Focusing light spot oscillating type cigarette tipping paper laser boring method and device

A technology of cigarette tipping paper and laser drilling, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of not providing the realization method of tipping paper, and achieve beautiful and changeable appearance, easy technology, The effect of low equipment cost and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

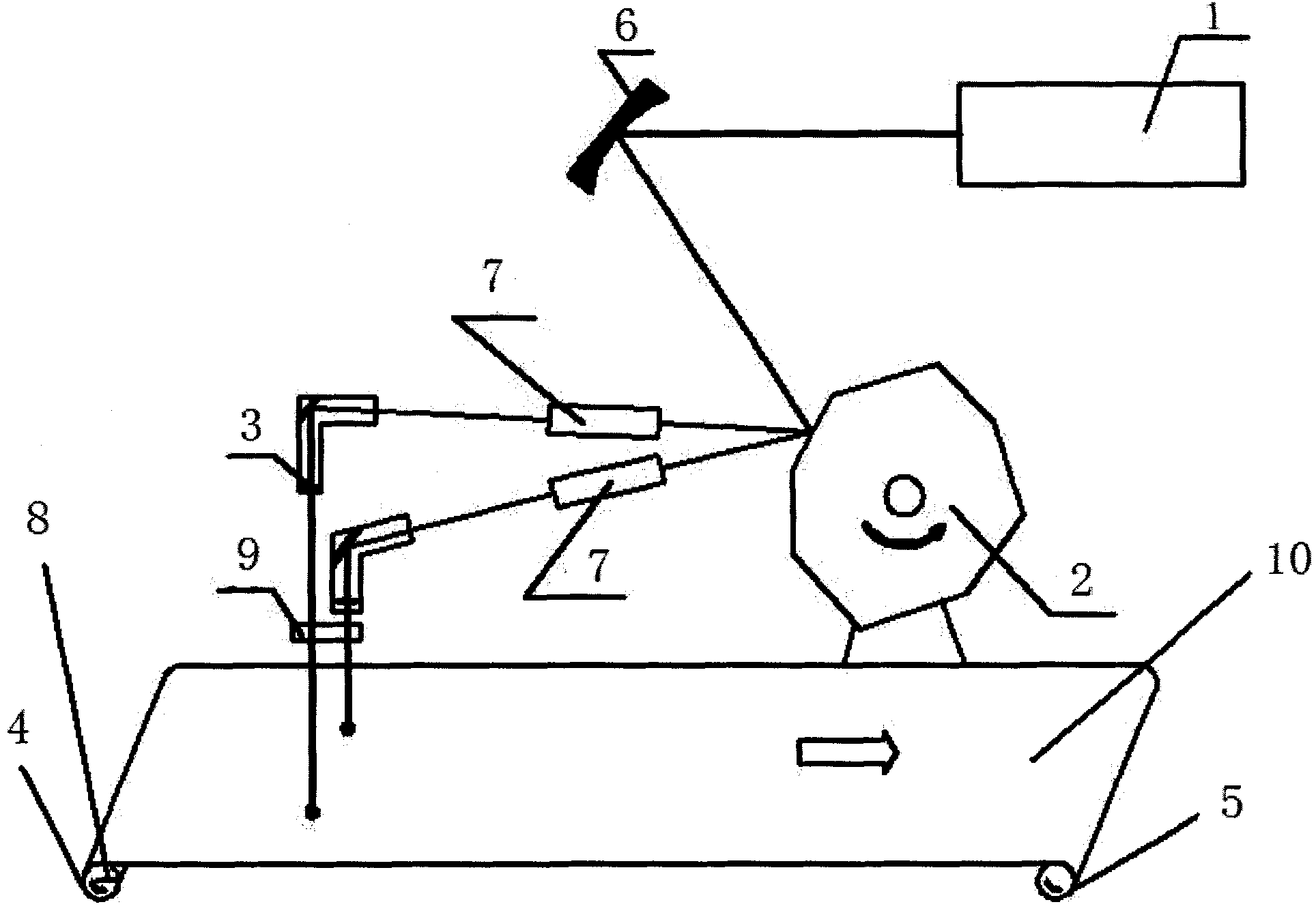

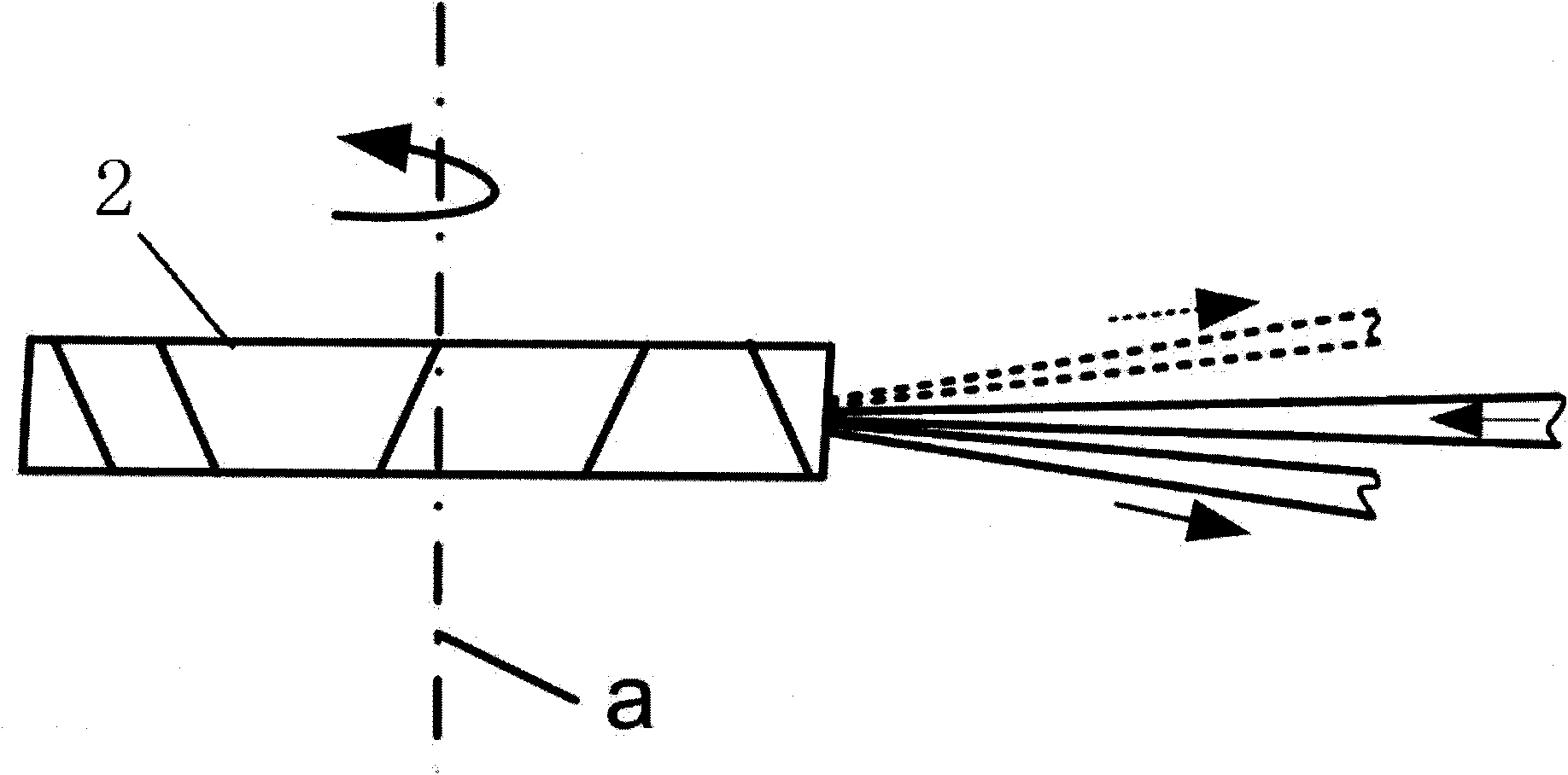

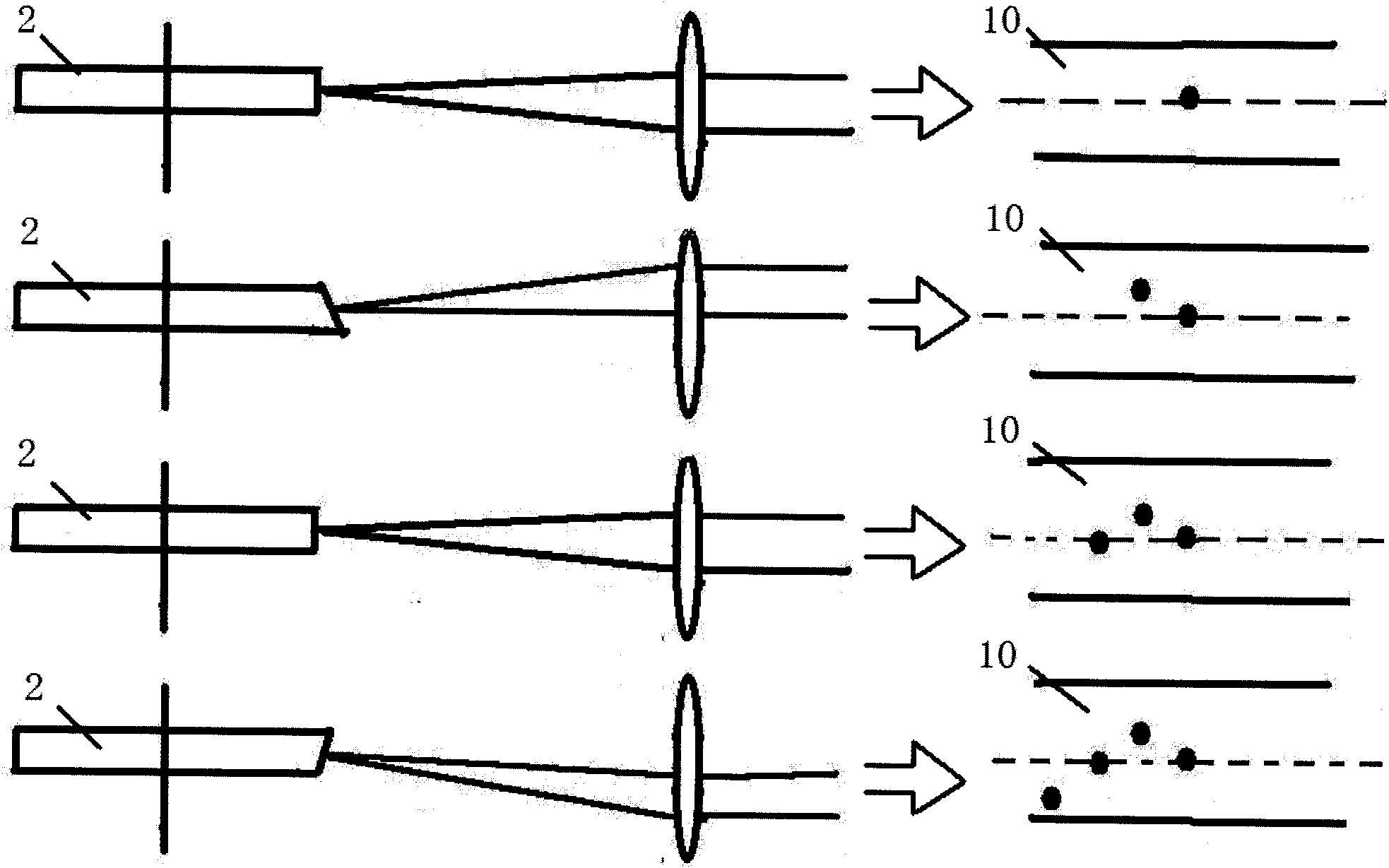

[0035] Example 1: Combining figure 1 Shown is a specific embodiment of the laser punching device for cigarette tipping paper of the present invention, which includes a laser 1, a polygonal mirror beam splitting mechanism, a focusing mechanism, a paper feeding mechanism that drives the tipping paper to move continuously, and a bottom end The focusing lens 9 and the control system (not shown in the figure), the tipping paper online speed detection device (8) and the laser cooling system (not shown in the figure) are jointly composed. Where: the laser 1 is a high-power continuous CO2 Laser, its output power is continuously adjustable from 50 to 2000 watts, and the laser output wavelength is 10.6 μm. The polygonal mirror beam splitting mechanism consists of a polygonal mirror 2, a high-speed motor (not shown) that drives the polygonal mirror 2 to rotate, a front-end focusing mirror 6 for focusing the continuous laser beam emitted by the laser 1 on a certain working surface of the ...

Embodiment 2

[0045] Example 2: Combining Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that each focusing head 3 can also complete focusing by means of reflection, specifically, there are two symmetrical arrangements inside it and are used to guide the continuous laser beam by 90° twice. 45° reflector 11 and a focusing head reflective focus mirror 13 for converging and outputting the reflected light after the aforementioned guidance. After the pulsed laser beam emitted from the pulse laser 101 passes through the first 45° reflector 11, the optical path changes by 90° , and then incident on the second 45 ° reflector 13, the optical path is changed by 90 °, and finally after being focused by the reflective focusing mirror 14, the focus falls on the surface of the tipping paper 10 to be processed. Others of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com