Suspended cloth cutting machine

A cutting machine and fabric technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of slow cutting speed, uneven fabric incision, and speed up fabric cutting, so as to achieve the effect of complete cutting and smooth incision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

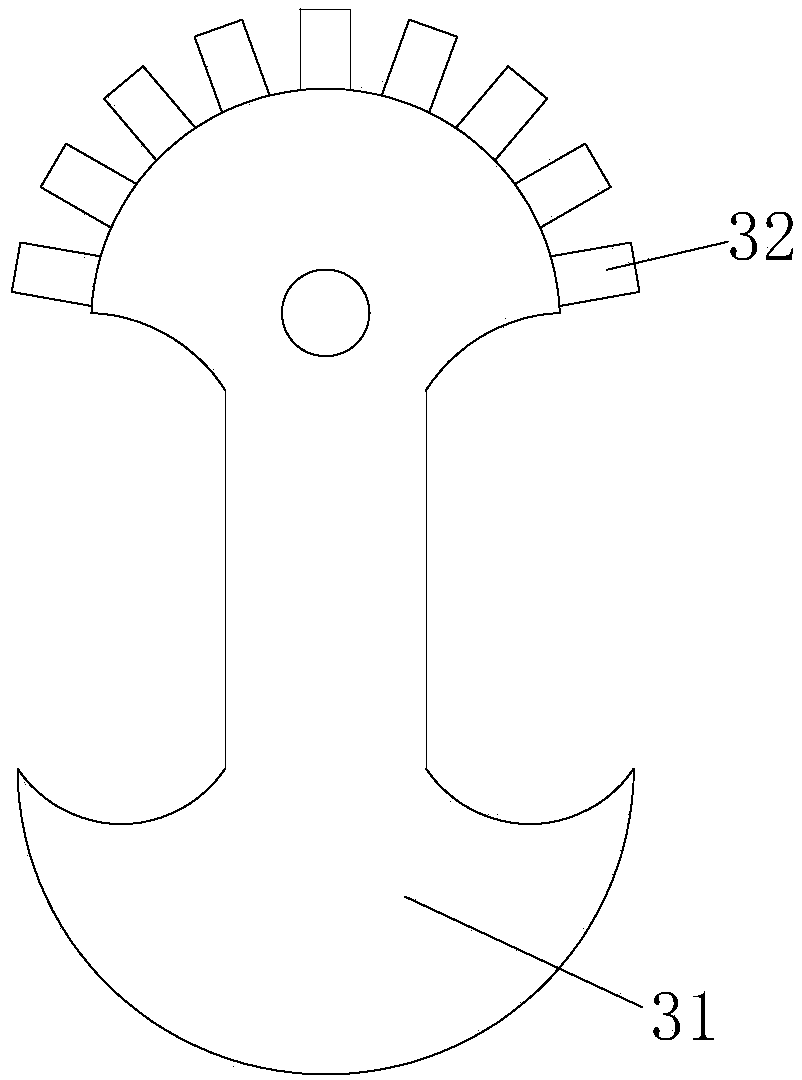

[0025] As an embodiment of the present invention, the cutter head of the cutting knife 31 is half-moon-shaped, and the blade is an arc-shaped blade. The design of the half-moon-shaped cutter head enables the cutting knife 31 to continuously cut the cloth during the swing process, and the arc-shaped blade Designed to make the blade sharper and better for cutting fabrics.

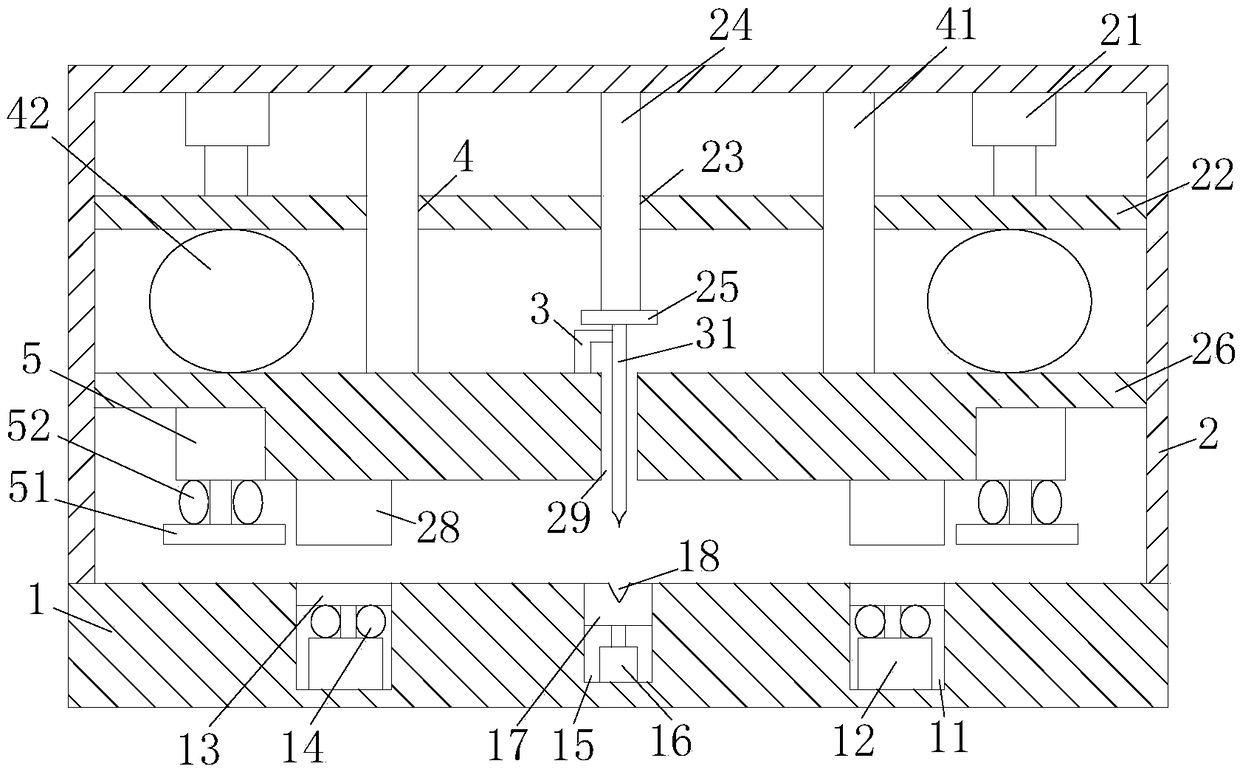

[0026] As an embodiment of the present invention, the brake plate 22 is provided with a second circular hole 4 on both sides of the first circular hole 23; the inner wall of the second circular hole 4 is provided with a thread groove; the rotating rod Both ends of 24 are provided with limit rods 41; the surface of the limit rods 41 is provided with threads corresponding to the thread grooves, and the limit rods 41 pass through the second round hole 4 and are connected to the top inner wall of the frame body 2 and fixed Between the upper surfaces of the plates 26; when working, the brake plate 22 moves up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com