Pneumatic flexible swinging joint

A joint and flexible technology, applied in the field of pneumatic flexible swing joints, can solve the problems of difficult control and difficult swing of pneumatic swing joints, and achieve the effect of easy control, good applicability and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

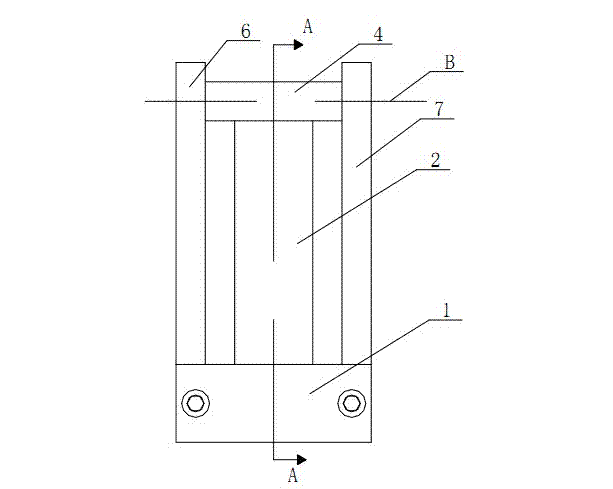

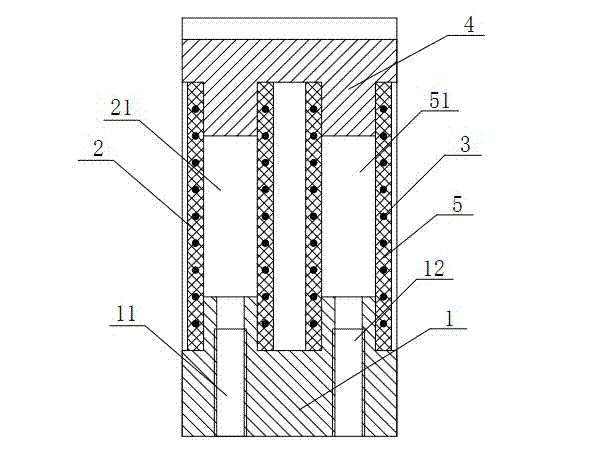

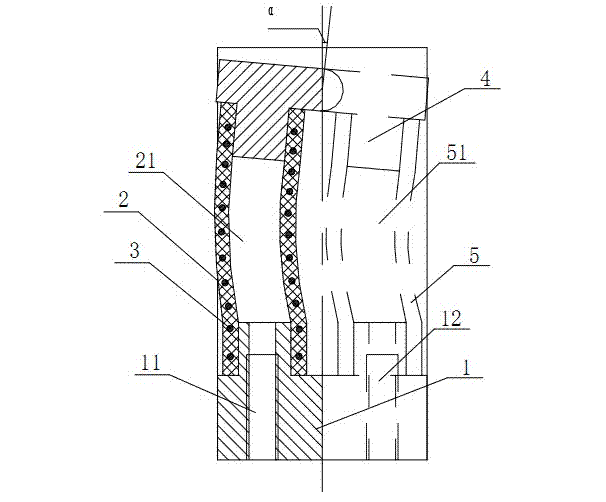

[0014] refer to Figure 1-3 , a pneumatic flexible swing joint, including a base 1 and an end cover 4, a first rubber tube 2 and a second rubber tube 5 arranged in parallel front and back are sealingly connected between the base 1 and the end cover 4, the first rubber tube 2 and the space in the second rubber tube 5 are respectively the first joint inner cavity 21 and the second joint inner cavity 51, and the first threaded hole 11 and the second threaded hole 12 communicating with the atmosphere are opened on the base 1, and the The first threaded hole 11 communicates with the first joint cavity 21, and the second threaded hole 12 communicates with the second joint cavity 51; both the first rubber tube 2 and the second rubber tube 5 are embedded with a wire 3 ; The base 1 is fixedly connected with a left baffle 6 and a right baffle 7, and the left baffle 6 and the right baffle 7 are hinged with the end cover 4.

[0015] The metal wire 3 is a helical steel wire.

[0016] An ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com