Self-stirring absorption tower

An absorption tower, self-stirring technology, applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of increasing equipment procurement costs, unfavorable energy conservation and emission reduction, and increasing production energy consumption, so as to reduce production costs and enhance turnover. , to avoid the effect of deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

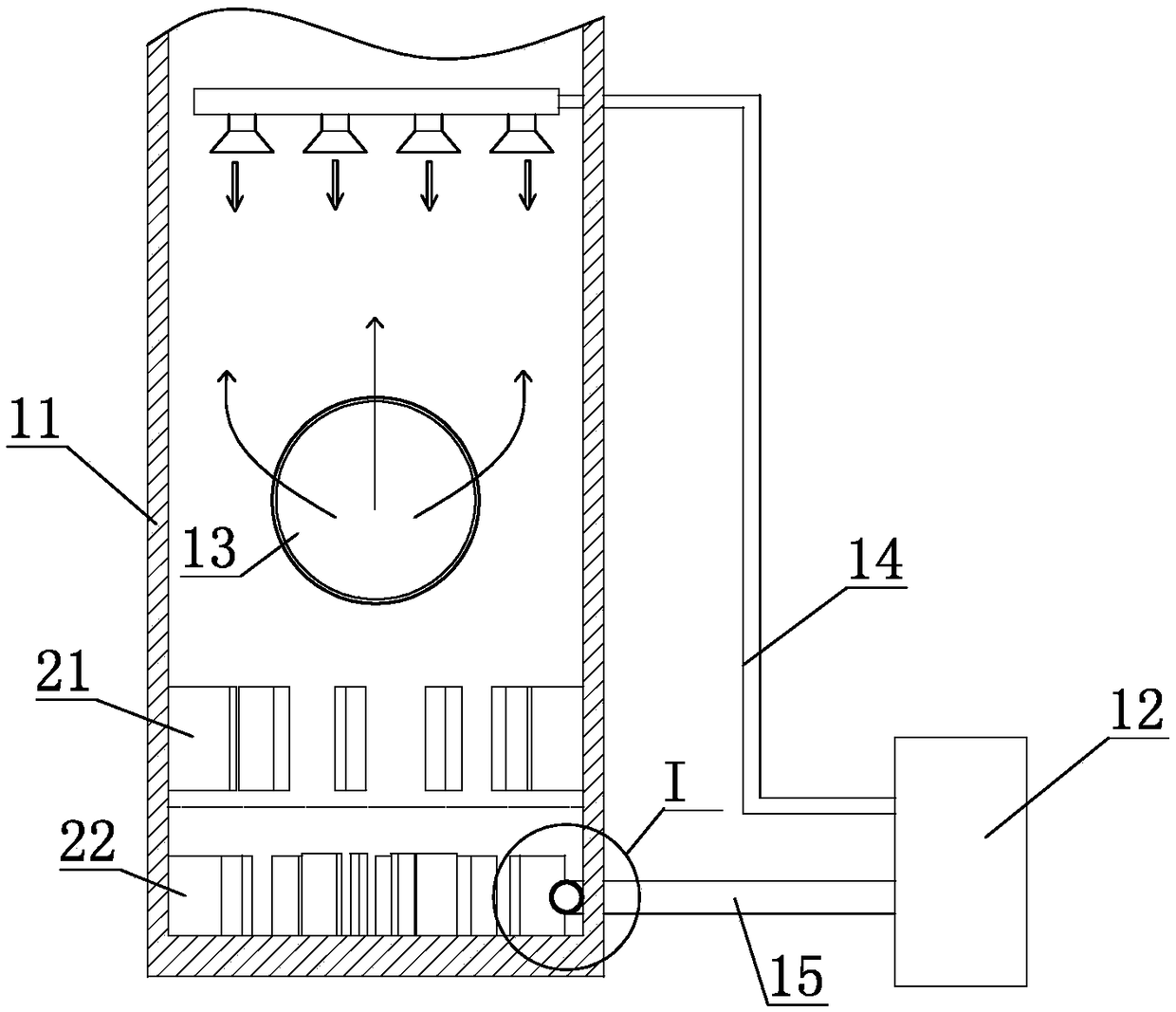

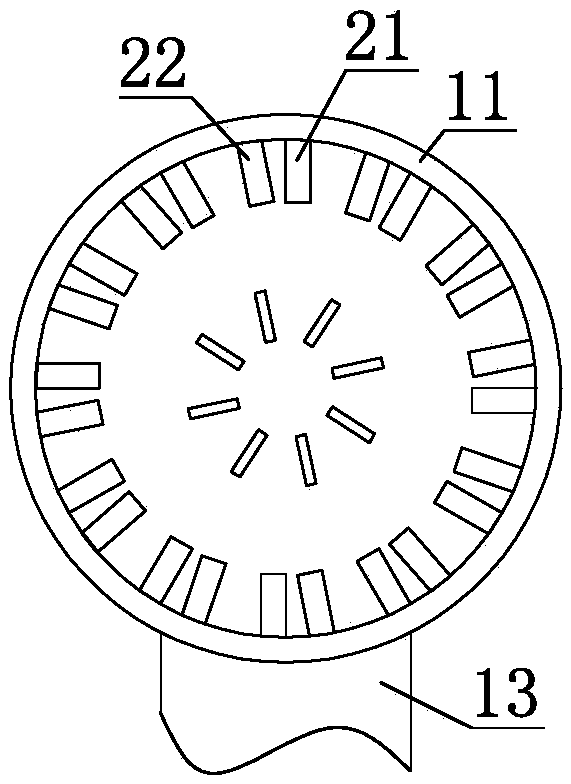

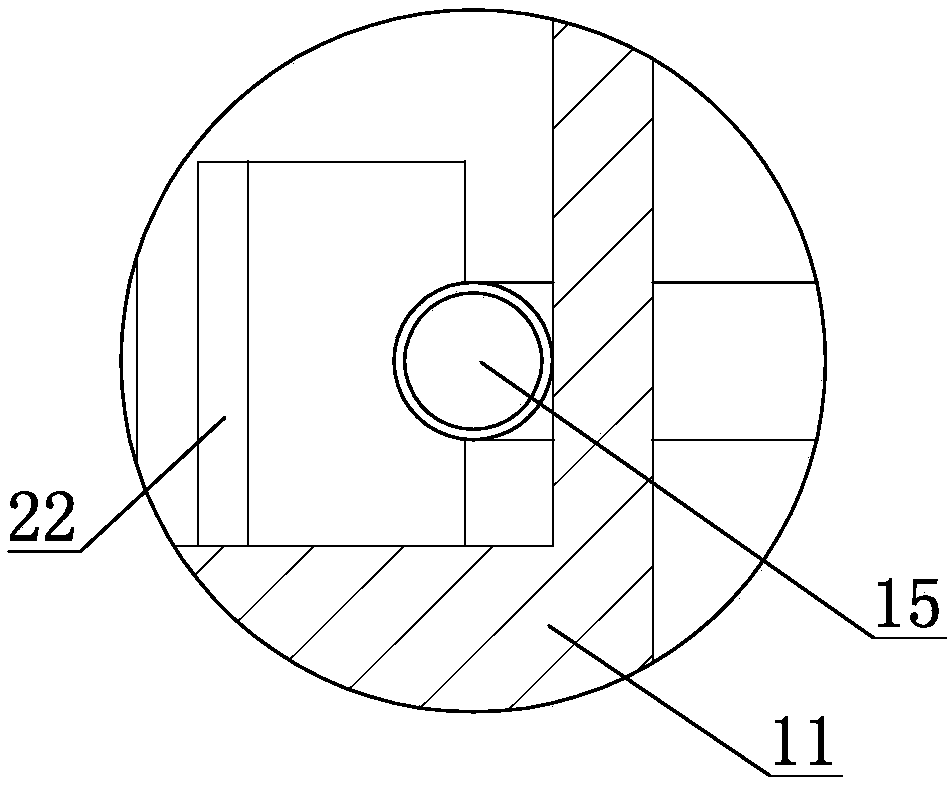

[0038] like Figures 1 to 3 As shown, the present invention is a self-stirring absorption tower, including an absorption tower 11, the absorption tower 11 is the main body of the absorption flue gas reaction, and the outside of the absorption tower 11 is connected with a slurry circulation pump 12 and a smoke inlet pipe 13. The slurry circulating pump 12 is used for recycling the slurry, the slurry circulating pump 12 is provided with a slurry ejection pipe 14 and a slurry recovery pipe 15, the slurry ejection pipe 14 is located at the upper part of the absorption tower 11, the The slurry recovery pipe 15 is located at the bottom of the absorption tower 11, the side wall of the absorption tower 11 is provided with a plurality of first spoilers 21, and the first spoilers 21 are distributed in a ring shape, and the bottom of the absorption tower 11 is provided with multiple A second spoiler 22, the second spoiler 22 is annular distribution, the second spoiler 22 is perpendicular...

Embodiment 2

[0042] like Figures 4 to 6As shown, the present invention is a self-stirring absorption tower, the first spoiler 21 is hinged to the side wall of the absorption tower 11, and the first rotating shaft 31 is arranged on the top of the first spoiler 21, and the The upper part of the first rotating shaft 31 is provided with a swing disc 32, the swing disc 32 is hinged with the first rotating shaft 31, by rotating the swing disc 32, the angle of the first spoiler 21 can be changed, and the angle of the first spoiler 21 can be changed according to the kinetic energy of the slurry. The size is adjusted to fix the angle of the first spoiler 21, so that the slurry can obtain the largest turning range, and at the same time, because it is easy to form the accumulation of slurry sediment between the first spoiler 21 and the absorption tower 11, adjust the first spoiler The angle of 21 can use the slurry to wash away the sediment, which ensures the working efficiency of the first spoiler ...

Embodiment 3

[0047] like Figures 7 to 8 As shown, the present invention is a self-stirring absorption tower, the first spoiler 21 is located at the top of the lowest liquid level, the lower part of the first spoiler 21 is provided with a pressure sensor 51, and the absorption tower 11 A receiver 52 is arranged outside, and the receiver 52 is connected with a pressure sensor 51. When the slurry is below the minimum liquid level, the surface pressure of the pressure sensor 51 is zero, and the absorption tower 11 can be obtained by observing the data received by the receiver 52. The amount of internal slurry is convenient for the staff to add slurry in time.

[0048] In order to ensure the operating efficiency of the whole device, the surface of the first spoiler 21 and the second spoiler 22 is provided with a protruding block 6, and the protruding block 6 can prevent sediment from being deposited on the first spoiler 21 and the second spoiler 22. The surface of the second spoiler 22 gather...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com