Method of mfg. pyrometric cone device by dynamic regulating tension speed, heating temp, and amplitude

A technology of heating temperature and swing amplitude, applied in the information field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

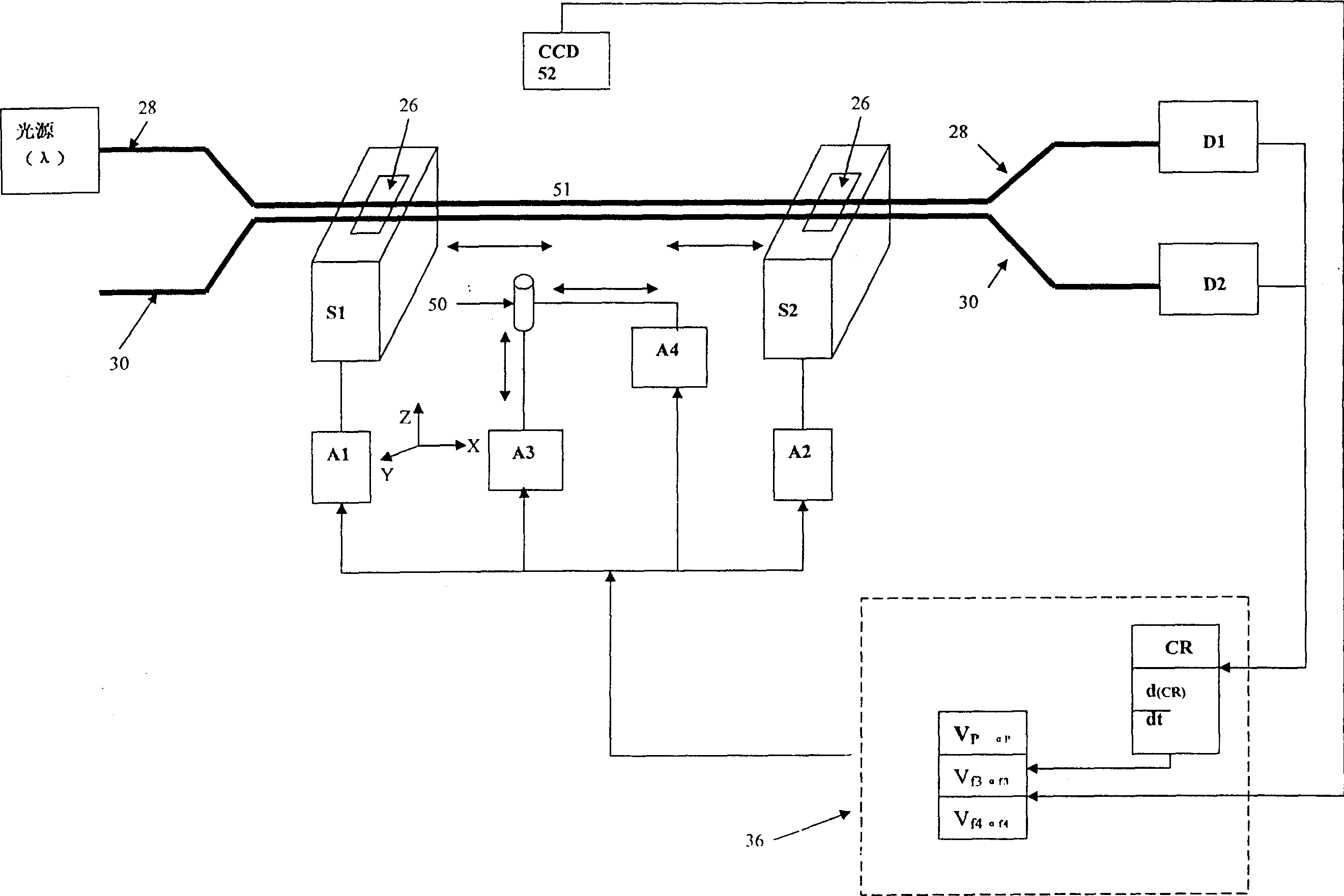

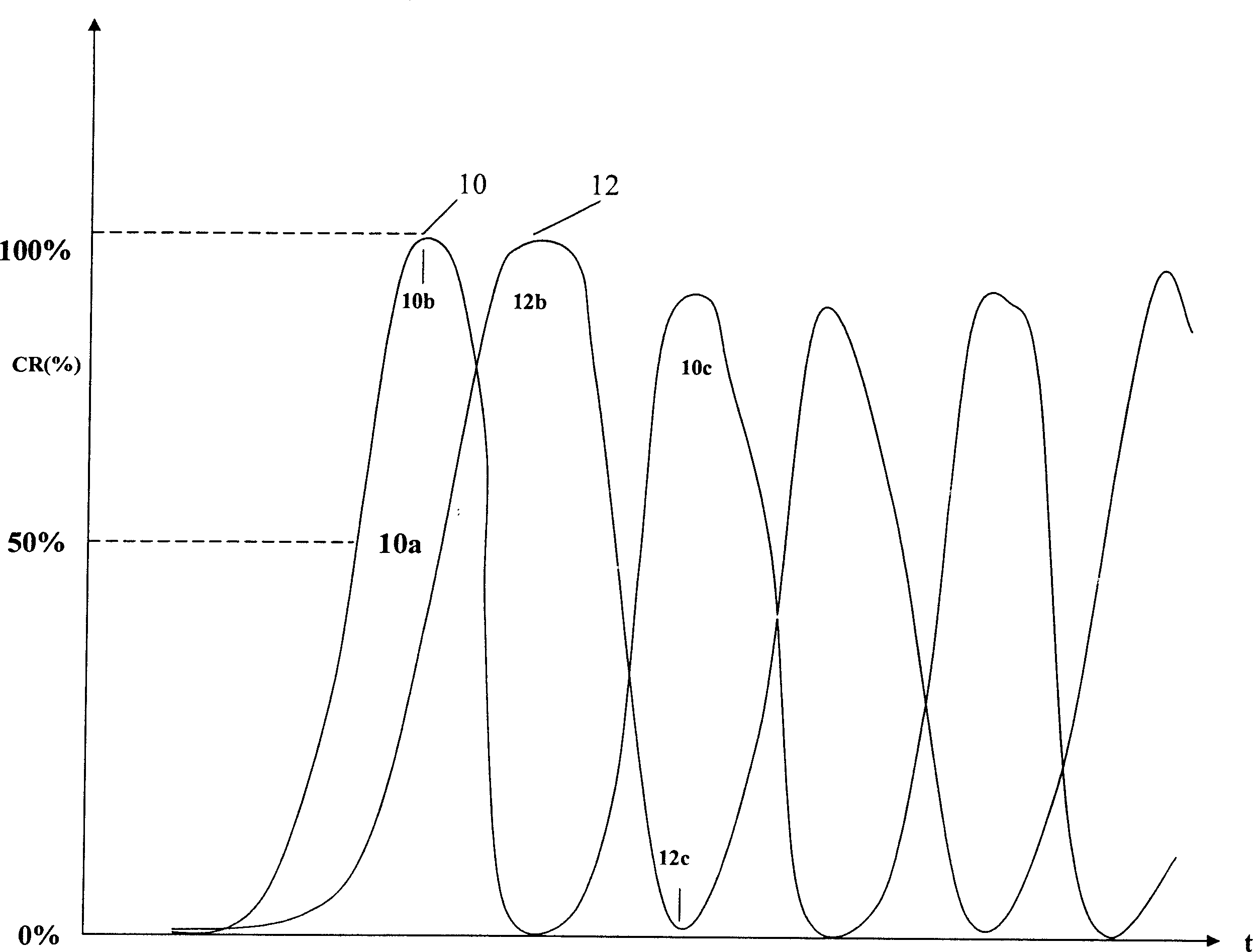

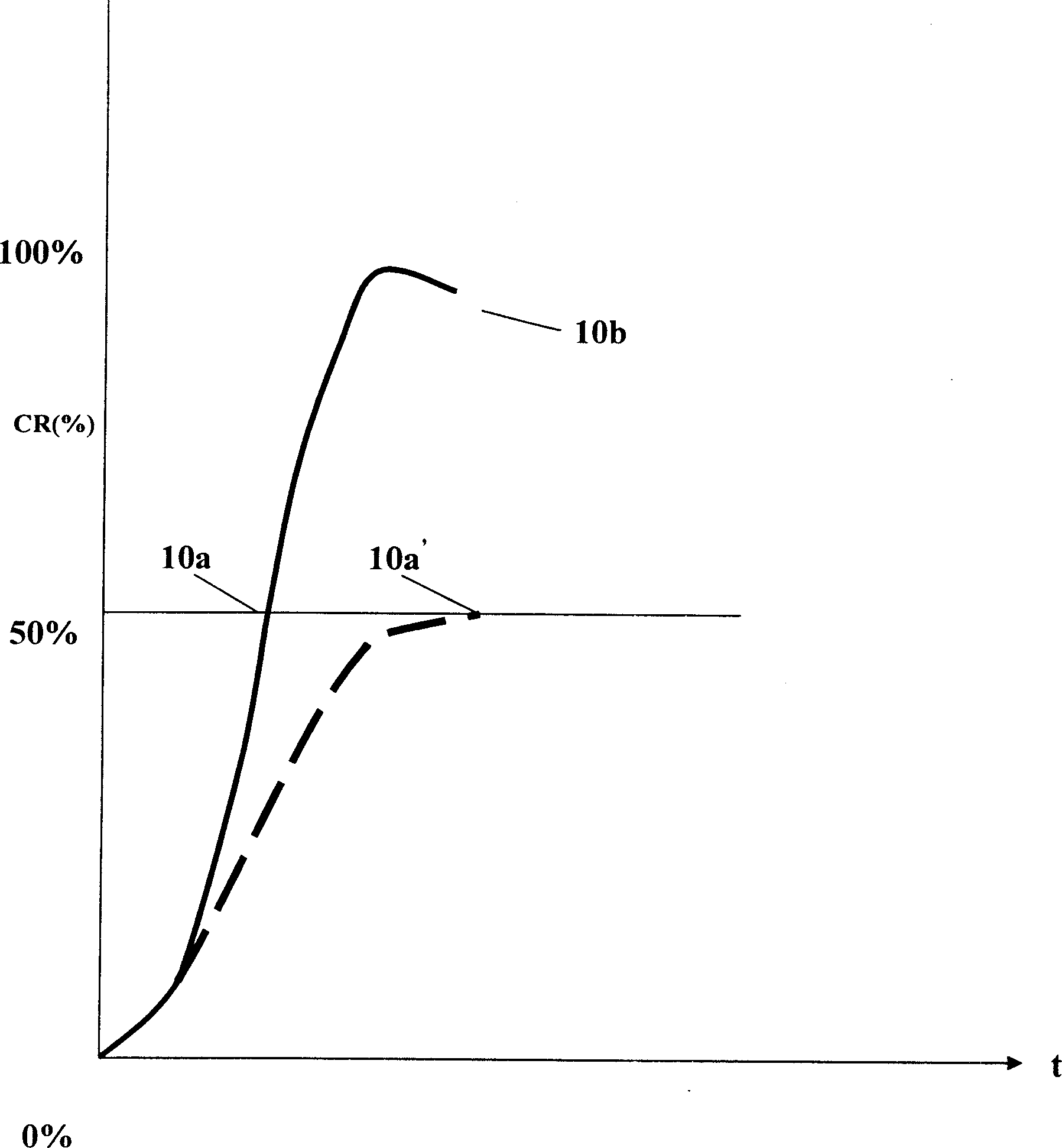

[0015] The invention regulates the flame temperature, the swing amplitude and the pulling speed of the optical fiber during the whole process of manufacturing the coupler. Figure (1) is a system block diagram of the present invention. Once the fusion drawer starts to run, the initial height d of the flame 50 leaving the fiber heating zone after it is put in place according to the preset gas and oxygen flow rates is 0 and initial swing heating while platform S 1 , S 2 pull speed V from rest p = 0 starts with acceleration α p The optical fiber is stretched at a variable speed, and after a time t, the fiber is drawn at a constant speed V pstretch the fiber. As the melting cone area is heated and elongated, the flame swing is correspondingly increased, so that the melting cone area is always in the heating range. The setting of these parameters should ensure that the shape of the fusing cone area displayed in real ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com