Low moisture coke quenching device and coke quenching method adopting same

A low-moisture, coke quenching technology, applied in the field of coke quenching, can solve the problems of poor quality of blue carbon products and inability to accurately control the temperature of blue carbon, and achieve the effect of avoiding secondary drying, no gas consumption, and eliminating secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

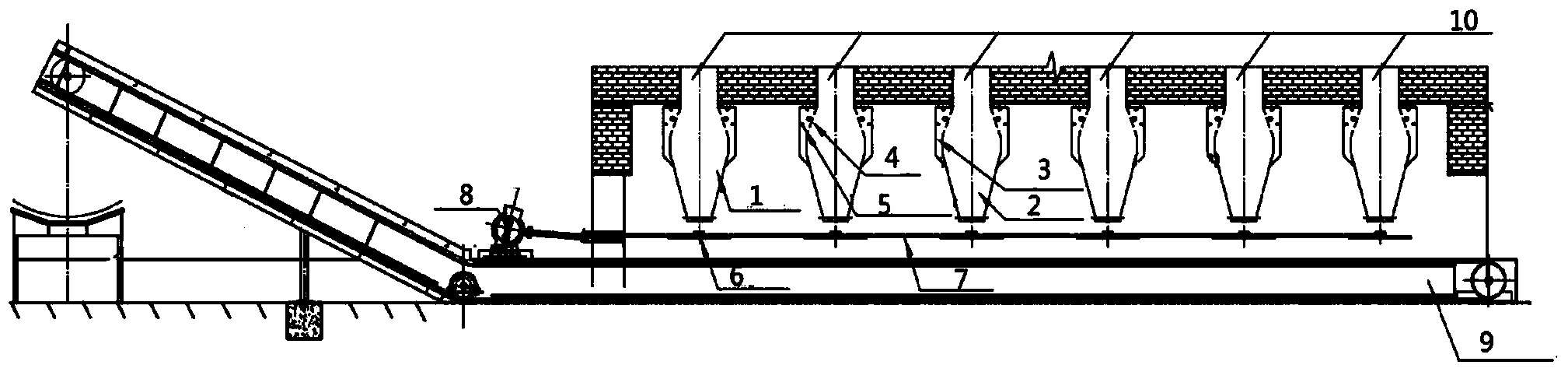

[0060] This embodiment provides a low-moisture coke quenching device, such as figure 1 As shown, it is arranged below the carbonization chamber, and the structure of the coke quenching device includes:

[0061] A plurality of coke quenching boxes 1, the coke inlet of each coke quenching box 1 is arranged in communication with the carbonization chamber; the coke inlet of each coke quenching box 1 can also be connected to the carbonization chamber through a cooling section 10 Connected and arranged, the cooling section 10 is a groove body with a constant cross section;

[0062] The pressure control system includes an in-furnace pressure sensor, a coke quenching pressure sensor, and a differential pressure regulating valve, the in-furnace pressure sensor is located on the raw gas output pipeline communicated with the carbonization chamber, and the coke quenching pressure sensor is located in the The coke quenching box 1 is connected to the gas output pipeline, and the differenti...

Embodiment 2

[0080] This embodiment provides a low-moisture coke quenching device, which is arranged below the carbonization chamber, and the structure of the coke quenching device includes:

[0081] A plurality of coke quenching boxes 1, the coke inlet of each coke quenching box 1 is arranged in communication with the carbonization chamber; the coke inlet of each coke quenching box 1 can also be connected to the carbonization chamber through a cooling section 10 Connected and arranged, the cooling section 10 is a groove body with a constant cross section;

[0082] The coke removal device includes a coke support plate 6 arranged under the coke outlet of the coke quenching box 1, a scraper conveyor 9 and a coke pusher 8 arranged under the coke support plate 6, and the coke pusher 8. A coke push rod 7 is provided, and the coke push rod 7 is suitable for pushing the coke on the coke support plate 6 to the scraper conveyor 9.

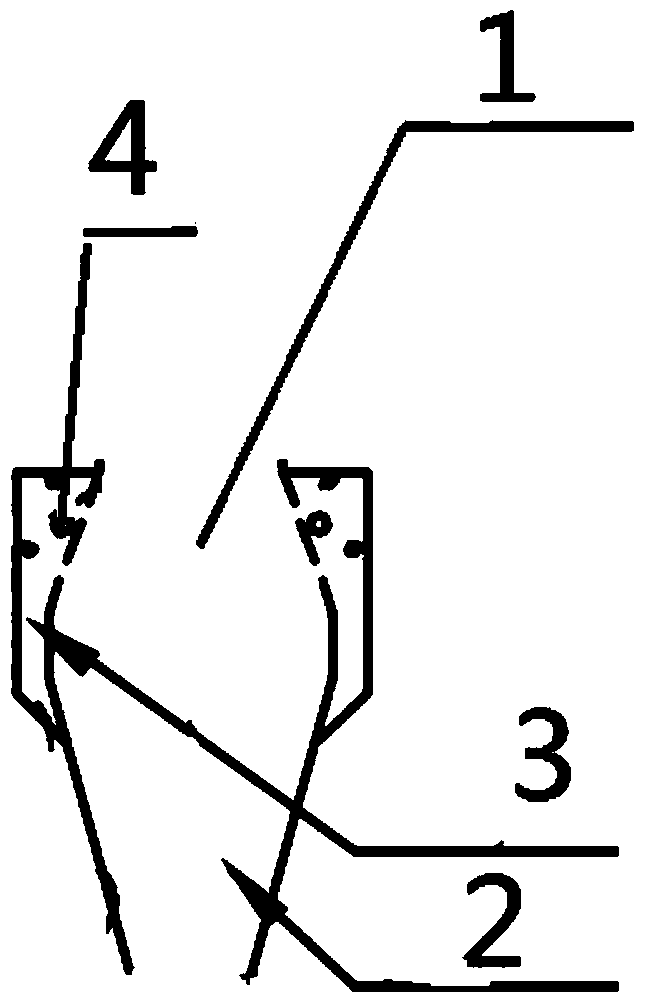

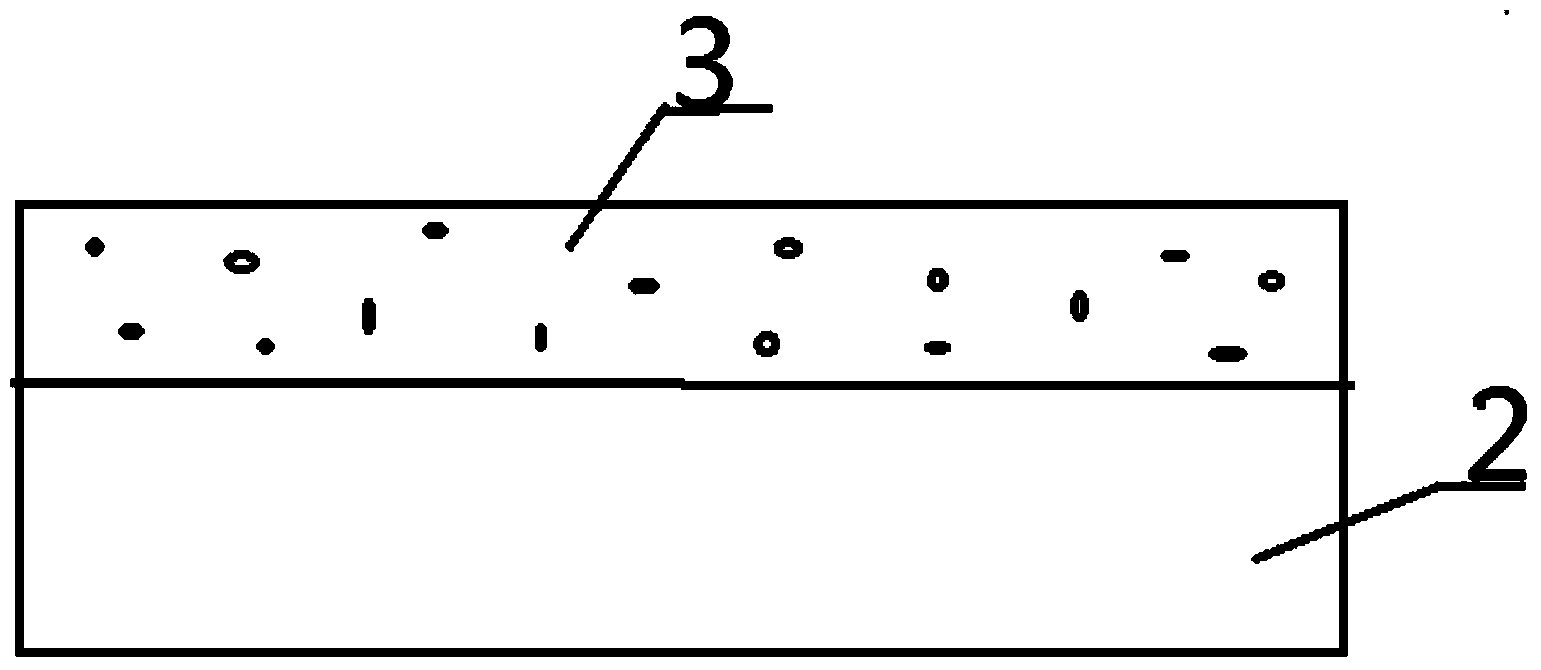

[0083] Among them, such as image 3 , Figure 4 The cross-secti...

Embodiment 3

[0095] This embodiment provides a low-moisture coke quenching device, which is arranged below the carbonization chamber, and the structure of the coke quenching device includes:

[0096] A plurality of coke quenching boxes 1, the coke inlet of each coke quenching box 1 is arranged in communication with the carbonization chamber; the coke inlet of each coke quenching box 1 can also be connected to the carbonization chamber through a cooling section 10 Connected and arranged, the cooling section 10 is a groove body with a constant cross section;

[0097] The pressure control system includes an in-furnace pressure sensor, a coke quenching pressure sensor, and a differential pressure regulating valve, the in-furnace pressure sensor is located on the raw gas output pipeline communicated with the carbonization chamber, and the coke quenching pressure sensor is located in the The coke quenching box 1 is connected to the gas output pipeline, and the differential pressure regulating va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com