Balanced material distribution control method for chain grate machine

A control method and grate machine technology, which is applied in the direction of furnace control devices, furnaces, lighting and heating equipment, etc., to reduce the impact force of mechanical equipment, distribute materials evenly, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

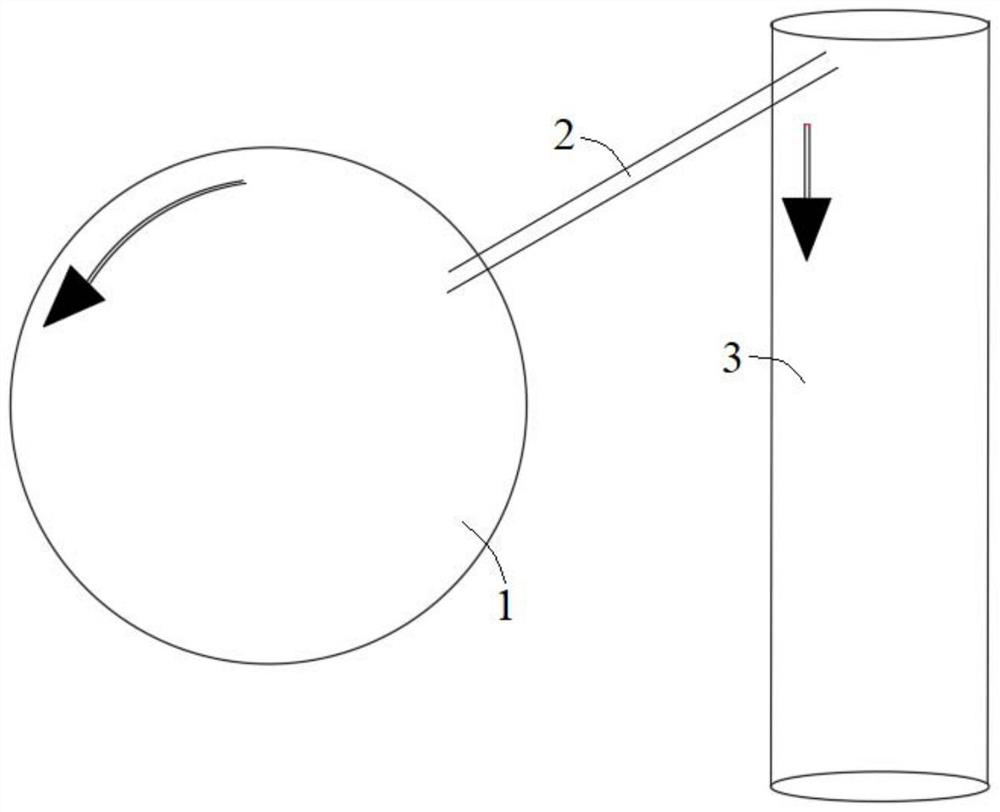

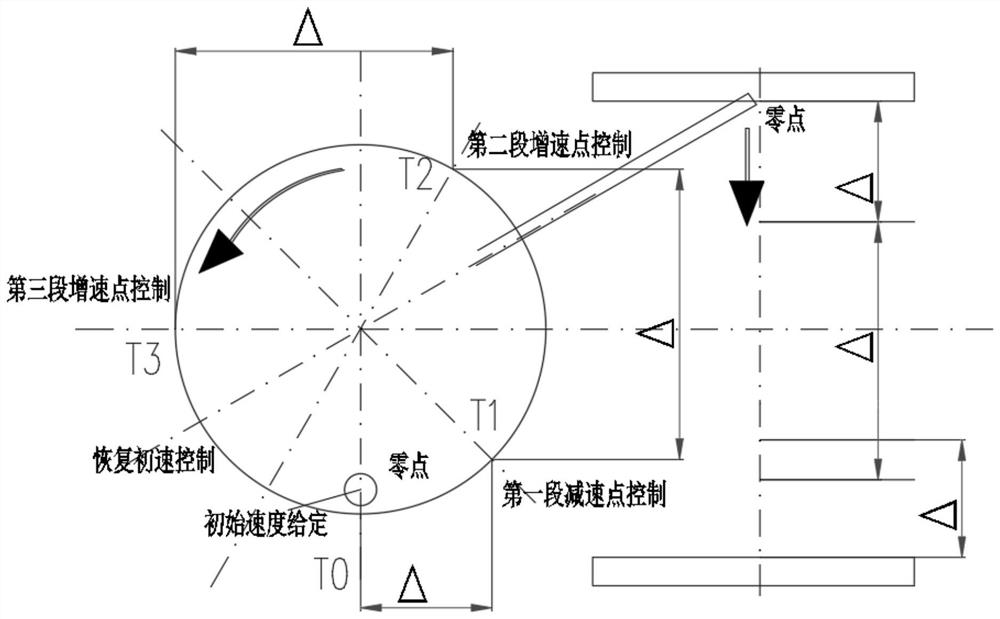

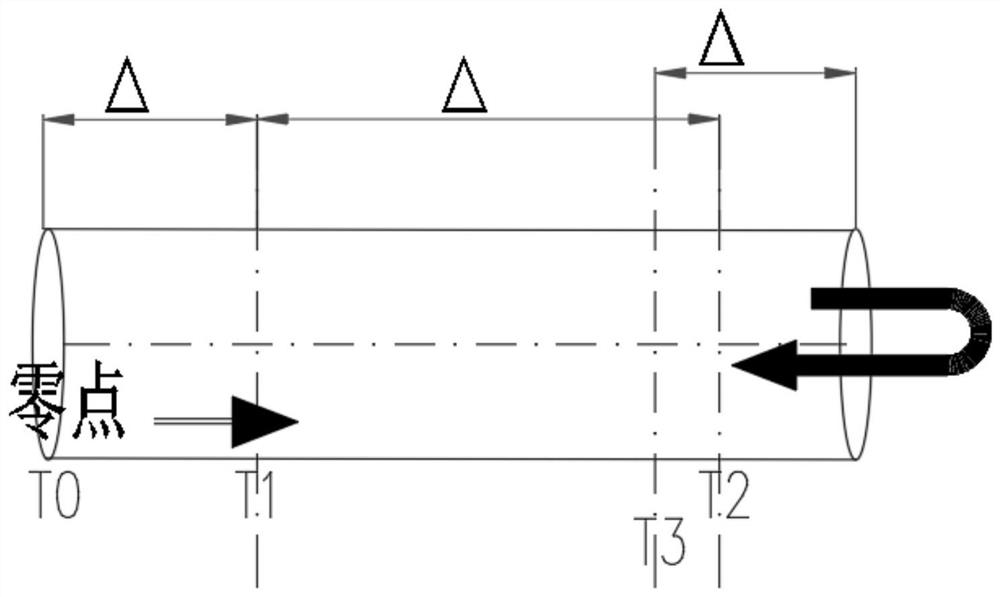

[0031] combine Figure 1-Figure 3 , a kind of grate machine balanced distribution control method of the present invention, its steps are:

[0032] Step 1: Set the initial movement speed of the swing head 2 and the wide belt 3, and measure the thickness of the material layer during operation: the thickness of the material layer is measured by a material layer thickness gauge installed on the wide belt 3. The movement rate of the swing head 2 is obtained by setting the motor frequency of the grate turntable 1; the speed of the wide belt 3 is set according to the movement rate of the swing head 2. This embodiment includes both the horizontal and vertical aspects of the grate material layer. The speed of the wide belt 3 is set according to the movement speed of the swing head 1, and the distribution gap is also controlled in the vertical direction to fully and effectively realize uniform distribution.

[0033] Step 2. Measure the running time of the swing head 2 of the grate on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com