Hydraulic fast-oscillating valve

A hydraulic and valve body technology, which is applied in the field of hydraulic valves, can solve problems such as inability to lay horizontally, use restrictions, etc., and achieve the effect of low energy consumption and high production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

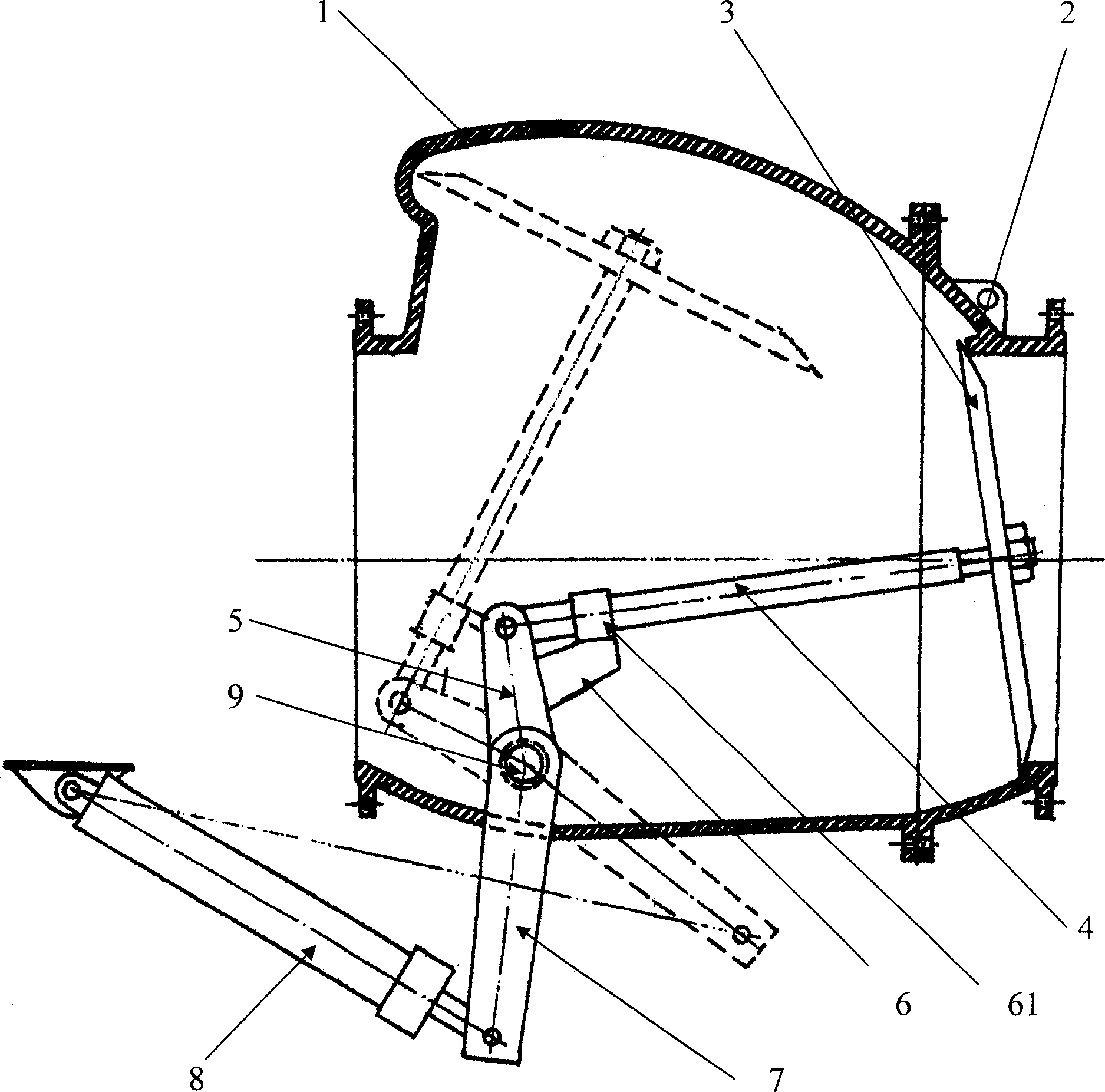

[0007] Such as figure 1 As shown, the hydraulic quick-swing valve of the present invention comprises a tubular valve body 1, which is rotatably provided with a rotating shaft 9 that is airtight with the valve body through the valve body 1 on one side of the valve body 1, and the axis of the valve body 1 is in line with the The axes of the rotating shaft 9 are vertical; the two ends of the rotating shaft 9 extend out of the valve body 1 and the power arm 7 connected with the hydraulic cylinder 8 is installed; the crank 5 is fixed on the rotating shaft 9 in the valve body 1, and the The other end is provided with a connecting rod 4, and the other end of the connecting rod 4 is equipped with a circular valve plate 3, and a valve seat 2 suitable for the circular valve plate 3 is provided in the inlet end of the valve body 1 toward the valve plate 3 , there is enough space for the circular valve plate 3 to rotate along the rotating shaft 9 in the valve body 1; when the hydraulic cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com