Parallel three-freedom-degree mechanism device based on oscillating cylinder driving and control method

A swing cylinder and mechanism device technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of insufficient flexibility and concession, large instantaneous current of motor, gap and friction, etc., to avoid multi-circuit interference and angle selection The effect of large and large system rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present application will be further described in detail below in conjunction with the drawings and specific embodiments.

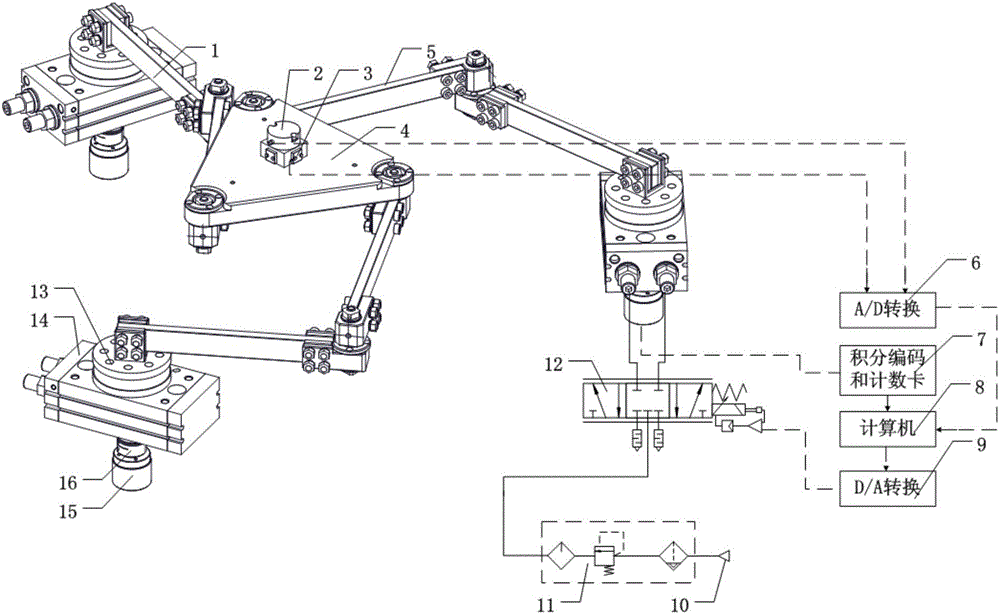

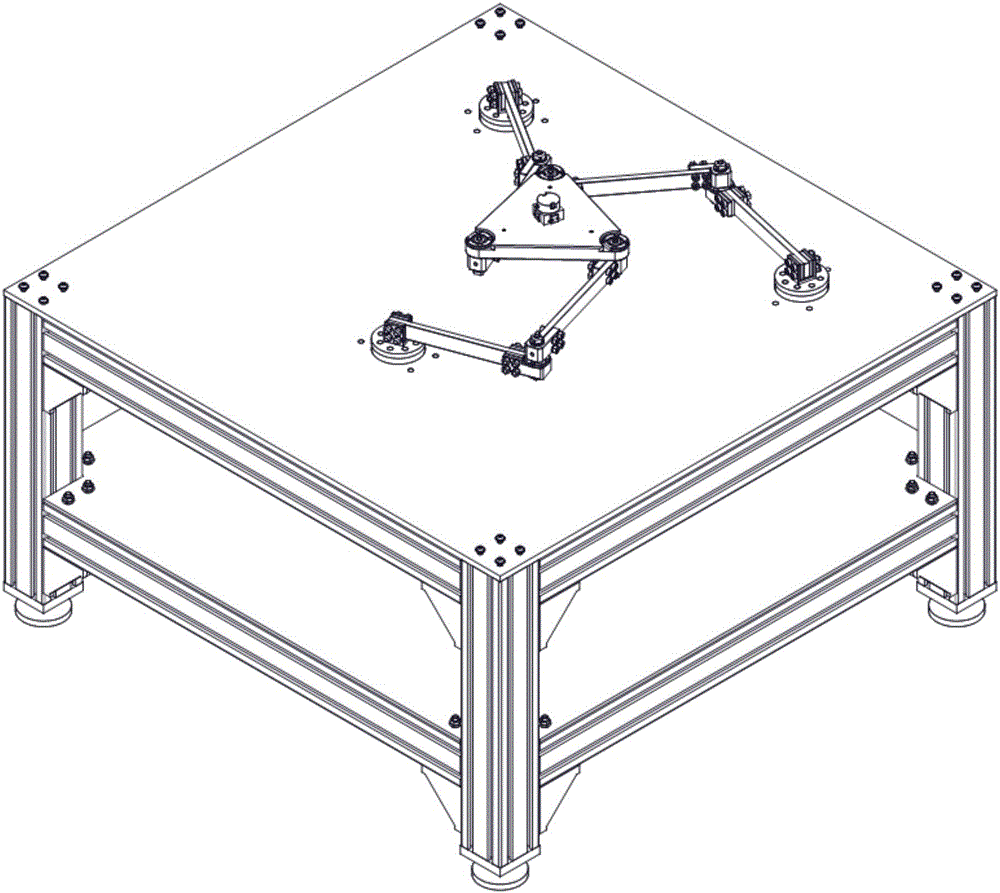

[0031] Such as figure 1 , figure 2 As shown, the present invention provides a parallel three-degree-of-freedom mechanism device driven by a swing cylinder, including a fixed platform, a moving platform 4, three parallel drive control branches, a pneumatic unit, a signal detection module and a control unit, figure 1 The structure of the fixed platform is hidden in , the purpose is to describe the control unit of the device more clearly, figure 2 The fixed platform is expressed in detail, figure 1 The dotted line connection in represents the connection of electric signal and control unit, and the connection of solid line represents the connection of pneumatic unit, and control unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com