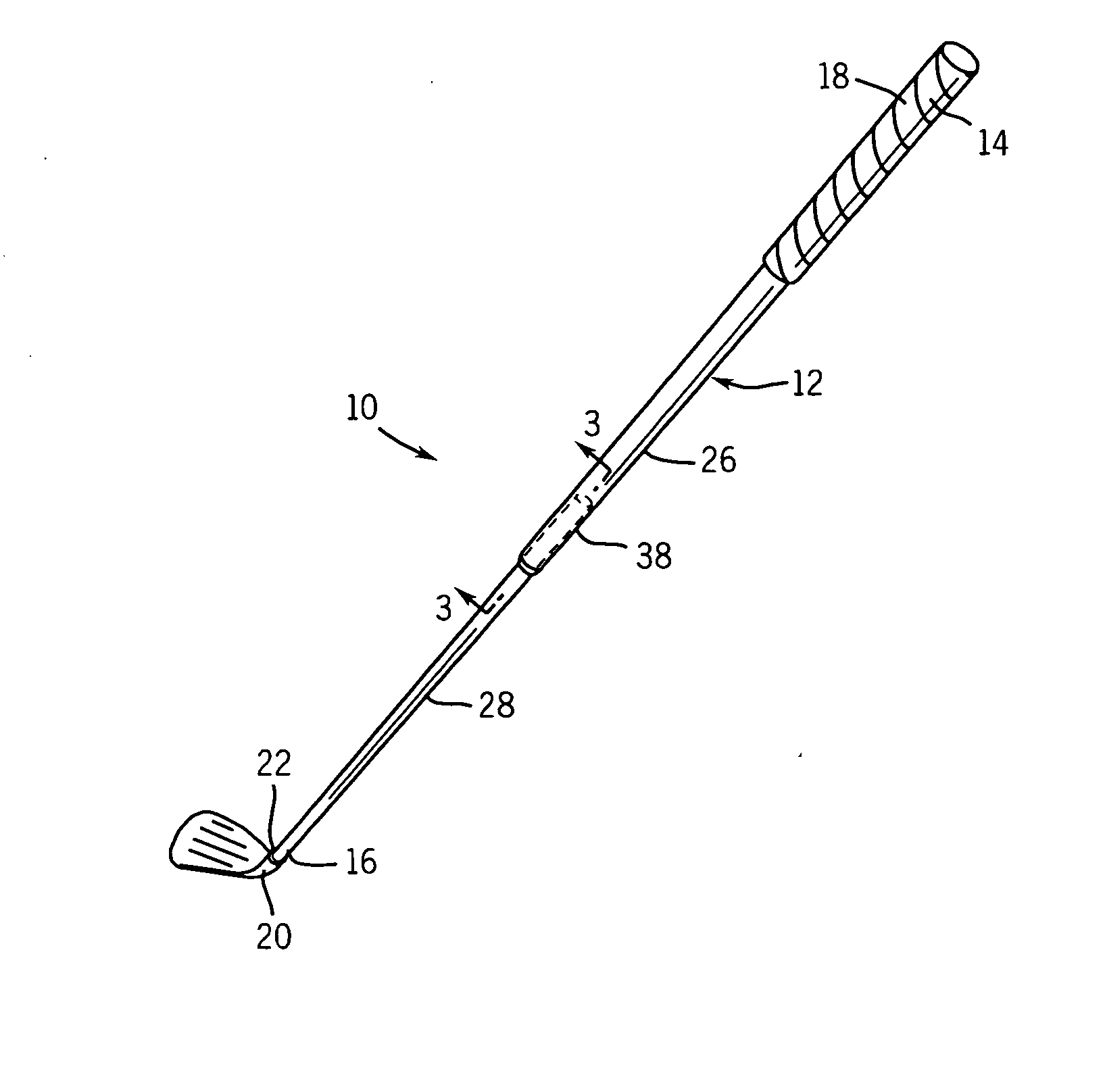

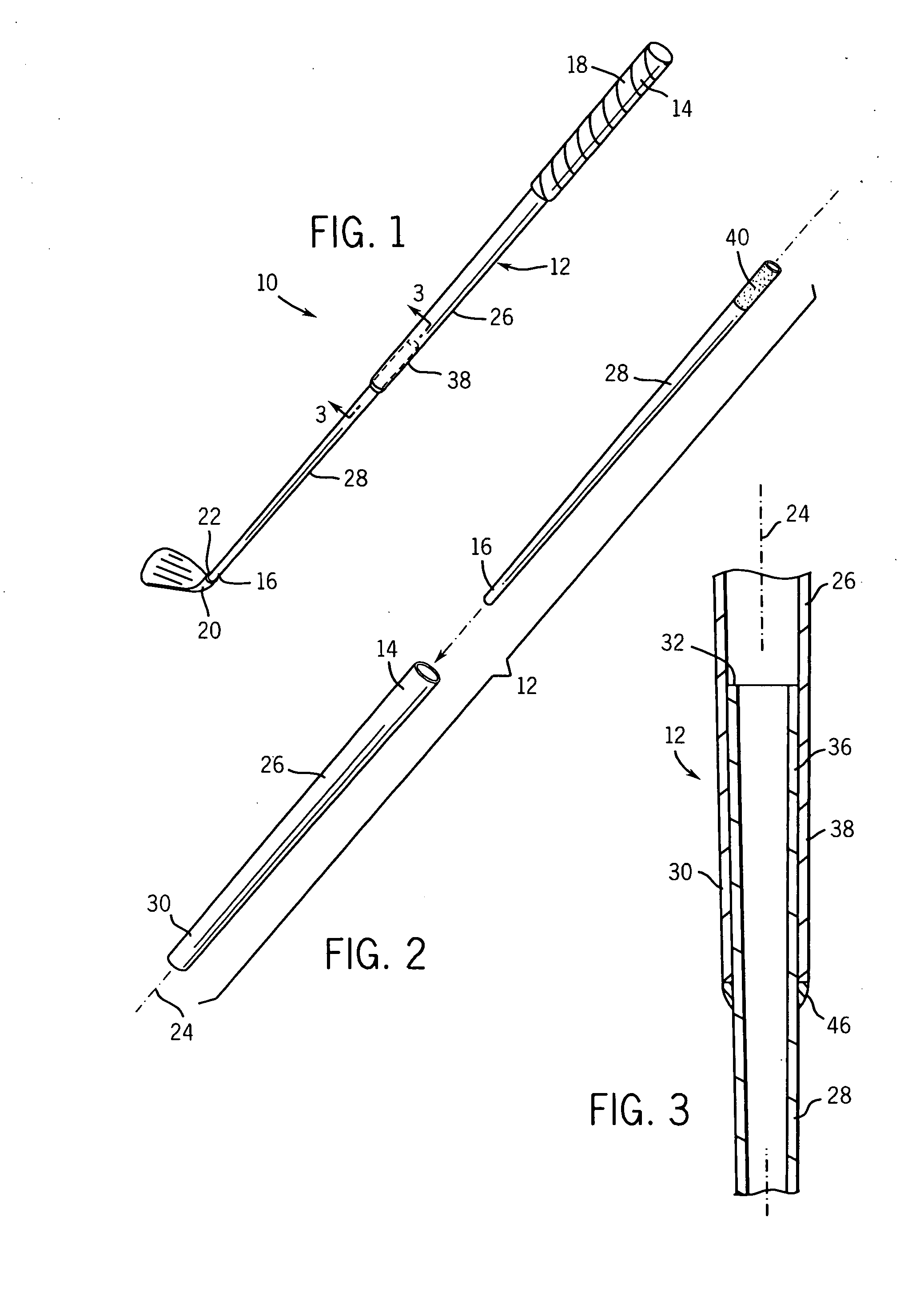

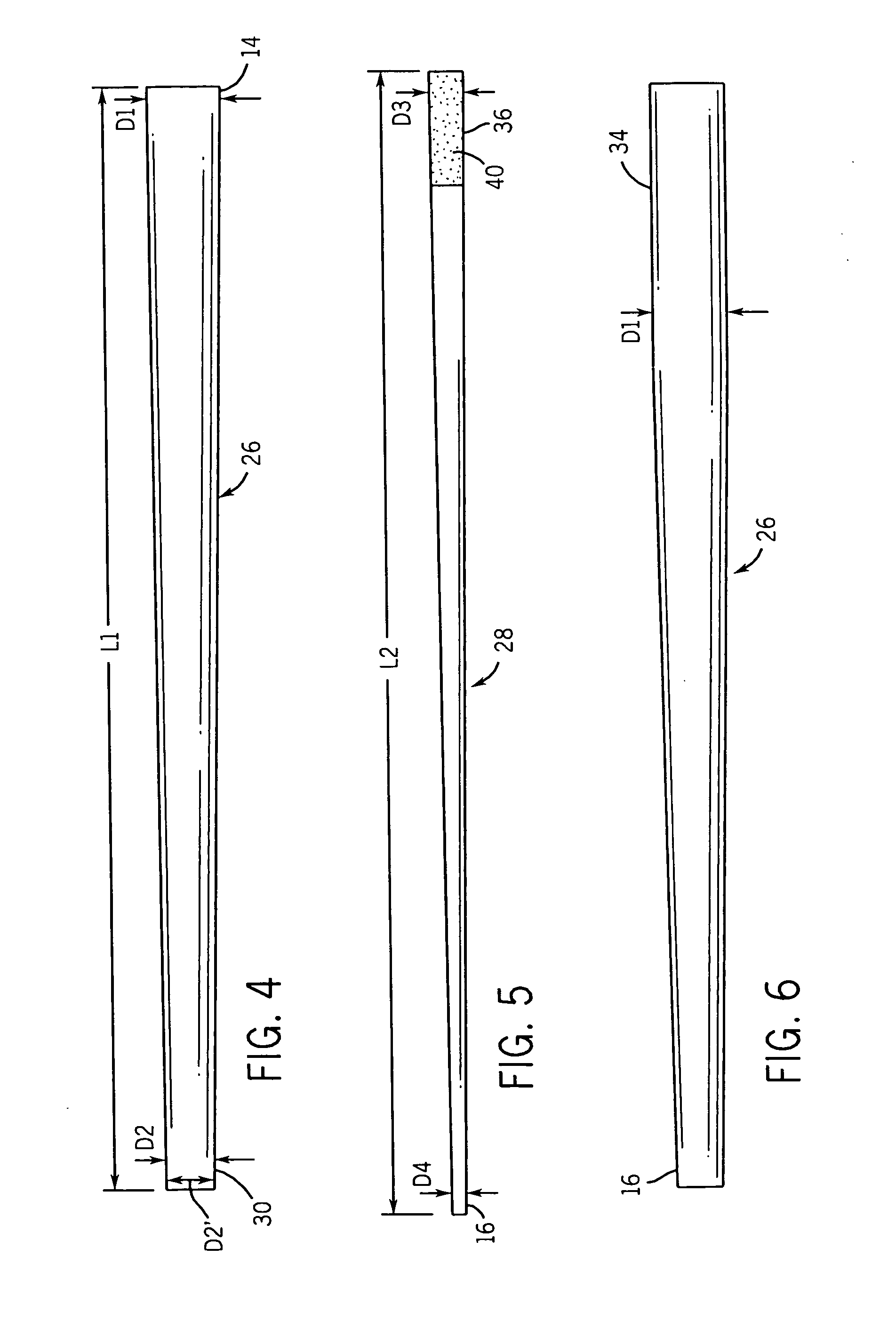

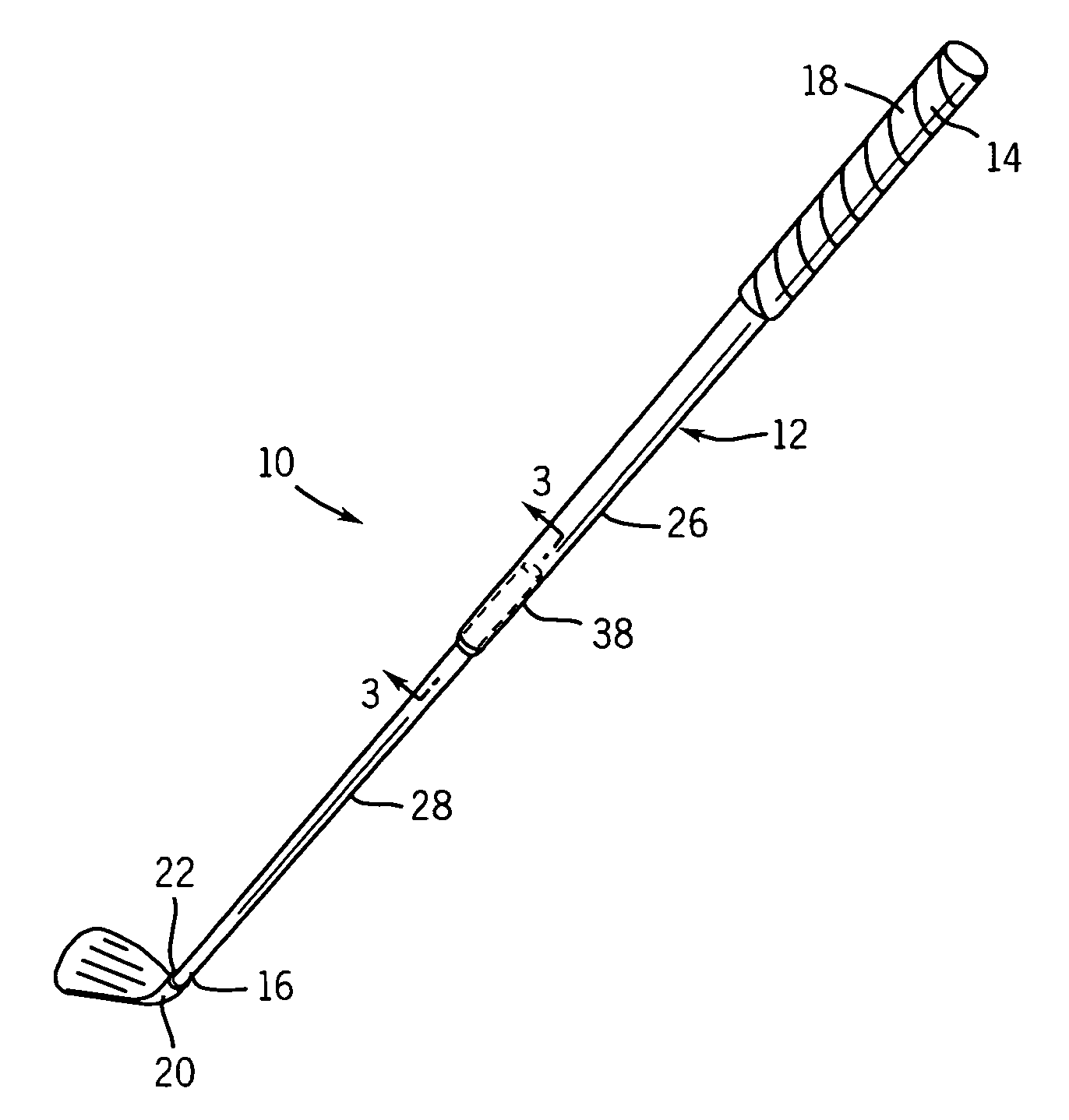

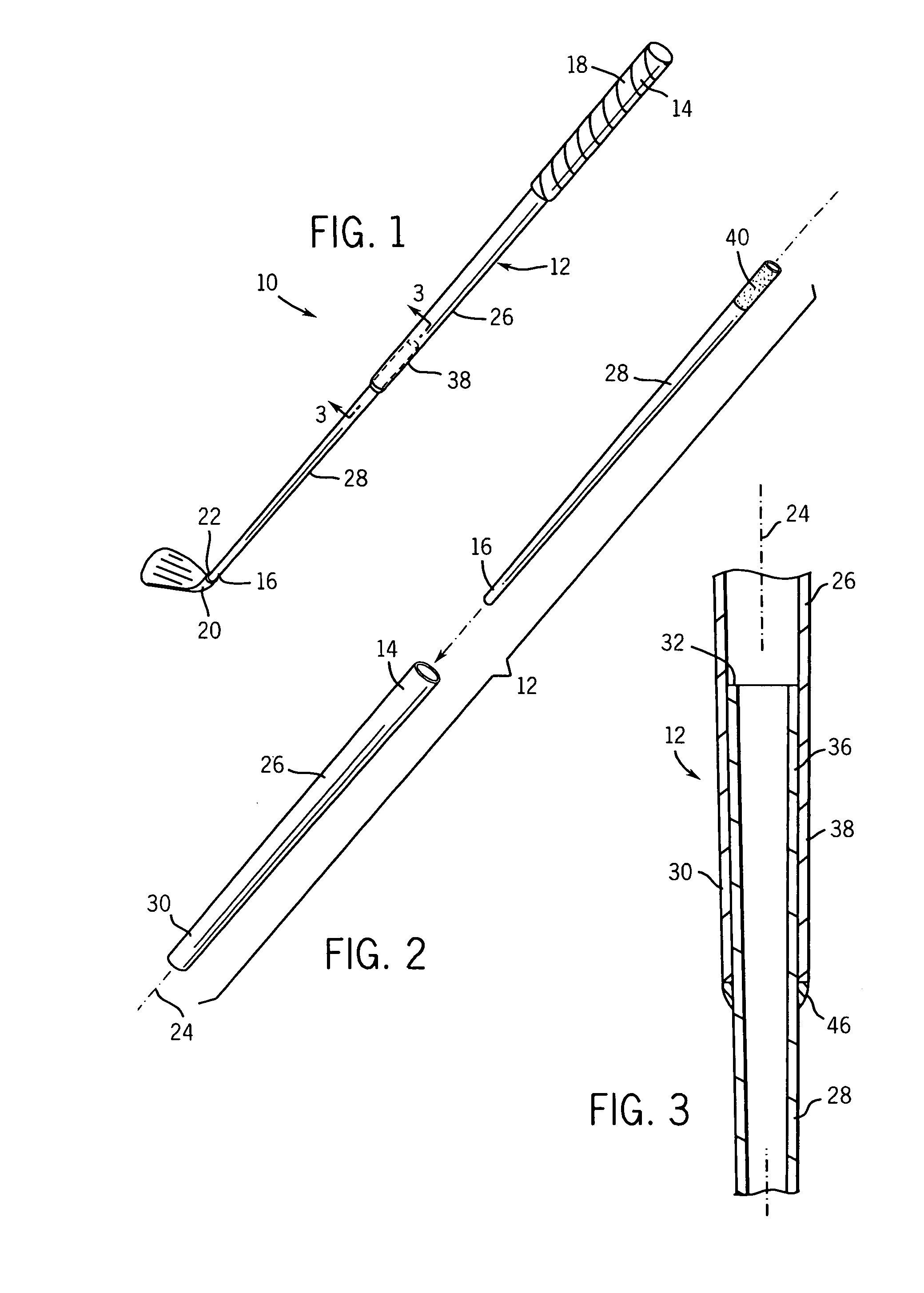

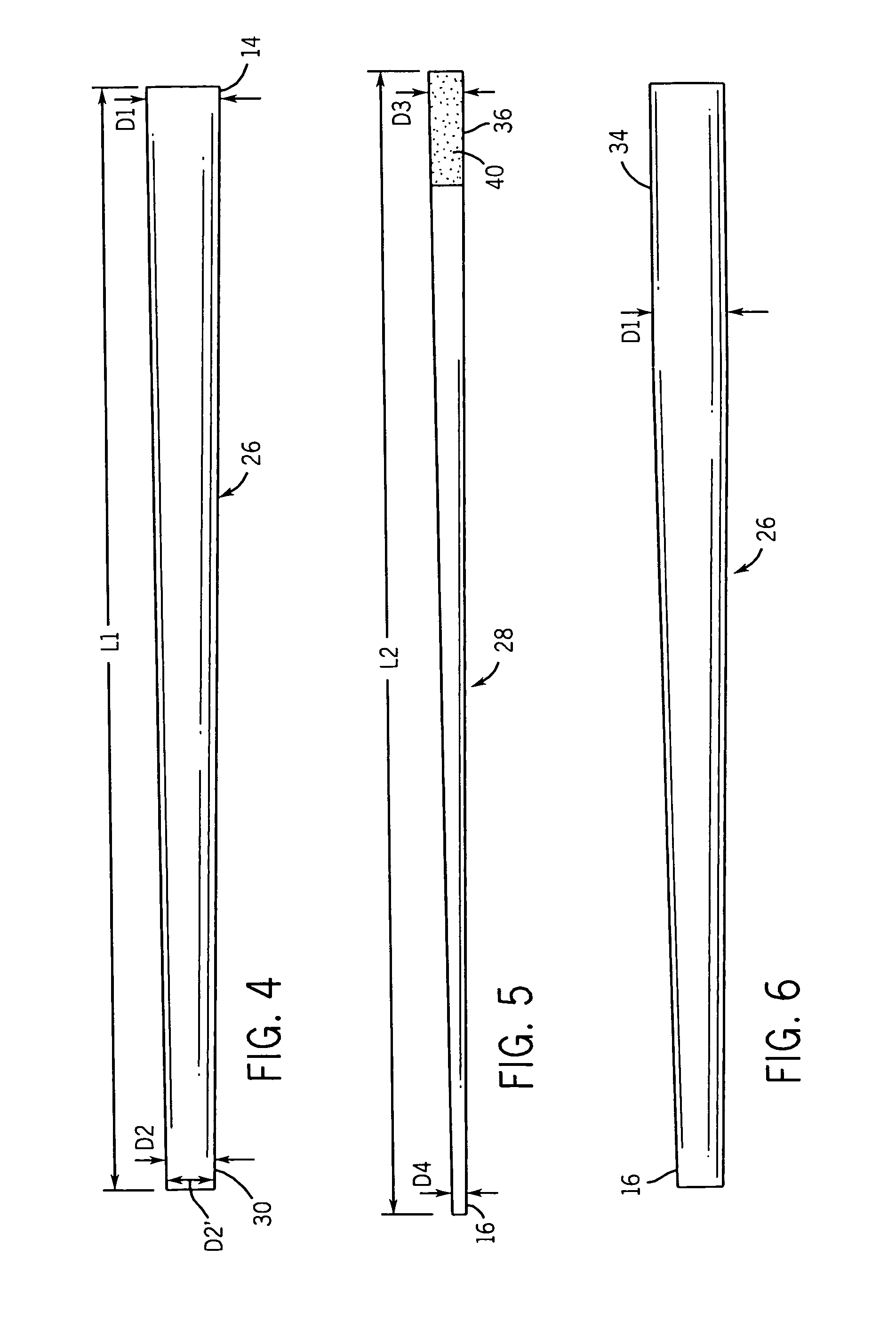

Multi-sectional co-cured golf shaft

ActiveUS20100317457A1Exceptional controlExceptional accuracyGolf clubsRacket sportsEngineeringGolf club

A shaft for a golf club having a total length and a total weight. The shaft includes first and second tubular portions. The first and second tubular portions are formed of first and second materials, respectively. The second tubular portion has a proximal end and a tip end. The tip end has an outside diameter of less than 0.400 inches. The distal end of the first tubular portion is co-cured to the proximal end of the second tubular portion. The shaft has a resistance to twisting about a longitudinal axis of the shaft, when tested under a torsional stability test and measured at an approximate midpoint of the total length of the shaft, of less than 2.0 degrees in a torsional stability test. The shaft when measured from the tip end of the shaft in a balance point test device has a balance point of less than 46 percent.

Owner:WILSON SPORTING GOODS

Multi-sectional co-cured golf shaft

A shaft for a golf club having a total length and a total weight. The shaft includes first and second tubular portions. The first and second tubular portions are formed of first and second materials, respectively. The second tubular portion has a proximal end and a tip end. The tip end has an outside diameter of less than 0.400 inches. The distal end of the first tubular portion is co-cured to the proximal end of the second tubular portion. The shaft has a resistance to twisting about a longitudinal axis of the shaft, when tested under a torsional stability test and measured at an approximate midpoint of the total length of the shaft, of less than 2.0 degrees in a torsional stability test. The shaft when measured from the tip end of the shaft in a balance point test device has a balance point of less than 46 percent.

Owner:WILSON SPORTING GOODS

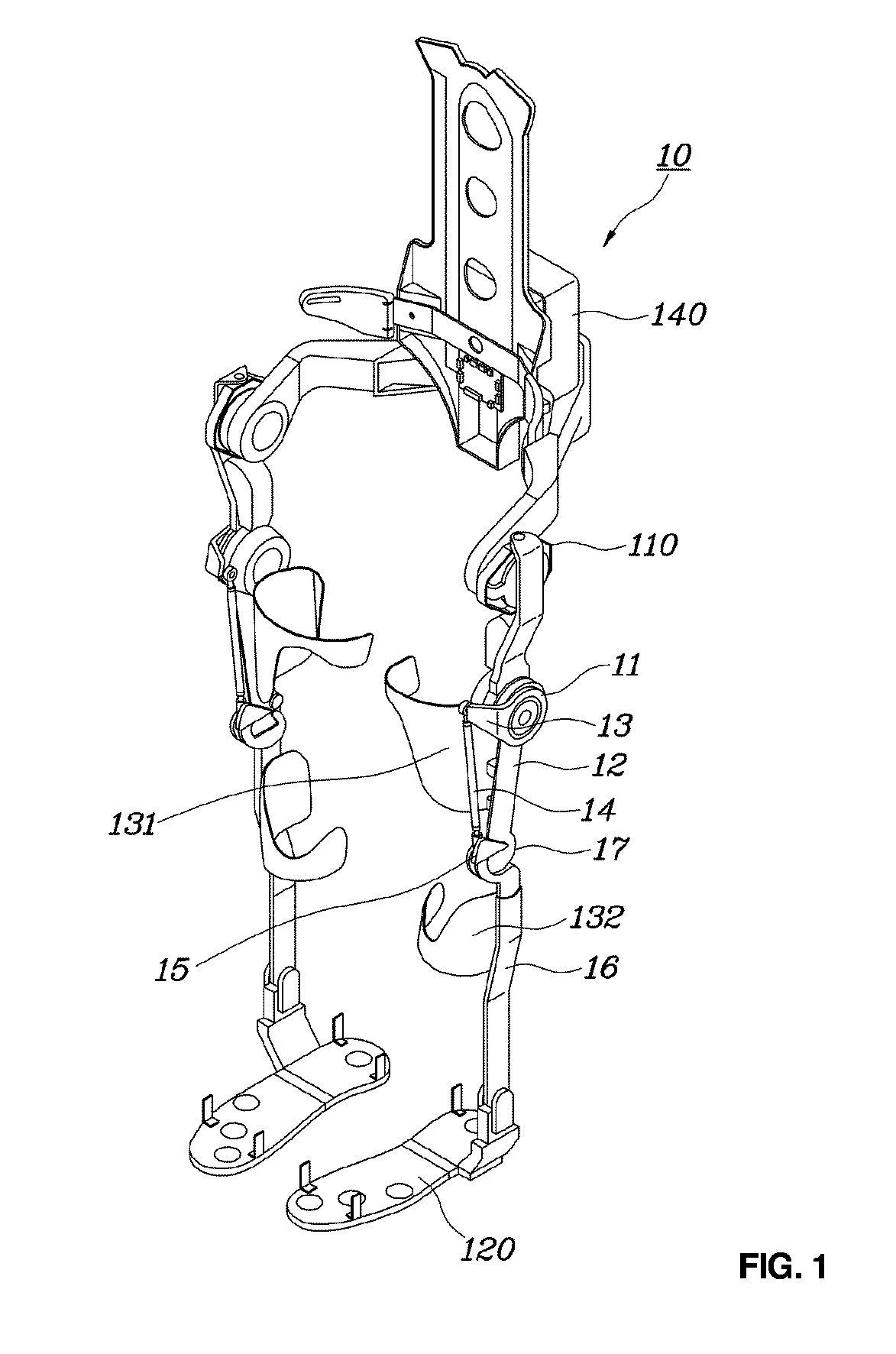

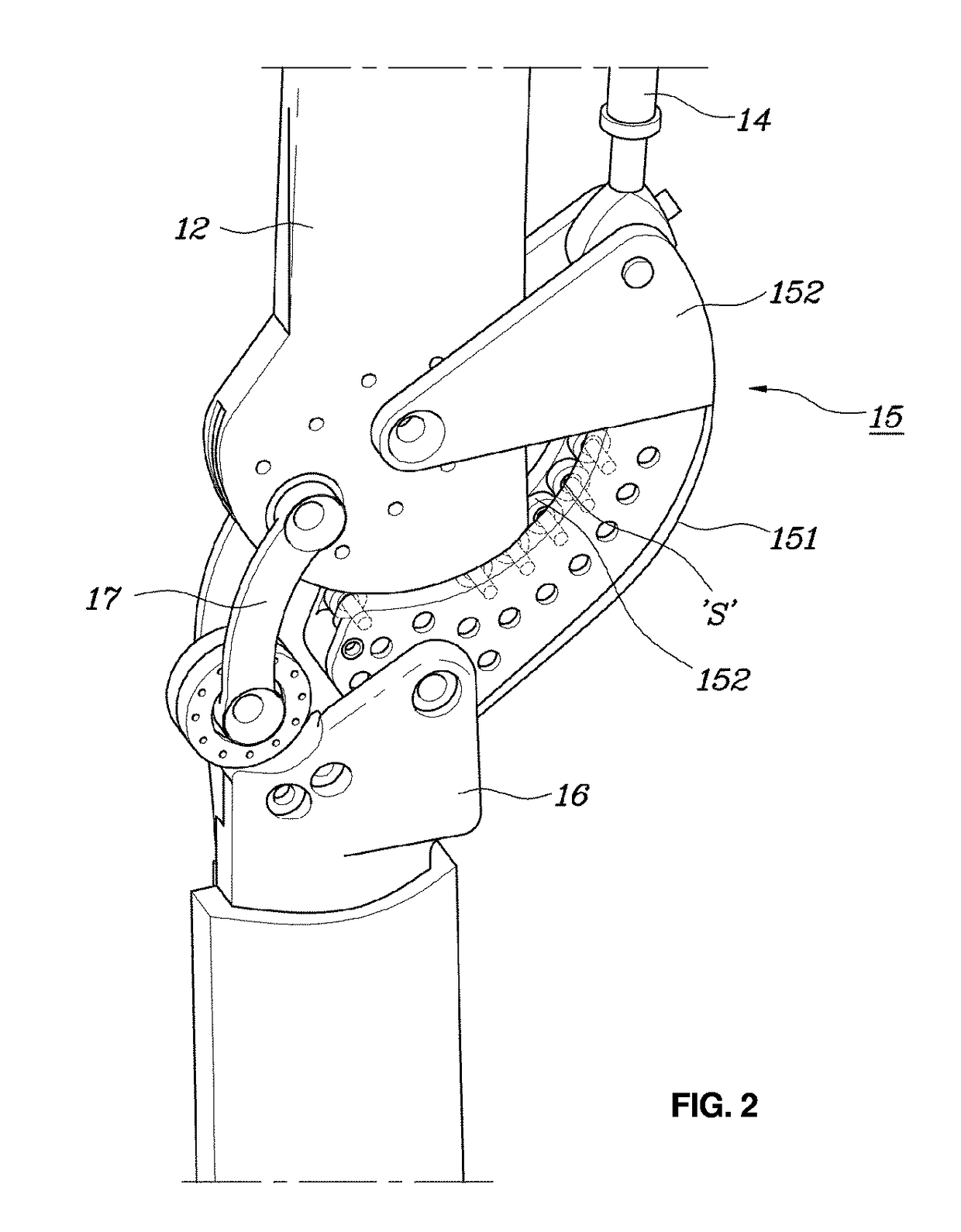

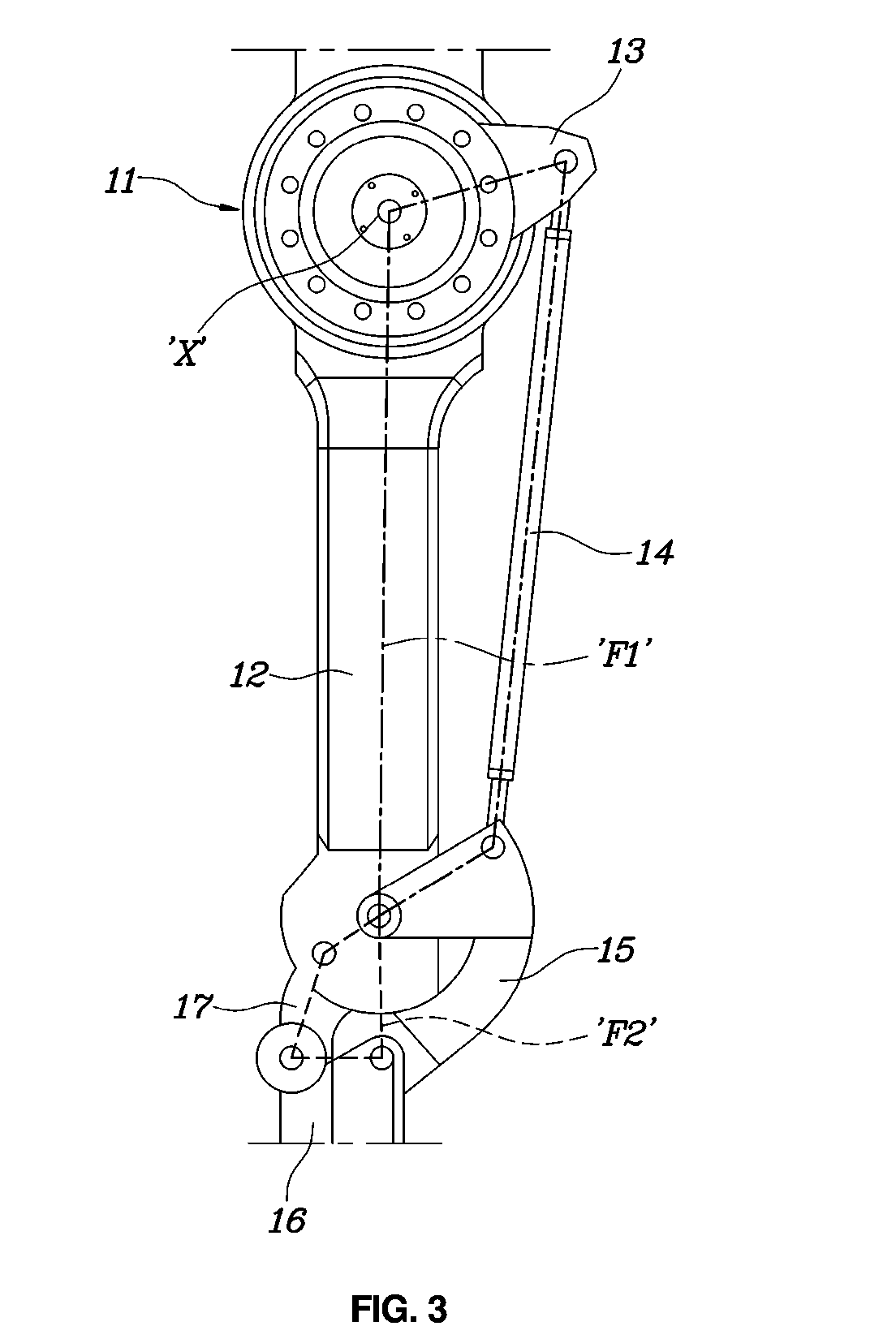

Multi-bar linkage, lower-limb exoskeleton robot using the same, and method of controlling the same

ActiveUS20190001493A1Comfortable to wearIntrinsic stability to resistProgramme-controlled manipulatorExoskeleton robotDrive shaft

Owner:HYUNDAI MOTOR CO LTD +2

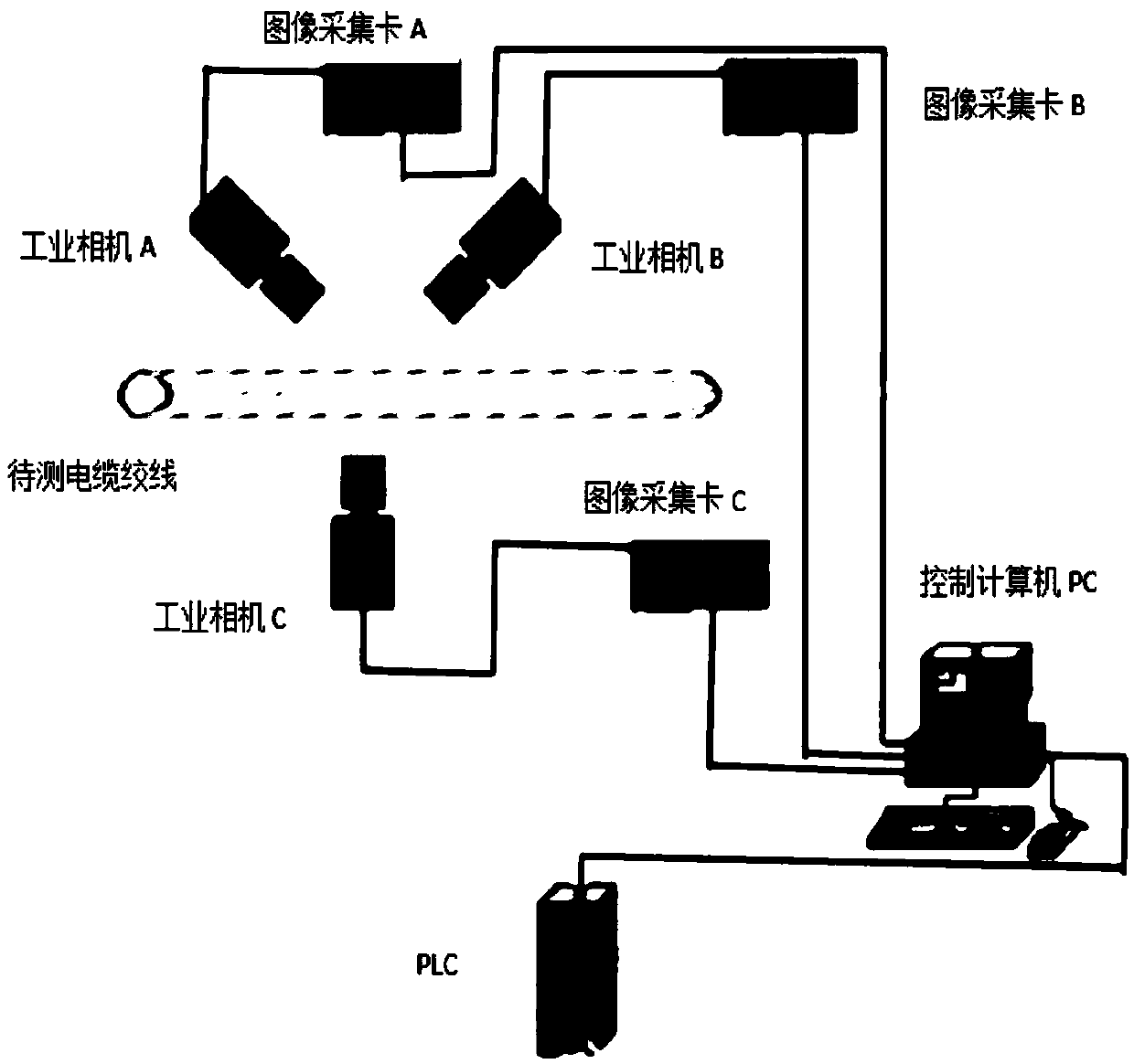

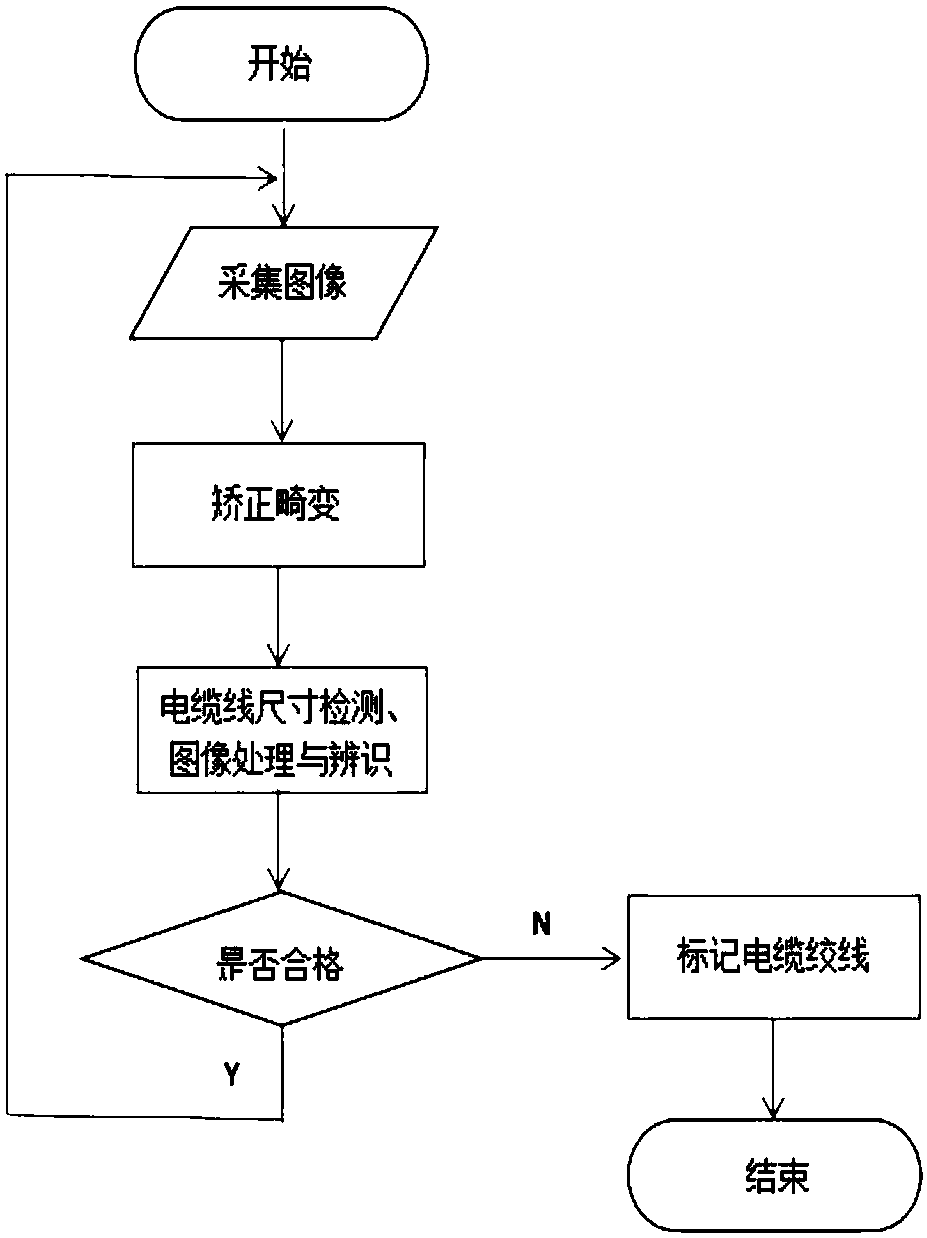

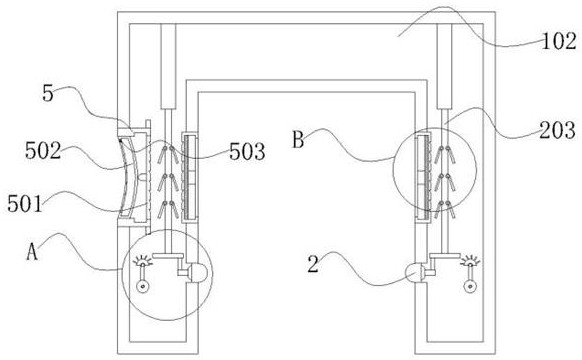

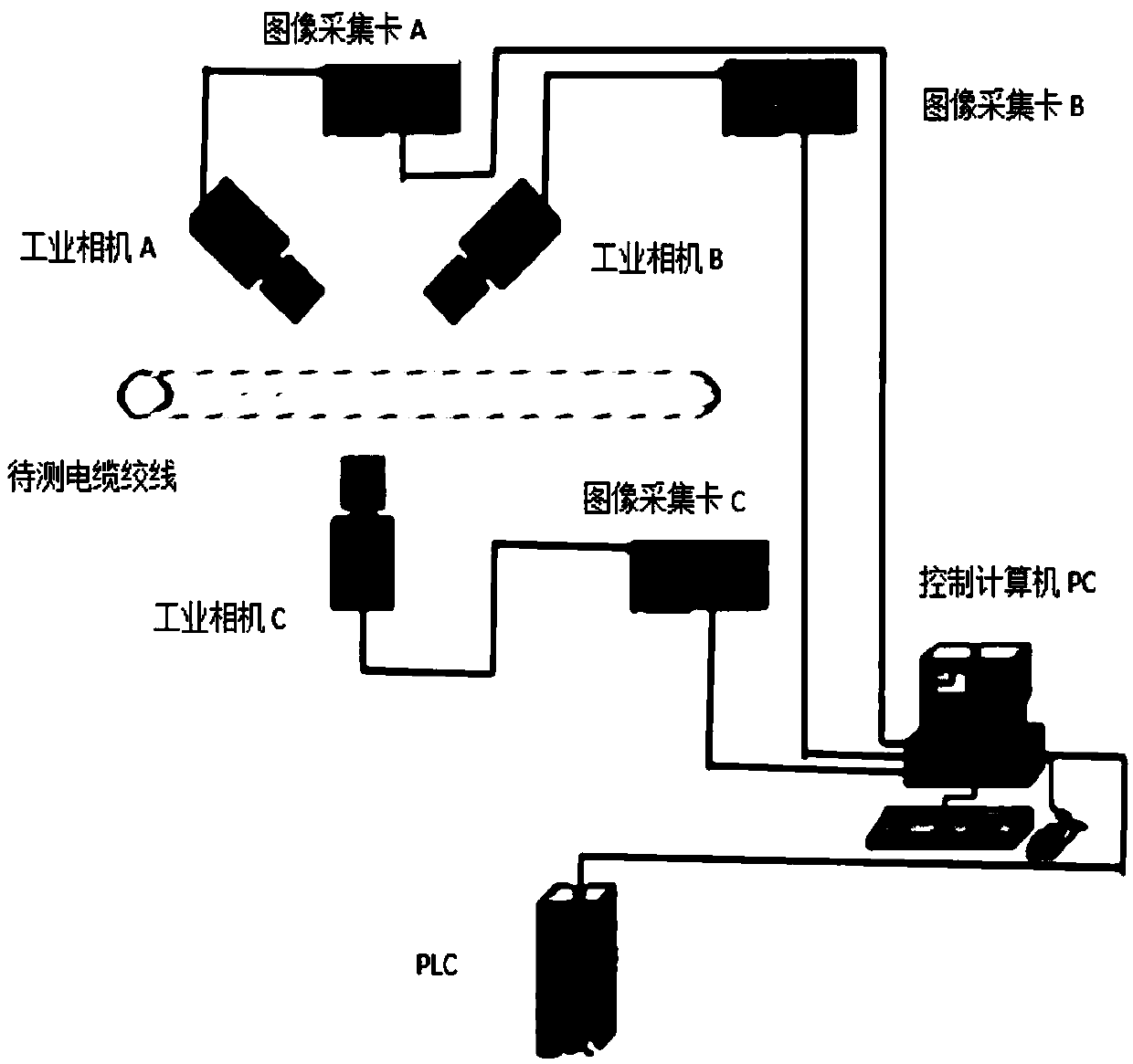

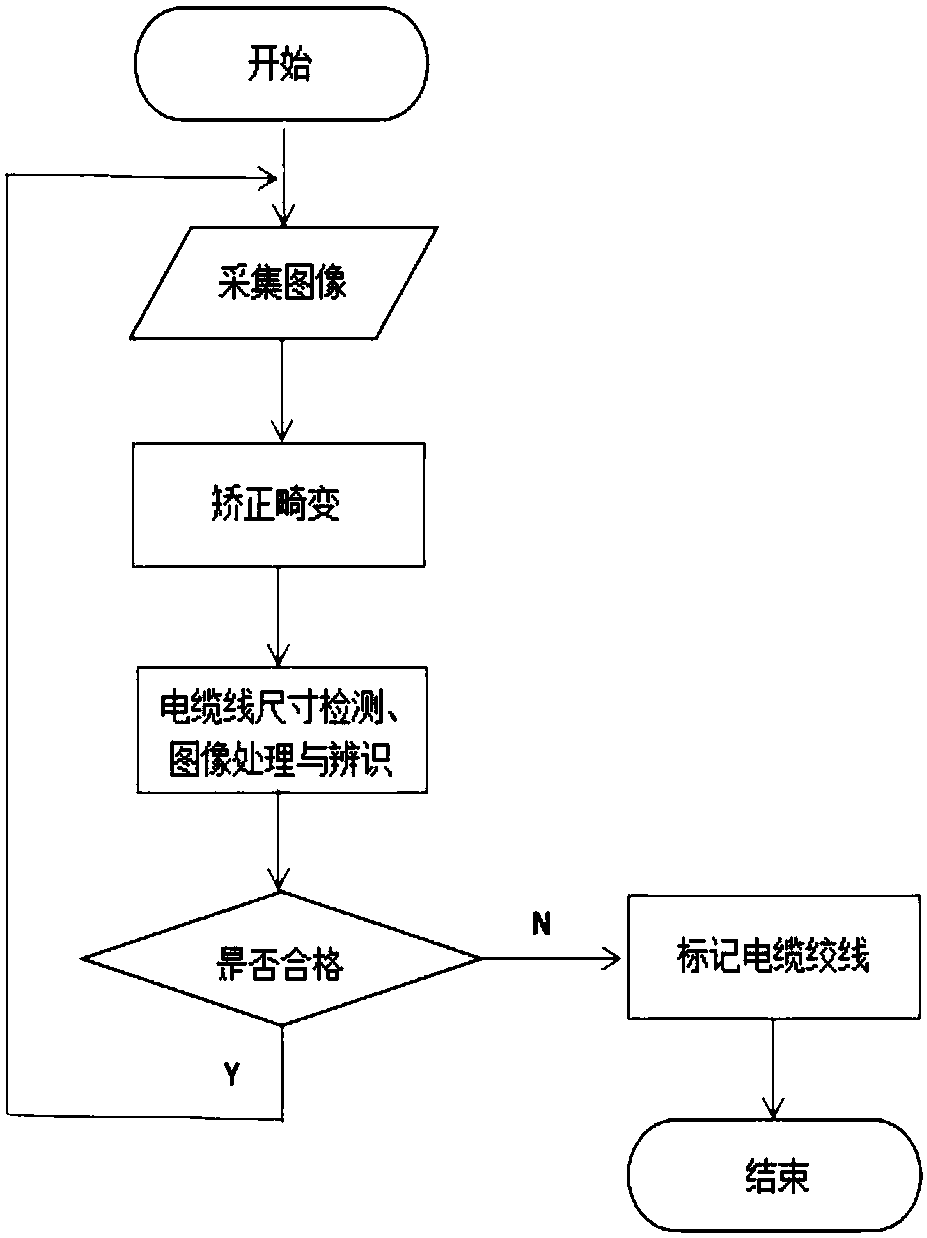

Twisted cable quality detection system based on machine vision and detection method for same

PendingCN107703148AAvoid scratchesImprove detection efficiencyOptically investigating flaws/contaminationUsing optical meansImaging processingMachine vision

The invention discloses a twisted cable quality detection system based on machine vision and a detection method for same. The system includes an image collection module, an image processing and identifying module, and a marking and positioning module. The signal receiving end of the image processing and identifying module is connected to the image collection module while a control end is connectedto the marking and positioning module. The image processing and identifying module is used for processing, identifying and size-detecting the collected image; the image collection module is used forcollecting an image of the twisted cable on line; the marking and positioning module is used for positioning and marking an unqualified twisted cable. The system can achieve on-line quality detectionand defect marking of the twisted cable, can greatly improve detection efficiency and avoid human influence, greatly reduces error, is more accurate in detection and avoids influence on production schedule due to detection. The detection is free of contact between hands and equipment and the twisted cable, so that damage on the twisted cable and injury on hands are avoided. The system is safer tooperate.

Owner:GUIZHOU UNIV

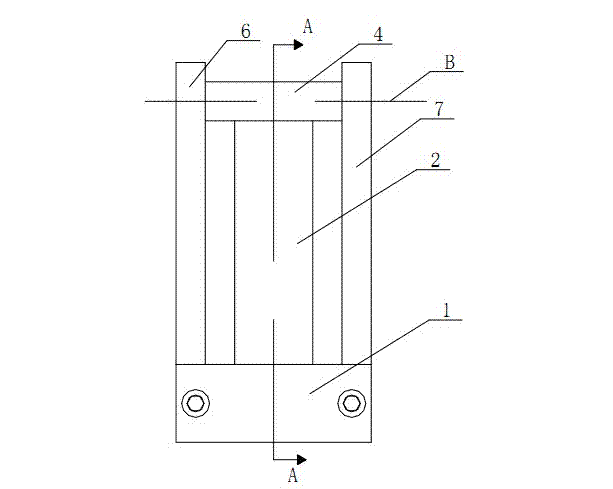

Hydraulic fast-oscillating valve

InactiveCN1743709ASwing fastQuick deflectionOperating means/releasing devices for valvesLift valveHydraulic cylinderEngineering

A hydraulic quick swing valve, which contains pipe shape valve body, rotation axle with air seal, power arm set on axle and connected with hydraulic cylinder, crank on rotation axle, linking lever on another end of crank, round valve board on end of linking lever, valve base matched with round valve board. Said invention utilizes lever principle making crank and linking lever rotating and swing to generate speed and pressure difference resulting quick rotating and swing to obtain high production and low energy consumption.

Owner:刘瑞祥

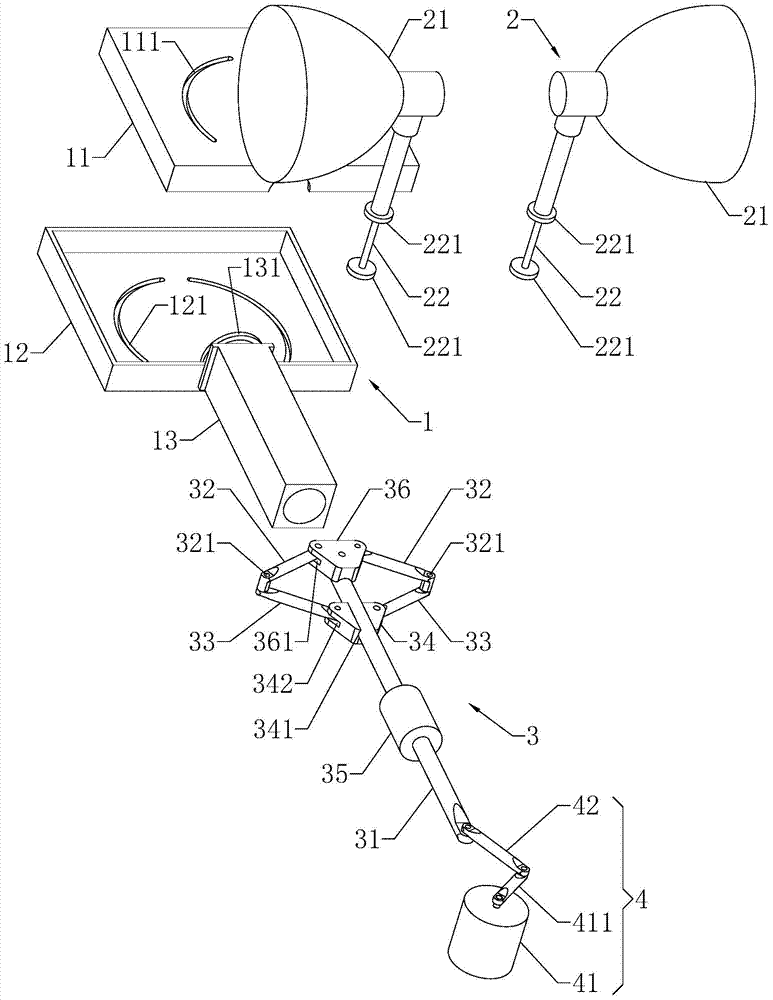

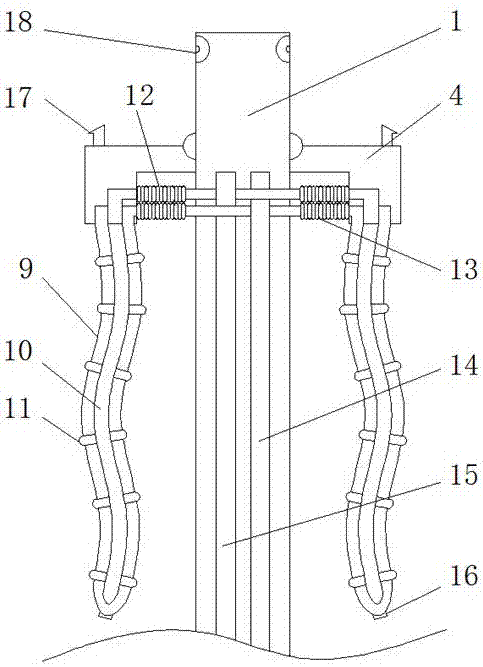

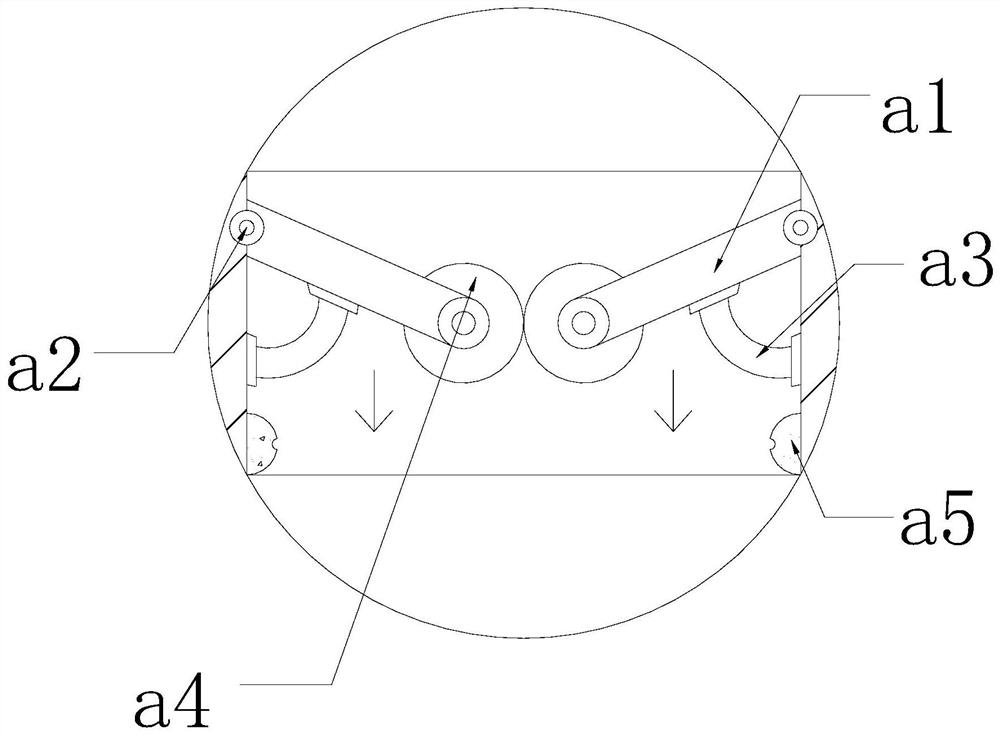

Lamp cap swing mechanism

The invention provides a lamp cap swing mechanism. The lamp cap swing mechanism comprises a shell component, a lamp cap component, a linkage component and a power component, wherein the shell component comprises an upper shell, a lower shell and a guide cylinder; the upper shell covers the lower shell to form one shell; the shell is provided with a cavity; the guide cylinder is arranged on the shell; the upper shell is provided with at least one first arc-shaped slotted hole; the lower shell is provided with a second arc-shaped slotted hole corresponding to the first arc-shaped slotted hole; the lamp cap component comprises a lamp cap and a rotating shaft; the rotating shaft is arranged at the lower end of the lamp cap and is inserted into the first arc-shaped slotted hole and the second arc-shaped slotted hole; the linkage component is used for driving the rotating shaft to slide in the first arc-shaped slotted hole and the second arc-shaped slotted hole and comprises a movable rod and a first hinge rod; the movable rod is inserted into the guide cylinder and penetrates into the cavity; one end of the first hinge rod is hinged to the movable rod, and the other end of the first hinge rod is provided with a shaft hole for the rotating shaft to pass through; the power component is used for driving the movable rod to do reciprocating motion in the guide cylinder; the movable rod is connected with the power component. According to the mechanism, the lamp cap can stably and quickly swing within a certain angle to emit light in a sweeping manner.

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +1

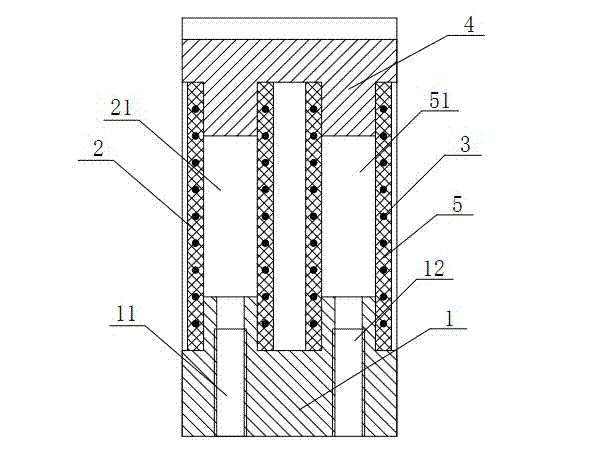

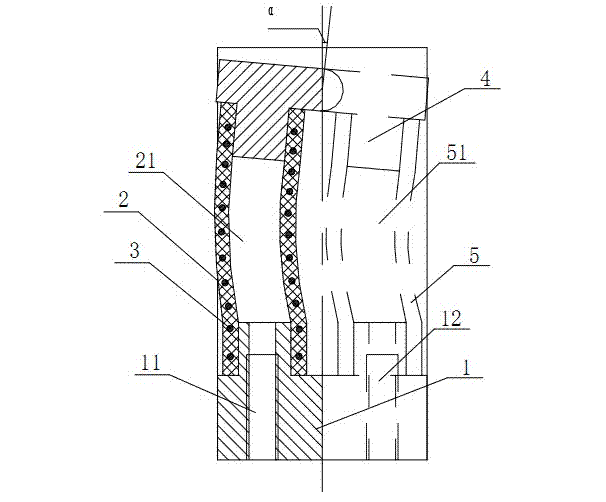

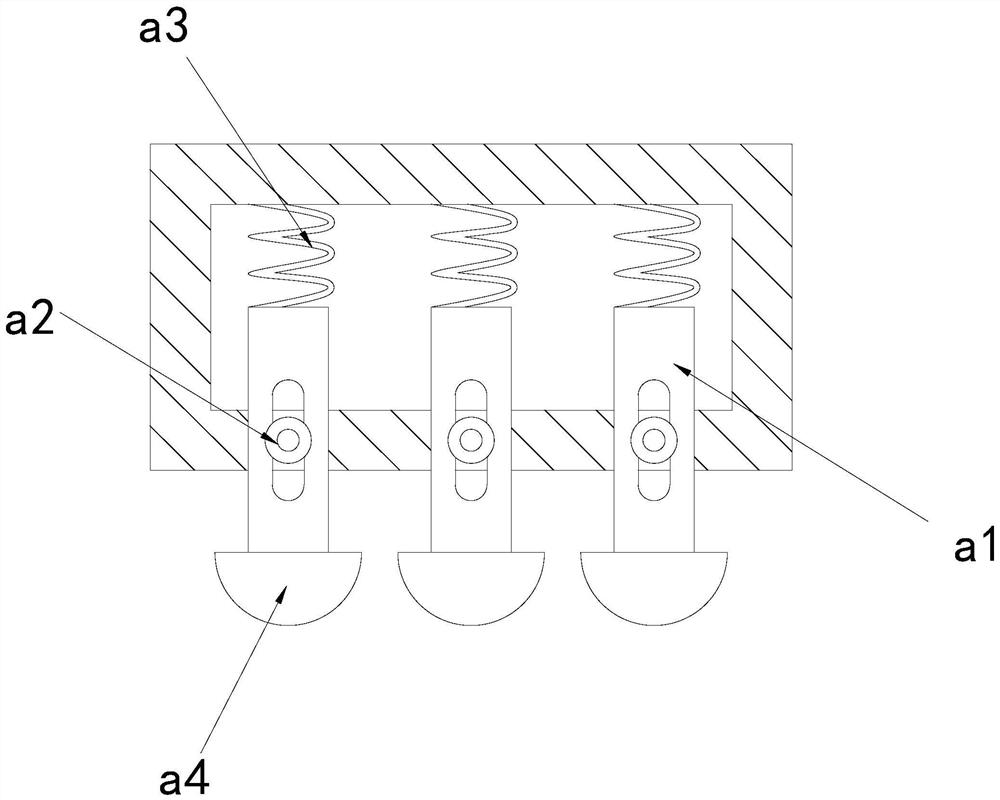

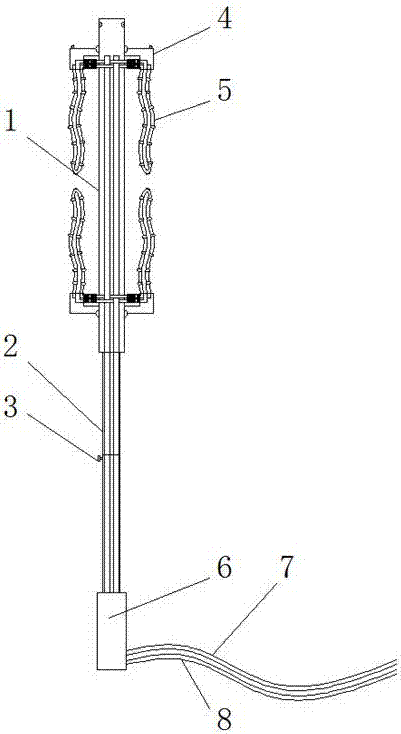

Pneumatic flexible swinging joint

The invention relates to a pneumatic flexible swinging joint which comprises a base and an end cover, wherein a first rubber hose and a second rubber hose, which are parallel from front to back, are hermetically connected between the base and the end cover; spaces in the first rubber hose and the second rubber hose are respectively a first internal joint cavity and a second internal joint cavity; a first threaded hole and a second threaded hole which are communicated with atmosphere are formed on the base; the first threaded hole is communicated with the first internal joint cavity; the second threaded hole is communicated with the second internal joint cavity; metal wires are embedded in both of the first rubber hose and second rubber hose; a left baffle and a right baffle are fixedly connected to the base; and the left baffle and the right baffle are hinged with the end cover. The pneumatic flexible swinging joint has the advantages that the structure is simple, the pneumatic flexible swinging joint can be easily miniaturized and can be conveniently assembled, disassembled and maintained, the operation is flexible, and the application value is higher.

Owner:ZHEJIANG UNIV OF TECH

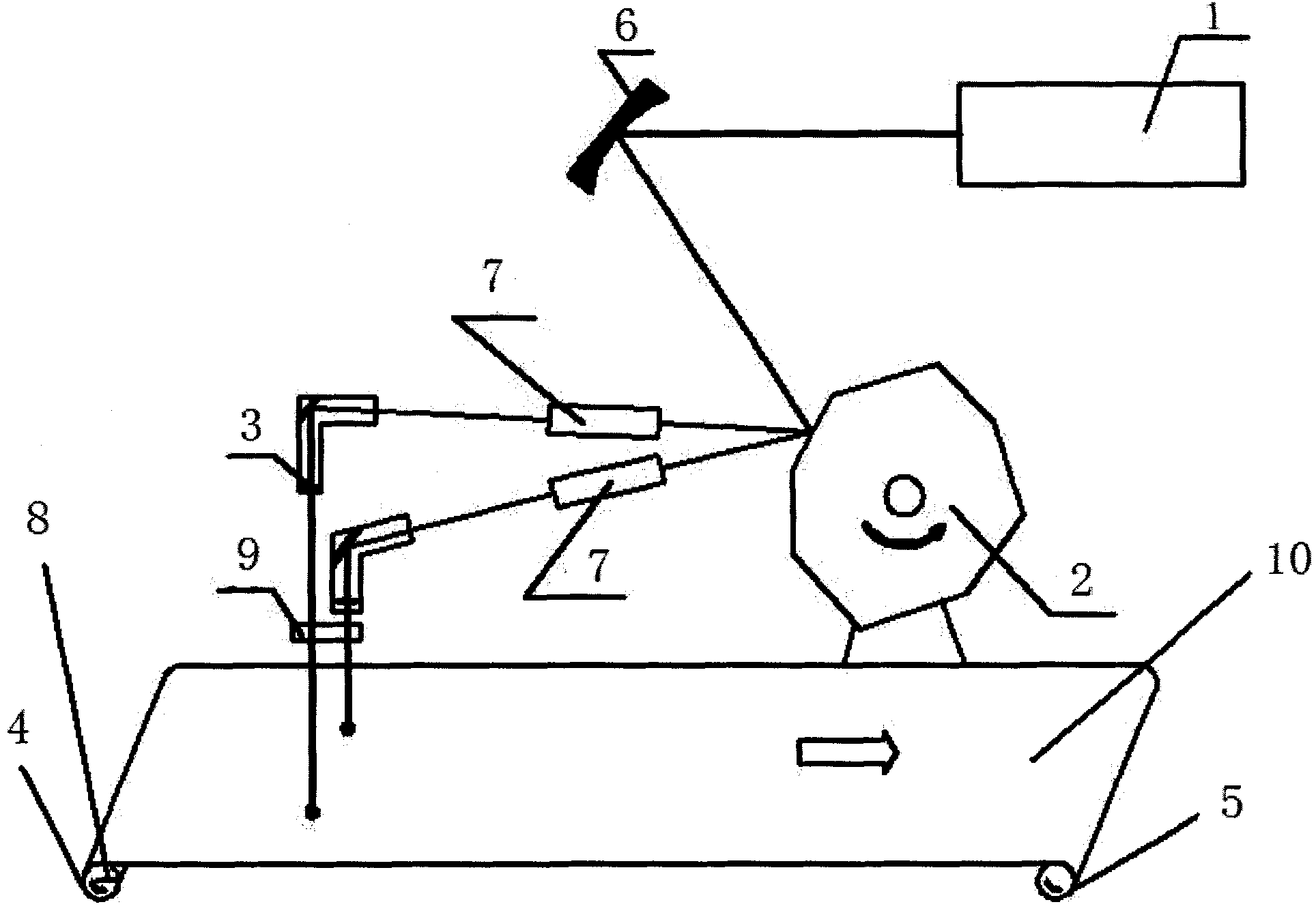

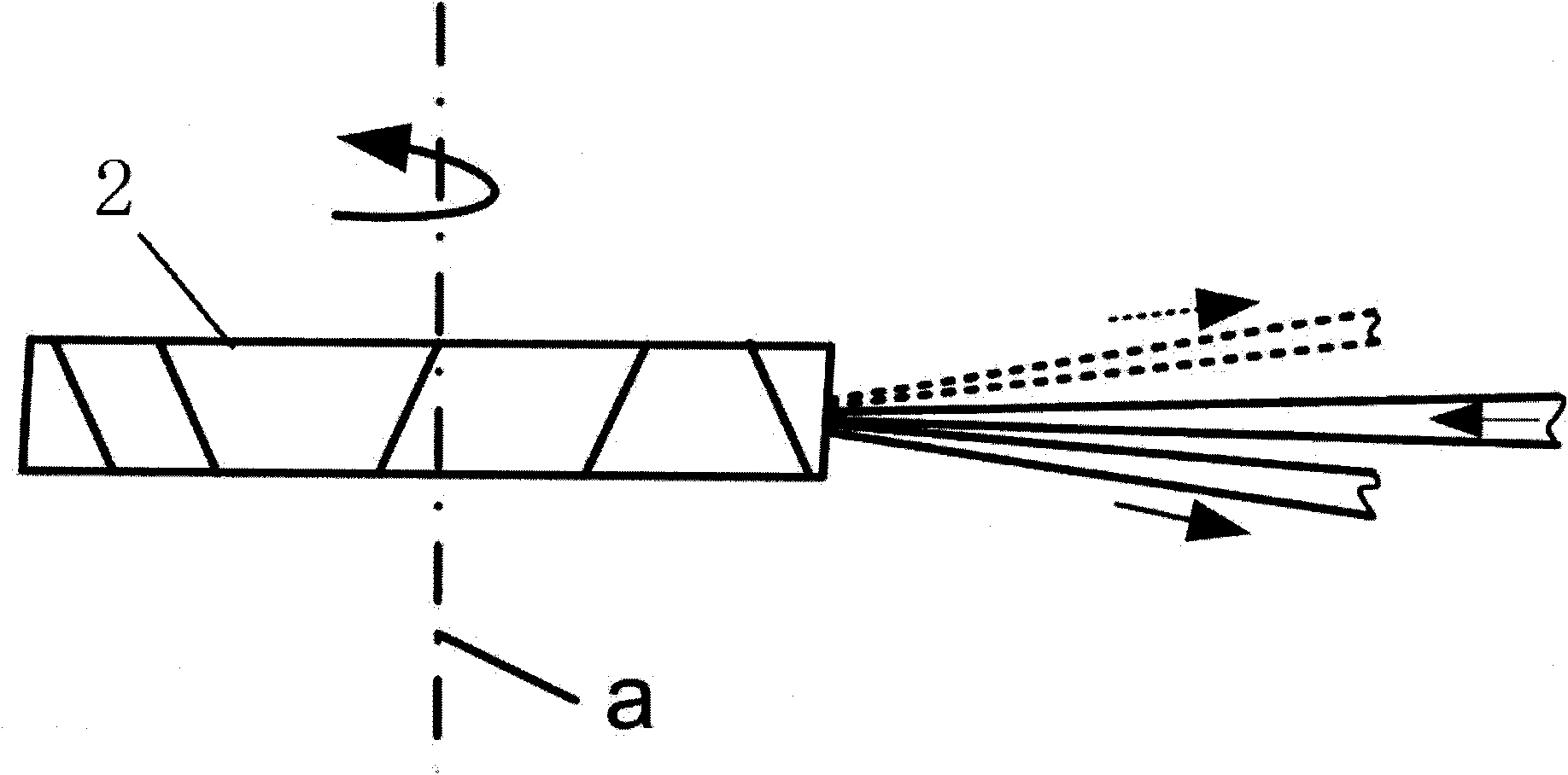

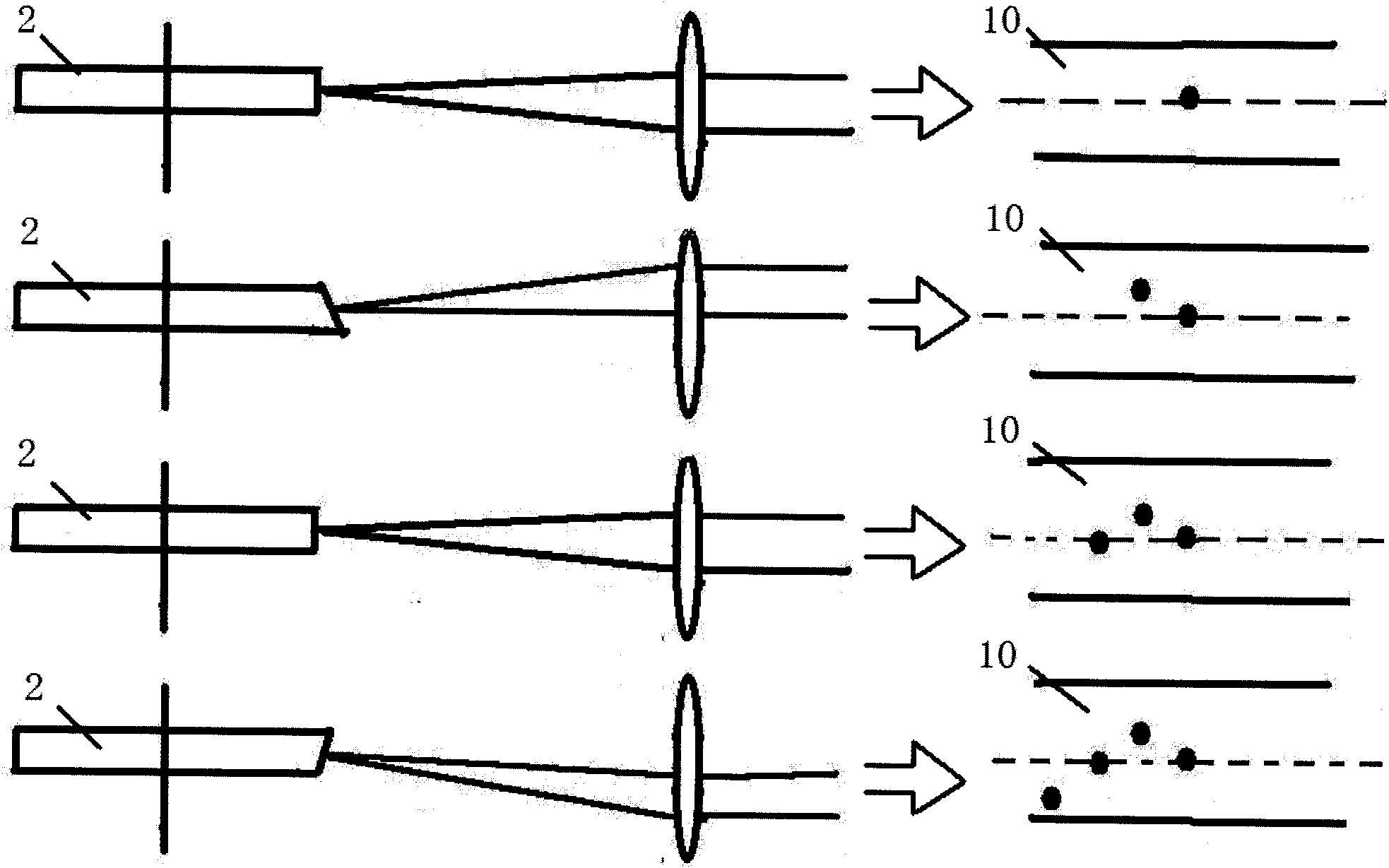

Focusing light spot oscillating type cigarette tipping paper laser boring method and device

InactiveCN101879663ASwing fastControllable defocus effectLaser beam welding apparatusBobbinBeam splitting

The invention discloses a focusing light spot oscillating type cigarette tipping paper laser boring method. Continuous laser beams output by a continuous laser are focused on a certain working surface of a high speed rotating prism, wherein, the included angles of normal direction of each working surface and mirror axis are inconsistent; K-path pulsed laser beams which can rapidly oscillate along the direction vertical to the rotary direction of the prism is formed by scanning and beam splitting of the prism; K focusing light spots which can horizontally and rapidly oscillate along a moving cork paper bobbin are formed by that K focusing heads focus and output the K-path pulsed laser beams; and repeated regular punching distribution of K nonlinear line lattices is formed on the surface of the cork paper bobbin, wherein, K is more than or equal to 1. The method of the invention can realize the continuous motion that the focusing light spot horizontally and rapidly oscillate along the cork paper bobbin to match with the cork paper bobbin, and drills small holes which are distributed in a curved shape or arrangement distribution of repeat graphs in the length direction of the cork paper bobbin on the surface of the cork paper bobbin.

Owner:苏州市博海激光科技有限公司

Suspended cloth cutting machine

The invention belongs to the technical field of textiles and particularly relates to a suspended cloth cutting machine. The suspended cloth cutting machine comprises a frame body and a base, and the sides, away from a cutter, of square airbags are provided with fourth pneumatic cylinders fixedly connected to the lower surface of a fixing plate; the fourth pneumatic cylinders are communicated withthe square airbags, the protruding ends of the fourth pneumatic cylinders are disposed vertically downward and fixedly connected with second pressing plates respectively, and the second pressing plates and first pressing plates are staggered; a second groove is formed in the portion, below the cutter, of the base, a vertical third pneumatic cylinder is fixedly connected in the second groove, the protruding end of the third pneumatic cylinder is fixedly connected with a jacking block, a cutting groove is formed in the upper surface of the jacking block, and the width of the cutting groove is greater than the thickness of the cutter. According to the suspended cloth cutting machine, through swing cutting of the cutter and the design of the arc surface of a cutting blade of the cutter, a cloth is cut more thoroughly; through the staggered arrangement of the first pressing plates and second pressing plates, the cloth is tightly pulled, so that cutting is smoother.

Owner:杭州杰西亚家居有限公司

Biological filtration waste gas removal equipment

InactiveCN112295330AReduce generationAccelerated corrosionDispersed particle filtrationTransportation and packagingFiltrationExhaust fumes

The invention discloses biological filtration waste gas removal equipment which structurally comprises a tower body, a discharge pipe and a gas inlet pipe, the discharge pipe is horizontally welded atthe bottom end of the front surface of the tower body, the gas inlet pipe is mounted in the right side of the front surface of the tower body, and when sulfuric acid is retained on the outer layer ofa filter screen, the filter screen is corroded by sulfuric acid, so that the thickness of the filter screen is gradually reduced; a pushing mechanism swings up and down under the pushing force of waste gas to push and vibrate the filter screen, sulfur dioxide substances retained on the outer wall of the filter screen shake and fall off, sulfuric acid generated by reaction of the sulfur dioxide substances, water molecules and oxygen is reduced, corrosion of the filter screen is reduced, the filter screen can fully filter the waste gas, as water molecules in waste gas cannot be completely filtered and absorbed by the filter screen and are easily retained on the inner side of the swing plate, the water molecules on the inner side of the swing plate are removed by the blades after the swing plate swings and resets, the bearing force of the swing plate is favorably reduced, the swing speed of the swing plate is increased, and the push vibration of the filter screen is accelerated.

Owner:赵乐洋

Catkin sucking umbrella

The invention discloses a catkin sucking umbrella and belongs to the technical field of catkin suction. The catkin sucking umbrella comprises a fixing tube. Suction mechanisms are arranged symmetrically on the two sides of the fixing tube. Each suction mechanism comprises L-shaped connecting rods and softened sucking bars. One ends of the L-shaped connecting rods are hinged to the fixing tube, and the other ends of the L-shaped connecting rods are connected with the softened sucking bars correspondingly. The L-shaped connecting rods are connected with buckles. The fixing tube is provided with clamping grooves matched with the buckles. Each softened sucking bar comprises an outer gas bar body and an inner gas bar body, wherein the inner gas bar body is located on the inner side of the outer gas bar body, the inner gas bar body is connected with a plurality of sucking tubes which are uniformly arranged on the inner gas bar body, and the sucking tubes penetrate through the outer gas bar body to extend outwards. The catkin sucking umbrella provided by the invention is convenient to operate, catkin on poplars and willows can be directly sucked, the catkin content in the air is decreased from the source, and influences on the poplars and the willows in the sucking process are reduced.

Owner:何永刚

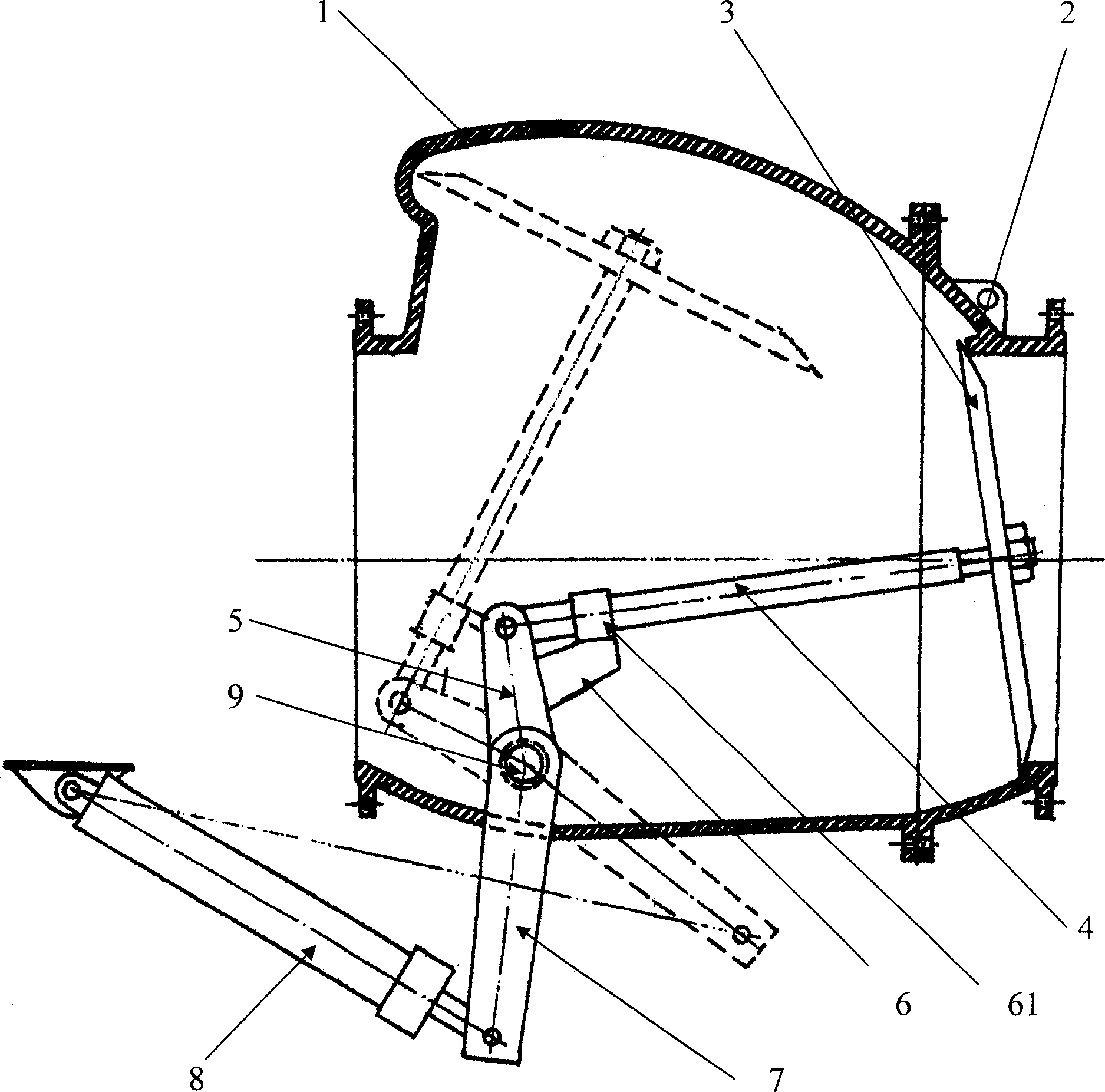

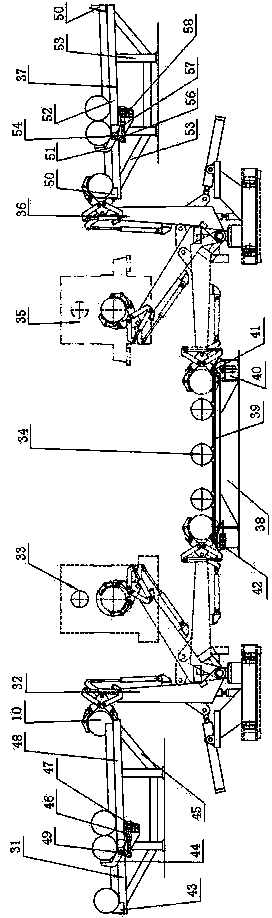

Automatic sleeve-loading and unloading and sleeve-transporting integrated device of cold-rolling mill

The invention discloses an automatic sleeve-loading and unloading and sleeve-transporting integrated device of a cold-rolling mill. The automatic sleeve-loading and unloading and sleeve-transporting integrated device comprises an inlet side sleeve manipulator, an outlet side sleeve manipulator, a sleeve transporting machine, an inlet side sleeve storing platform, an outlet side sleeve storing platform, wherein the lower end of a swinging arm of the inlet side sleeve manipulator or the outlet side sleeve manipulator is hinged on the upper end face of a chassis; a cylinder body of a swinging arm hydraulic cylinder is hinged at the upper end of a frame, the end part of a piston rod of the swinging arm hydraulic cylinder is hinged on a connecting plate I of the swinging arm; a sleeve clamp comprises two groups of synchronously-operating clamps which are hinged in the middle together and are hinged on a support block; the support block is hinged at the upper end of the swinging arm, a connecting plate II extends out of the support block, the end part of the connecting plate II is hinged at the end part of a piston rod of a fixture swinging hydraulic cylinder; a cylinder body of the fixture swinging hydraulic cylinder is hinged at the lower part of the swinging arm; a motor of the sleeve transporting machine drives a transporting chain to transport a sleeve from an uncoiling machine to a coiling machine. The automatic sleeve-loading and unloading and sleeve-transporting integrated device can complete a complete set of unloading, transporting, feeding and the like of an empty sleeve within a short time, and is high in working efficiency, stable and reliable to take or place the sleeve, free from damaging the sleeve, and low in energy consumption.

Owner:涿神有色金属加工专用设备有限公司

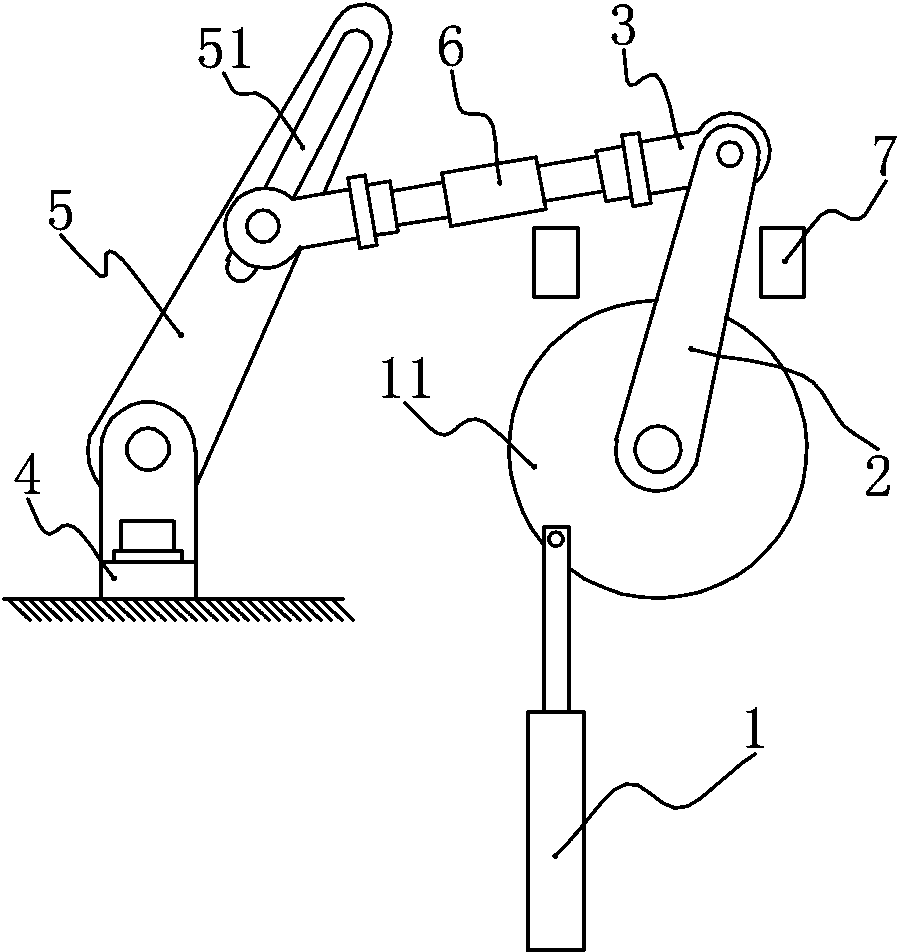

Pneumatic rotary feeding device

The invention discloses a pneumatic rotary feeding device which comprises a support. A cylinder is fixed onto the support, a piston rod of the cylinder is eccentrically hinged onto a rotary plate, and a rotary rod is coaxially fixed onto a rotary shaft of the rotary plate; a connecting rod is fixedly connected with a free end of the rotary rod and is divided into a hinge end and a slide end; a fixing seat is further arranged on the support, a swing rod for conveying workpieces is hinged onto the fixing seat, a slide groove is formed in the middle section of the swing rod, and the slide end of the connecting rod is fixed into the slide groove. The pneumatic rotary feeding device has the advantages that the rotary plate is driven by the cylinder to swing in a reciprocating manner, and the rotary rod fixed onto the rotary plate can be driven to swing in a reciprocating manner; the rotary rod is hinged to the connecting rod, and the slide end of the connecting rod is fixed into the slide groove in the swing rod, so that the swing rod can be driven by the connecting rod to swing in a reciprocating manner, and a swinging angle of the swing rod can be larger than a swinging angle of the rotary rod.

Owner:CHONGQING CHENGSHUO TECH

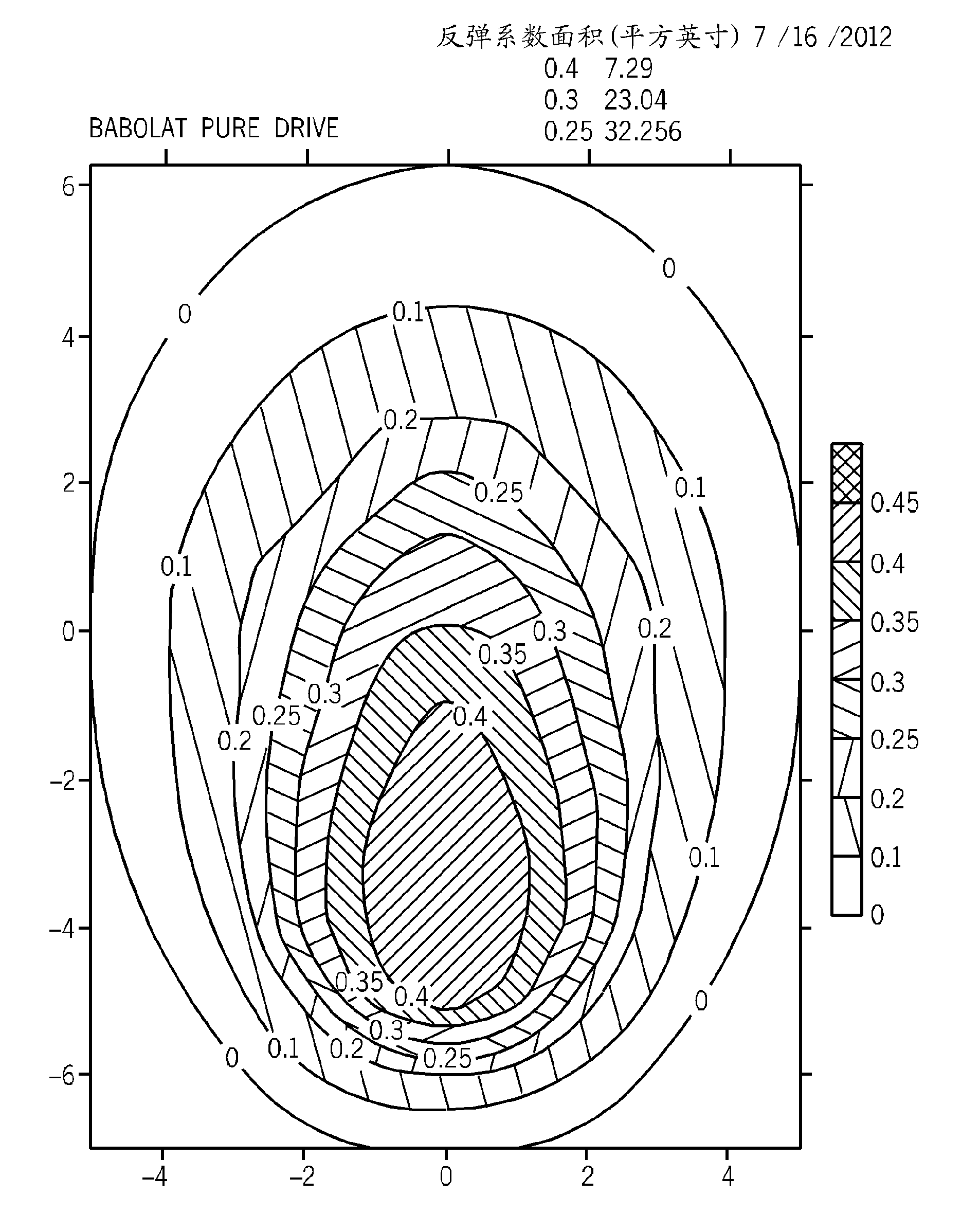

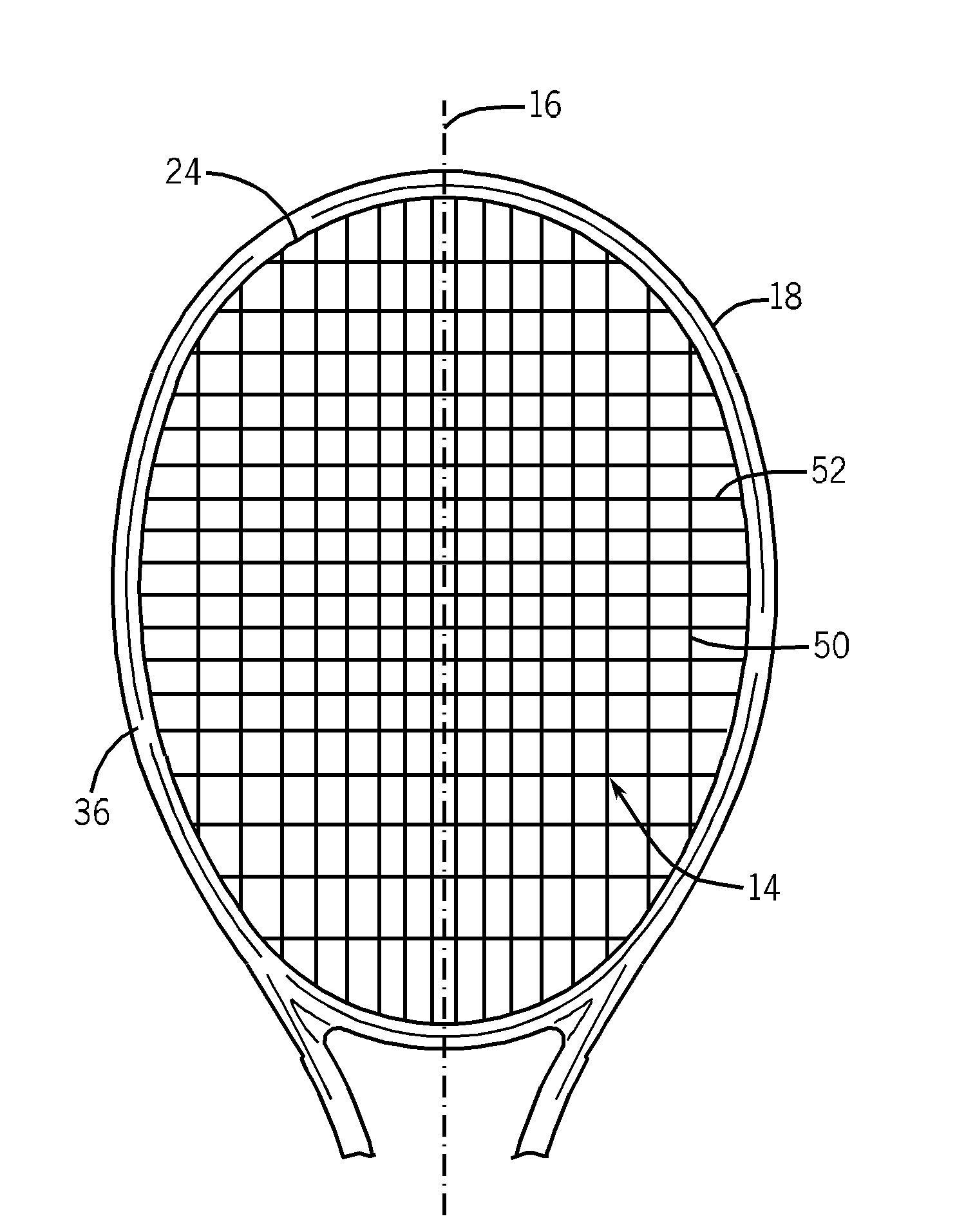

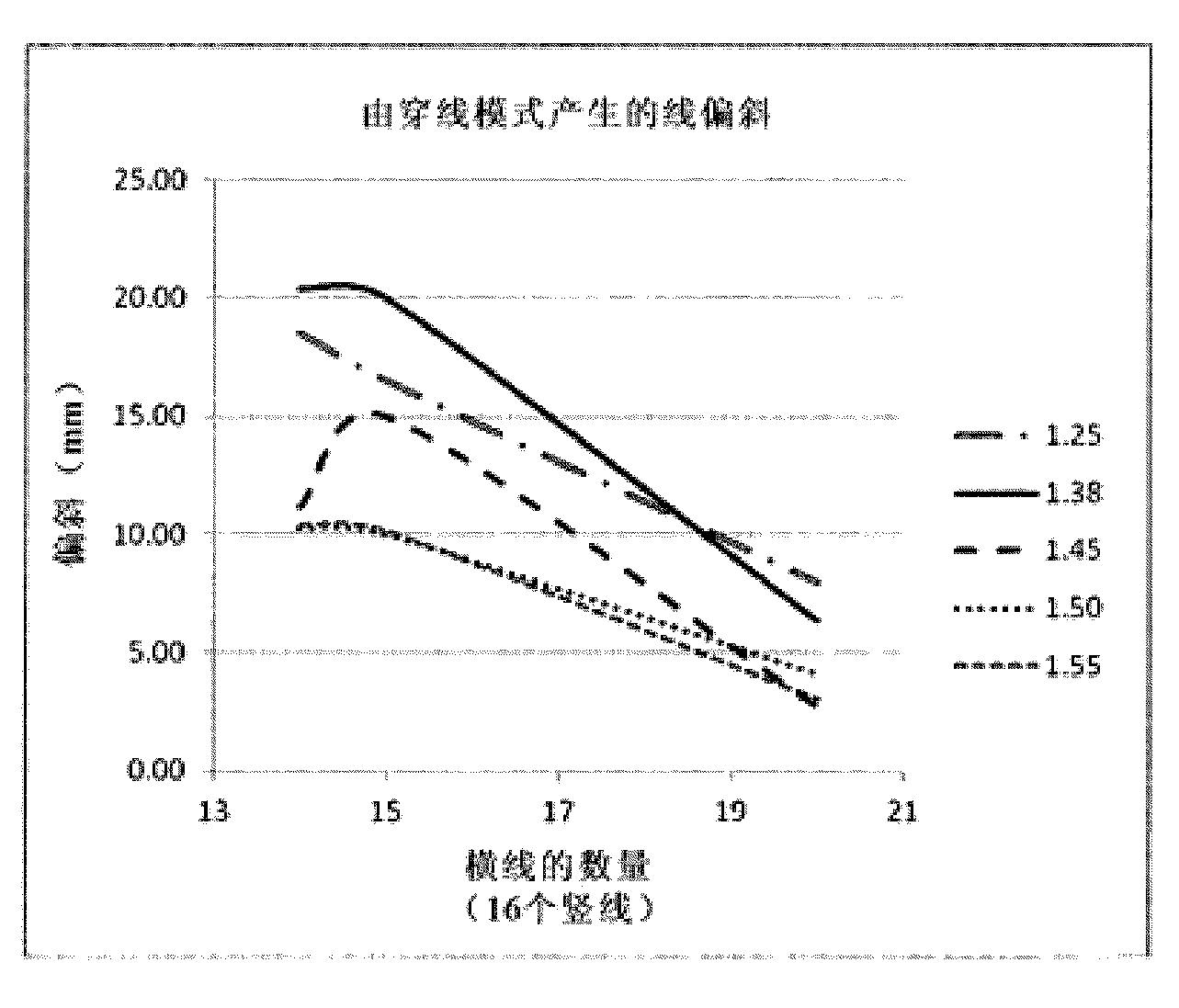

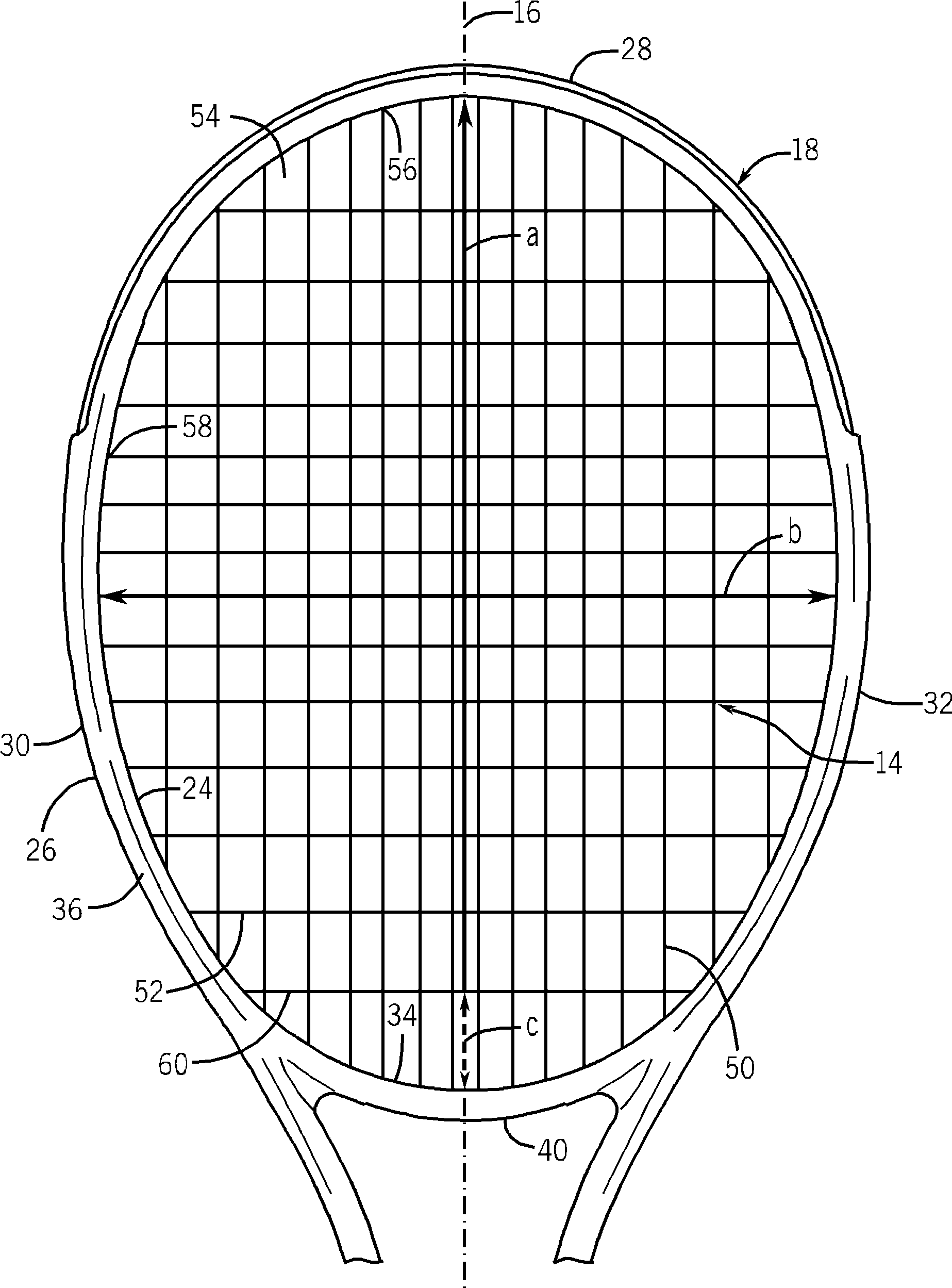

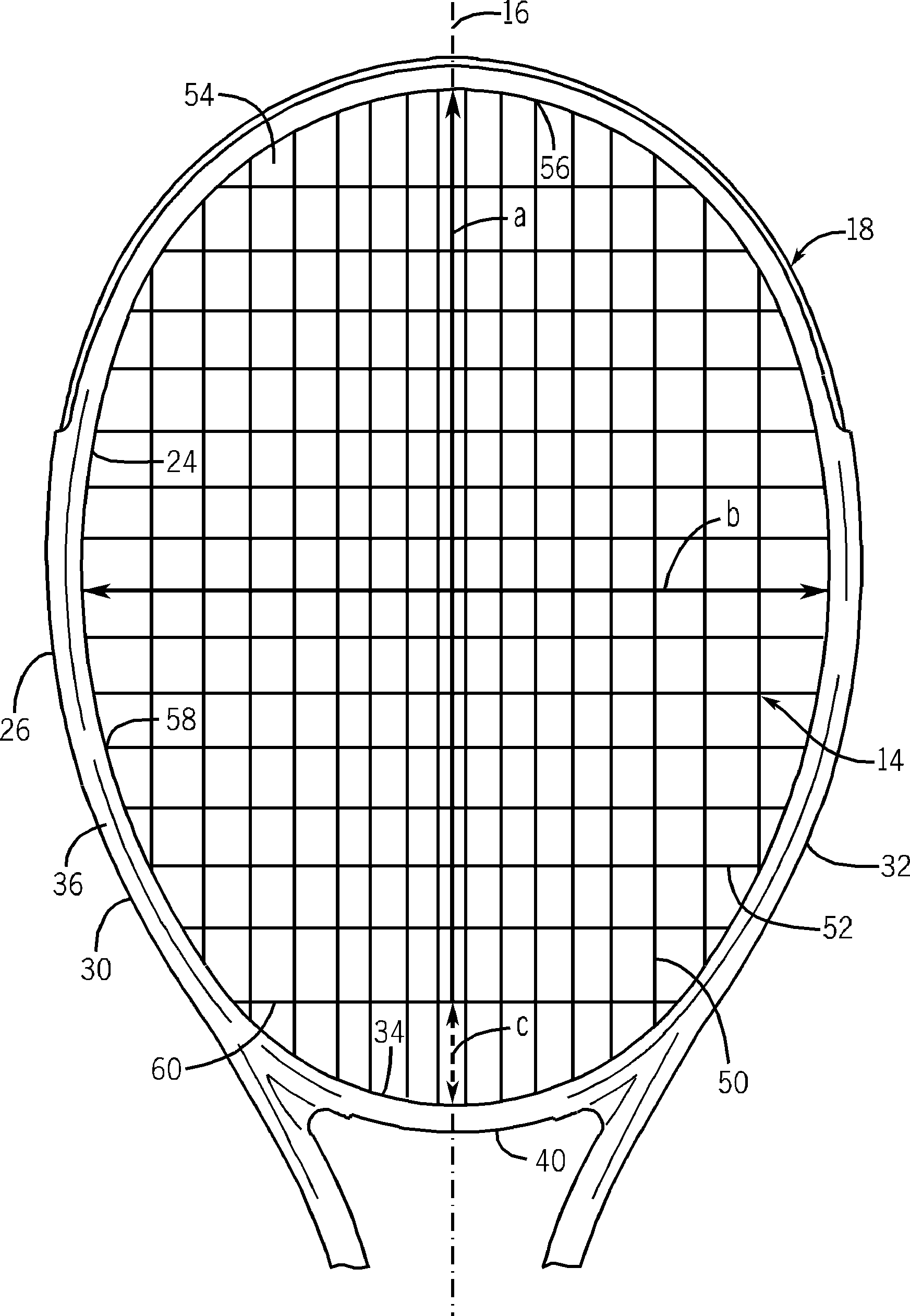

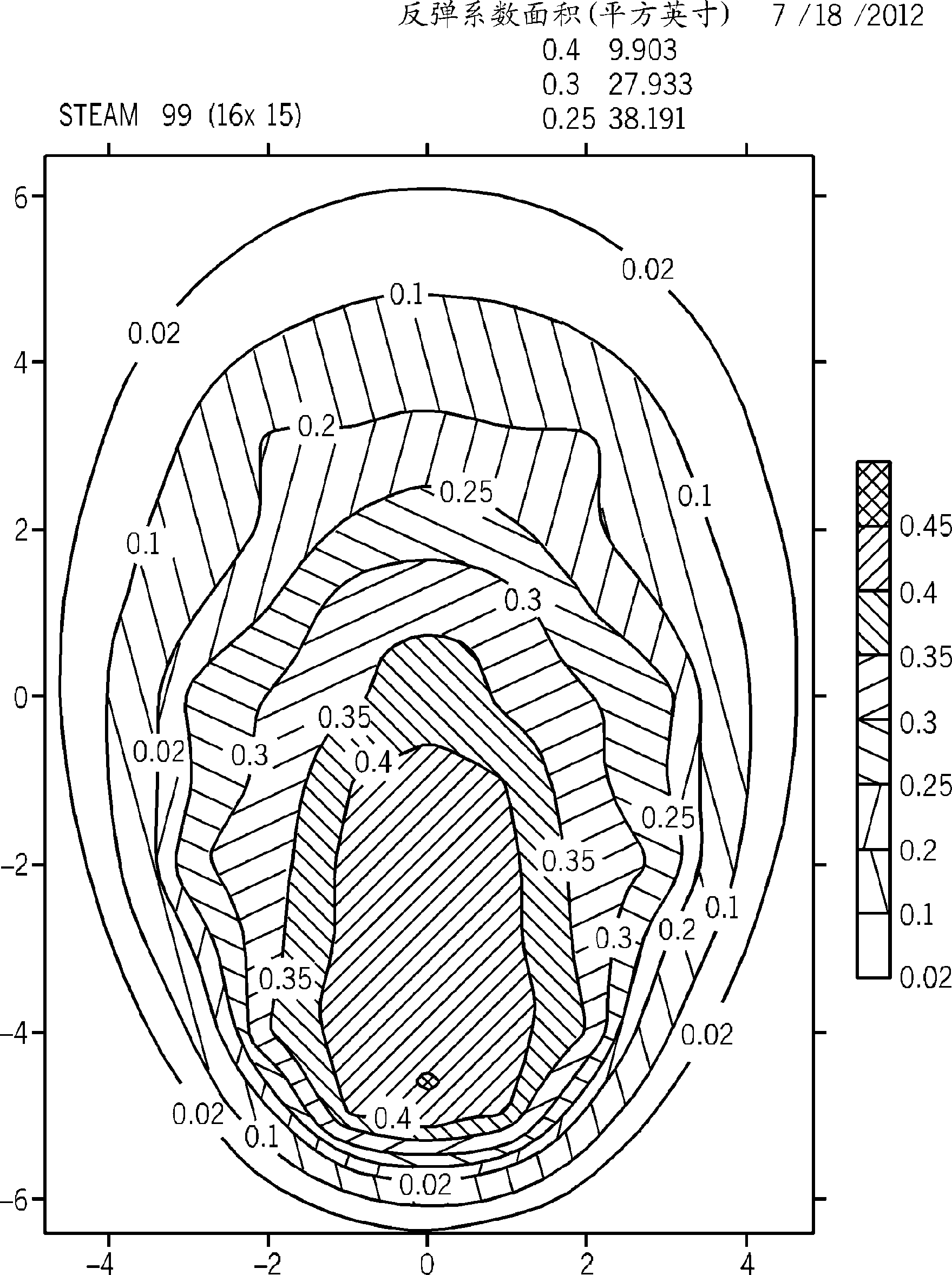

Racquet configured with fewer cross strings than main strings

A racquet configured with fewer cross strings than main strings is disclosed. The racquet includes polyester, monofilament racquet strings and a frame extending along a longitudinal axis and including a head portion coupled to a handle portion. The head portion includes a hoop having inner and outer peripheral walls. The hoop defines a head size having maximum longitudinal and transverse dimensions, a, and, b, respectively. The dimension a is at least 1.2 times the dimension b. The inner peripheral wall includes string holes. The string has a diameter within the range of 1.10 to 1.55 millimeters. The string forms a string bed of interlaced main and cross string segments. Each of the cross segments transversely extends from one of the string holes to another, and each of the main segments longitudinally extends from one of the string holes to another. The string bed has at least one more main segment than cross segment. At least one of the main segments contacting the tennis ball exhibits a snap back velocity of at least 1 meter per second.

Owner:WILSON SPORTING GOODS

Spraying device for agricultural irrigation

InactiveCN112293212AExpand the irrigated areaBest spraying efficiencyClimate change adaptationWatering devicesAgricultural engineeringAgricultural irrigation

The invention discloses a spraying device for agricultural irrigation. The spraying device comprises a base and a communicating pipeline, the base is fixedly installed on the ground, a water pipe is fixedly installed on the base, the two ends of the communicating pipeline are fixedly connected to the water pipe and a spray head correspondingly, and the interiors of the water pipe and the spray head which are connected with the communicating pipeline are communicated through the communicating pipeline; and an adjusting mechanism acting on irrigation water is installed on the spray head, and a driving mechanism acting on the adjusting mechanism is installed on the communicating pipeline. According to the spraying device for agricultural irrigation, through the adjusting mechanism, the spraying range of the irrigation water can be automatically and circularly adjusted, so that the area where the irrigation water is sprayed is not limited to a certain area, and the irrigation area is greatly improved; meanwhile, the adjusting mechanism is driven by water power, so that the energy-saving effect is achieved; and according to the spraying device, a water dispersing frame is fixedly installed in a through hole in a movable block, the irrigation water sprayed out of the spray head is in a scattered state, and therefore it is guaranteed that the spraying efficiency is optimal.

Owner:李海花

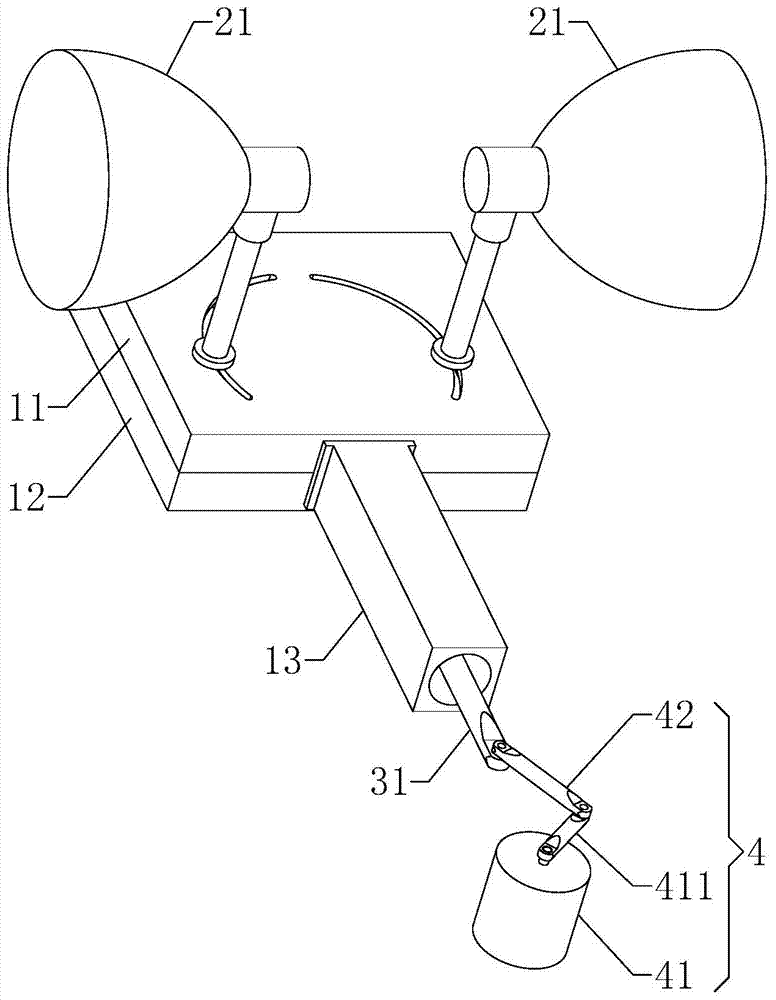

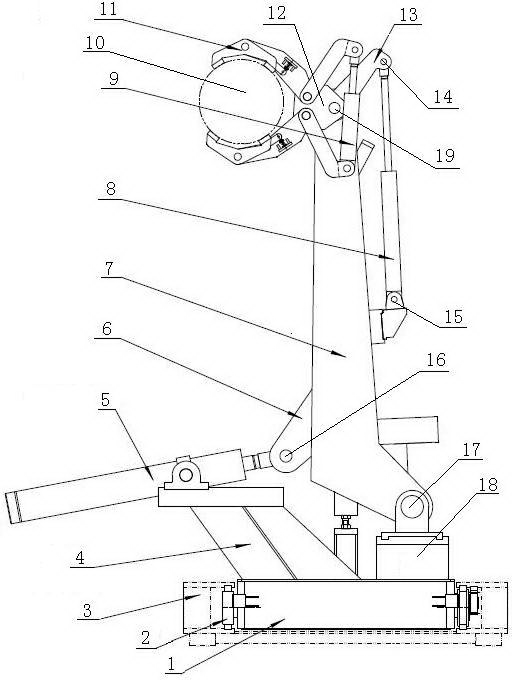

Parallel three-freedom-degree mechanism device based on oscillating cylinder driving and control method

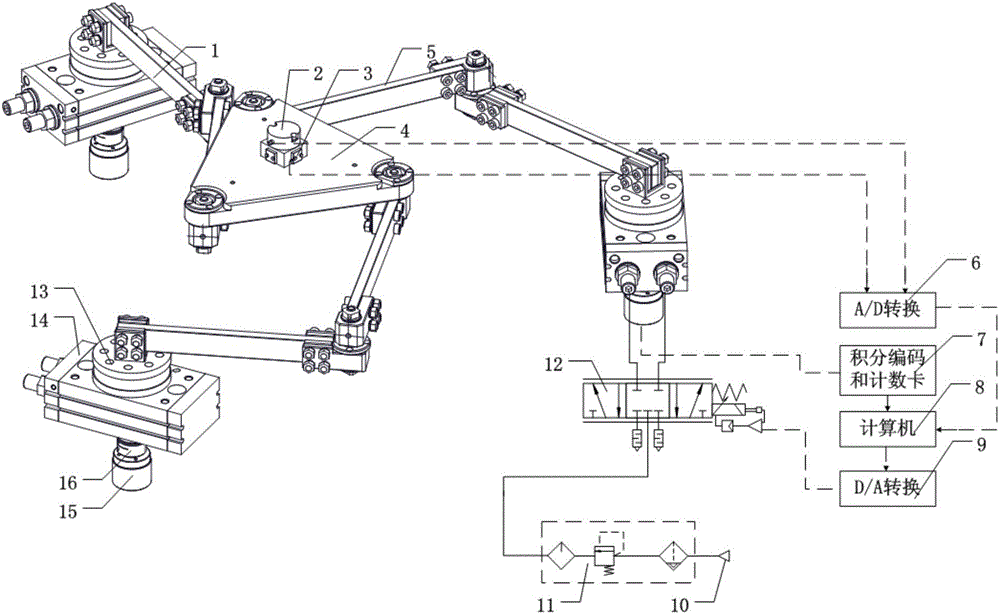

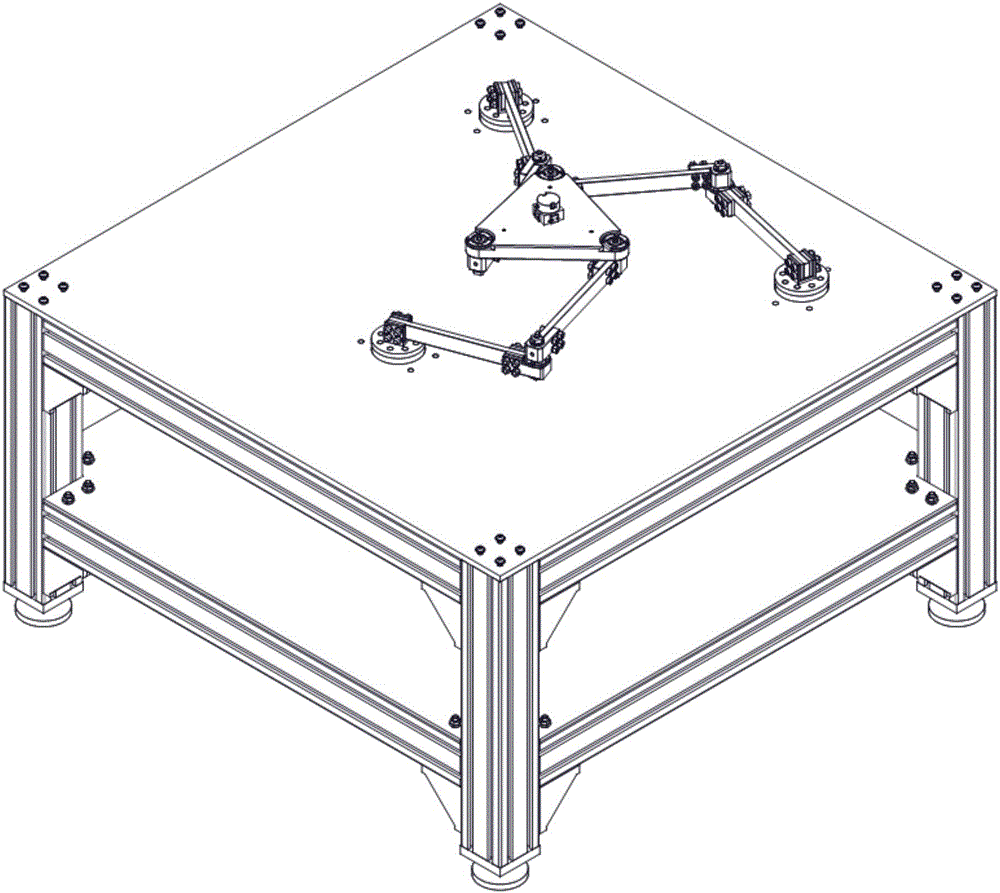

PendingCN106625572AQuality improvementSimple structureProgramme-controlled manipulatorEngineeringFeedback control

The invention discloses a parallel three-freedom-degree mechanism device based on oscillating cylinder driving and a control method. The device comprises a fixed platform, a movable platform, three parallel driving control branches, a pneumatic unit, a signal detection module and a control unit. Each parallel driving control branch comprises an oscillating cylinder, a drive rod and a driven rod which are sequentially connected, wherein the oscillating cylinder is fixedly connected to the fixed platform and connected with the pneumatic unit, and the driven rod is fixedly connected with the movable platform. The signal detection module comprises an acceleration sensor, an angular speed sensor and angular displacement encoders. The acceleration sensor and the angular speed sensor are installed on the movable platform. The angular displacement encoders are connected to the bottoms of the oscillating cylinders through couplers. The control unit is connected with the pneumatic unit and the signal detection module. According to the parallel three-freedom-degree mechanism device based on oscillating cylinder driving and the control method, proper design of the oscillating cylinders and a mechanical arm is selected to be applied so that the device can achieve the optimal working space and the optimal working track which correspond to the device, and feedback control over the movement of the device can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

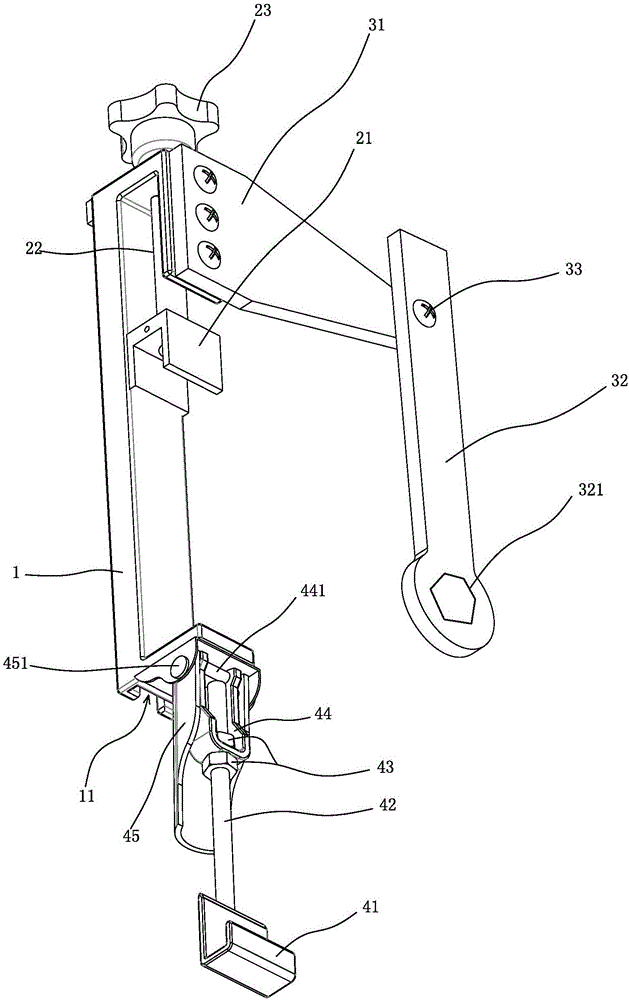

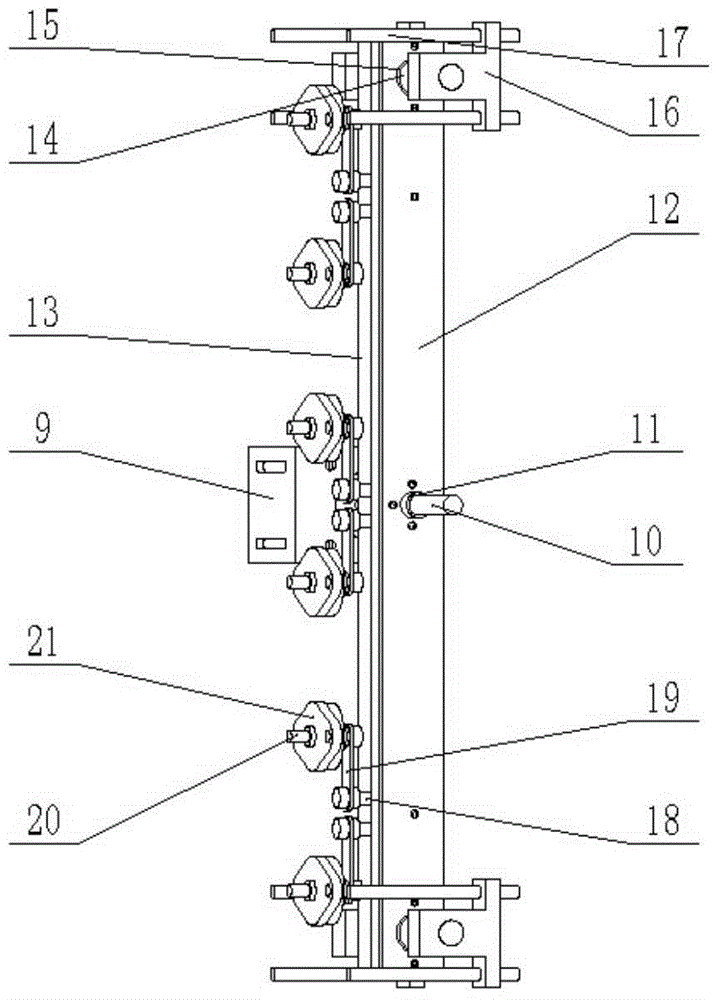

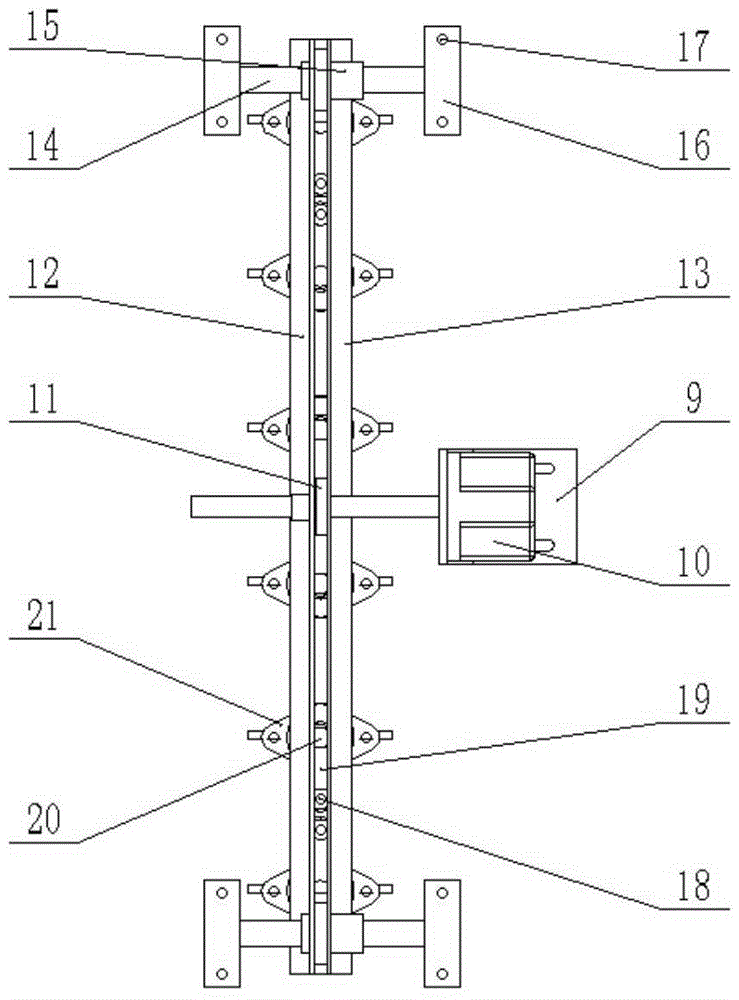

Portable grounding down lead reset mounting apparatus and method

ActiveCN106486918AQuick combinationImprove bindingCable installation apparatusLocking mechanismEngineering

Disclosed is a portable grounding down lead reset mounting apparatus used for being matched with a lifting mechanism to reset and mount the grounding down lead to a tower angle iron. The portable grounding down lead reset mounting apparatus comprises a locking mechanism for tightly holding the tower angle iron detachably, wherein the locking mechanism comprises a main beam used for fixing the lifting mechanism, a first tightening assembly which is arranged at one end of the main beam and can buckle one side edge of the tower angle iron, and a second tightening assembly which is arranged at the other end of the main beam and can buckle the other side edge of the tower angle iron; the second tightening assembly comprises a tightening seat which can be hinged at the other end of the main beam in a swinging manner in a locking position and a releasing position, a pull rod which can be hinged on the tightening seat in a swinging manner, and a second buckling part which is arranged on the pull rod and can buckle the other side edge of the tower angle iron; and it is set that when the tightening seat swings from the releasing position to the locking position, the pull rod can be driven to retract backwardly so as to enable the second buckling part to tightly buckle the edge of the tower angle iron.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

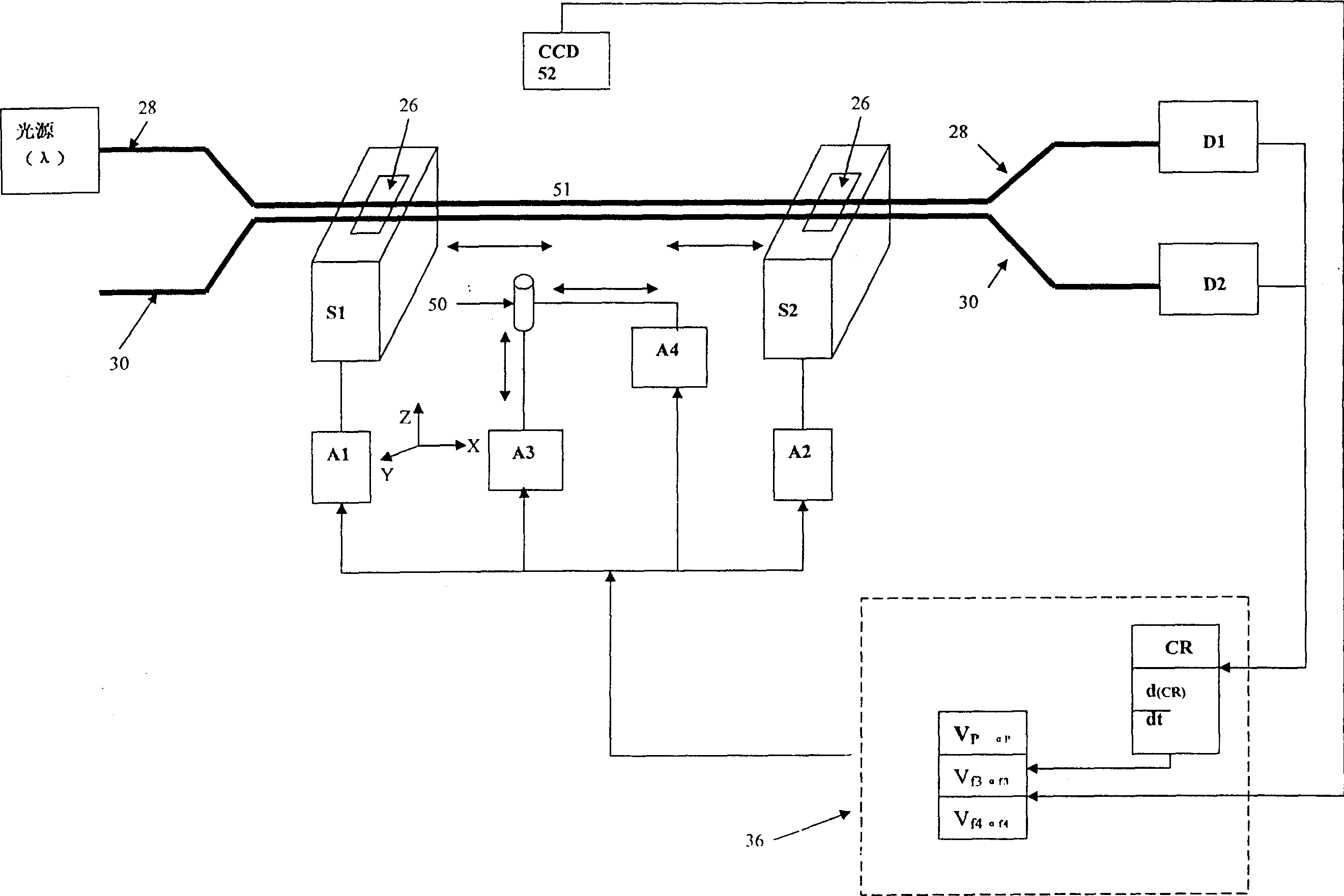

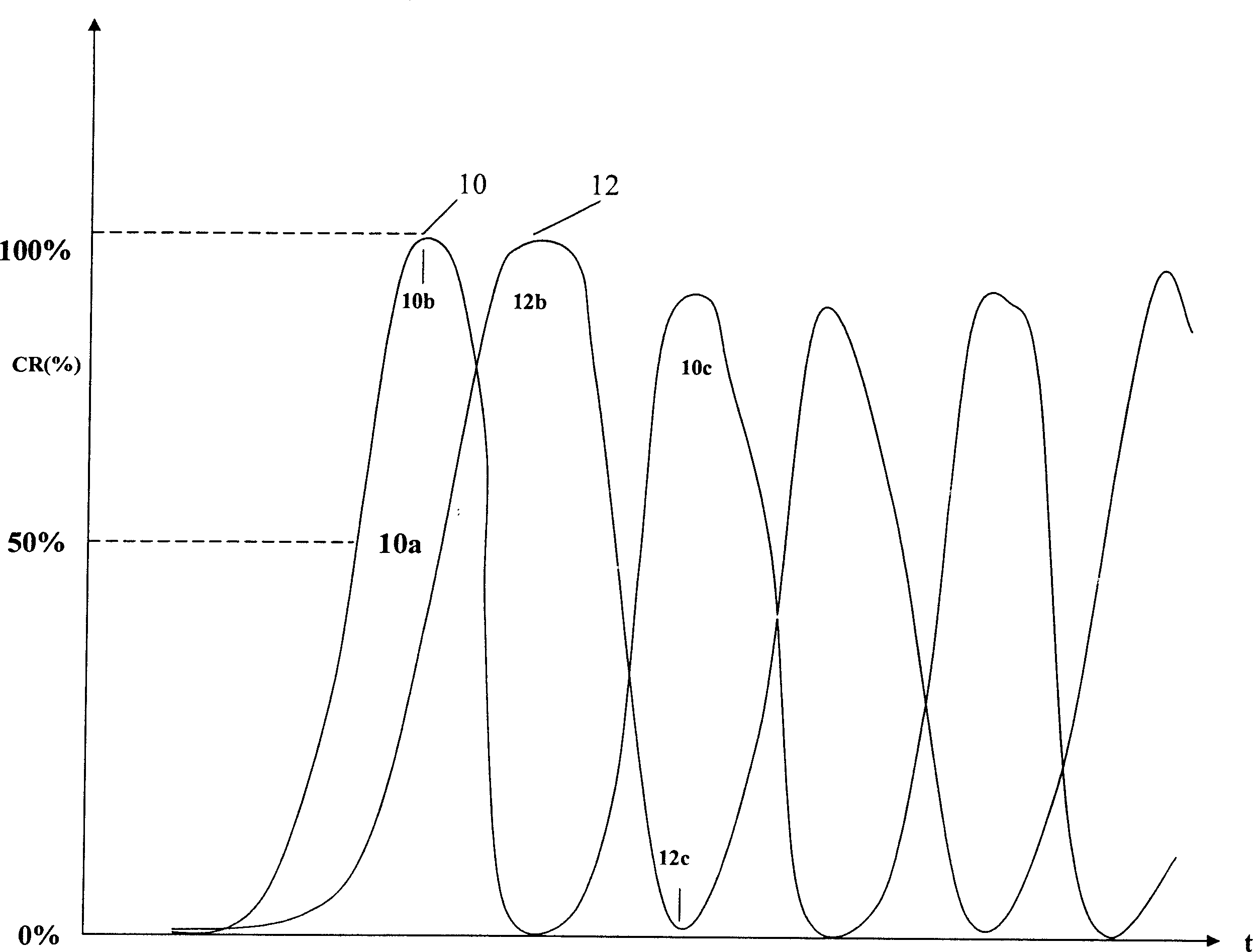

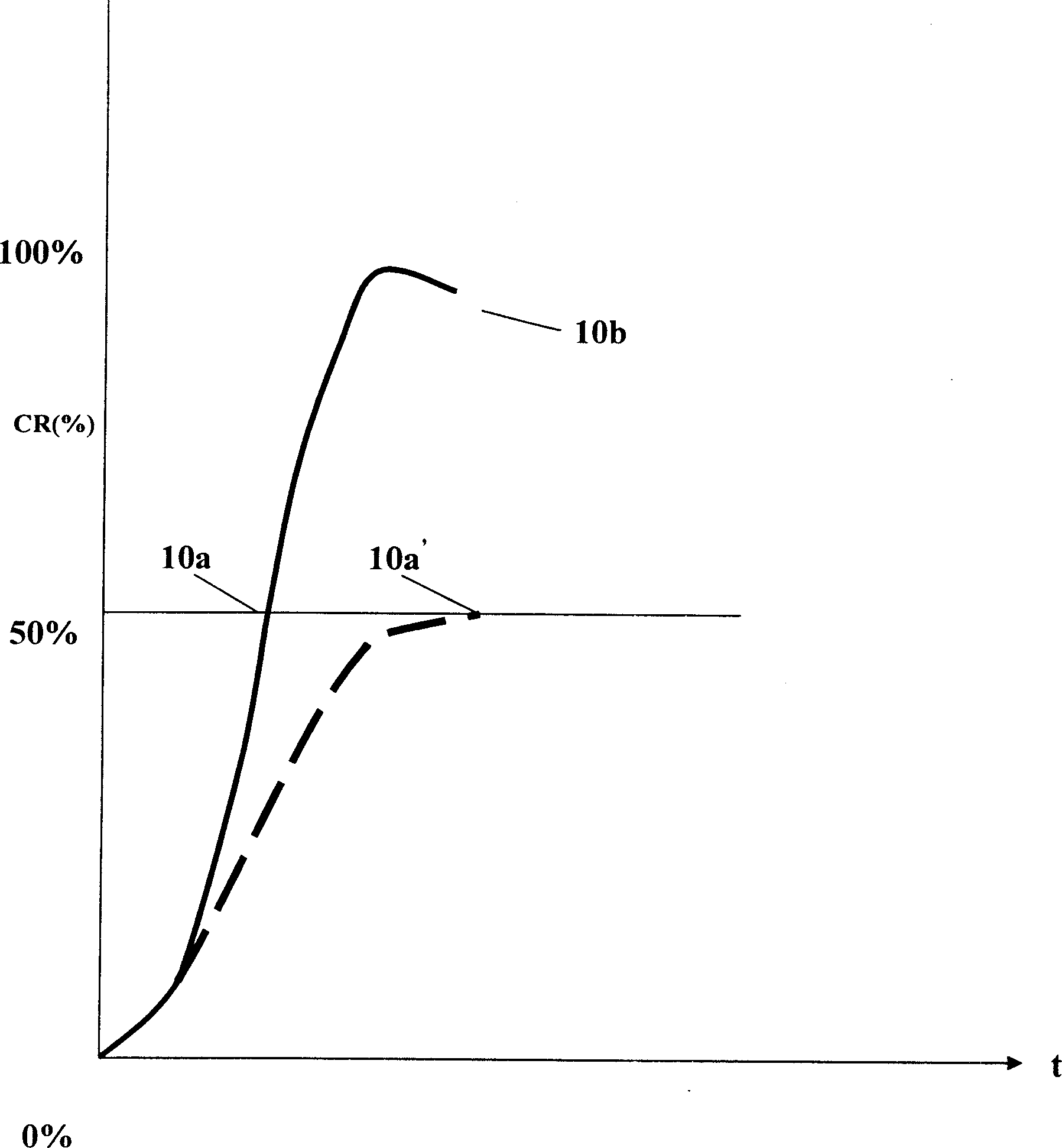

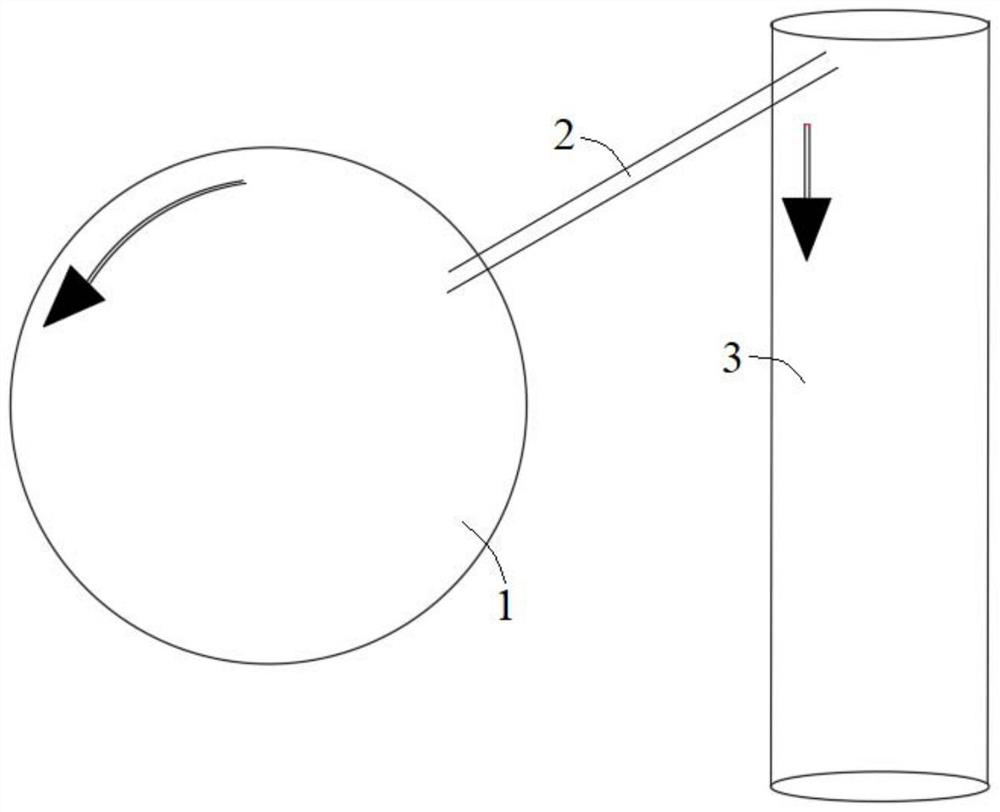

Method of mfg. pyrometric cone device by dynamic regulating tension speed, heating temp, and amplitude

InactiveCN1861536ASwing fastSpeed up the swingGlass making apparatusGlass productionClosed loopCoupling ratio

A process for preparing the melting cone device of optical fiber by dynamically regulating the drawing speed, heating temp and amplitude includes such steps as heating optical fiber with flame by a certain distance, swinging at initial speed while drawing at initial speed and acceleration, drawing at uniform speed, using CCD monitor to observe the heated region of optical fiber while regulating the relative parameters until initial control point where the couple ratio between optical fibers is 1% or more, closed-loop control to flame temp, amplitude and drawing speed, choosing proper control point, choosing swinging acceleration and speed, stopping drawing, and fast swinging flame for eliminating internal stress.

Owner:上海凯通电讯设备厂

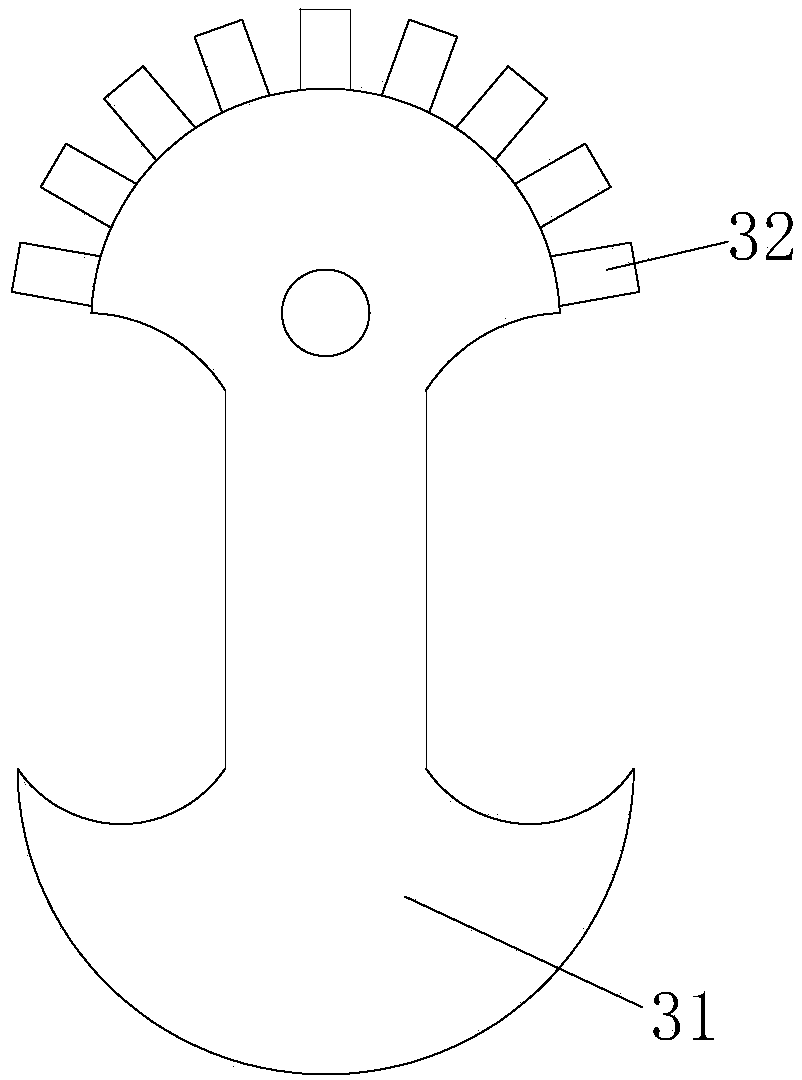

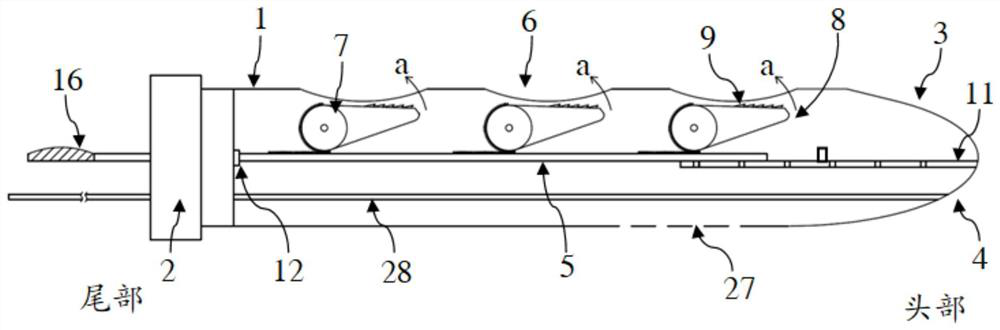

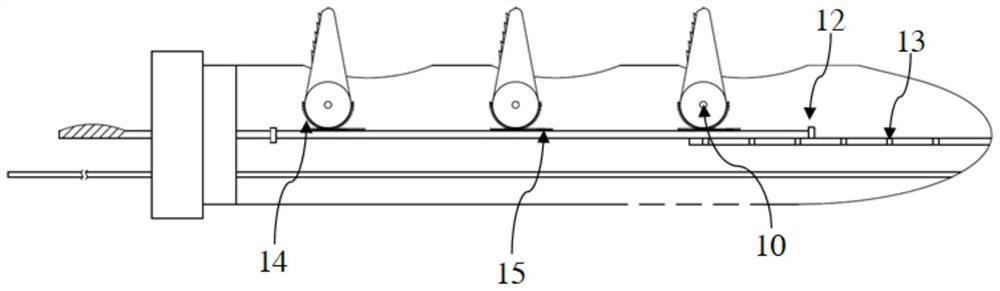

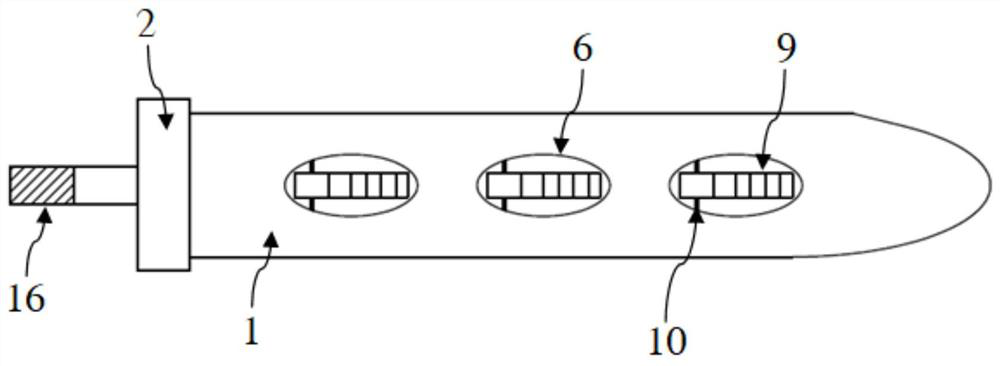

Interventional therapy catheter assembly for popliteal-iliofemoral deep venous thrombosis

ActiveCN112971923AReduce resistanceHigh speedExcision instrumentsEndoscopic cutting instrumentsVenous bloodThrombus

The invention provides an interventional therapy catheter assembly for popliteal-iliofemoral deep venous thrombosis. The interventional therapy catheter assembly comprises a hard catheter, a driving part and a thrombus breaking structure; a row of side openings, which are evenly spaced, are formed in the wall of the catheter; in the initial state, the thrombus breaking structure comprises a blade and is contained in the side openings; and, in the thrombus treatment process, the driving part is used for swinging the blade of the thrombus breaking structure out of the side openings to break the thrombus of a thrombus balloon. According to the invention, a knife body can be contained in the side openings through the driving part so as to be repeated; thrombus treatment can be achieved; and the knife body and the blade can (repeatedly) cut the thrombus balloon and cut up a broken thrombus. The driving part adopts a meshing mode, so that the knife body and the blade can enter and exit from the side openings in a swinging mode; furthermore, the knife body can be completely pushed out; the driving force is small and easy; and the blade can rapidly swing.

Owner:上海蕊源生物科技股份有限公司

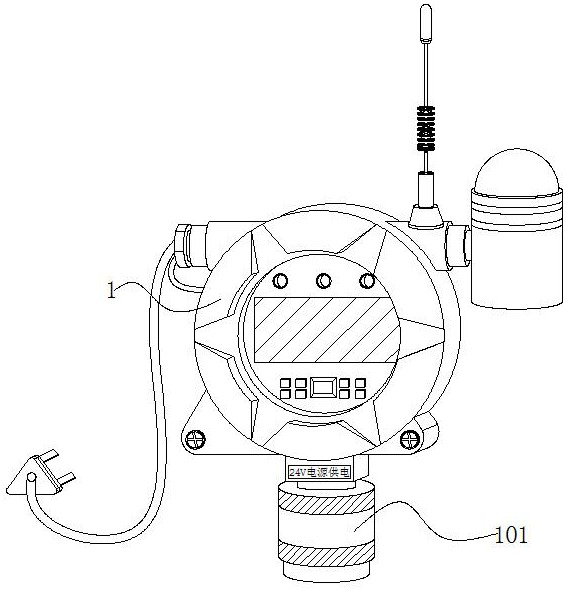

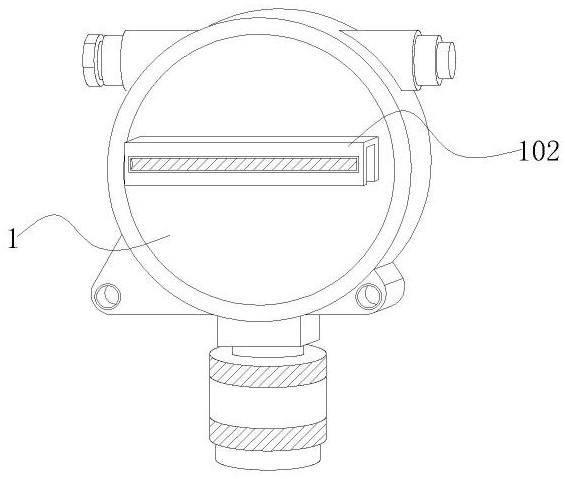

Fixed combustible gas detection alarm

The invention provides a fixed combustible gas detection alarm which comprises an alarm device, a sensor is installed at the lower end of the alarm device, a support is installed on the back face of the alarm device, a transmission mechanism capable of forming rapid installation through negative pressure is arranged in the support, the sensor is electrically connected with the alarm device, and the sensor is a gas sensor. When the support penetrates through the back face of the sensor and the shaft arm and moves to the other side of the lower end of the disc, an antenna is installed at the upper end of the alarm device, and the antenna is a transmission device for transmitting and receiving signals and can enhance signals of the information transmission device. Due to the fact that the swing arm is arranged at the lower end of the rotating shaft, and the weight of the swing arm is larger than that of the protruding strip and the rotating disc, the rotating disc rapidly returns after swinging for a short time, the rotating disc can assist the shaft arm in returning through the protruding strip, and meanwhile when one side of the sliding block loses extrusion, the sliding block can be driven by the shaft arm to return.

Owner:深圳市东大智勇工程有限公司

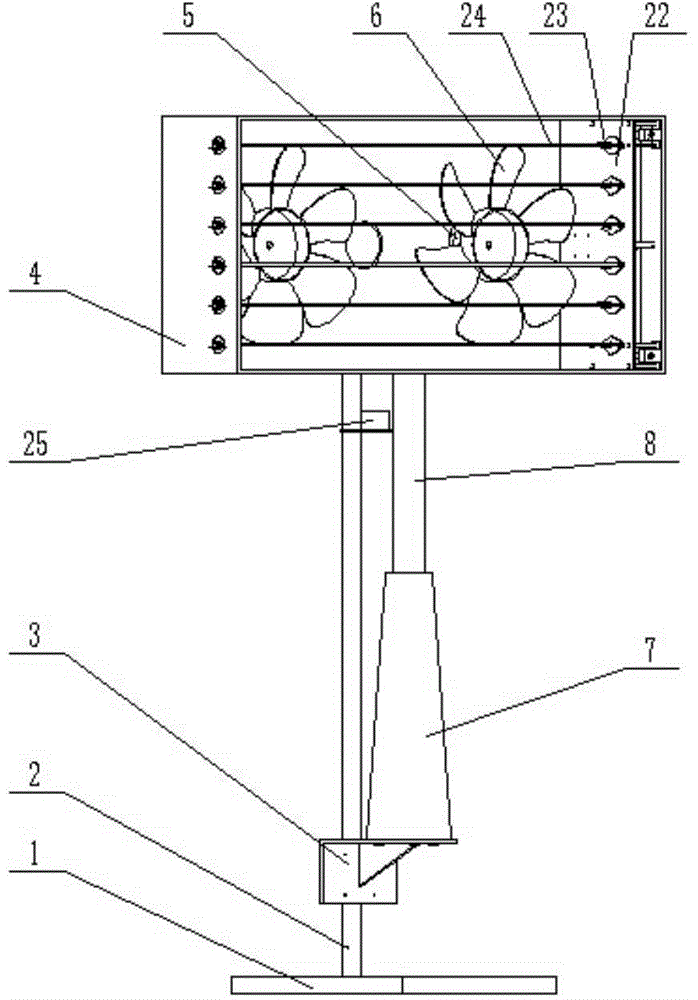

Music fan based on swing blade air changing and control method of music fan based on swing blade air changing

InactiveCN104612988AEasy to controlGood repeatabilityPump componentsPump controlLoop controlElectric machine

The invention relates to a music fan based on swing blade air changing and a control method of the music fan based on swing blade air changing. The music fan comprises a power unit, a supporting unit, a humidification unit, a swing blade driving unit and a control unit; the power unit comprises two fan bodies and is located in the outer shell; the supporting unit comprises a supporting structure and the outer shell; moisture of the humidification unit is led into the outer shell through moisture inlet holes; the swing blade driving unit comprises a front beam, a back beam, a stepping linear lead screw motor, two polish shafts, eight screws, six swing shafts, six fixedly-connected pieces, six rotating shafts, nuts, separating plates, six connecting sheets and six swing blades. An open-loop control linear lead screw motor for converting electric pulse signals into linear displacement is used in the music fan. Under the non-overload condition, the rotating speed and the stopping position of the motor are only determined by the frequency and the pulse number of the pulse signals and are not influenced by load changes; the angular displacement amount is controlled by controlling the number of pulses, and the aim of accurate positioning is accordingly achieved.

Owner:NORTHEASTERN UNIV

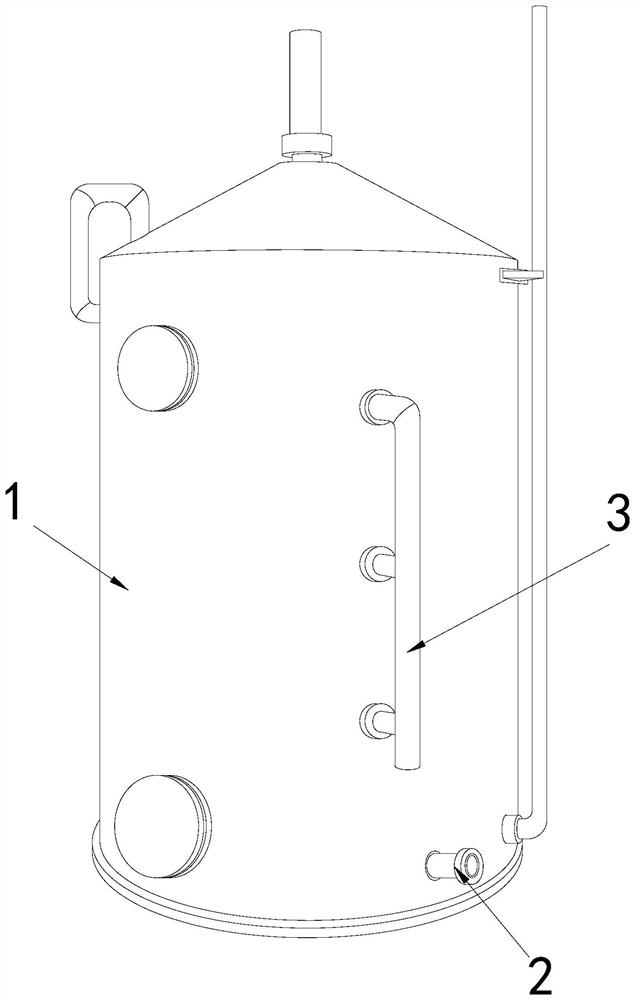

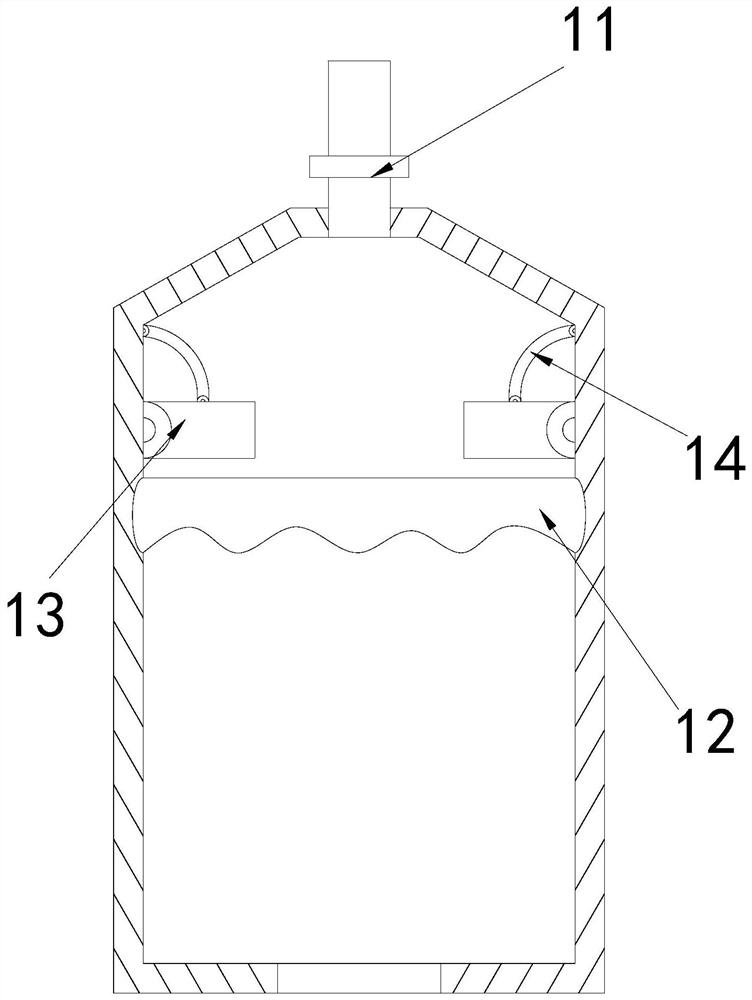

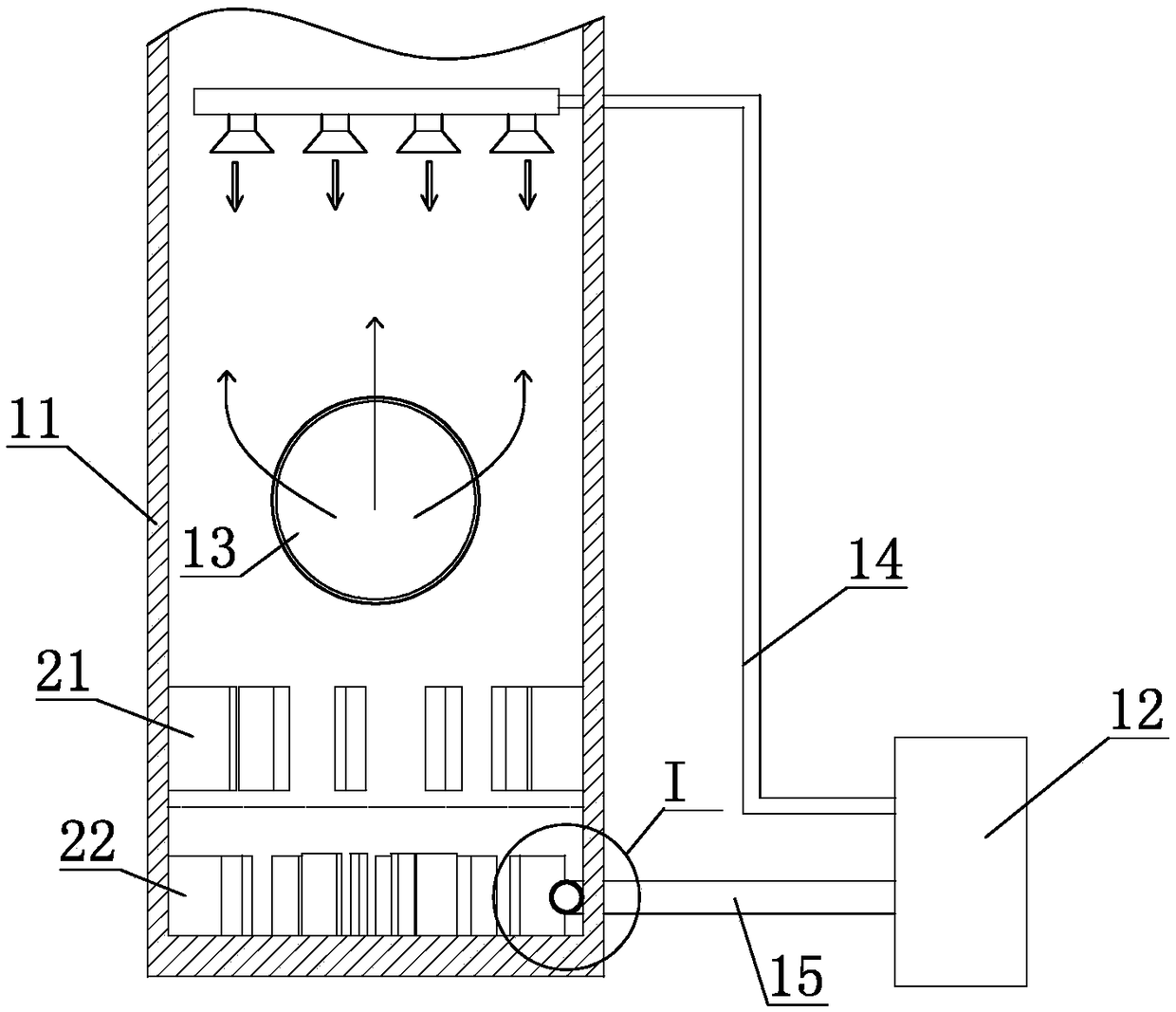

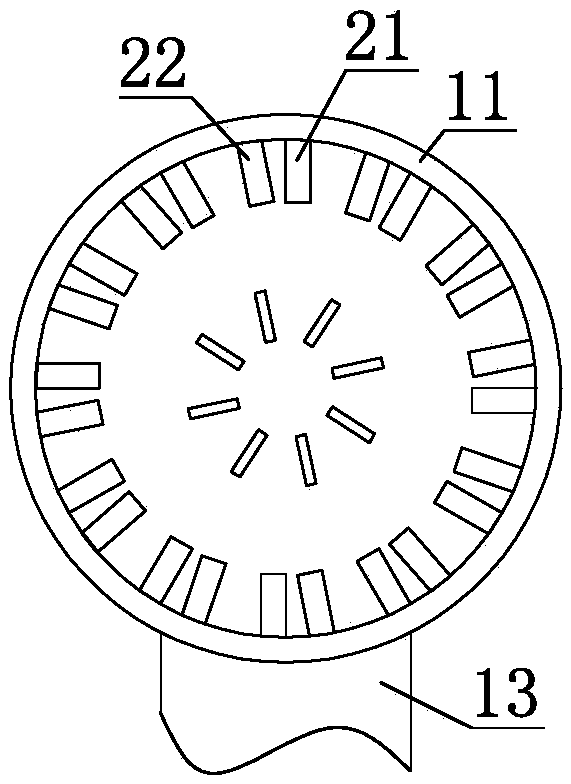

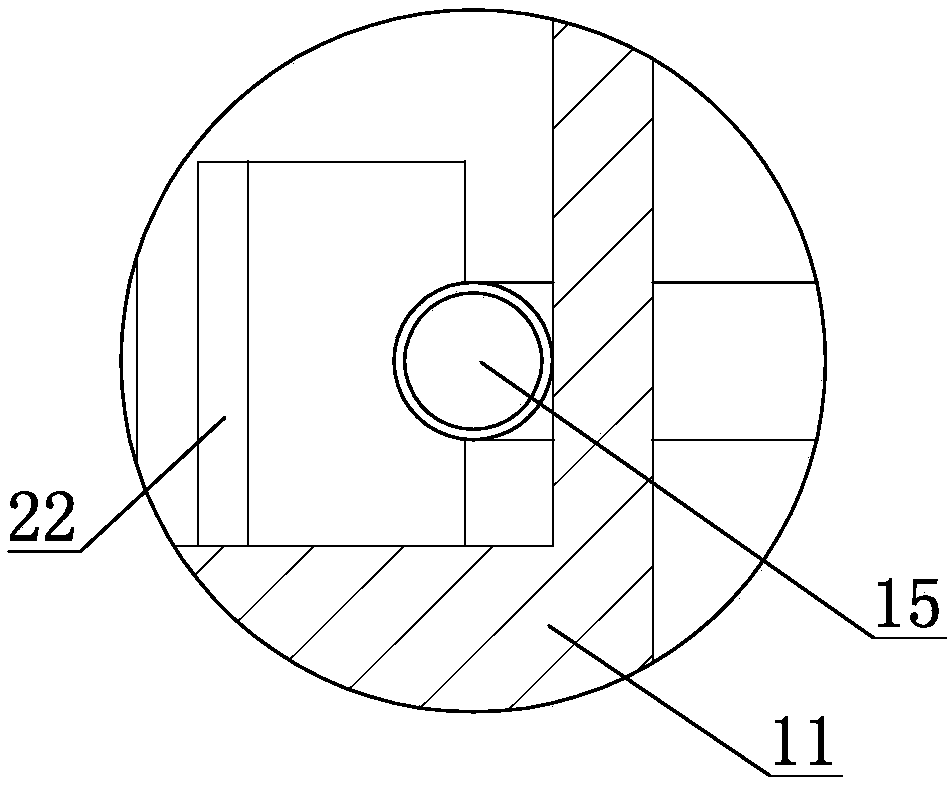

Self-stirring absorption tower

PendingCN109173688ARealize desulfurization treatmentEasy flipGas treatmentDispersed particle separationFlue gasEngineering

The invention discloses a self-stirring absorption tower and relates to the technical field of flue gas environmental protection treatment. The self-stirring absorption tower comprises an absorption tower, a slurry circulation pump and a smoke inlet pipe are arranged outside the absorption tower, the slurry circulation pump is communicated with a slurry injection pipe and a slurry recovery pipe, the slurry injection pipe is located at the upper part of the absorption tower, the slurry recovery pipe is located at the bottom of the absorption tower, the side wall of the absorption tower is provided with a plurality of first disturbance plates, the first disturbance plates are annularly distributed, the bottom of the absorption tower is provided with a plurality of second disturbance plates,the second disturbance plates are annularly distributed, the second disturbance plates are perpendicular to the bottom of the absorption tower, and the opening of the slurry recovery pipe is arrangedalong the direction the same to the tangential direction of the inner wall of the absorption tower. The self-stirring absorption tower can utilizes the kinetic energy of the slurry and prevent the deposition at the bottom of the absorption tower.

Owner:SHANDONG GUOSHUN CONSTR GRP

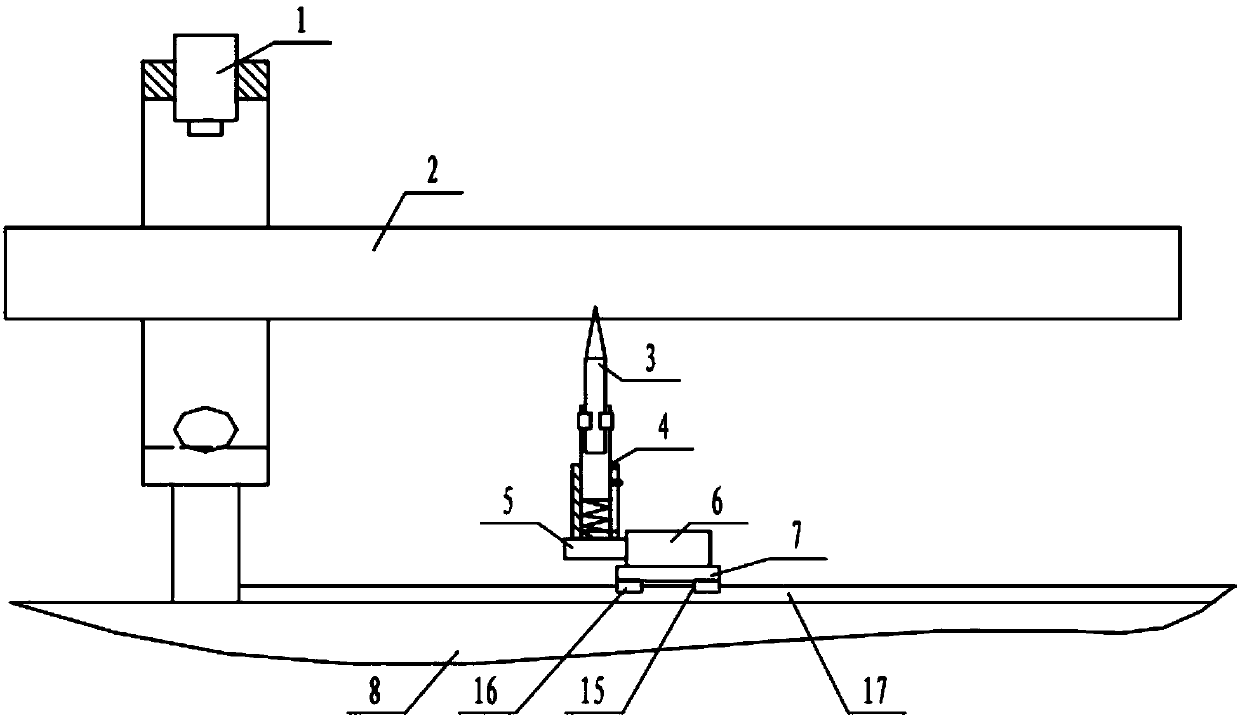

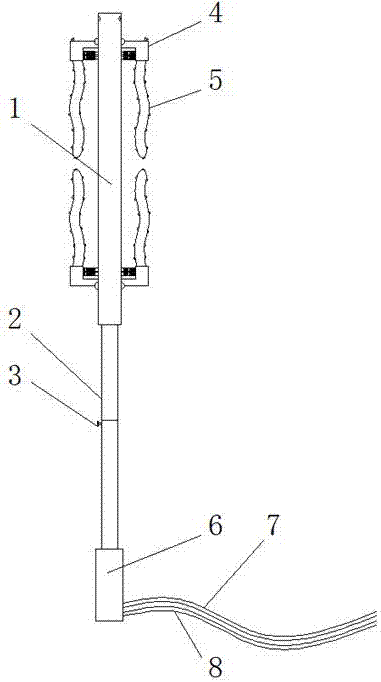

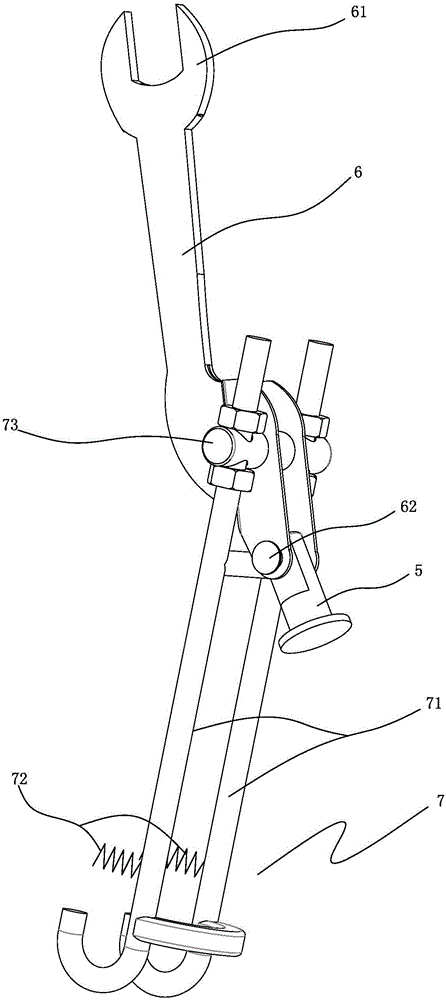

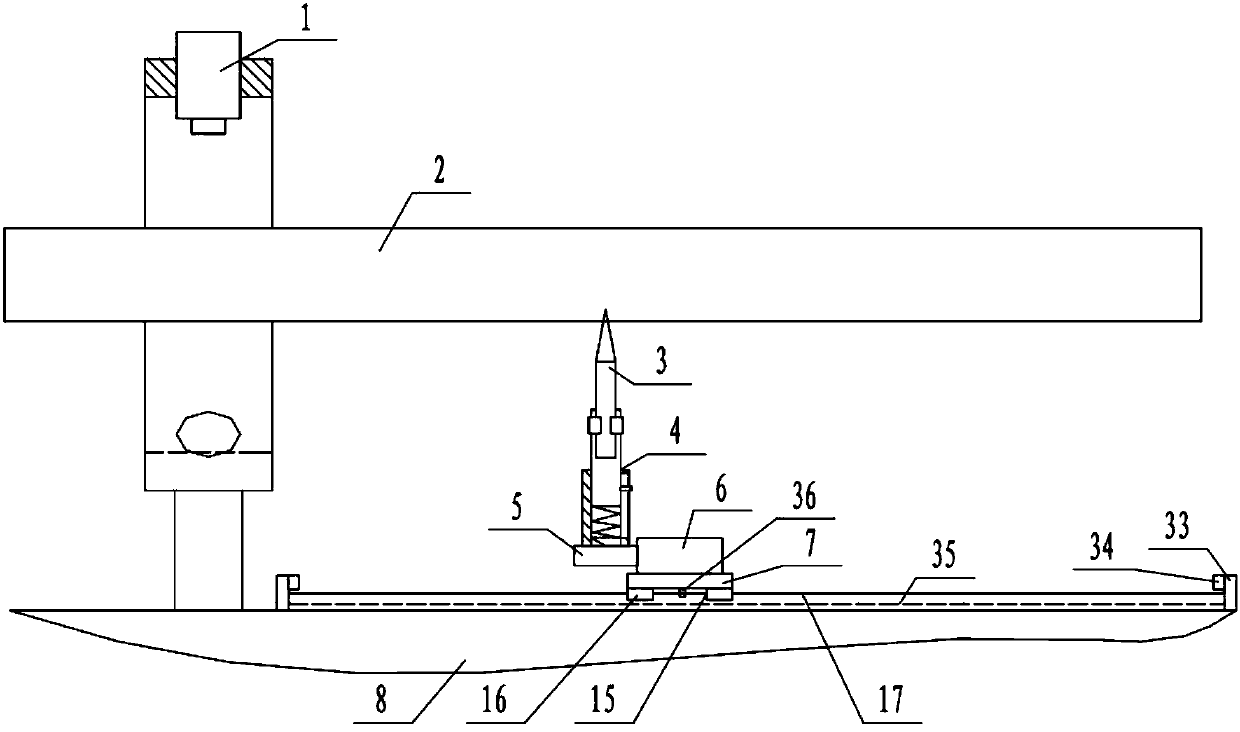

Marking and positioning apparatus for quality detection of twisted cables

PendingCN107703147AMove quicklyEasy to moveOptically investigating flaws/contaminationUsing optical meansMarking outElectric machinery

The invention discloses a marking and positioning apparatus for quality detection of twisted cables. The apparatus includes a drawing pen, which is connected to a telescopic rod. The tail end of the telescopic rod is connected vertically to a swinging shaft. The swinging shaft is connected to a swing motor mounted on a sliding base. The sliding base is connected to a fixed bench through a slide piece and guide rail pair. A driving mechanism, which drives the sliding base to move in the direction of the twisted cable, is connected to the sliding base. The telescopic drawing pen can move and swing during marking operation, so that a defect can be marked, thereby completing quick marking on the surface of the twisted cable. The apparatus has simple structure. Due to the elastically telescopicdrawing pen, marking range is wide and the marked symbol is more obvious. The apparatus also can avoid damage, due to hard collision, of the drawing pen. By means of the swinging shaft, the slide piece and guide rail pair and the driving mechanism, the drawing pen can swing quickly and move quickly along the cable. The marking and positioning apparatus has simple structure and low cost.

Owner:GUIZHOU UNIV

Racquet configured with fewer cross strings than main strings

A racquet includes polyester, monofilament racquet string and a frame extending along a longitudinal axis and including a head portion coupled to a handle portion. The head portion includes a hoop having inner and outer peripheral walls. The hoop defines a head size having maximum longitudinal and transverse dimensions, a , and, b , respectively. The dimension a is at least 1.2 times the dimension b . The inner peripheral wall includes string holes. Each of the cross segments transversely extends from one of the string holes to another, and each of the main segments longitudinally extends from one of the string holes to another. The end of the vertical size a closest to the cross segment and the handle is used to limit the second vertical size c. The ratio between the size a and the size c is at least 6.5. the line bed is provided with vertical segments, which are at least one more than the cross segments.

Owner:WILSON SPORTING GOODS

Negative pressure adsorption type hardware surface polishing machining equipment

InactiveCN112894596AReduce entryImprove adsorption capacityEdge grinding machinesPolishing machinesComputer hardwarePolishing

The invention discloses negative pressure adsorption type hardware surface polishing machining equipment. The negative pressure adsorption type hardware surface polishing machining equipment structurally comprises a polishing table, a control panel and a polisher, the control panel is arranged on the front face of the polishing table, the polisher is installed at the top of the left side of the polishing table, and the polishing table is provided with a stacking cavity, a negative pressure machine, a chip removal pipe, an airflow opening and a fan. Due to the fact that burrs fall down due to vibration force of the polishing table and easily enter the airflow opening of the negative pressure machine, a clamping block is arranged in an airflow opening of the negative pressure machine to block the burrs, the burrs entering the airflow opening can be reduced, the adsorption force of the air negative pressure machine to the burrs can be increased, and the discharging speed of the burrs generated by polishing of the top of the polishing table is increased; due to the fact that burrs are retained at the top of a supporting rod, the gravity of the supporting rod is increased, the supporting rod is provided with a moving plate, the moving plate moves up and down to push the burrs retained at the top of the supporting rod upwards, the bearing capacity of the supporting rod can be reduced, and the swing speed of the supporting rod is increased.

Owner:许志彬

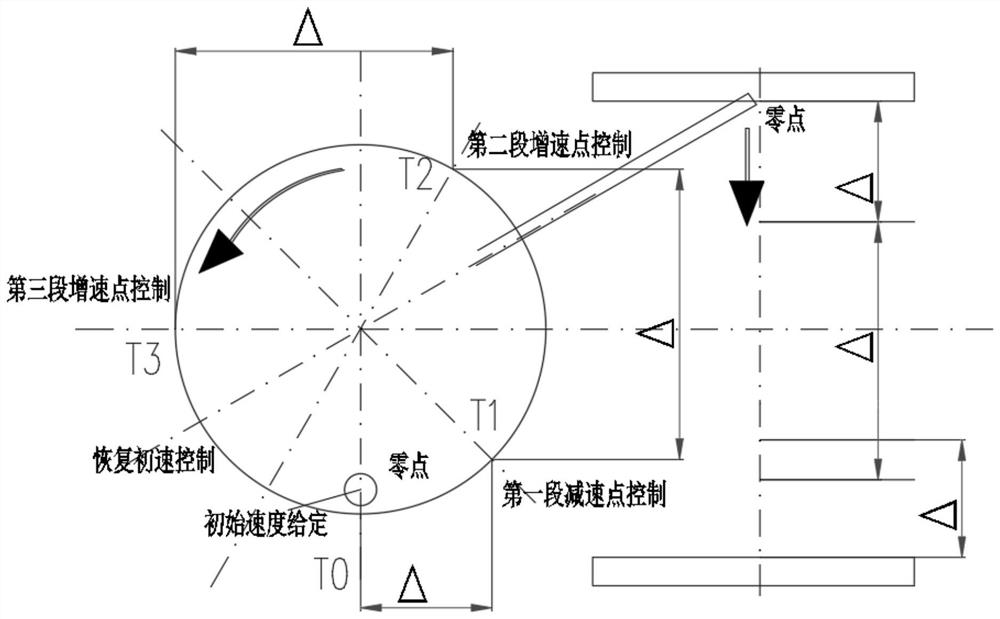

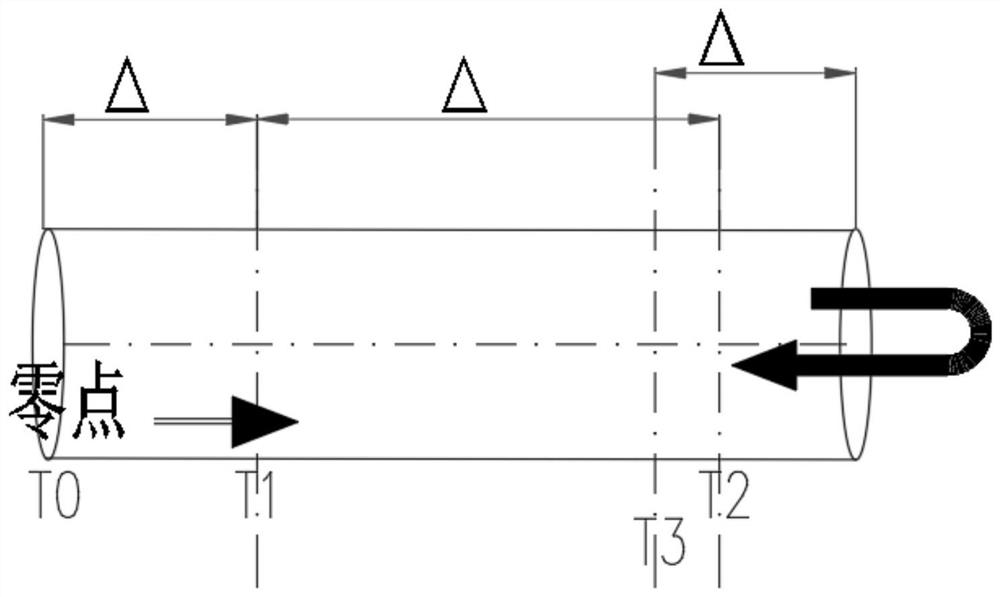

Balanced material distribution control method for chain grate machine

ActiveCN113203294AUniform clothShorten speedCharge manipulationControl devices for furnacesFrequency conversionControl engineering

The invention discloses a balanced material distribution control method for a chain grate machine, and belongs to the technical field of chain grate machine-rotary kiln pellet production. The method comprises the following steps: step 1, setting initial movement rates of a swinging head and a wide belt, and measuring the thickness of a material layer during operation; step 2, measuring the running time of the swinging head of the chain grate machine on the wide belt according to the set motion Hertz number, and taking the running time as initial time; step 3, partitioning the motion paths of a turntable and the swinging head, wherein the motion Hertz numbers of the swinging head in each partition are different; and 4, adjusting the Hertz number of the chain grate machine according to the speed of the chain grate machine and the green pellet amount. Segmented time-delay frequency conversion control is performed on the chain grate machine, and the time distribution required by the swing head to run from the zero point position to the other side of the wide belt is measured, so that segmented time-delay frequency conversion control is realized, the swing speed is increased in a thick material area, the swing head speed is reduced in a thin material area, and uniform material distribution of the chain grate machine is realized.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com