Patents

Literature

35results about How to "Smooth torque transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

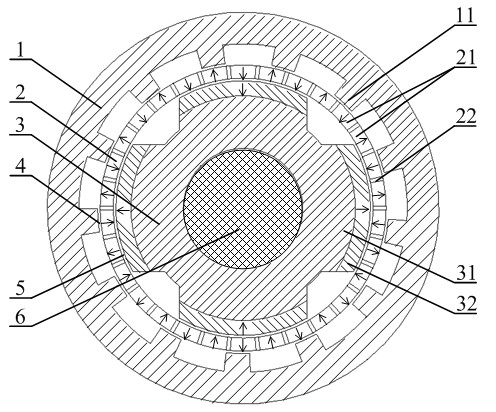

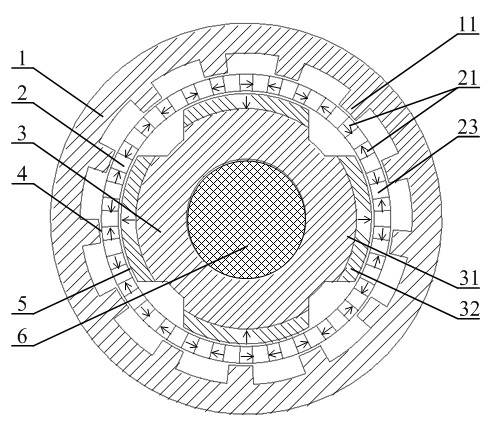

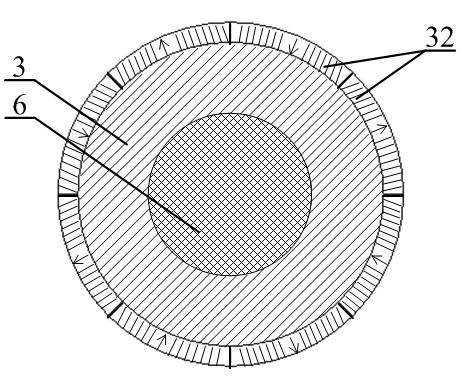

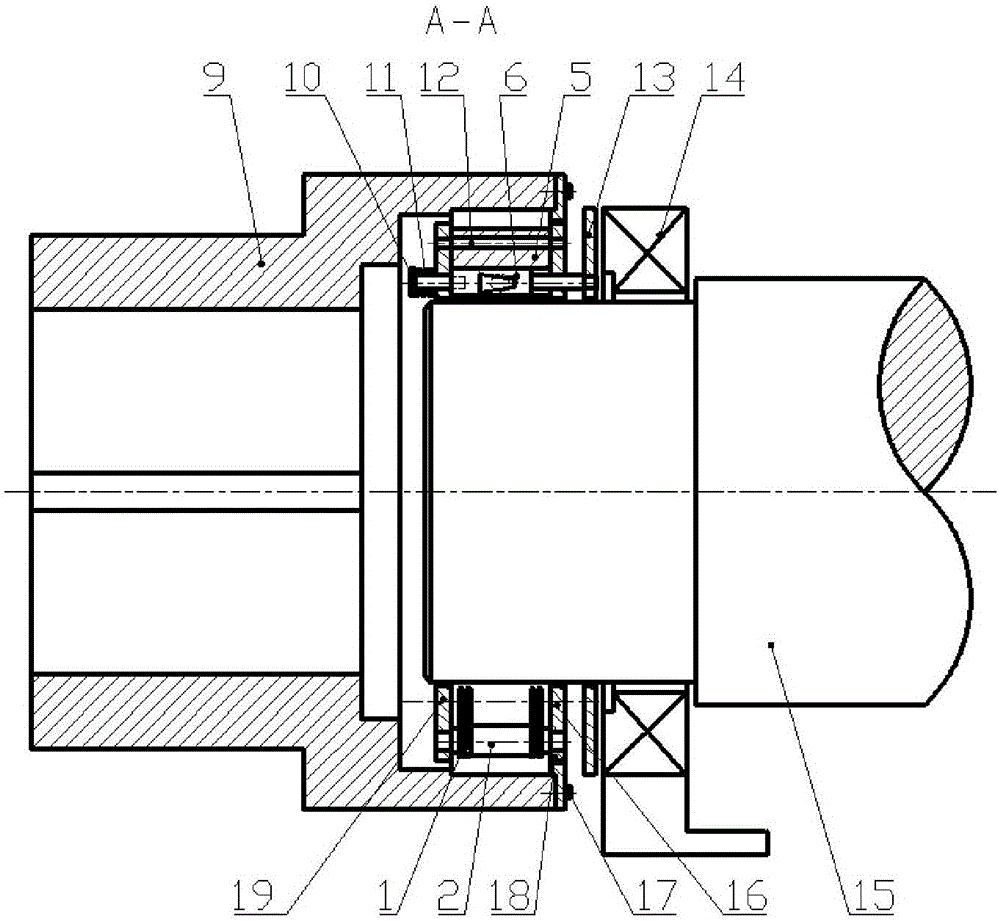

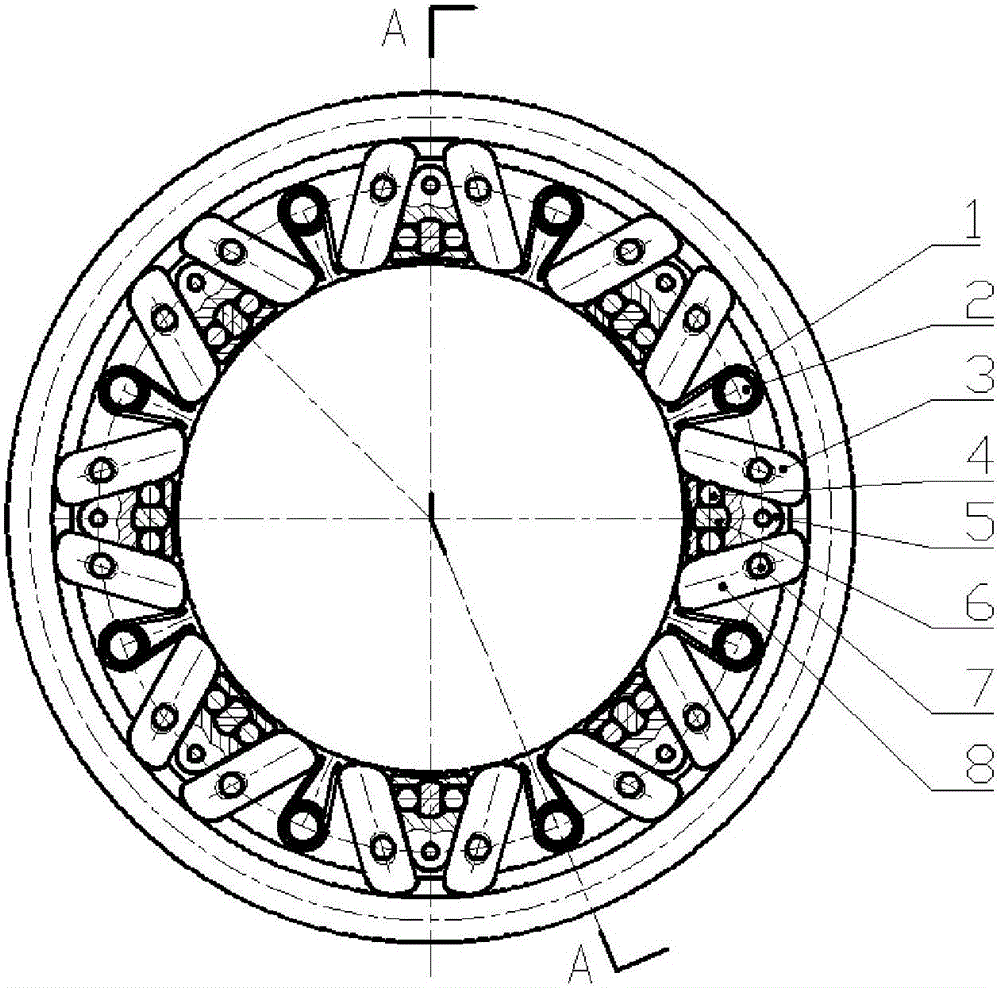

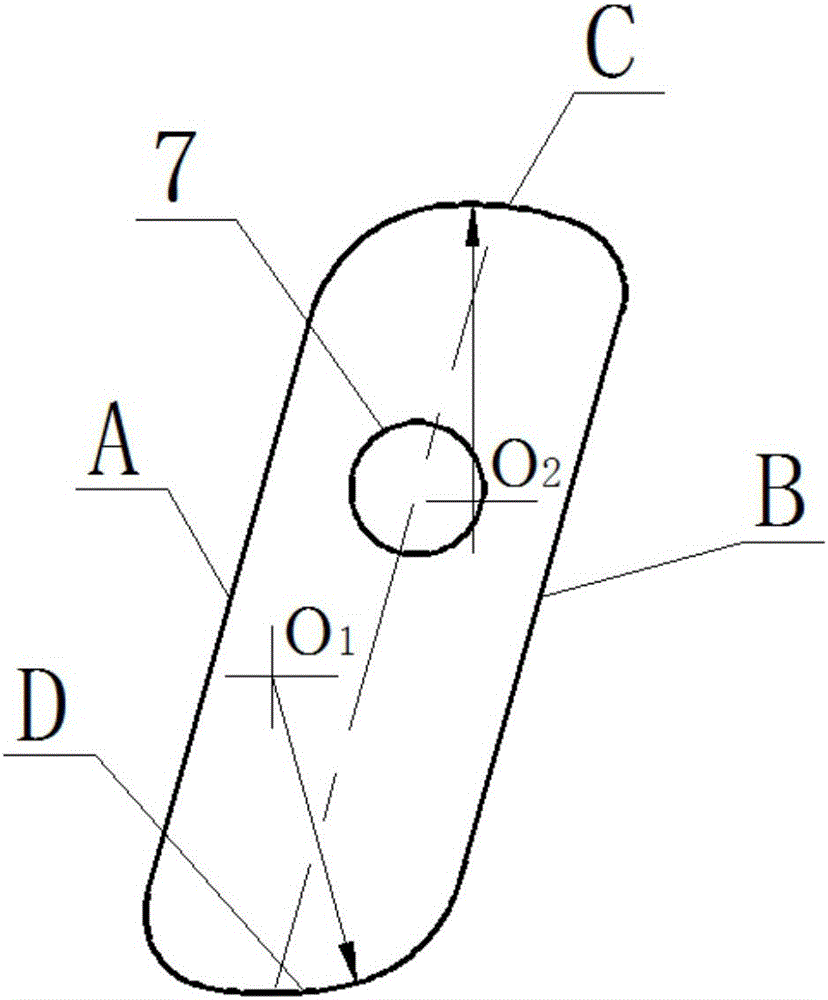

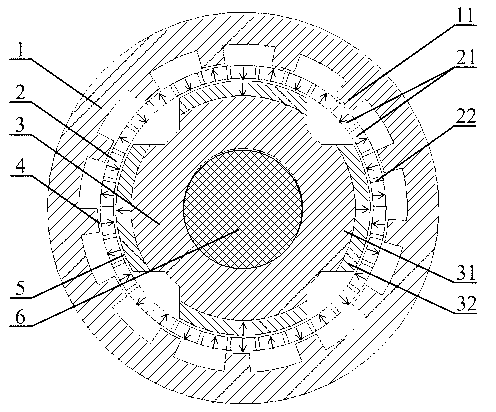

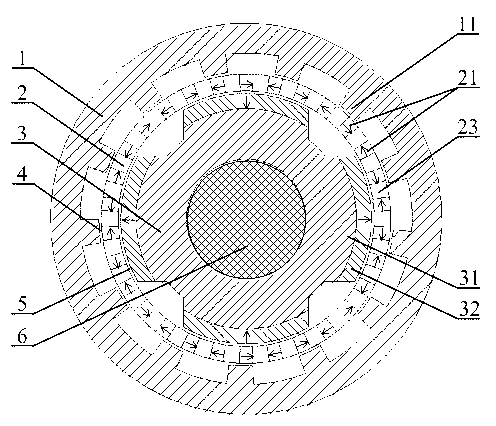

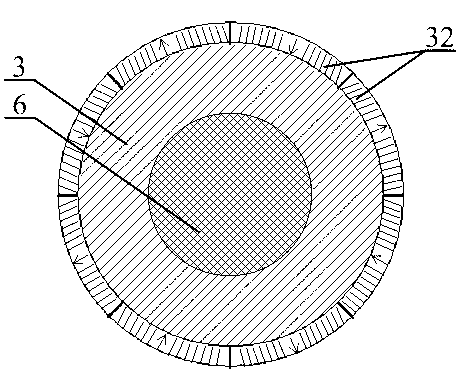

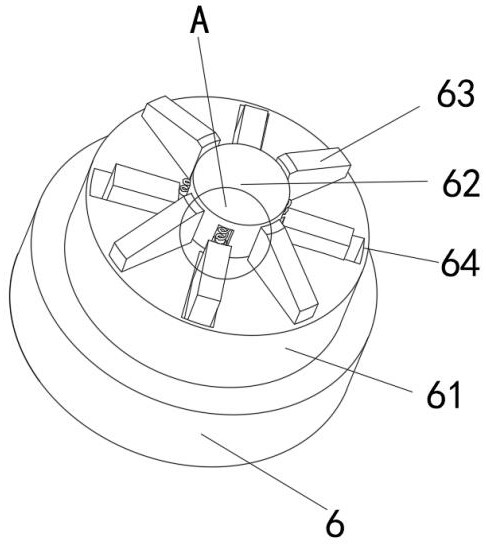

Coaxial magnetic gear

ActiveCN102324821AIncreased torque densityHigh mechanical strengthDynamo-electric machinesGear wheelMagnetic poles

The invention discloses a coaxial magnetic gear comprising an external rotor, a static magnetic ring and an internal rotor which are lined from outside to inside and share the same axis. The external rotor is a circular magnetic conductor, and external rotor convex poles which are lined with equal spacing are arranged on the inner ring of the external rotor; the static magnetic ring is fixedly arranged between the internal rotor and the external rotor, and comprises permanent magnets and non-permanent magnets which are lined at intervals; internal rotor convex poles are lined on the outer ring of the internal rotor with equal spacing, and internal rotor permanent magnet bodies are arranged on the outer ring of the internal rotor; the internal rotor can be also in other structural forms capable of producing effective N-S magnetic poles; and in order to ensure the normal rotation of the internal rotor and the external rotor, air gaps are left between the three parts. Through the convex pole structure of the external rotor, the coaxial magnetic gear enables a static magnetic ring magnetic field to modulate a series of harmonic rotation magnetic fields on an inner air gap side, the number of the polar pairs of the selected internal rotor permanent magnet bodies is the same with that of the pole pairs of a required harmonic magnetic field, and the stable torque transmission is realized by the coupling action of the polar pairs of the selected internal rotor permanent magnet bodies and the pole pairs of a required harmonic magnetic field. The magnetic gear has the characteristics of high torque density, high mechanical strength of the external rotor, and convenience in processing and manufacturing.

Owner:SOUTHEAST UNIV

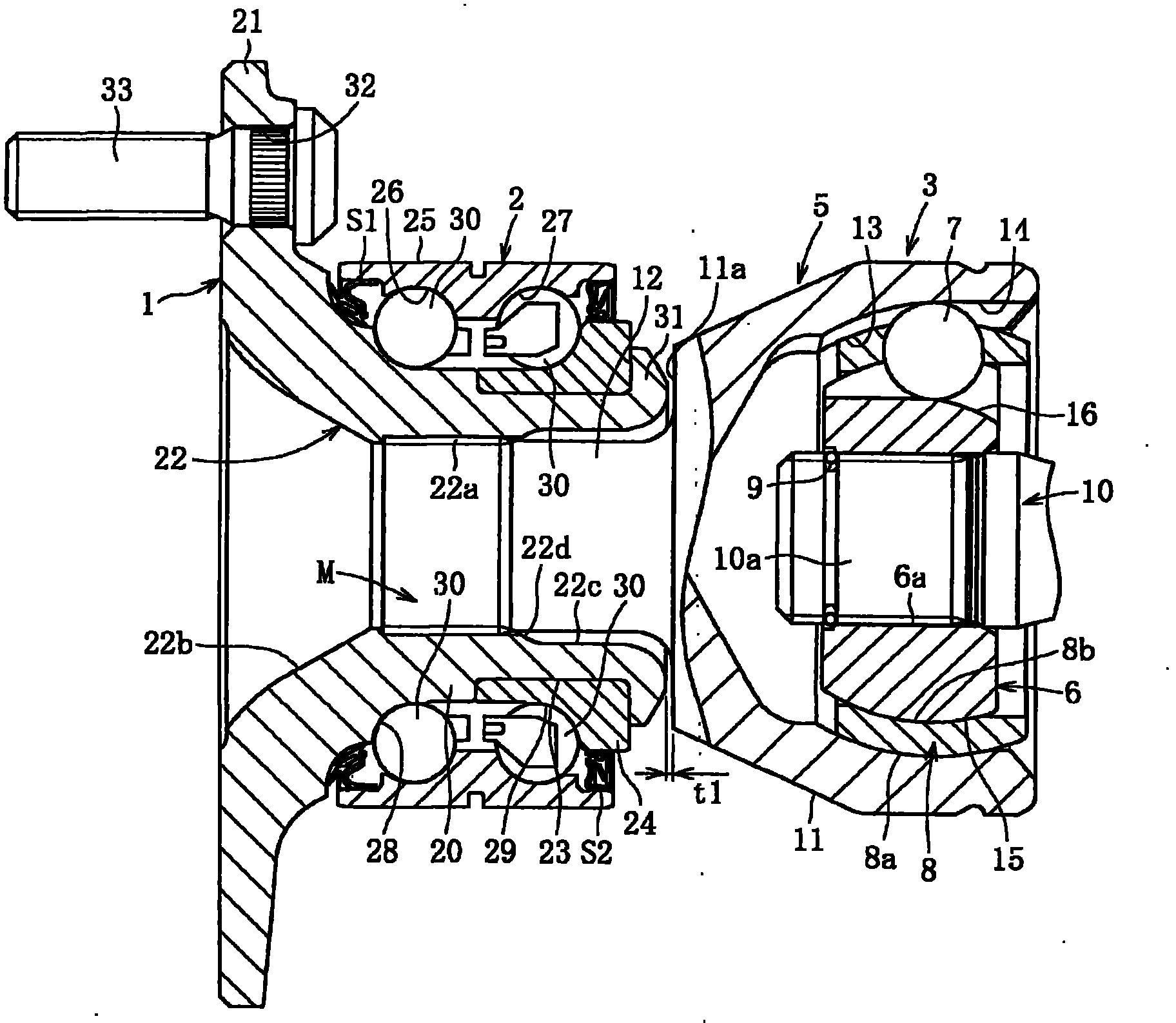

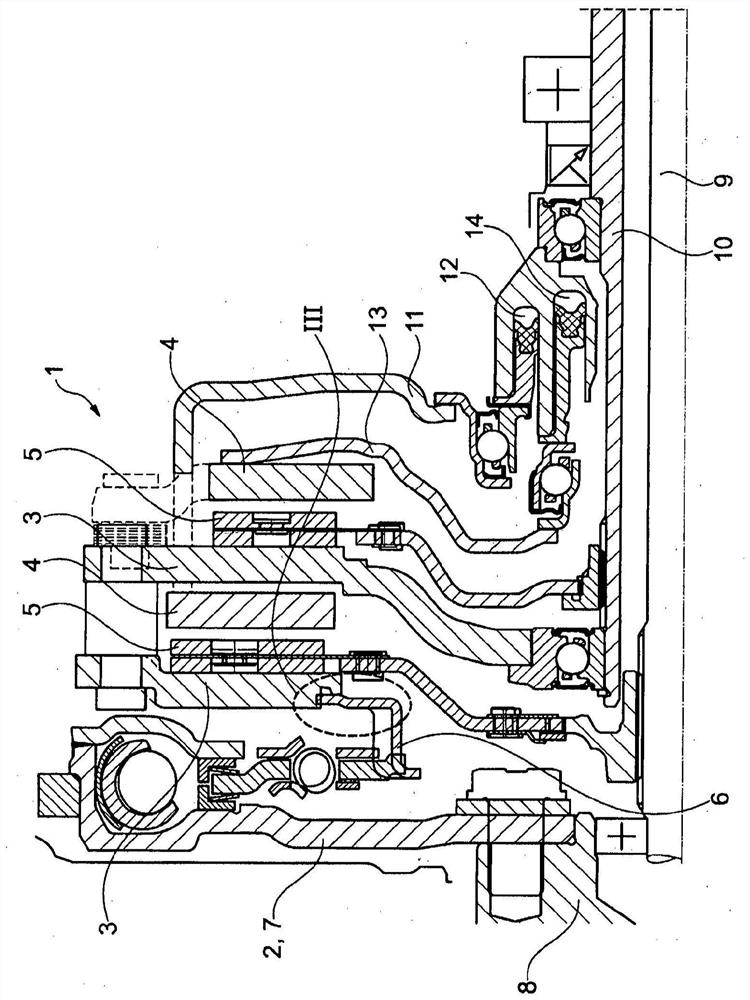

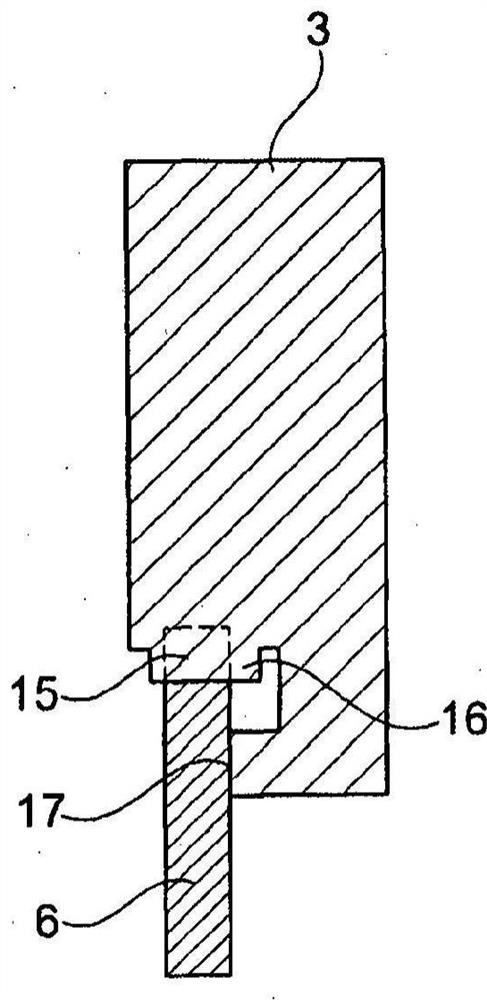

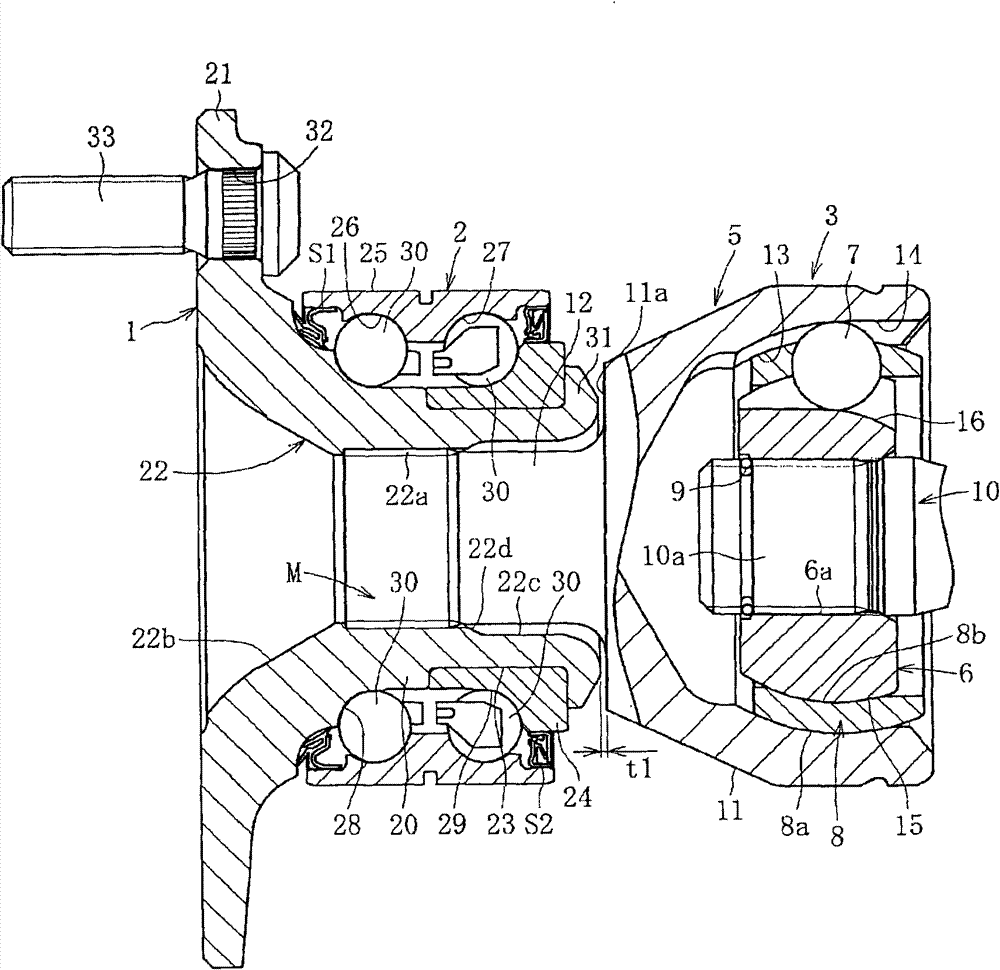

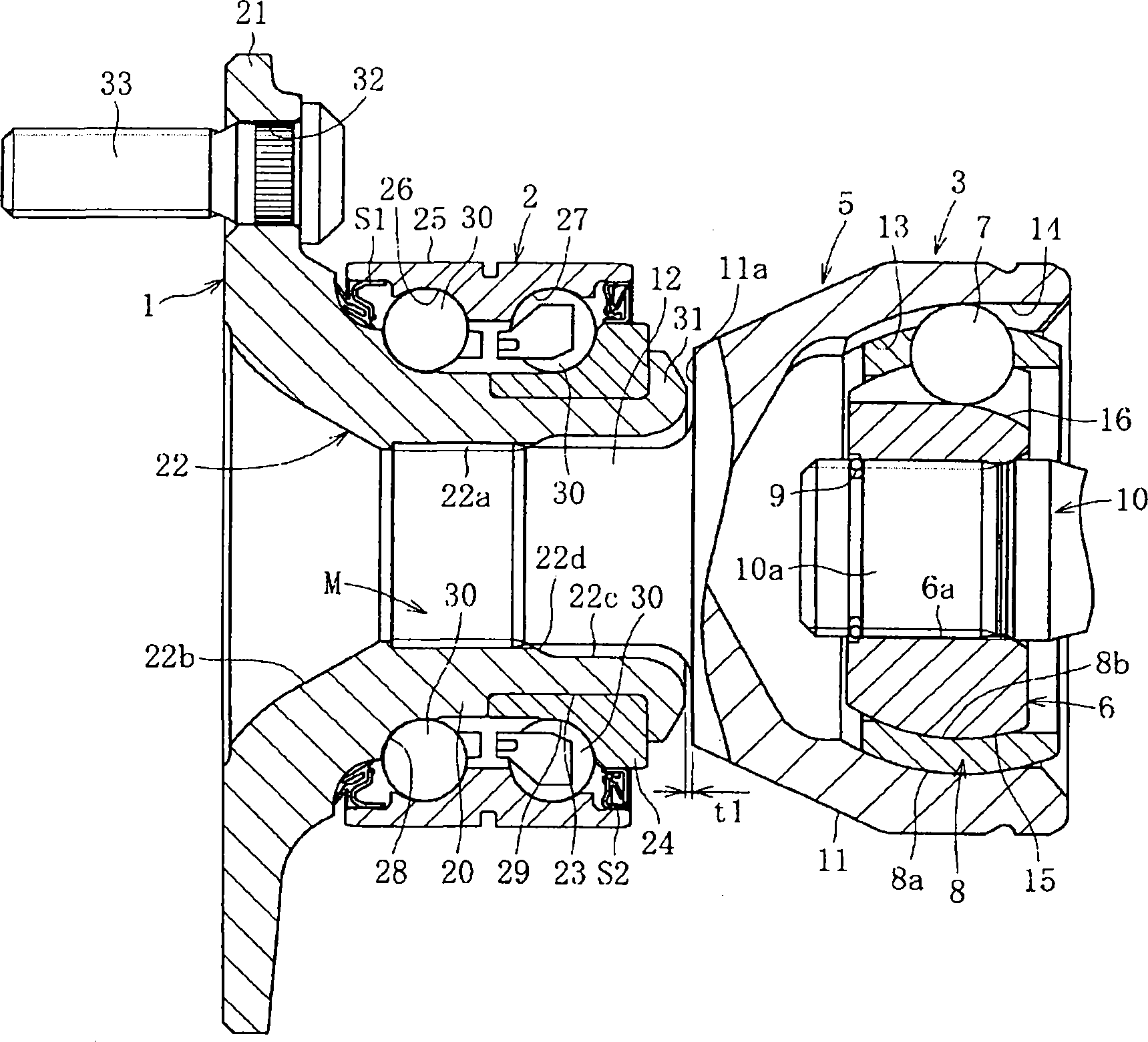

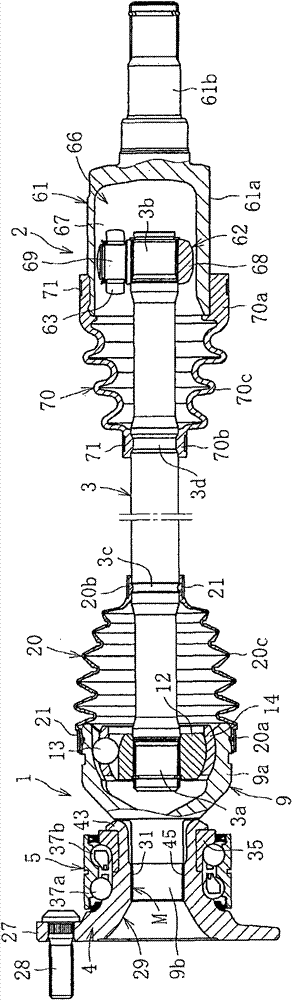

Bearing device for wheel, and axle module

Provided are a bearing device for a wheel, in which circumferential play is reduced, which provides excellent workability in connection between a hub ring and an outer joint member of a constant velocity universal joint, in which fitting between the hub ring and the outer joint member of the constant velocity universal joint is stable, and which has excellent strength, and an axle module using the bearing device. An axially extending projection is formed on either of the outer diameter surface of a shaft section of the outer joint member and the inner diameter surface of a hole of the hub ring. The projection is press-fitted to the other in the axial direction to form a recess in the other by the press-fitting. By this, a recess / projection fit structure is formed, in which the entire regions of those portions of the projection and the recess at which they are fitted to each other are in intimate contact with each other. The hardness of at least that portion of the projection at which the press-fit starts is higher than that of a portion where the recess is formed. The difference in hardness in HRC is 20 or more.

Owner:NTN CORP

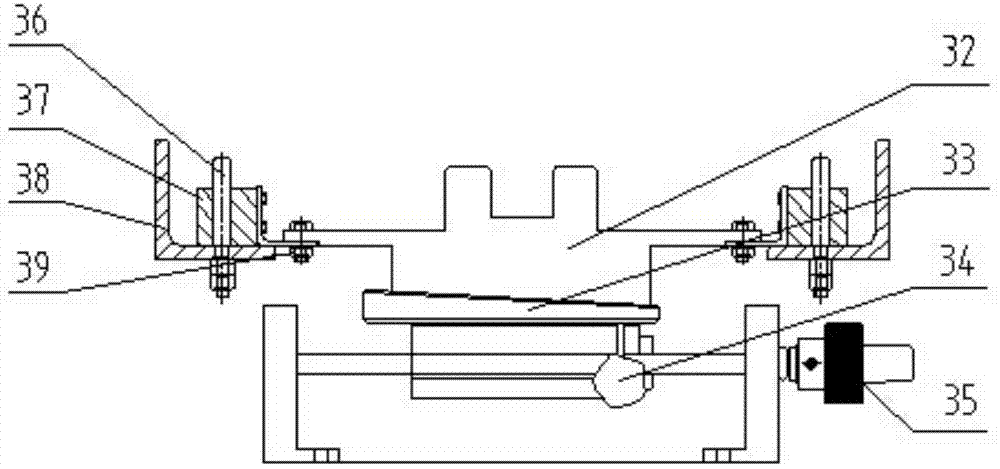

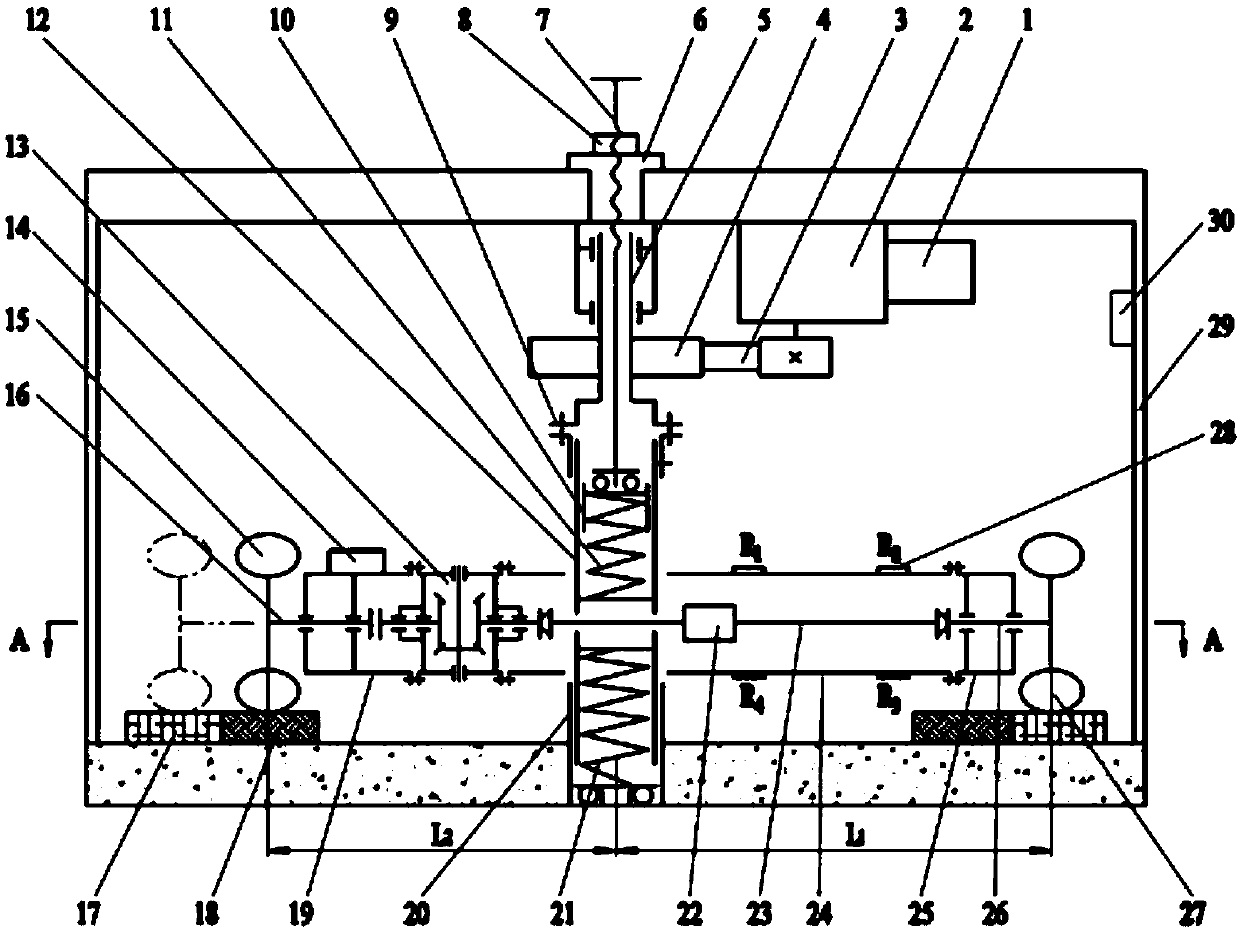

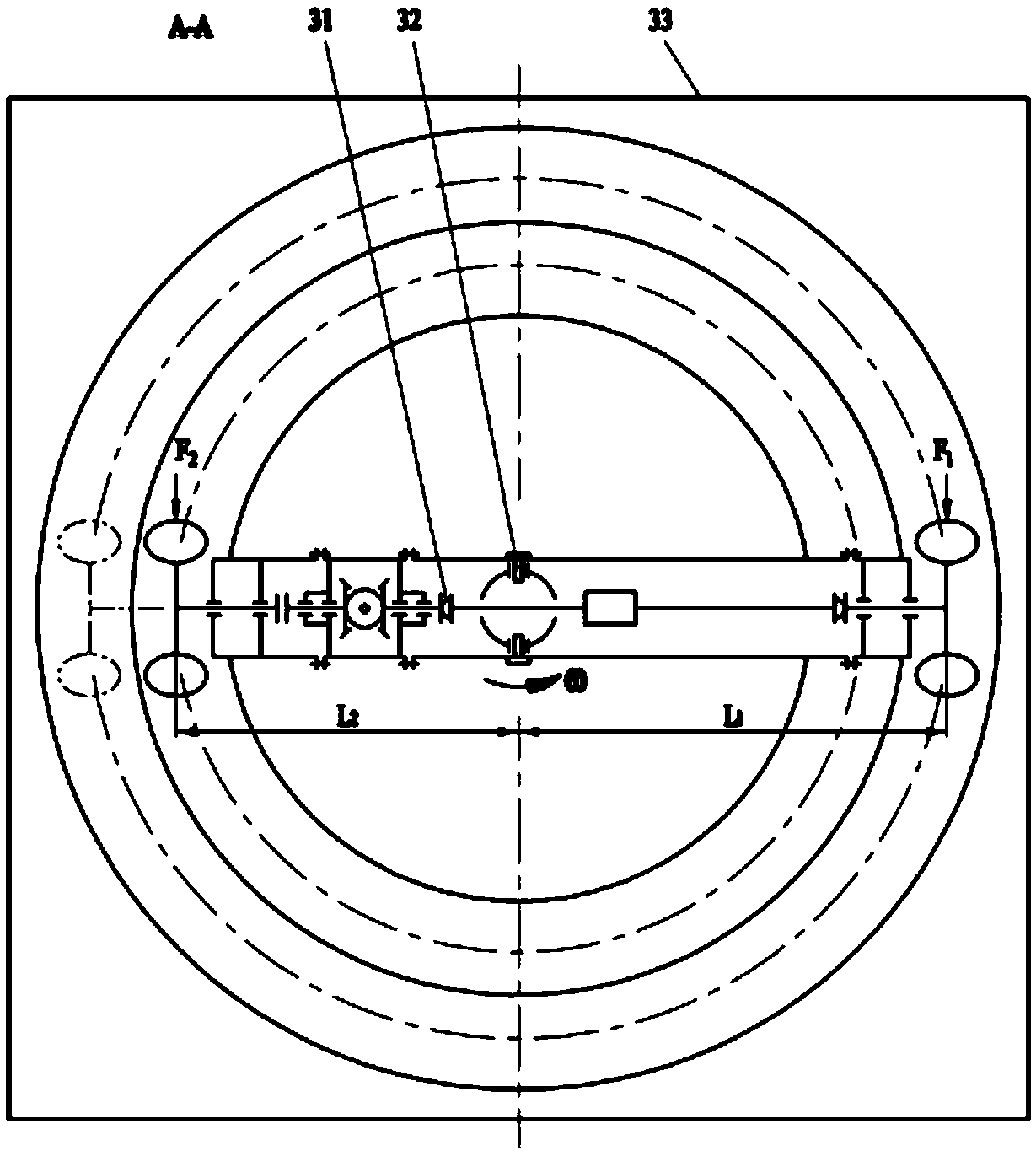

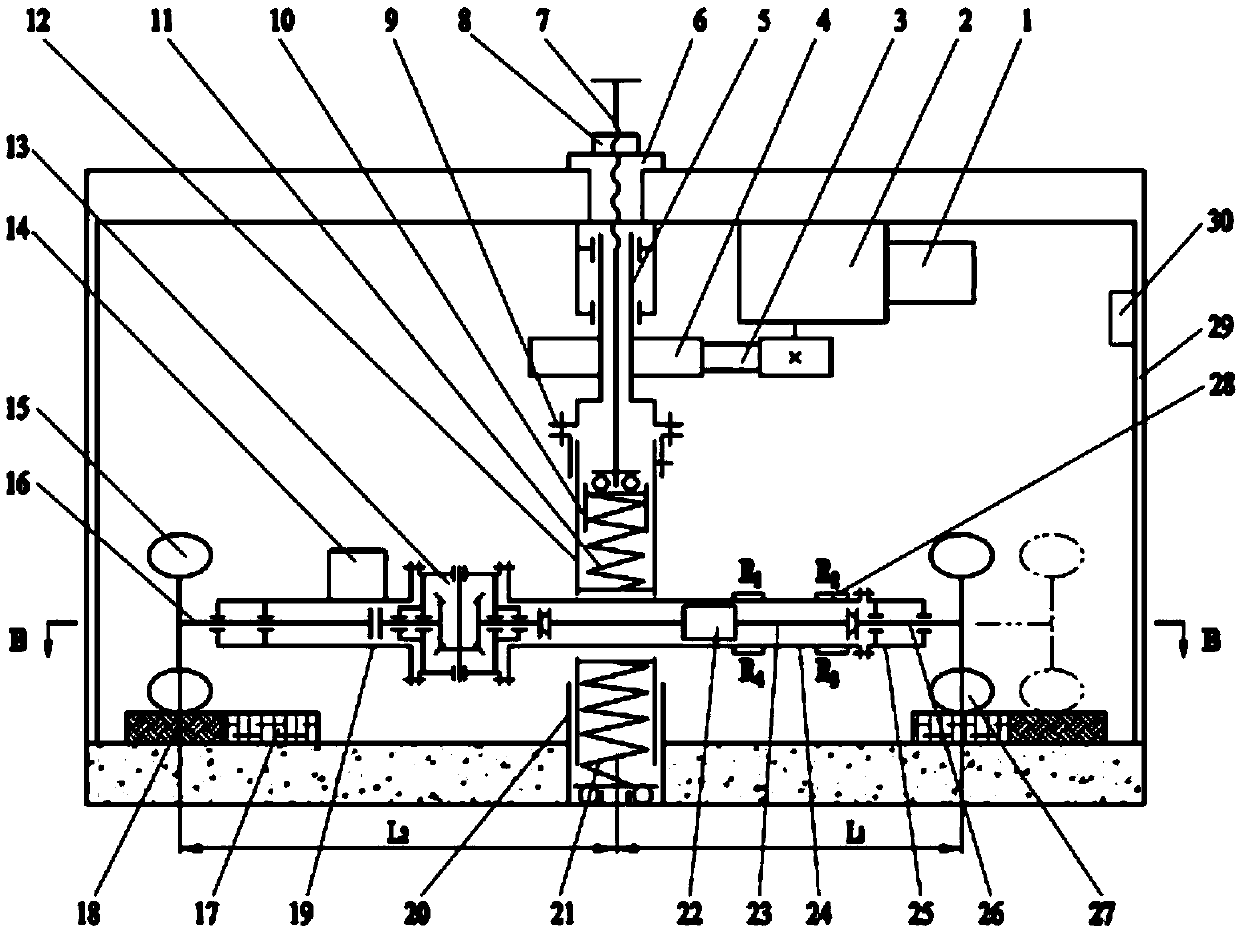

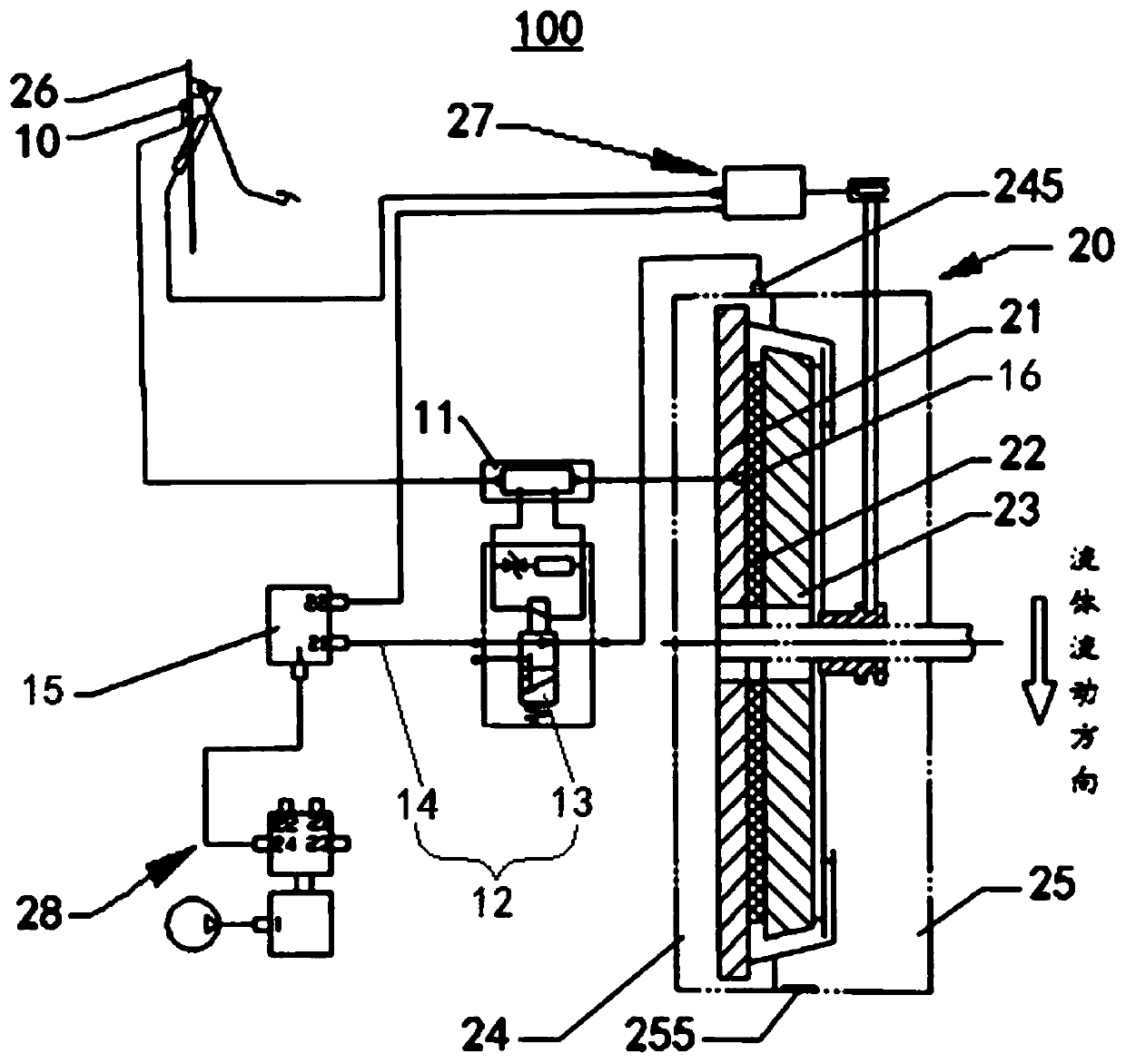

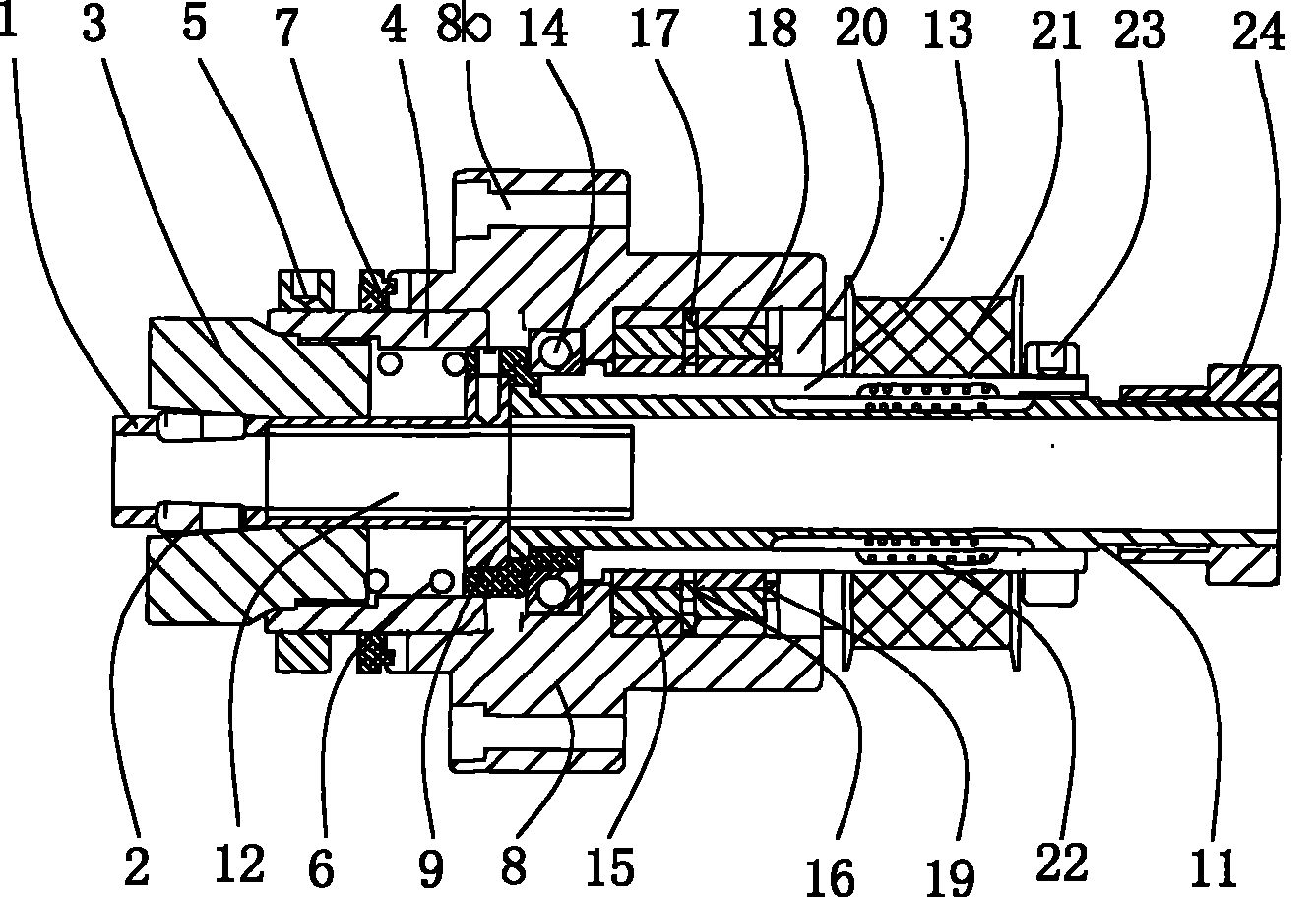

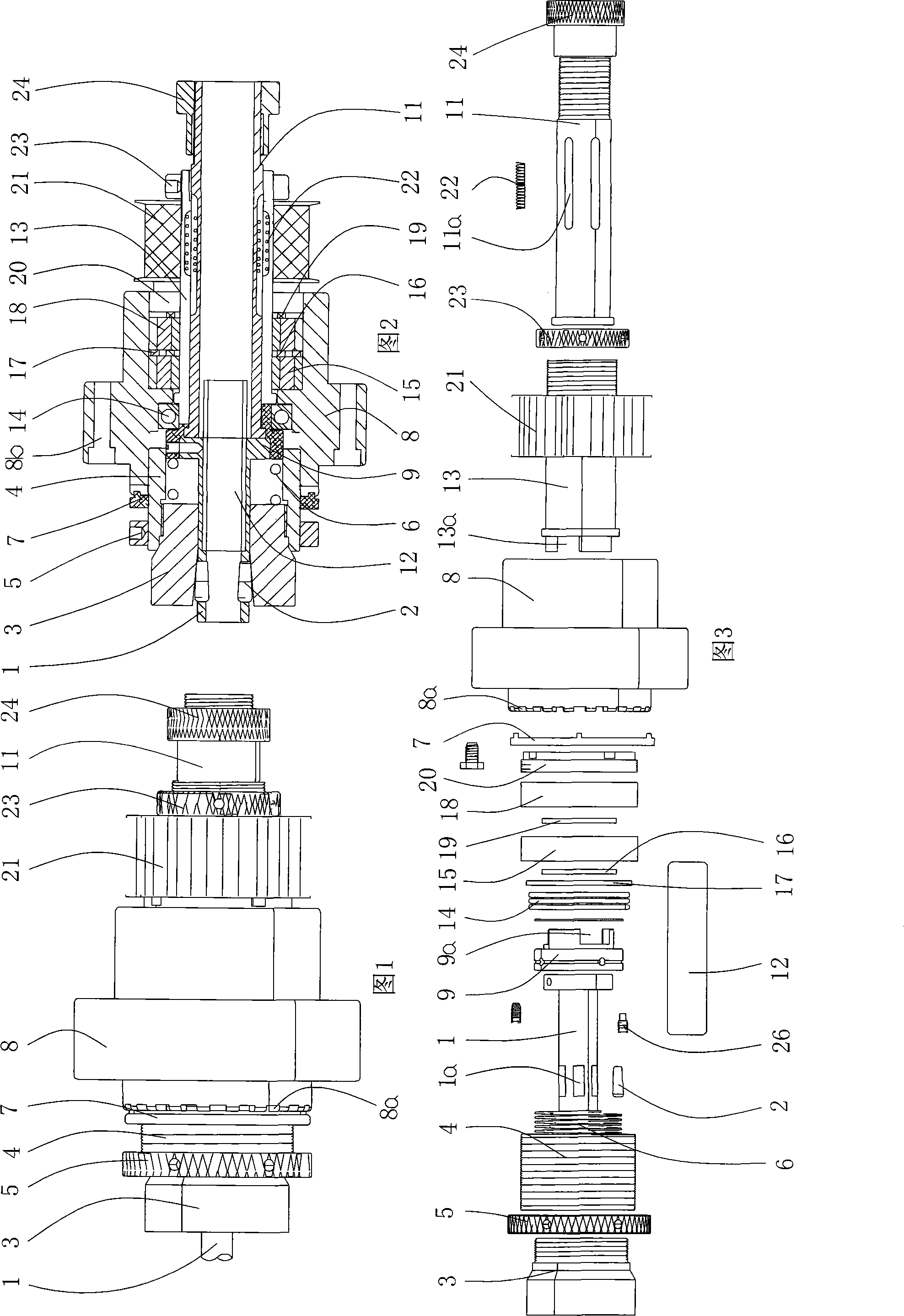

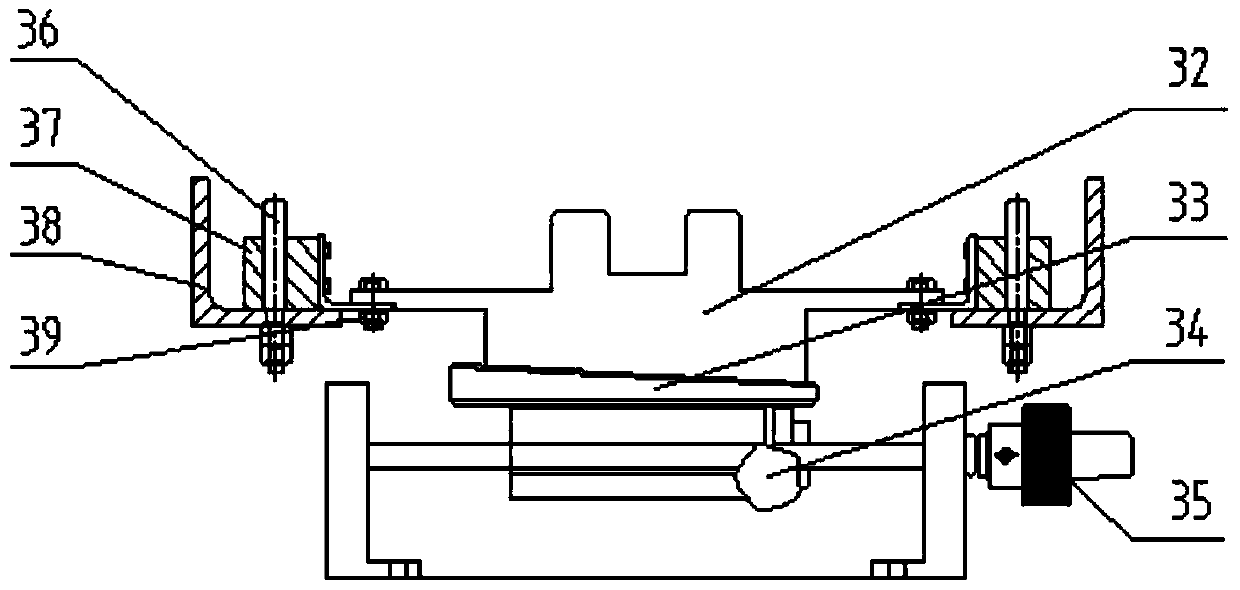

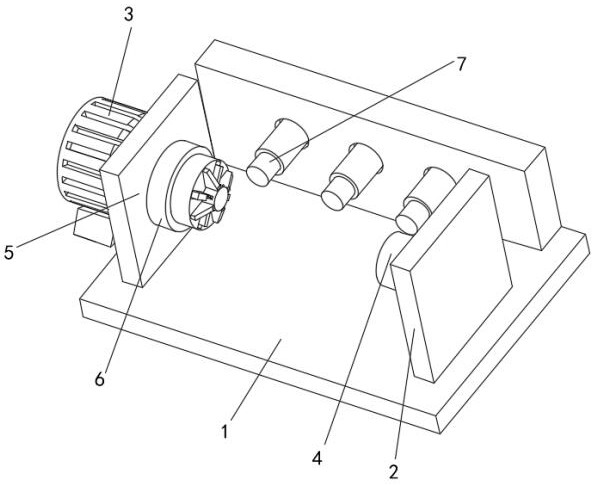

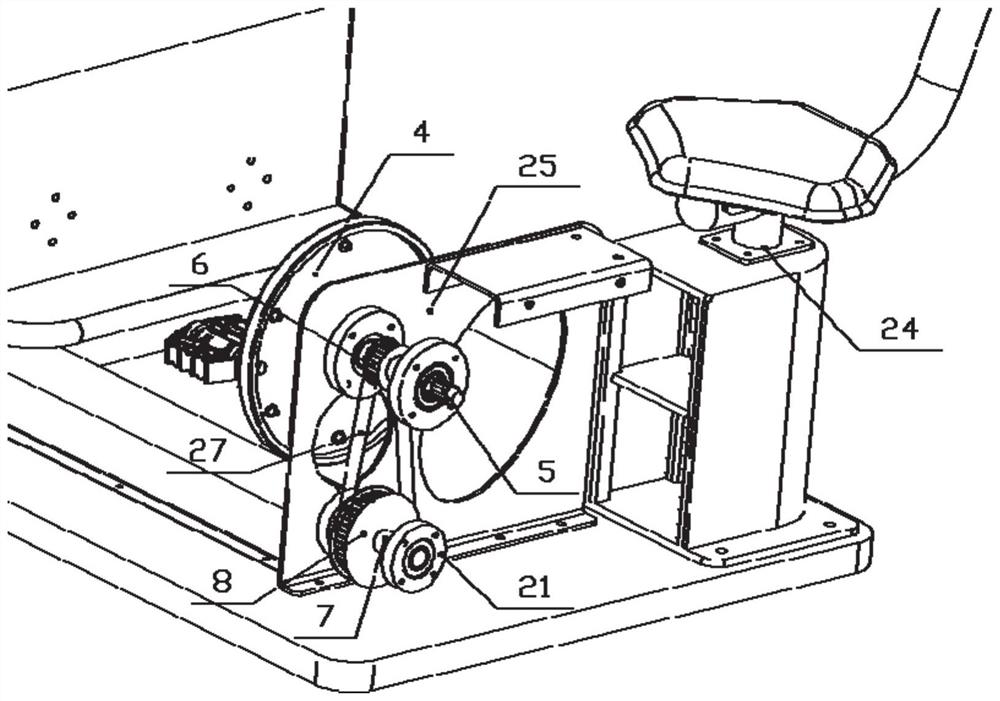

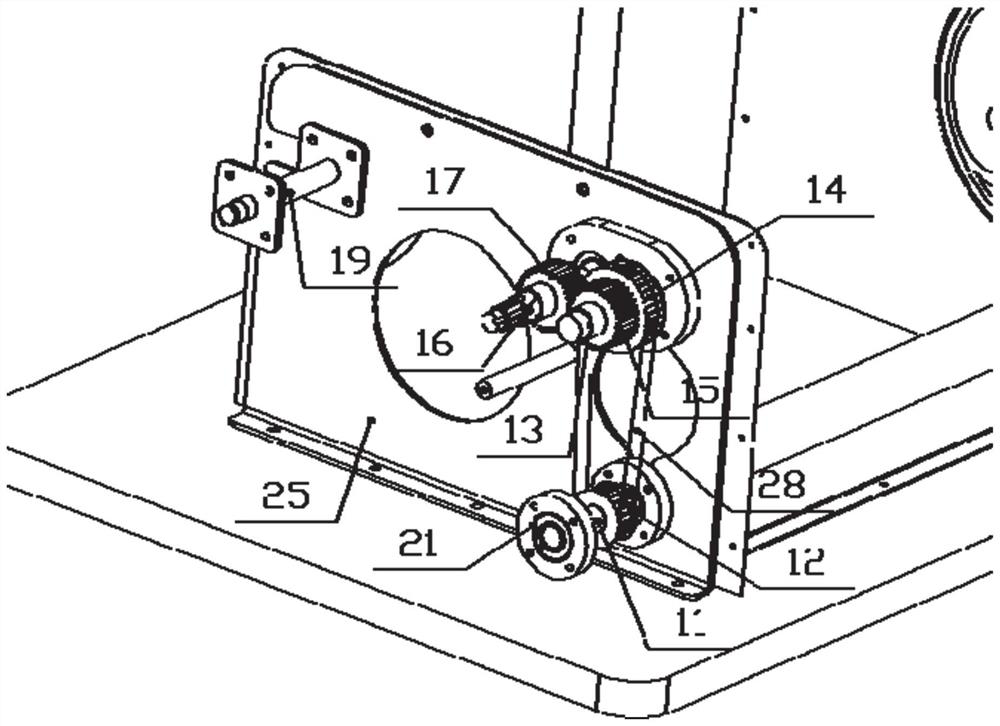

Vertical visual oil film power test device

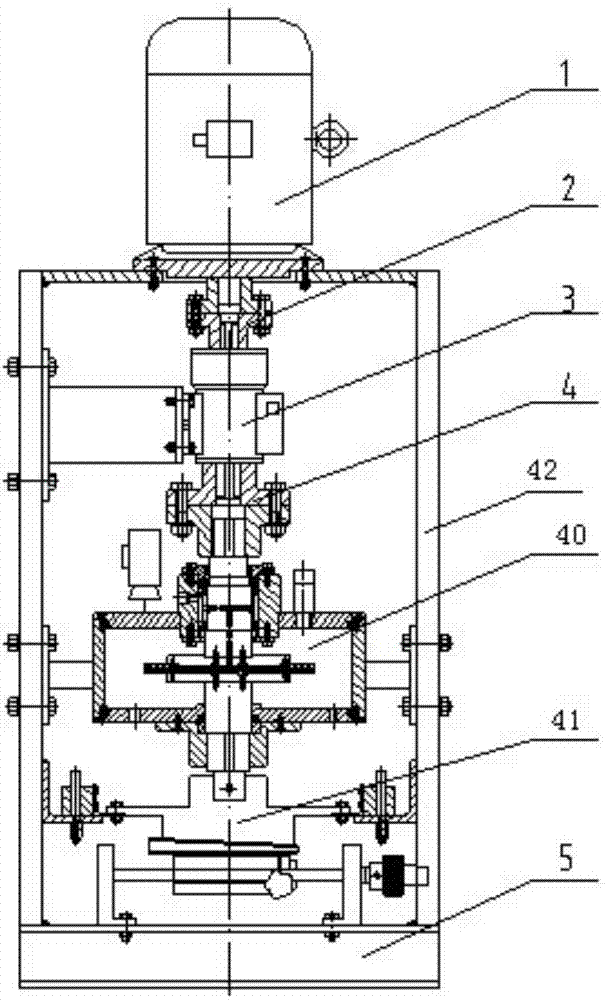

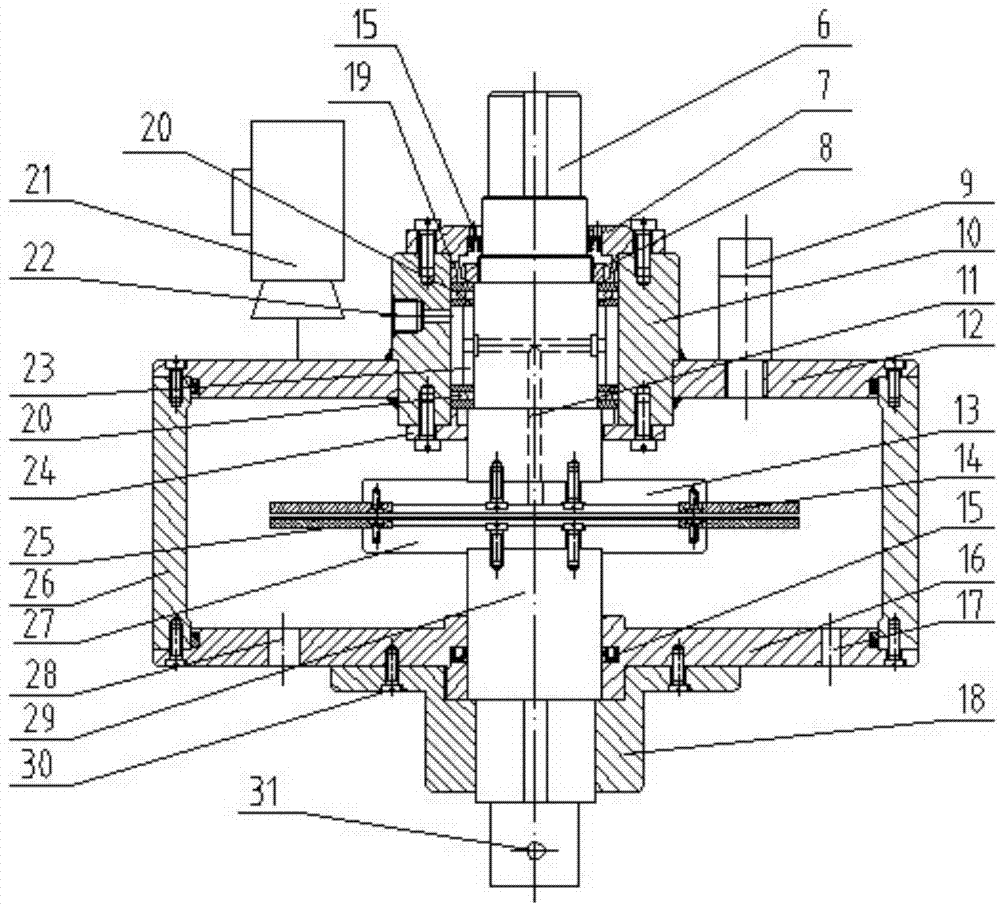

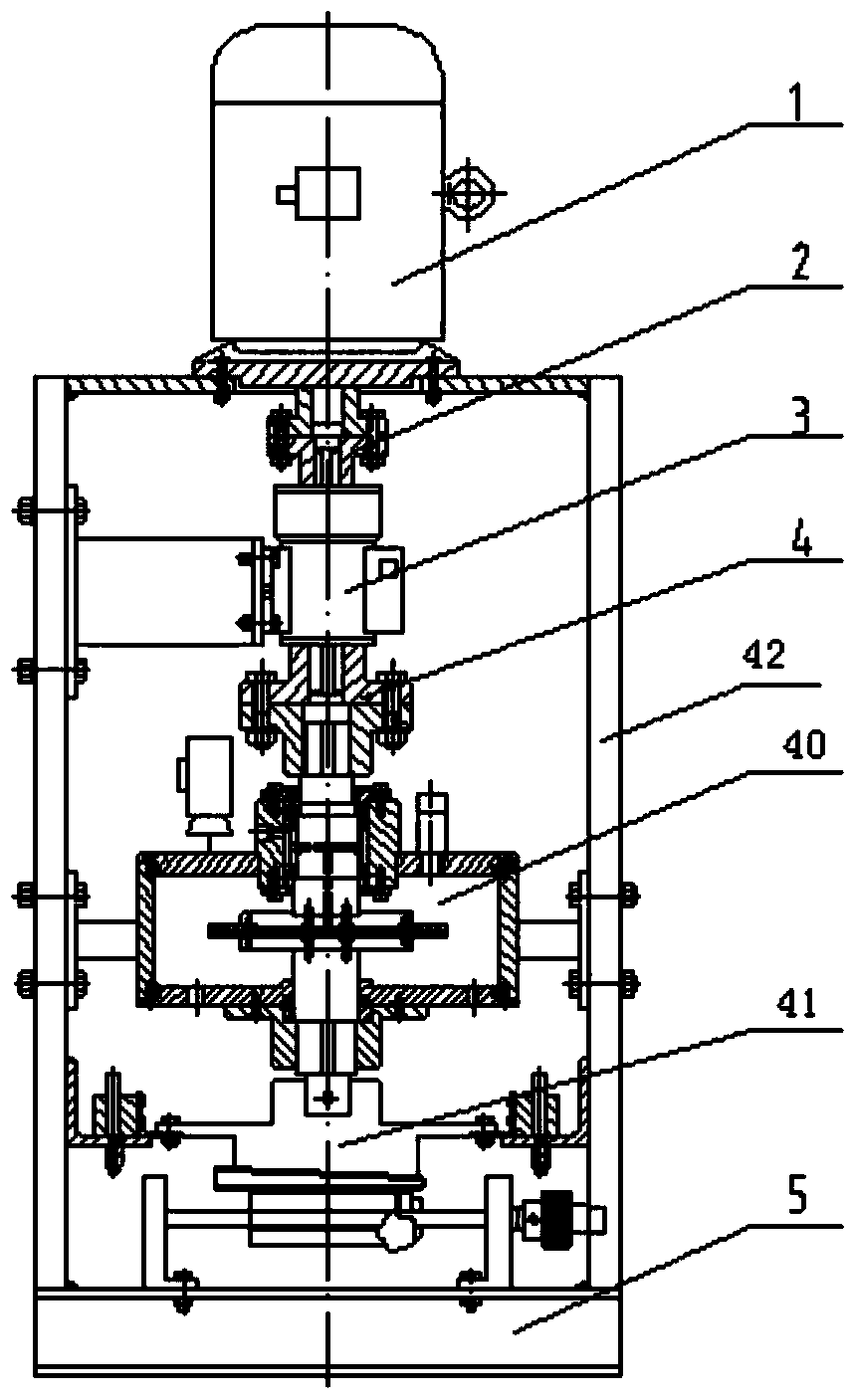

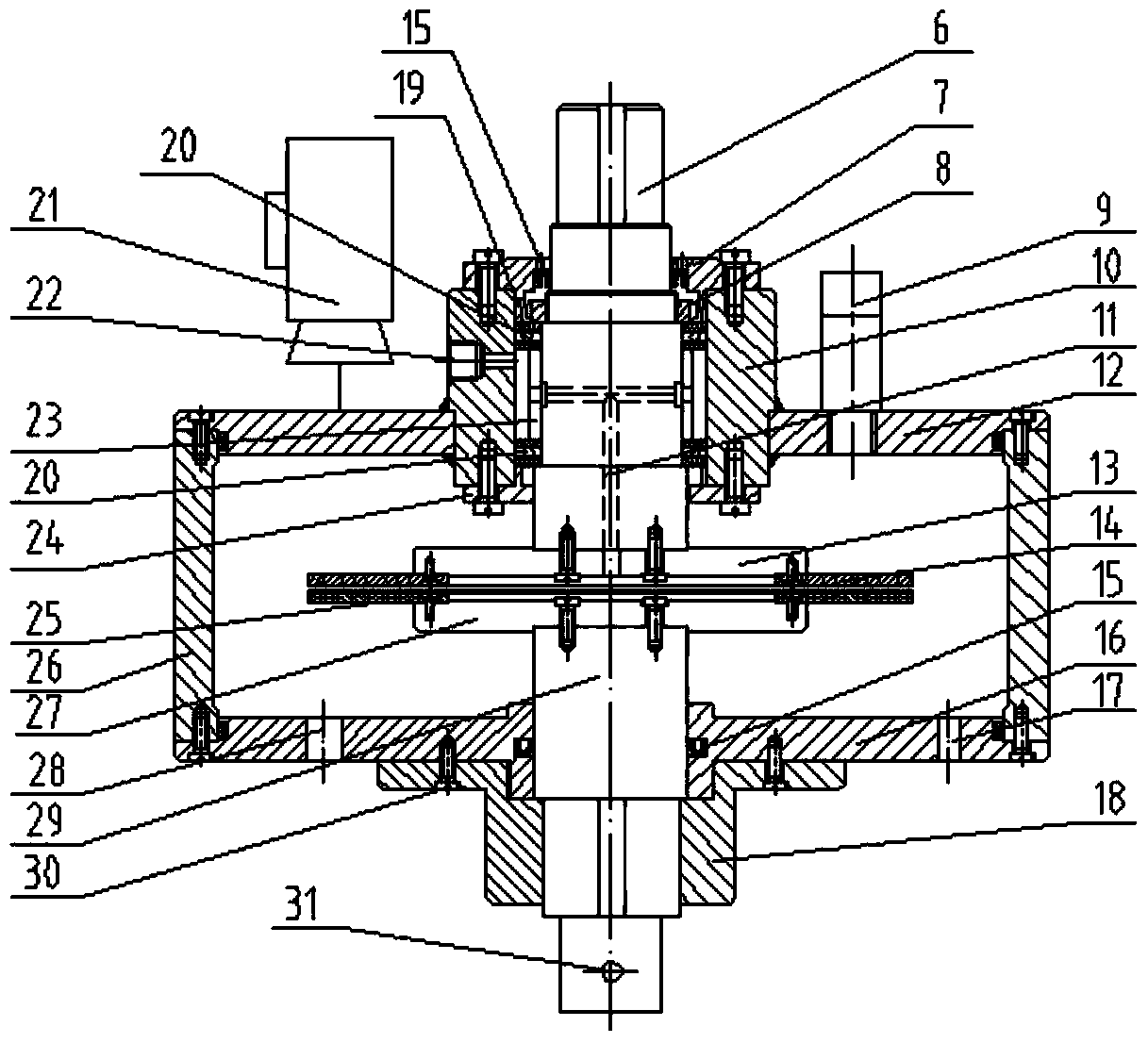

InactiveCN104502092ANeutral goodUniform thicknessMachine gearing/transmission testingLiquid viscosityEngineering

The invention discloses a vertical visual oil film power test device, which mainly comprises a prime power part, a liquid viscosity host machine, an oil film thickness regulating device, a support seat and the like, wherein an upper box cover, a lower box cover and a support plate of the liquid viscosity host machine are connected through screws to form a liquid viscosity host machine case, a sleeve passes through the upper box cover and is fixed with the upper box cover through welding, an input shaft passes through the sleeve to be connected with a driving sheet support seat, a driving friction sheet is fixedly arranged on the driving sheet support seat, a driven friction sheet is fixedly arranged on a driven sheet support seat, the driven sheet support seat is connected with an output shaft, the output shaft is connected with an output shaft fixing stop block and is fixedly arranged on the lower box cover, the output shaft is maintained not to rotate, meanwhile, the output shaft is fixed with a groove block through a pin post, the groove block is arranged on a wedge-shaped slide block, the wedge-shaped slide block moves through regulating a lead screw, and the ascending and the descending of the output shaft in the vertical direction are realized. The vertical visual oil film power test device has the advantages that the operation is convenient, the structure is simple, the detection is easy, and the functions of wide-range oil film thickness regulation, fine regulation, visible oil film flow state and the like can be realized.

Owner:JIANGSU UNIV

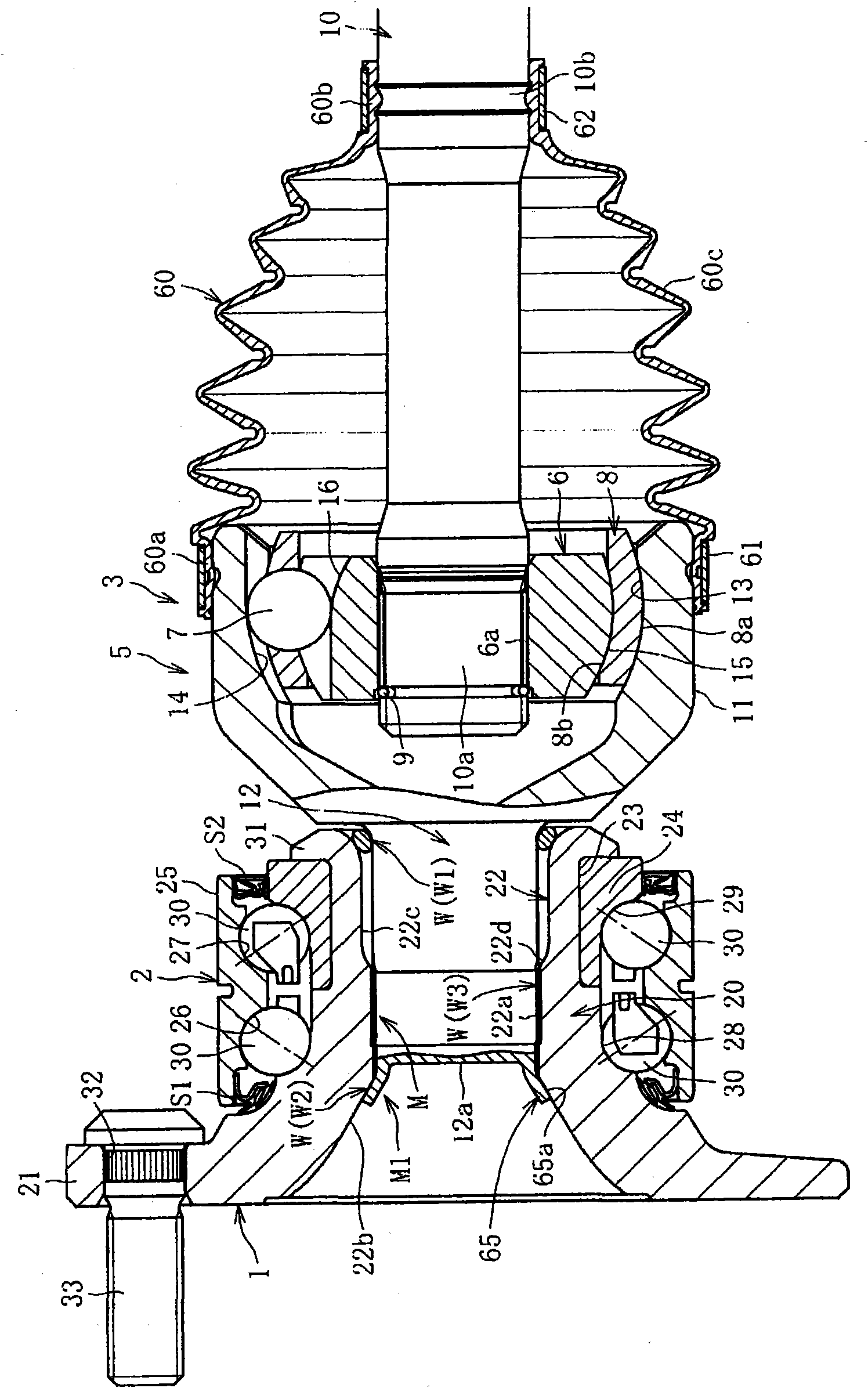

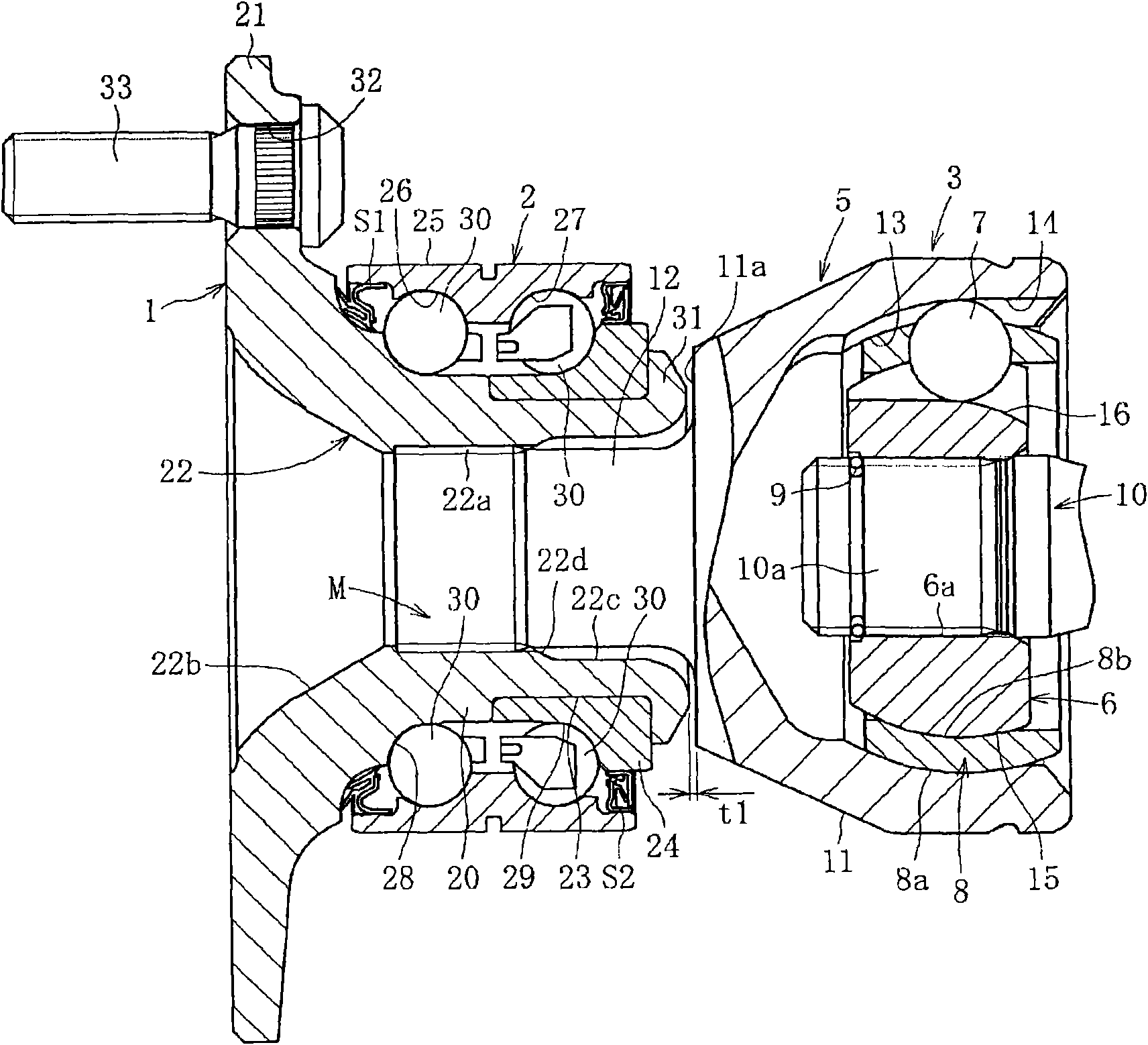

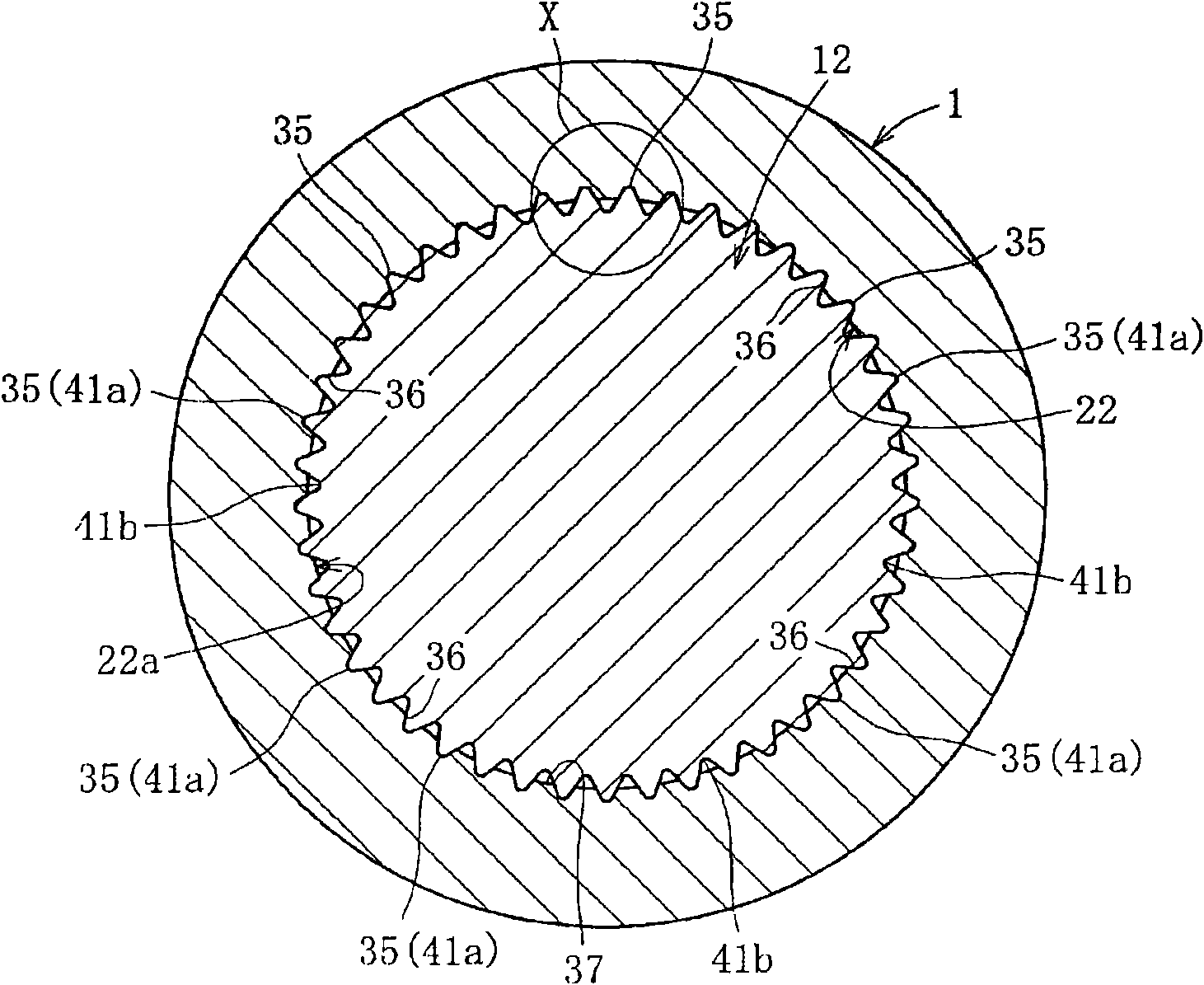

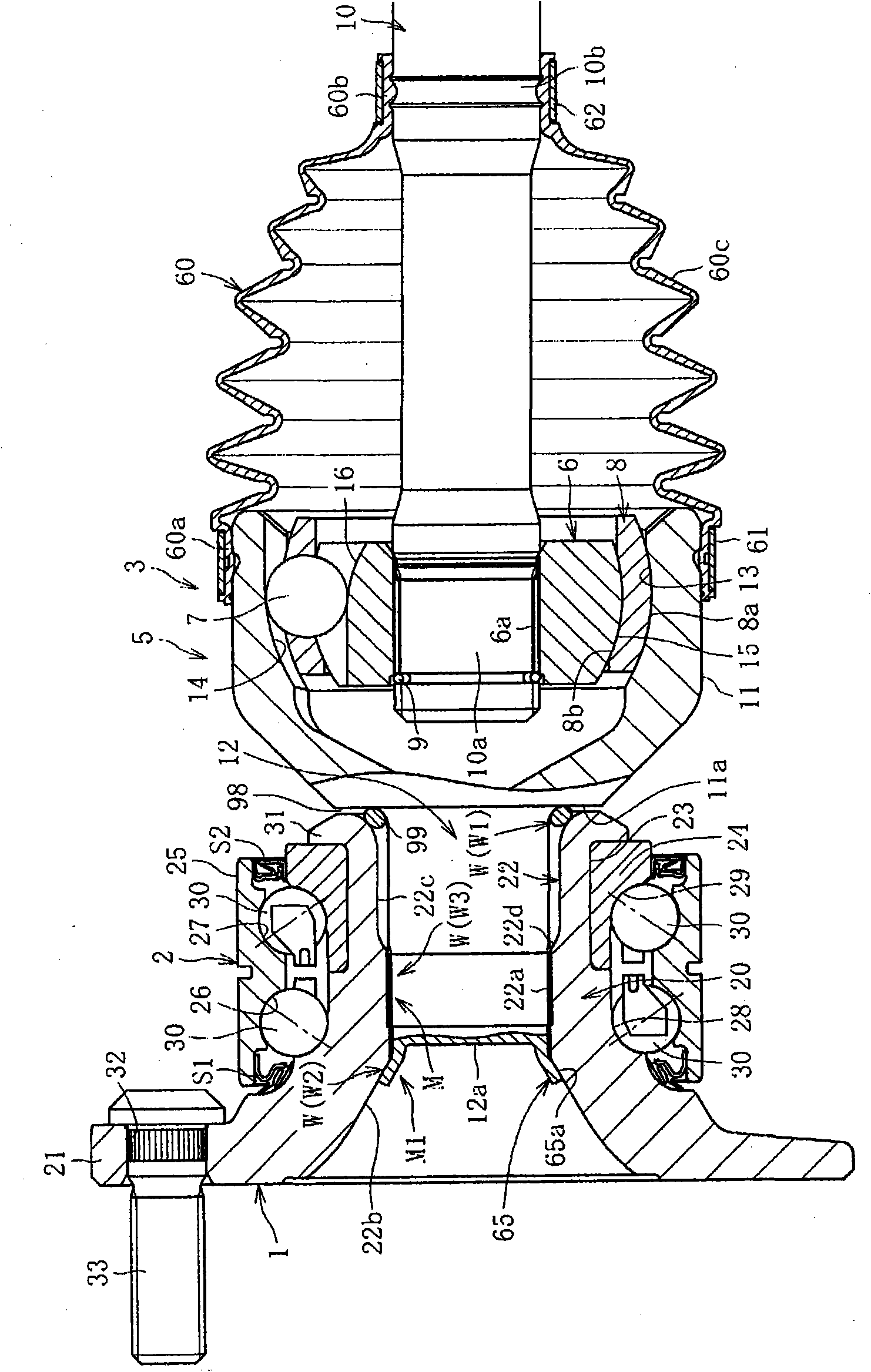

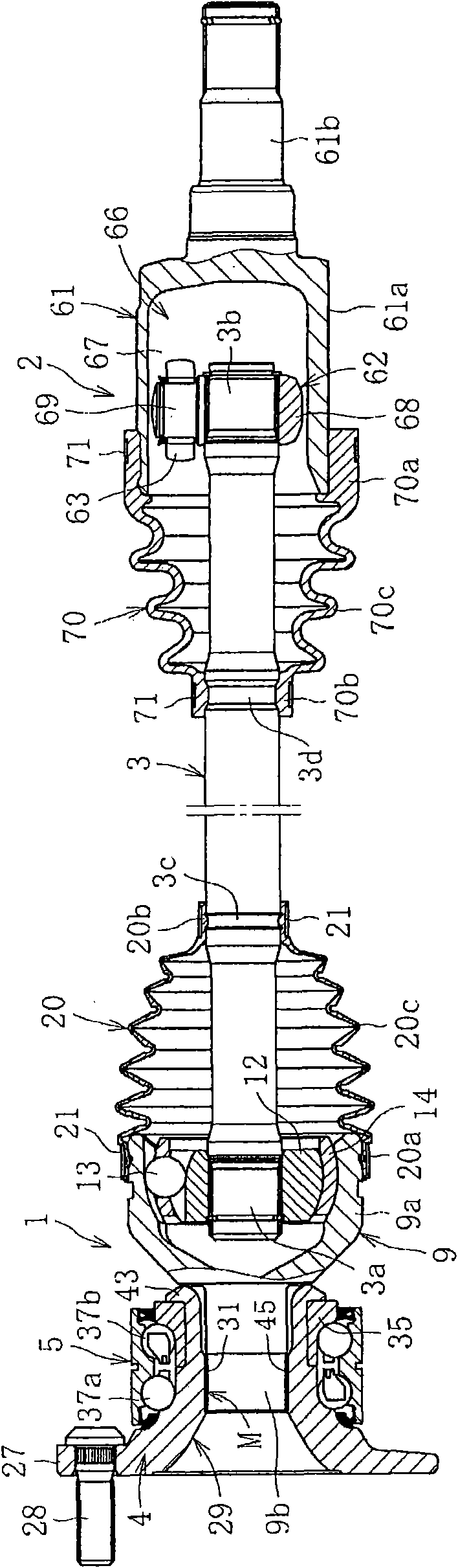

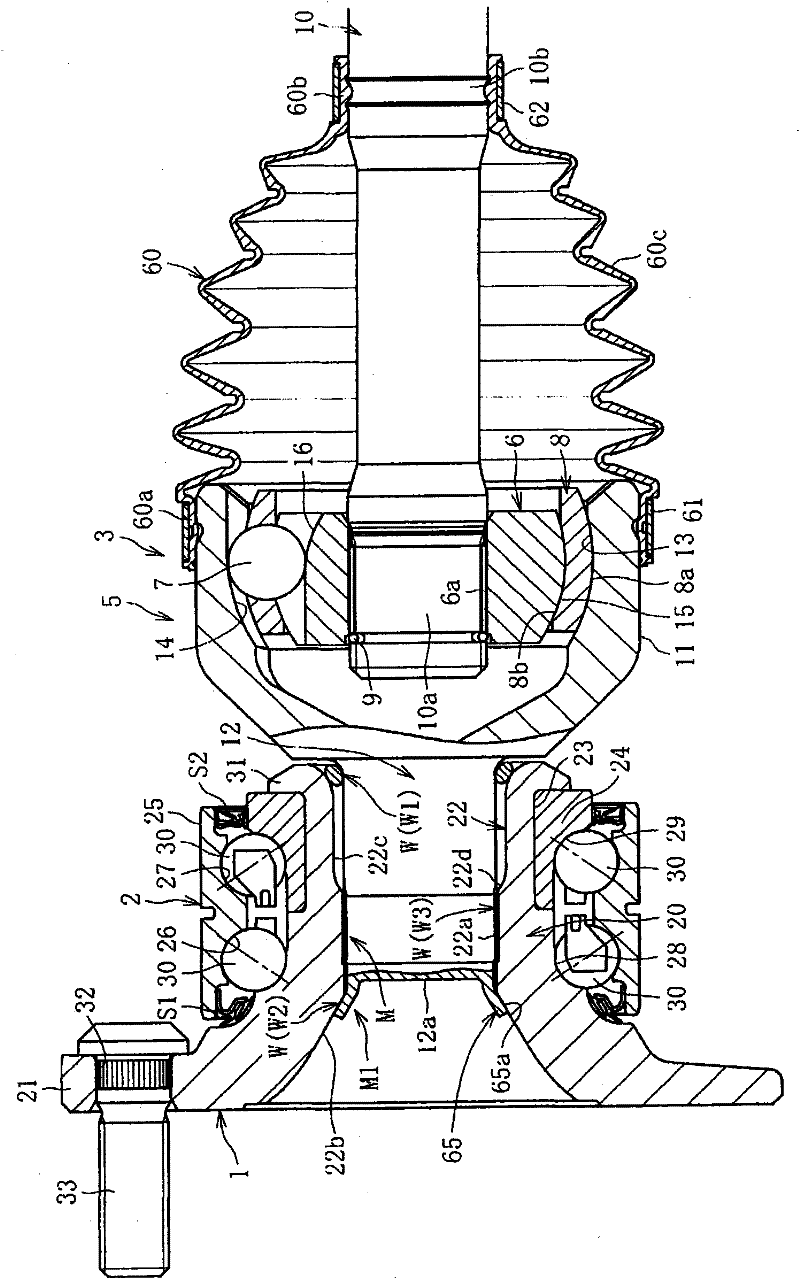

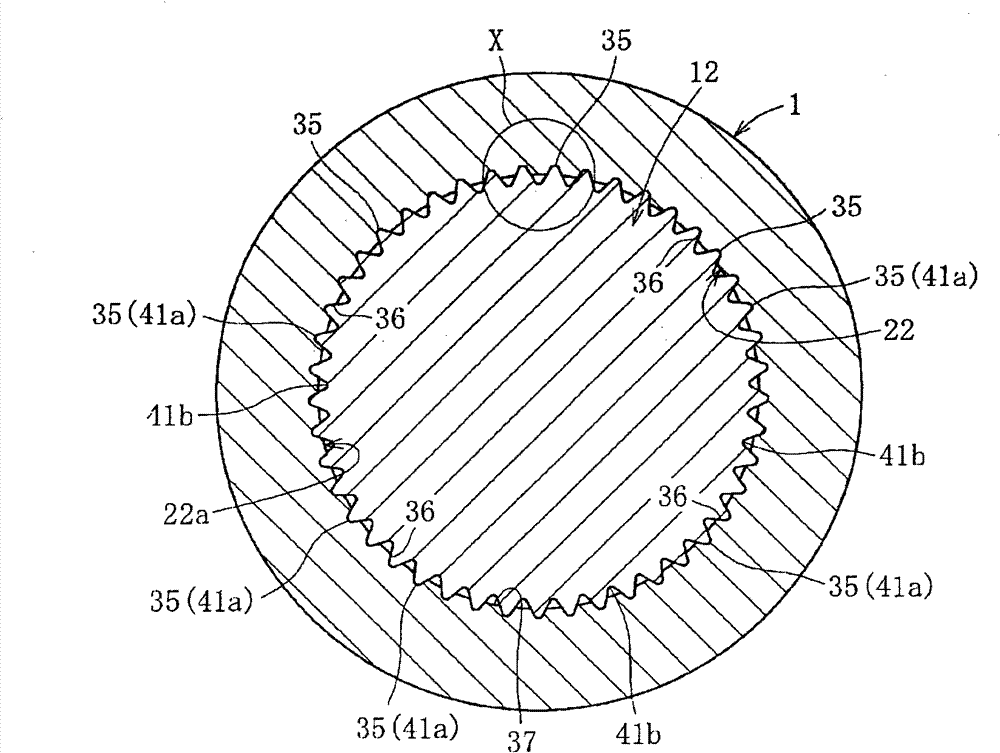

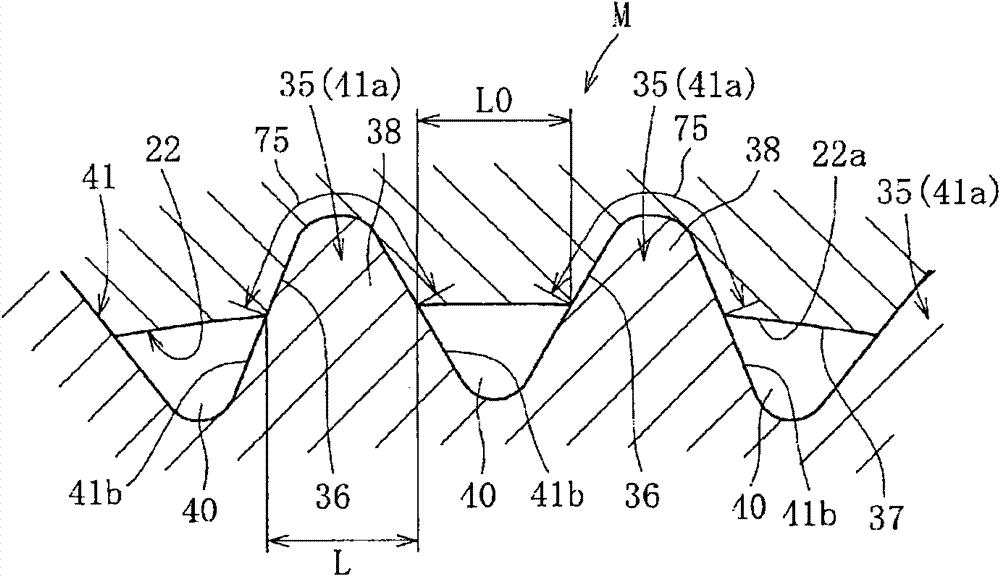

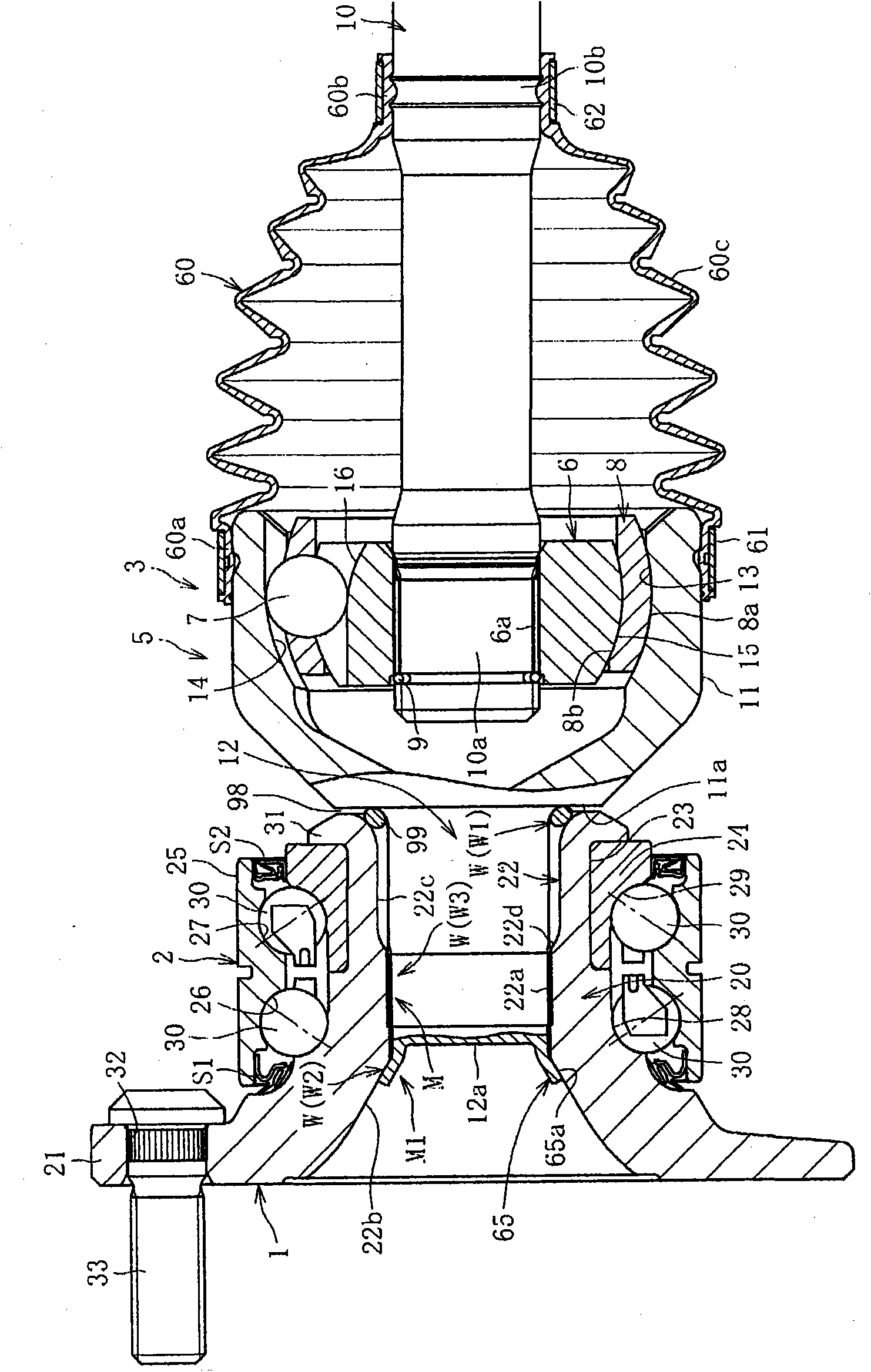

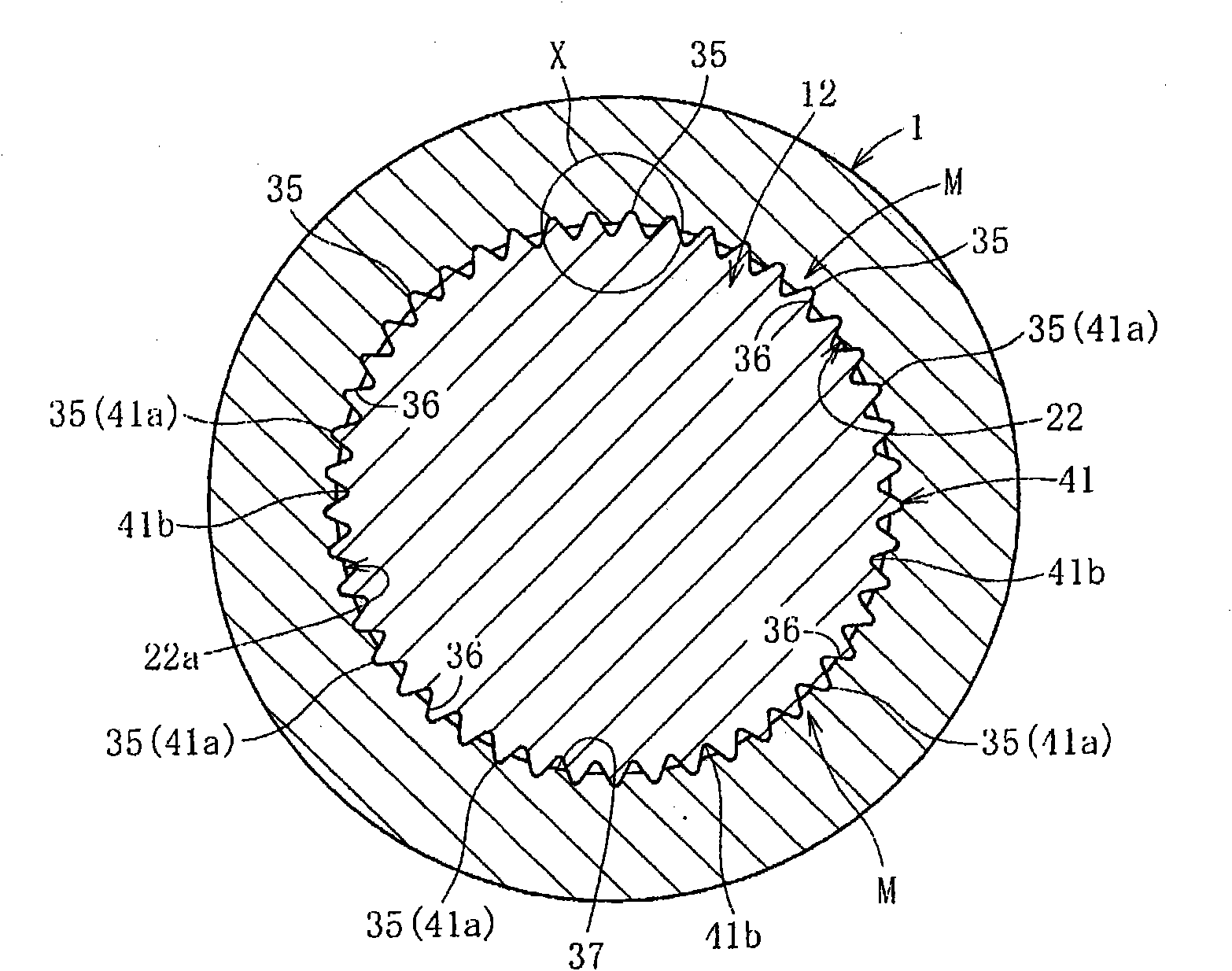

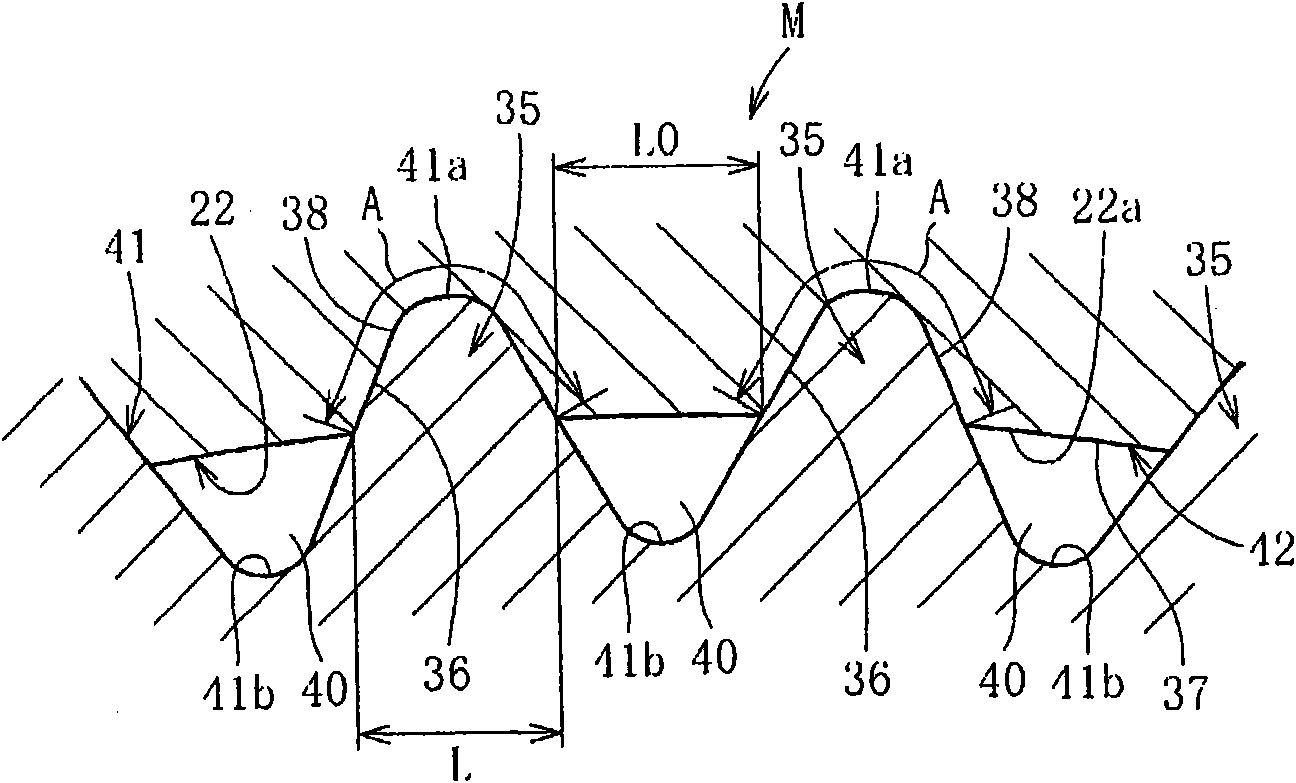

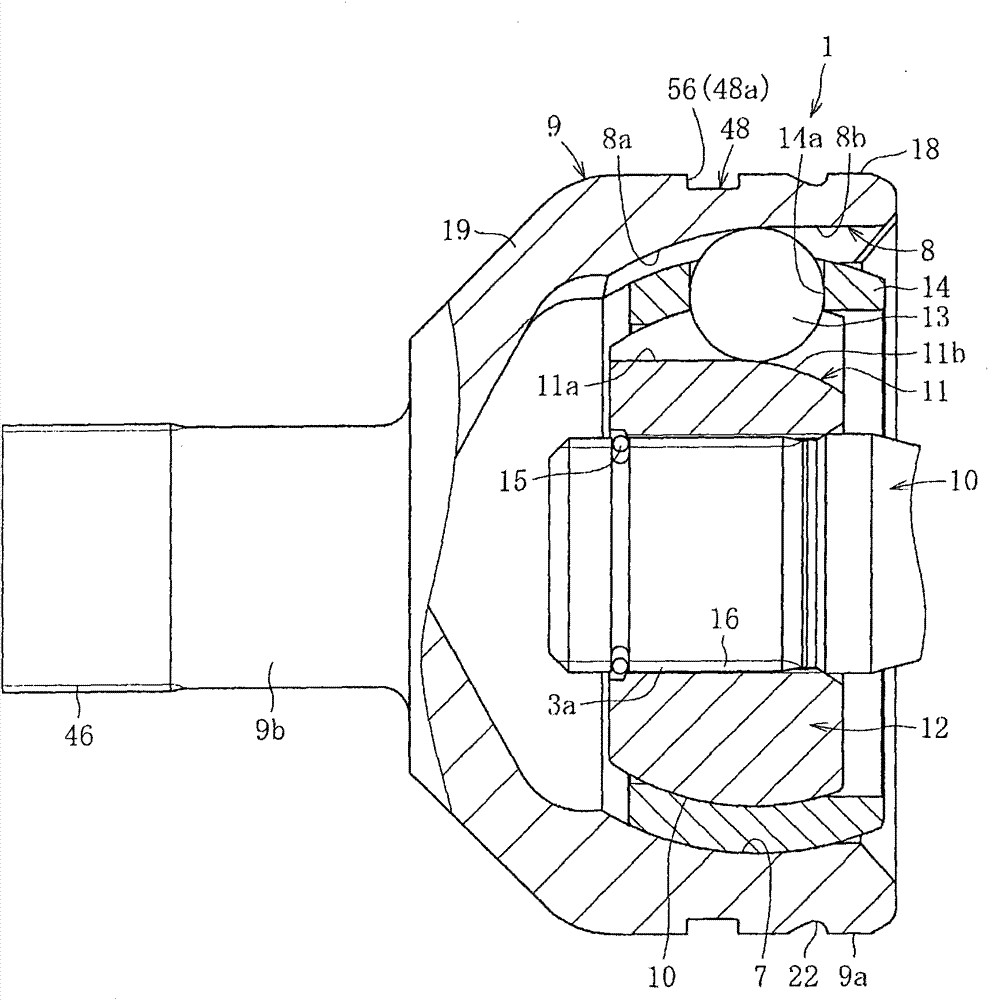

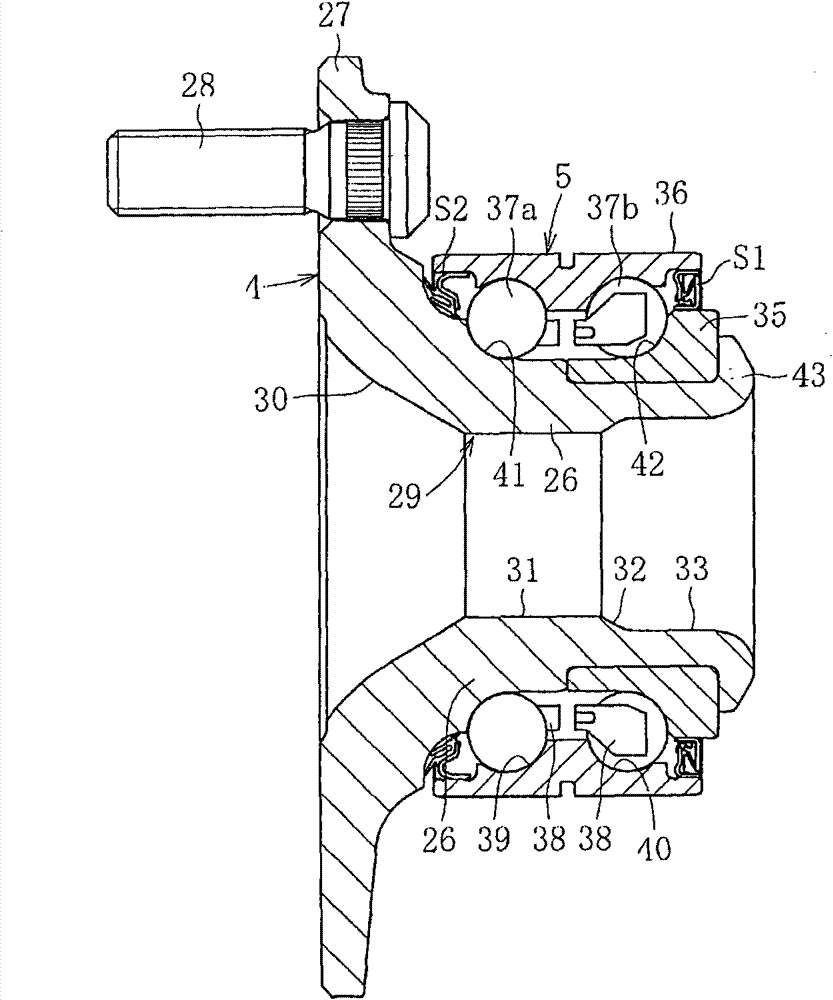

Bearing device for wheel

InactiveCN101641225ADoes not generate abnormal noiseHigh strengthRolling contact bearingsAxle unitsKnuckleEngineering

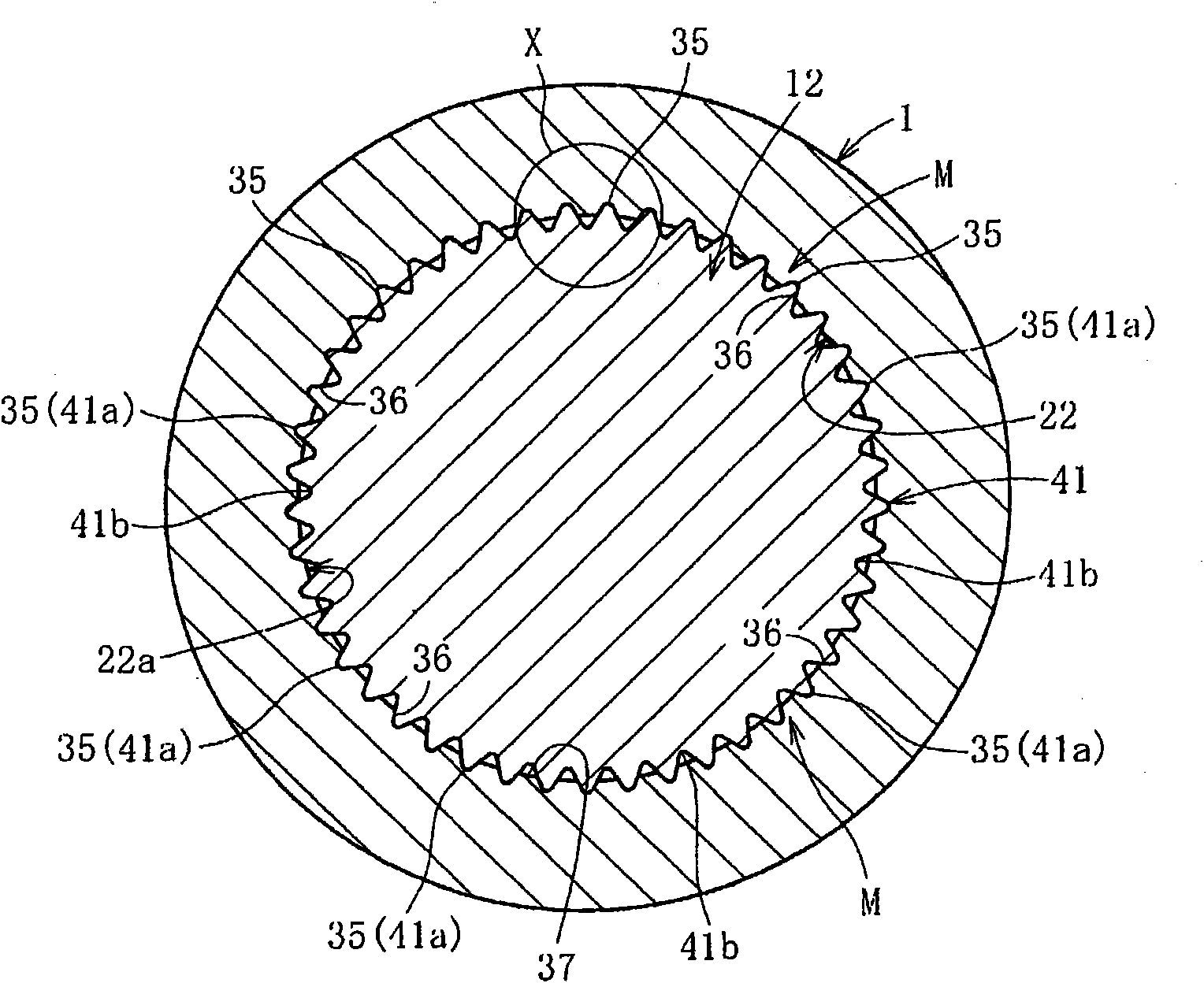

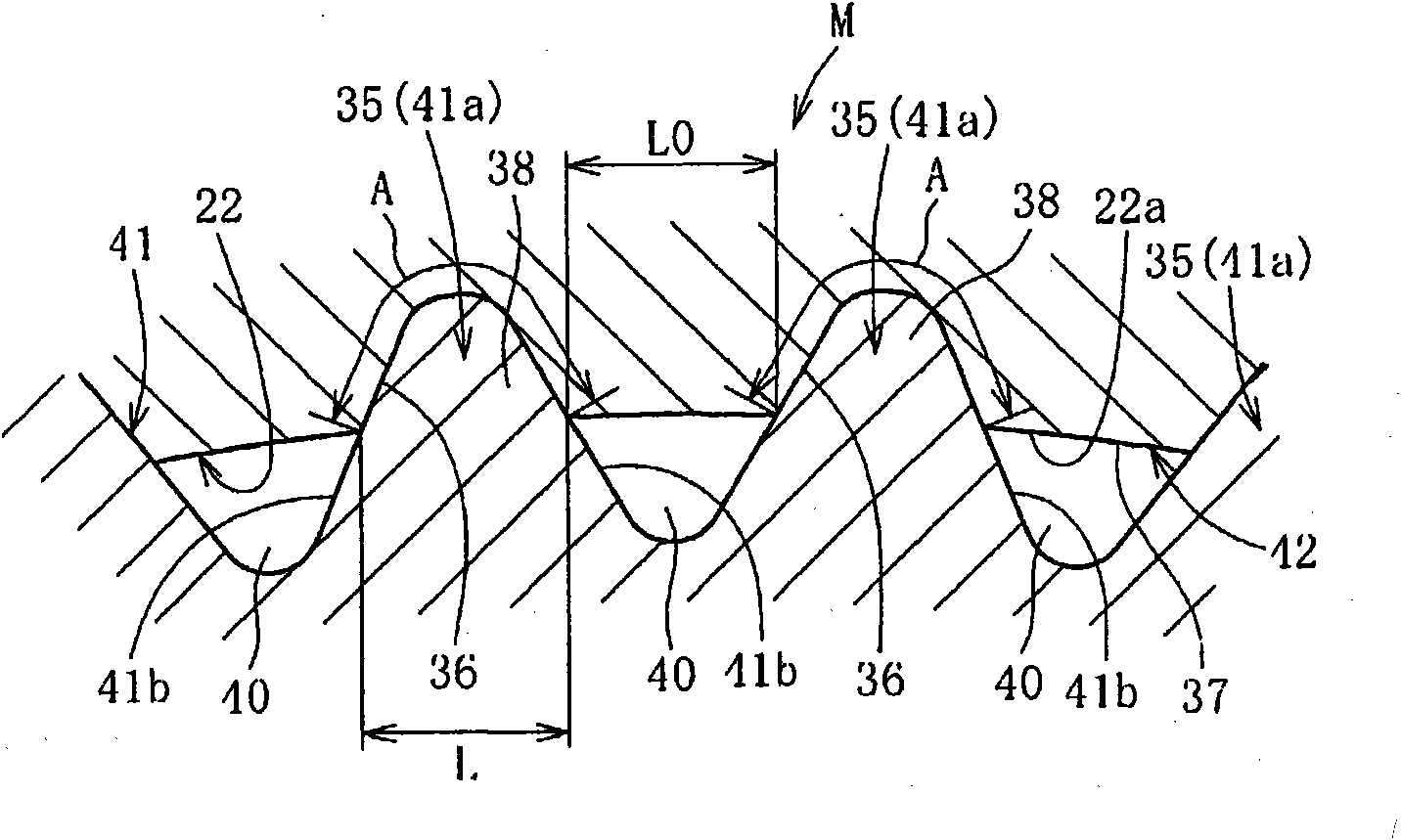

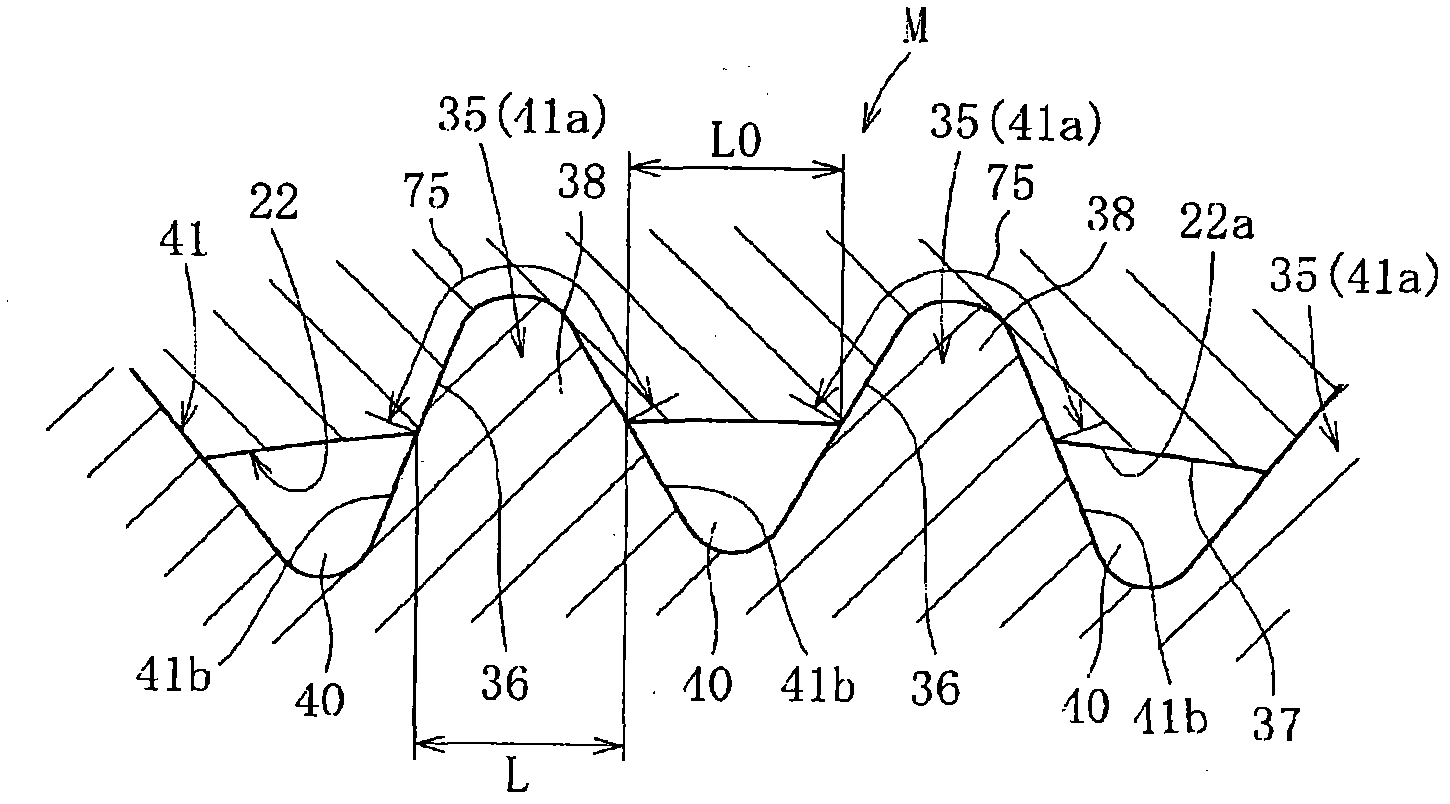

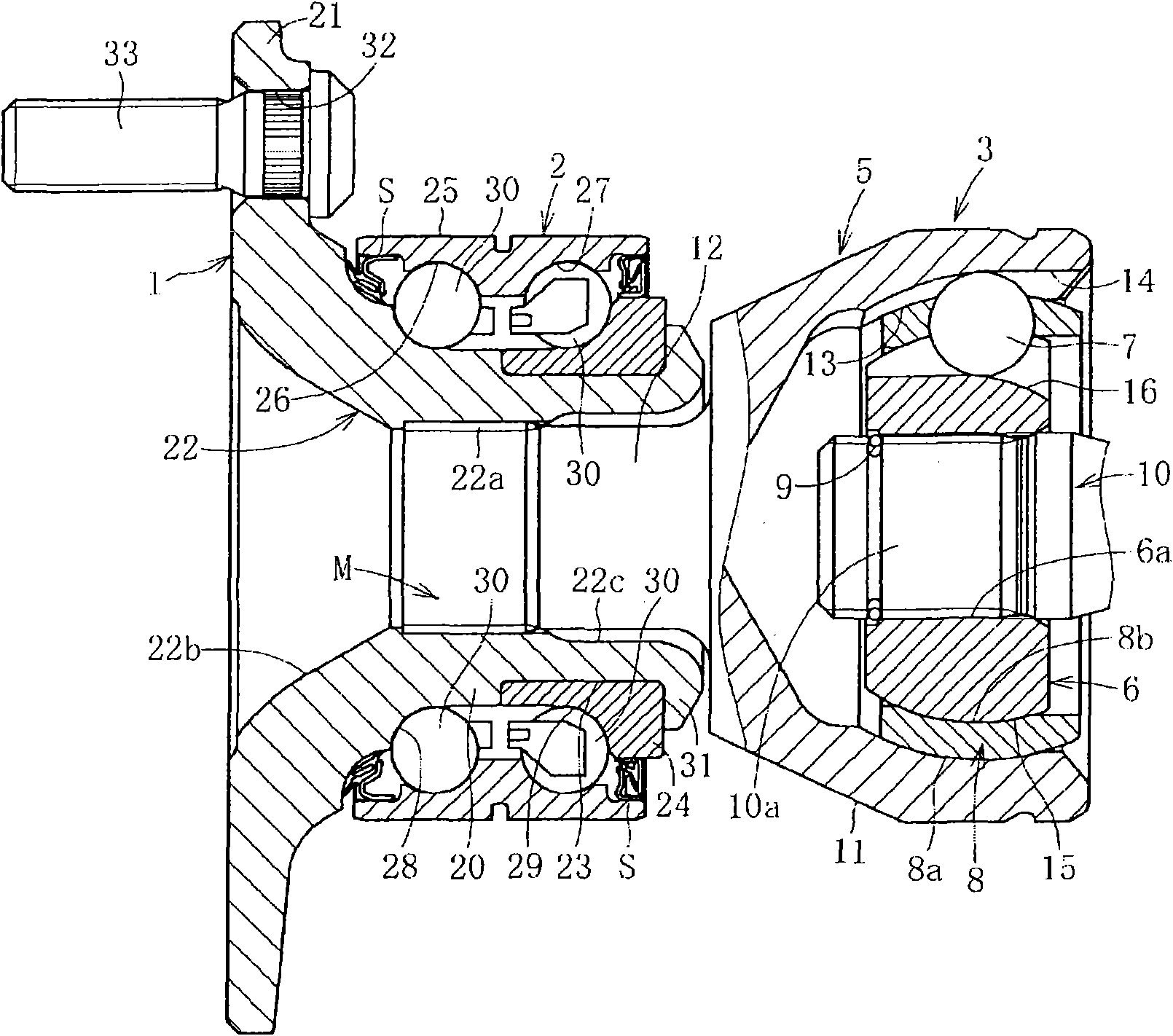

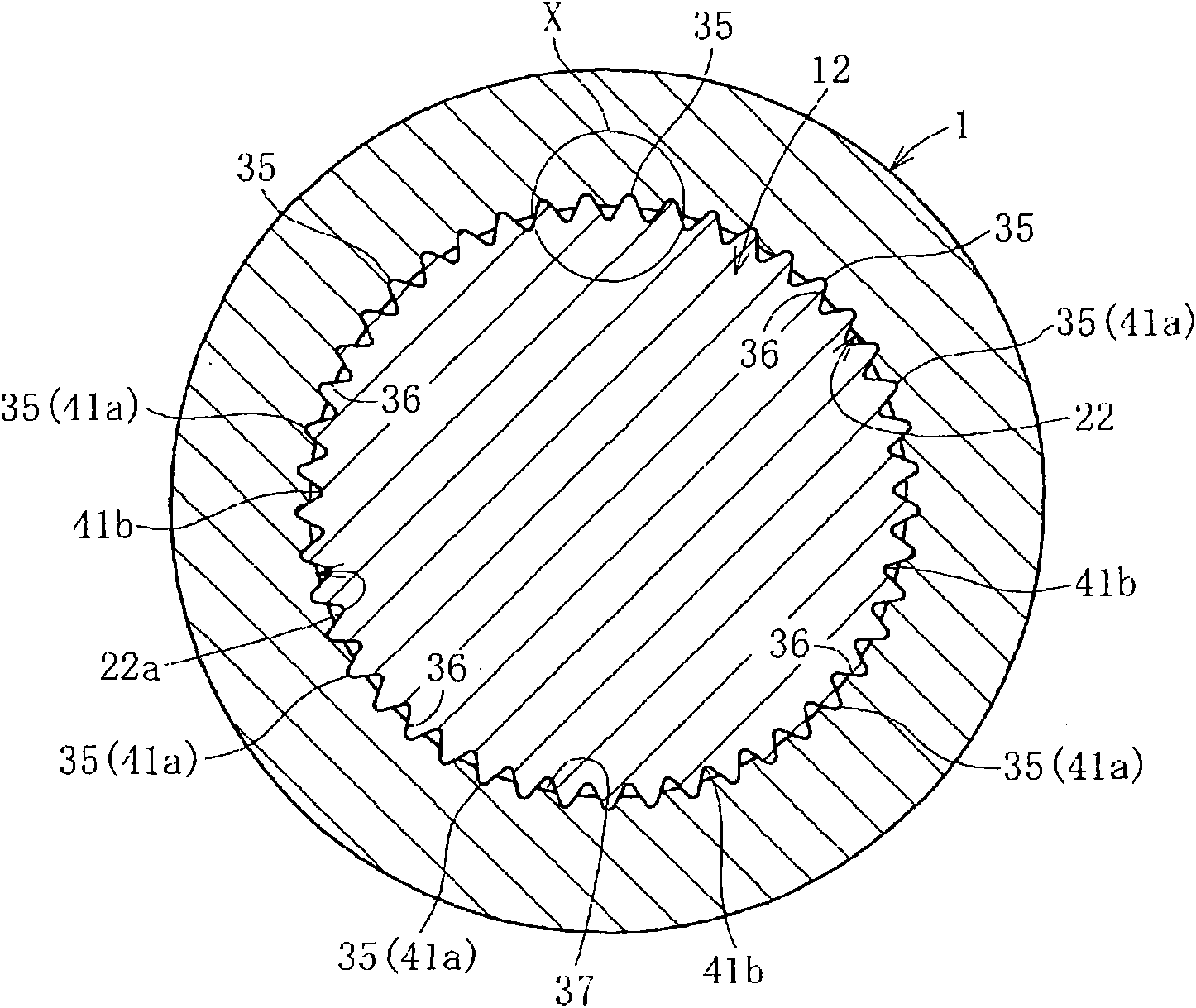

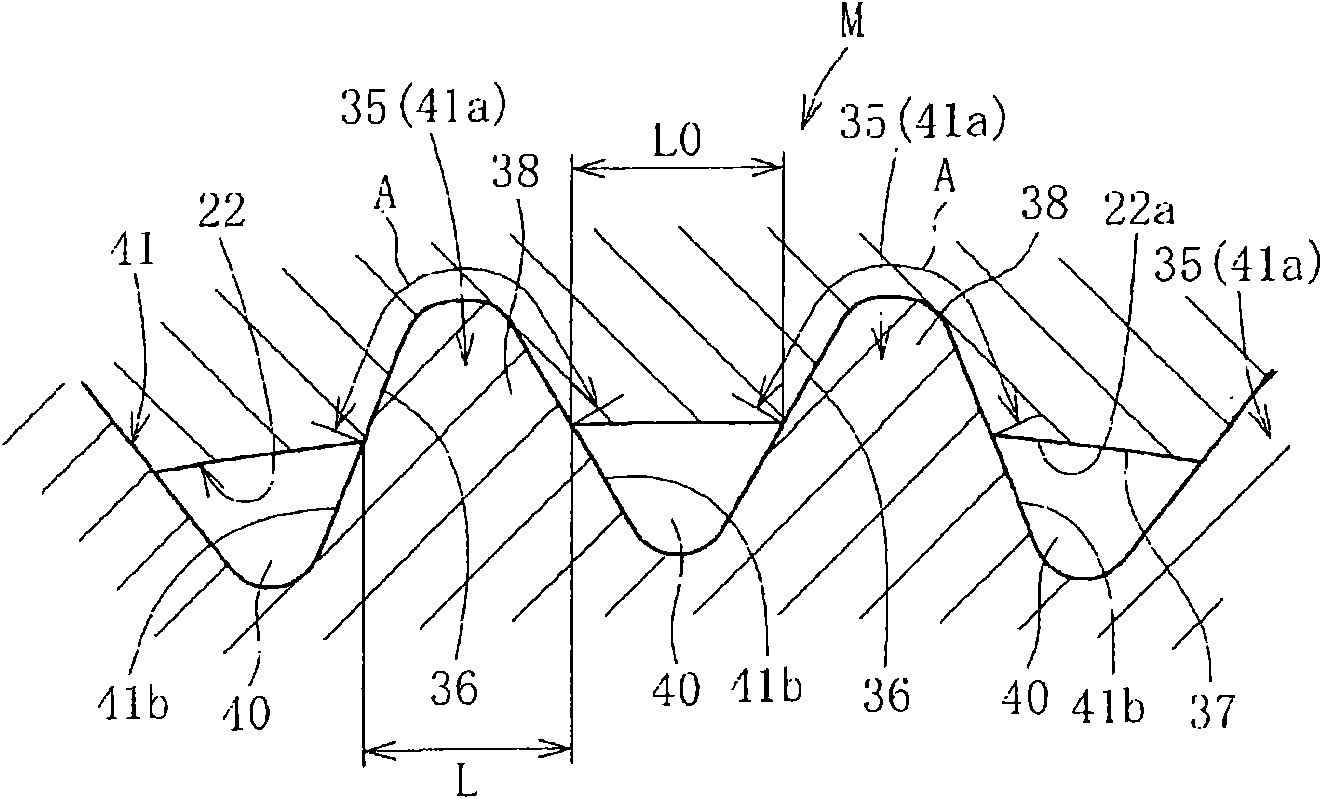

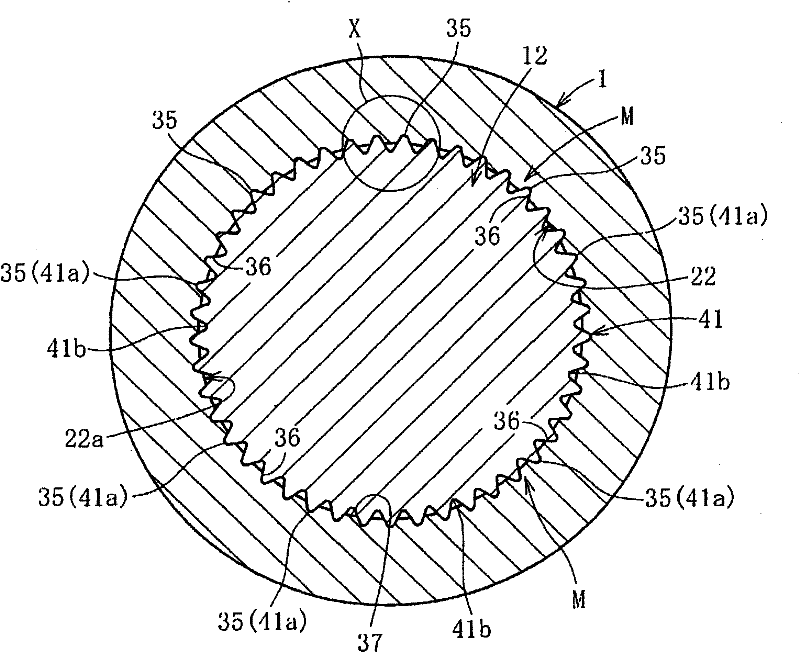

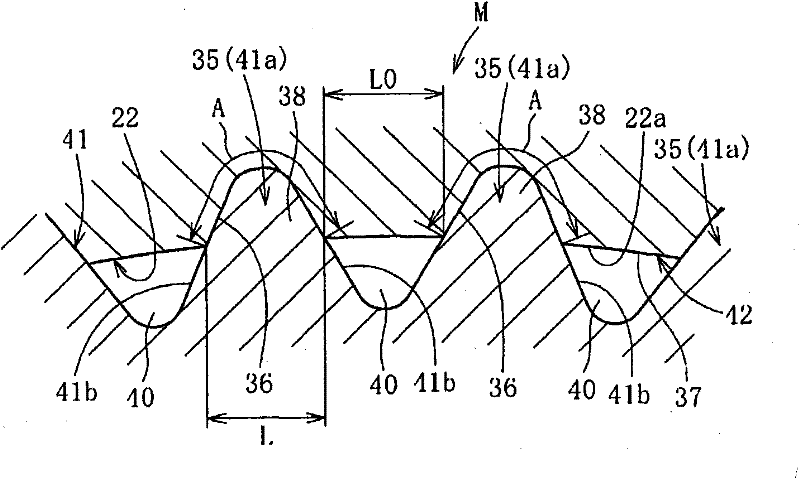

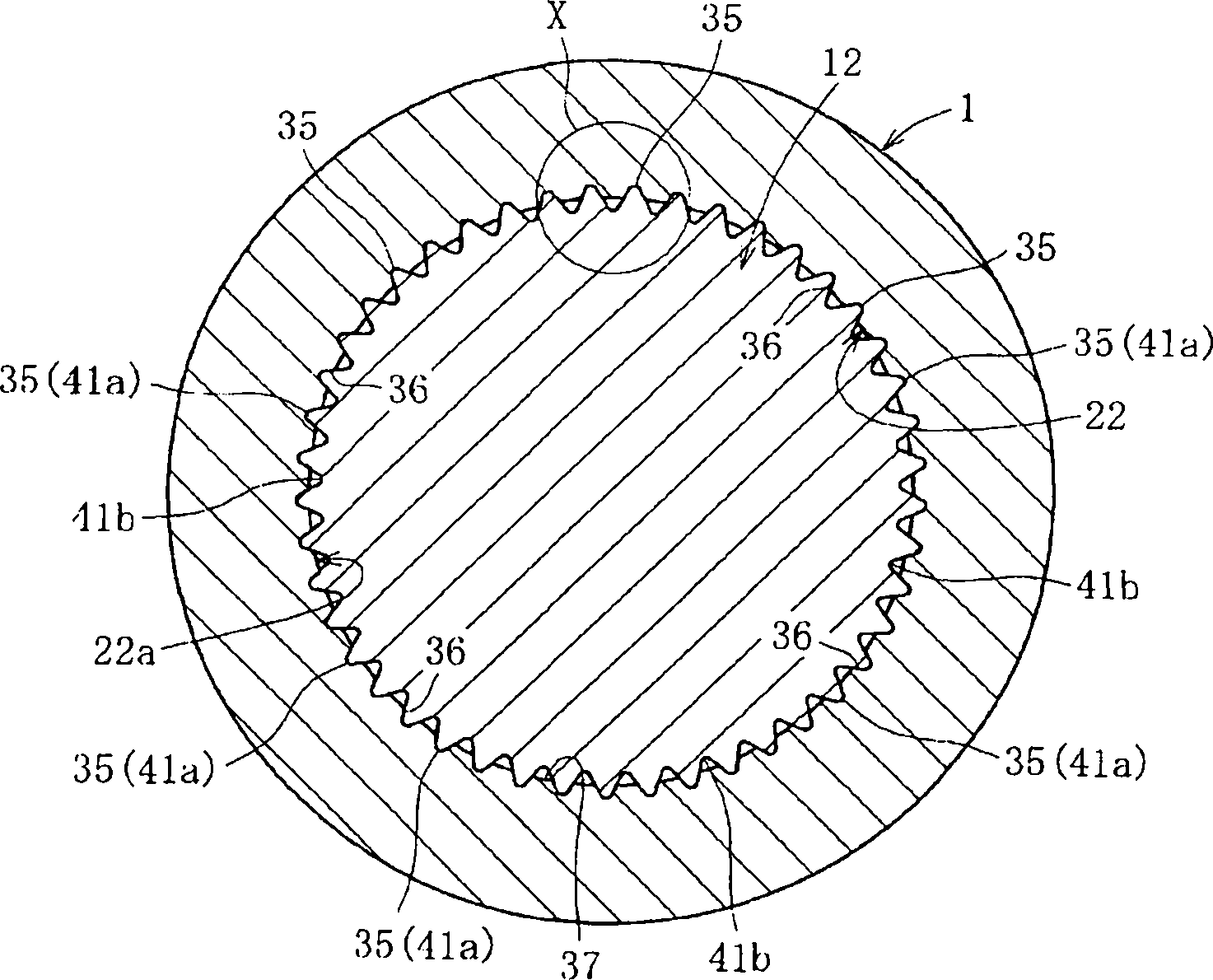

A bearing device for a wheel, in which circumferential play is suppressed, which facilitates connection between a hub ring and an outer coupling member, in which a reduction in NVH characteristics due to play at a joint between the hub ring and the constant velocity universal joint and by play between a bearing outer member and a knuckle is prevented, and which performs highly accurate transmission of rotational torque. The bearing device has a groove-ridge fitting structure (M) by which the hub ring (1) and a shaft section (12) of the outer coupling member of the constant velocity universal joint (3) are integrated together, and the shaft section (12) is fitted in a hole (22) of the hub ring (1). In the groove-ridge fitting structure (M), ridges (35) on the outer diameter surface of the shaft section (12) and grooves (36) in the inner diameter surface (37) of the hub ring (1) are fitted to each other in a fitting contact portion (38), and the ridges (35) and the grooves (36) are in intimate contact with each other in the entire fitting contact portion (38).

Owner:NTN CORP

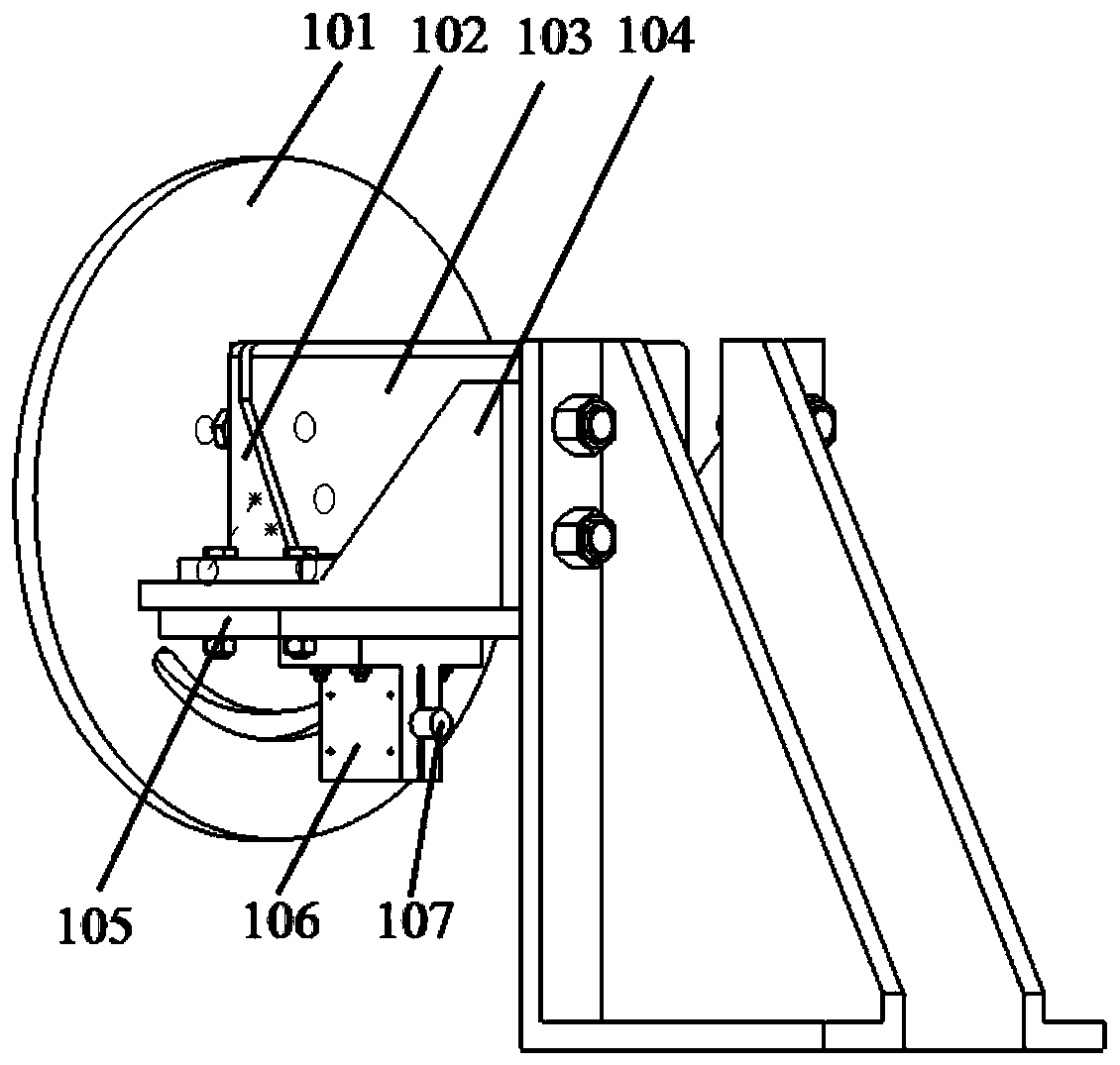

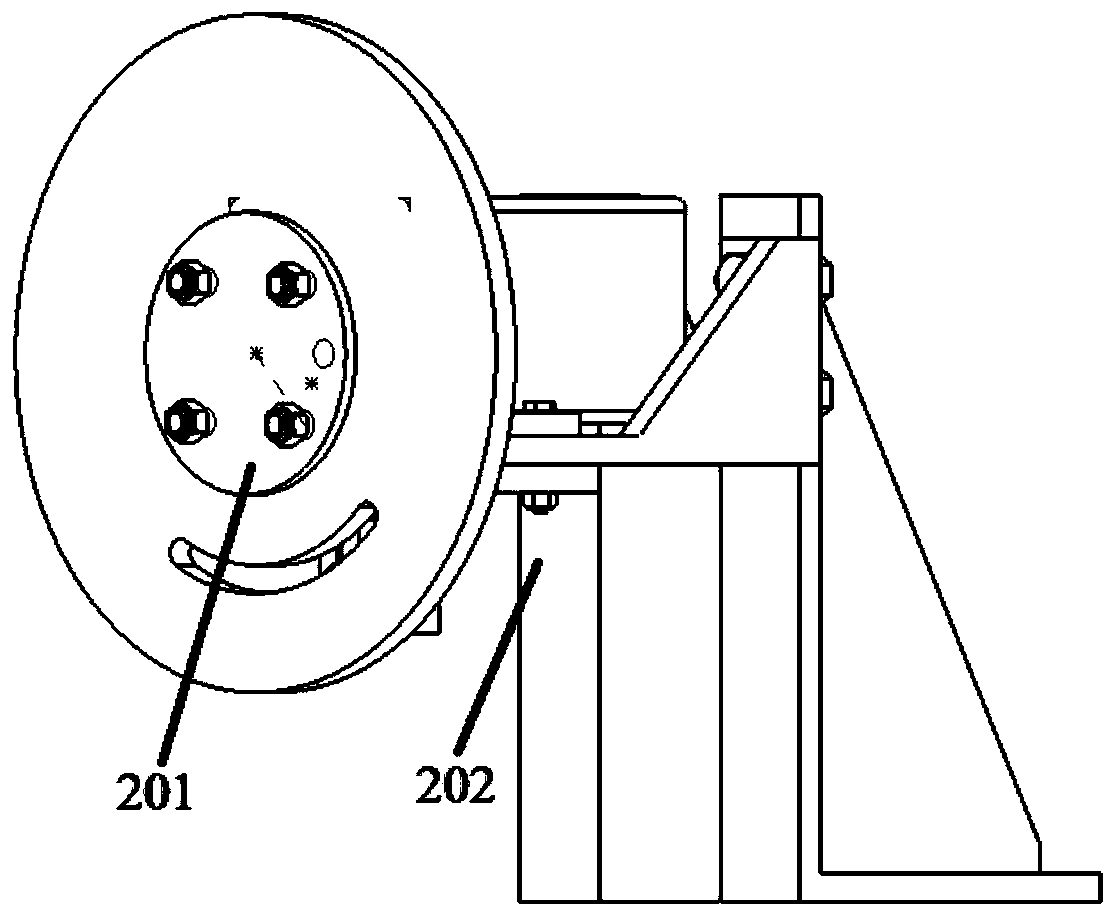

Test device and method for researching friction characteristics between tire and actual pavement

PendingCN109612929AExtended service lifeEliminate the influence of other additional loads such as centrifugal forceUsing mechanical meansVehicle tyre testingWear patternRoad surface

The invention discloses a test device and method for researching friction characteristics between a tire and an actual pavement, and belongs to the technical field of detecting equipment. Actual working conditions of the tire with load running on different pavements are well simulated through mechanical structures such as a loading sleeve, a loading sleeve base, a rotary arm and a rack, the test device and method for researching friction characteristics between the tire and the actual pavement can be used for testing a friction factor between the tire and the pavement and researching wear pattern between the tire and the pavement, compression amount of a loading spring can be adjusted through a loading screw according to requirements, and thus a test load is adjusted; meanwhile tire running speed is adjusted through a transmission system; changing is conducted on a slip rotary rate or a slip shift rate between the tire and a pavement through adjusting a connected relation between a tested wheel and an auxiliary wheel, multiple kinds of running conditions of the tire on the pavement are simulated, data such as the load, a rotate speed and a torque are detected in real time through asensor, and thus the friction factor between the tested tire and the tested pavement is obtained by formula calculation.

Owner:西安凯德液压机电有限责任公司

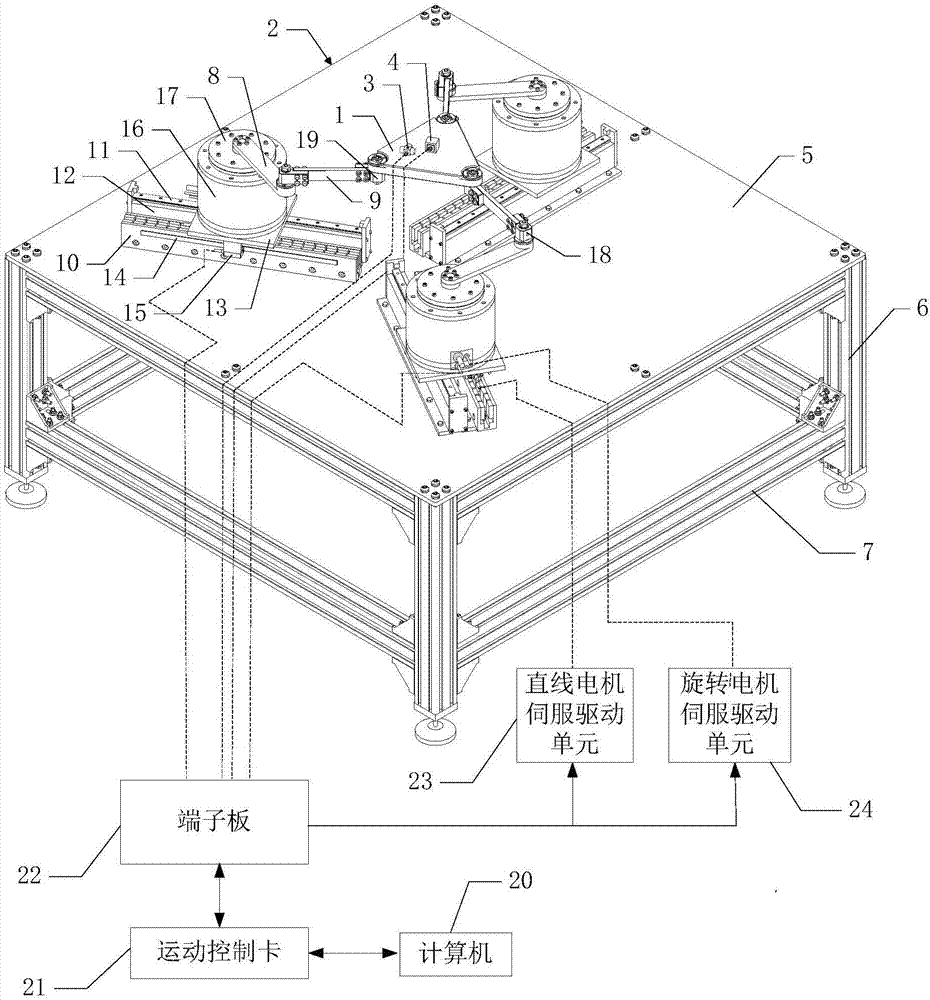

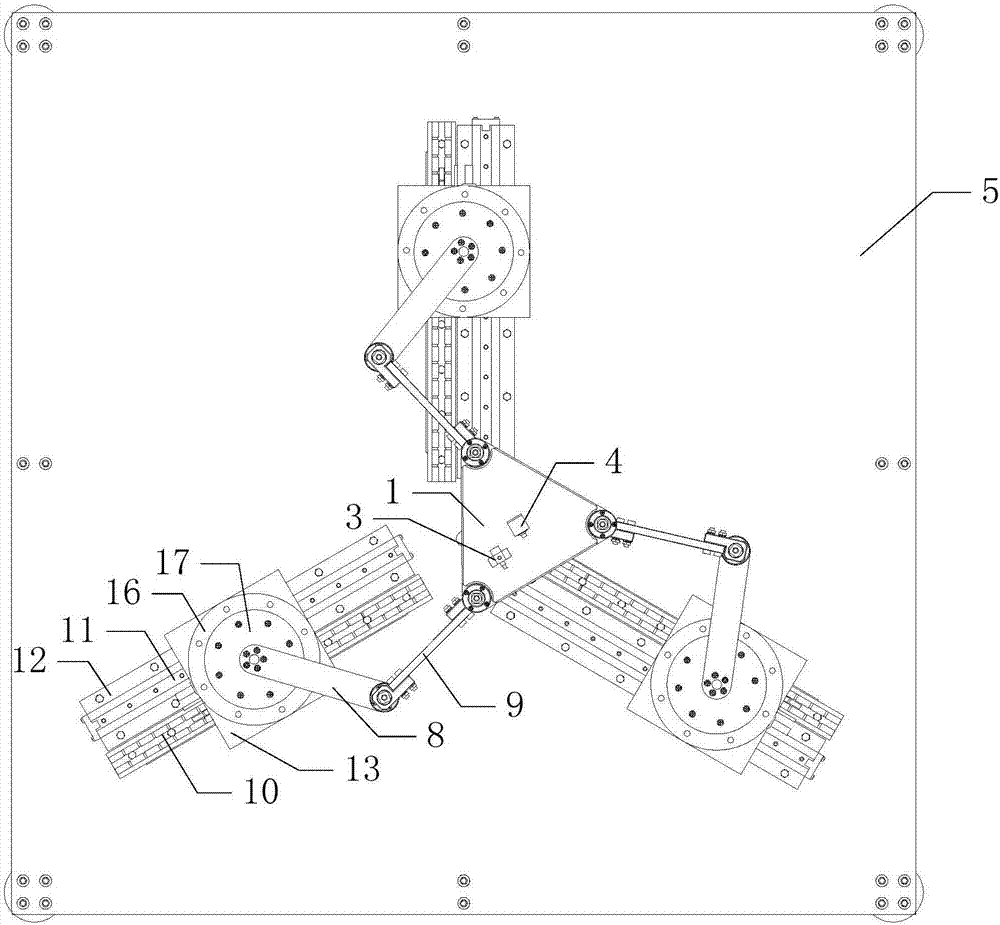

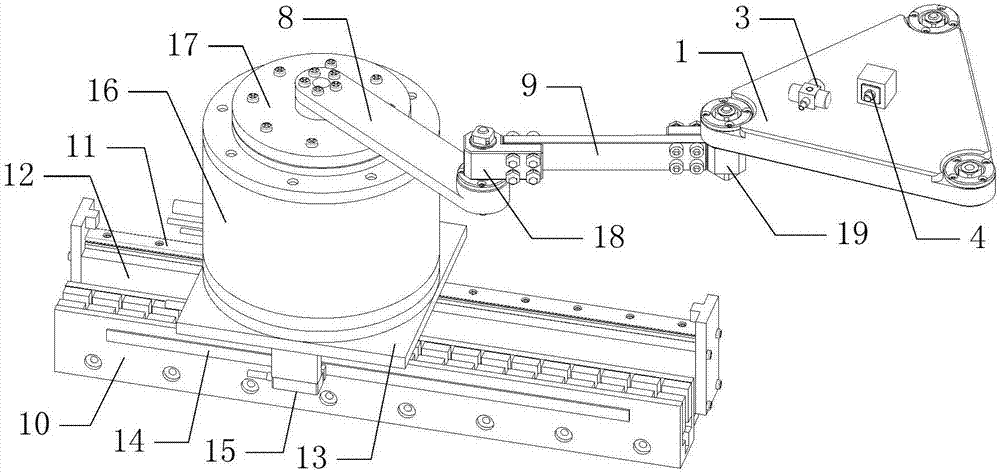

Direct-driven redundant planar parallel mechanism control device and redundant planar parallel mechanism control method

PendingCN107139193AEasy to controlReduce noiseProgramme-controlled manipulatorControl engineeringElectric machinery

The invention discloses a direct-driven redundant planar parallel mechanism control device and a redundant planar parallel mechanism control method. The device comprises a parallel mechanism body and a control unit. The parallel mechanism body comprises a movable platform and three parallel branches. The movable platform is in a shape of equilateral triangle and provided with an angular acceleration sensor and an acceleration sensor. Each parallel branch comprises a linear motor module with a displacement sensor, a rotary motor module with an encoder, a rigid active bar and a rigid passive bar. The control unit is connected with the angular acceleration sensor, the acceleration sensor, the linear motor module and the rotary motor module. Through hybrid driving of linear motors and rotary motors, the working space of the parallel mechanism is enlarged, and movement parameters of the movable platform are measured by means of the multiple sensors to serve as feedback signals, the movement control accuracy of the parallel mechanism reaches the high level.

Owner:SOUTH CHINA UNIV OF TECH

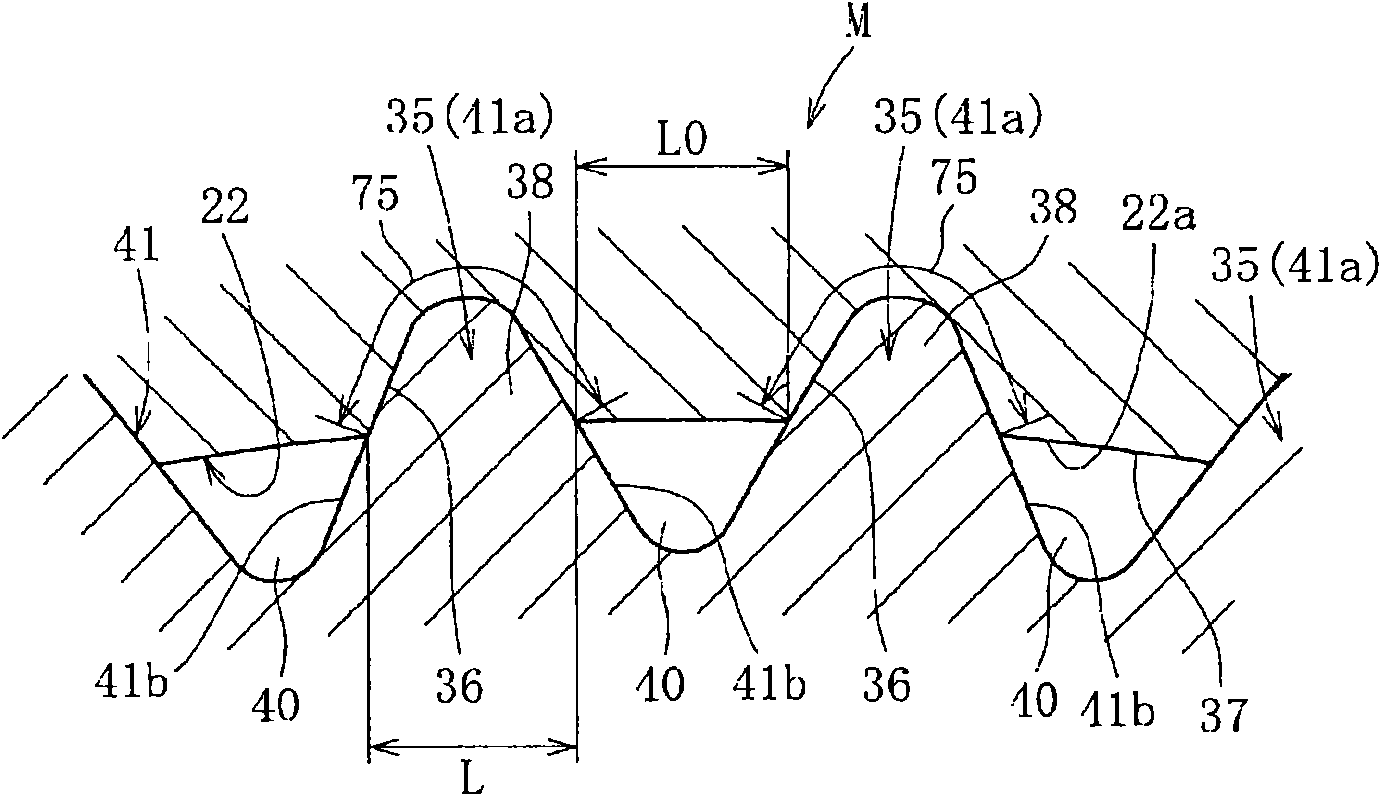

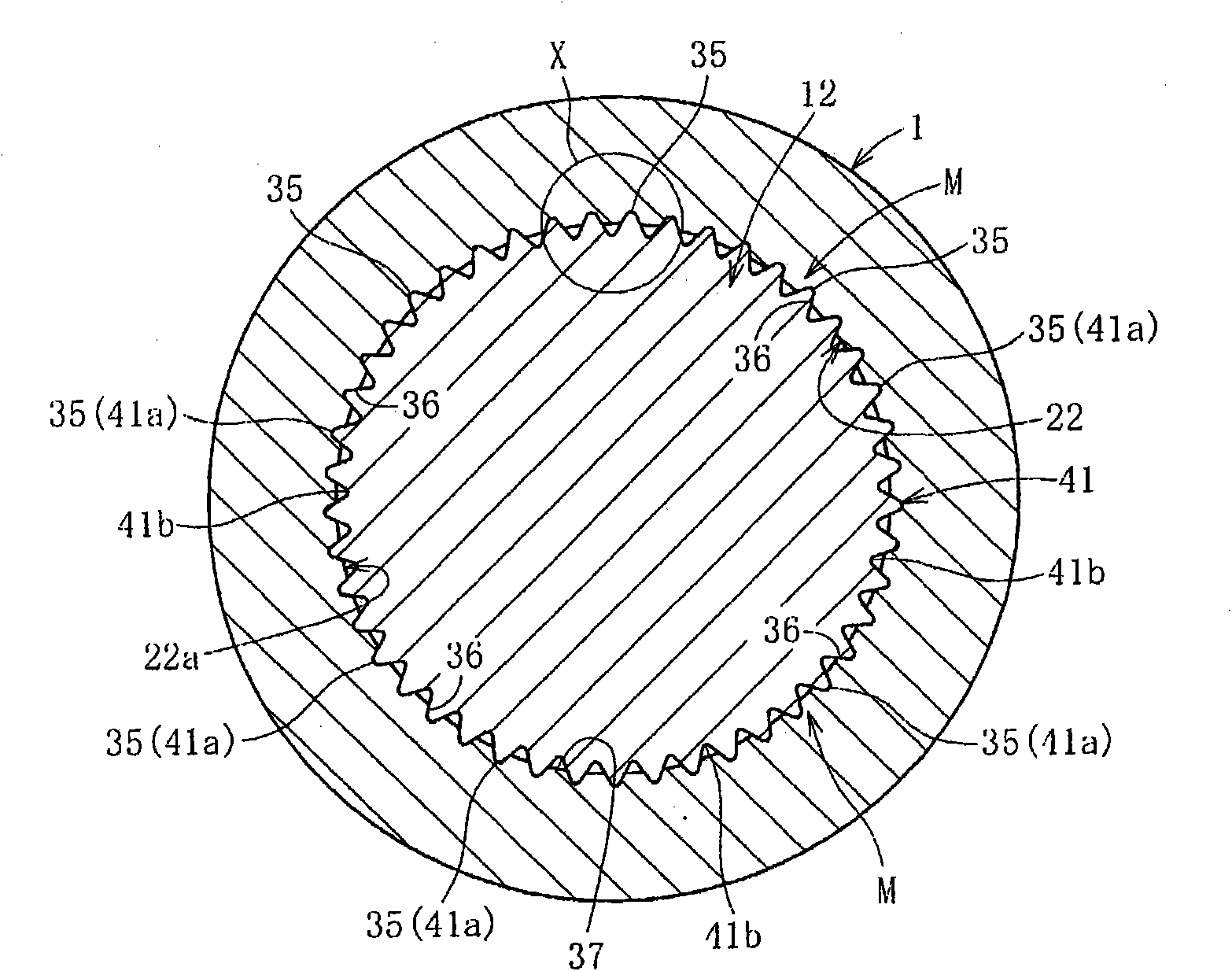

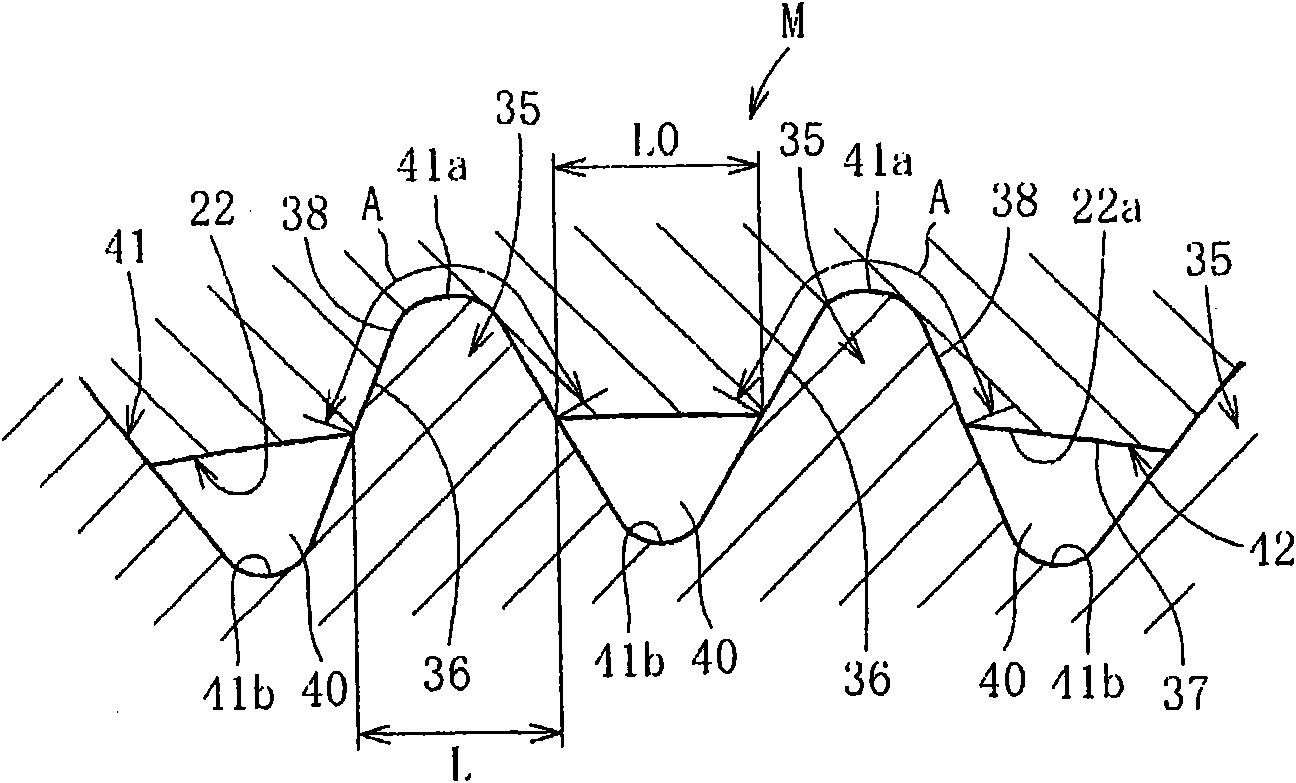

Bearing device for wheel

InactiveCN102152711AStable deliveryHigh strengthYielding couplingRolling contact bearingsUniversal jointTorque transmission

Provided is a bearing device for a wheel that can realize prevention of a backlash in a circumferential direction and is excellent in workability of connection of a hub wheel and an outer joint member of a constant velocity universal joint. Further, provided is a bearing device for a wheel that can prevent deterioration in NVH characteristics, which is caused by the backlash occurring in a joint section between the hub wheel and the constant velocity universal joint or between an outer member and a knuckle, and can perform rotation torque transmission with high accuracy. The bearing device includes a recess-projection fitting structure (M) in which the hub wheel (1) and a shaft section (12), which is fitted in a hole (22) of the hub wheel (1) of the outer joint member of the constant velocity universal joint (3) are unitized together. In the recess-projection fitting structure (M), entire fitting regions among projections (35) on the outer surface of the shaft section (12) of the outer joint member and recesses (36), which fit on the projections, are brought into intimate contact with each other.

Owner:NTN CORP

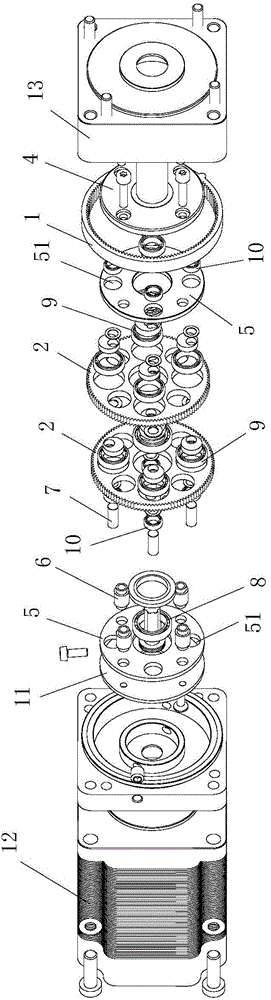

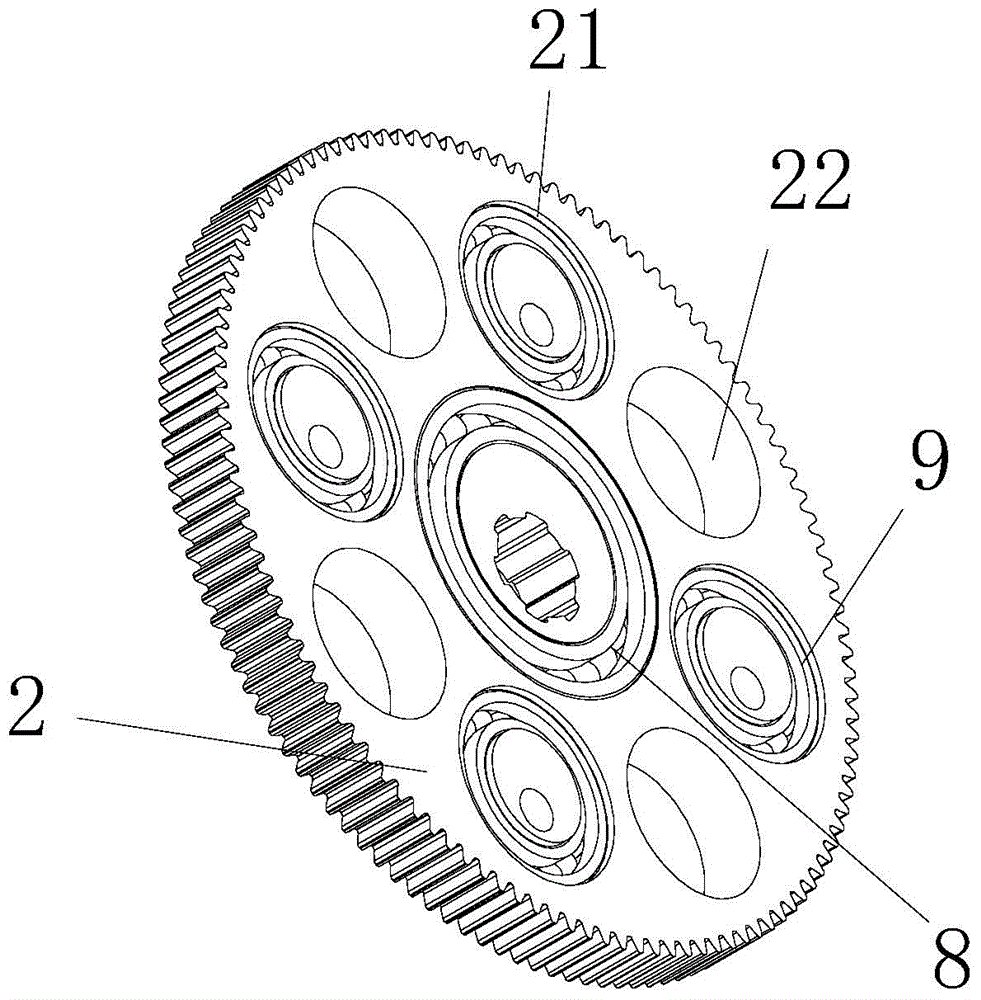

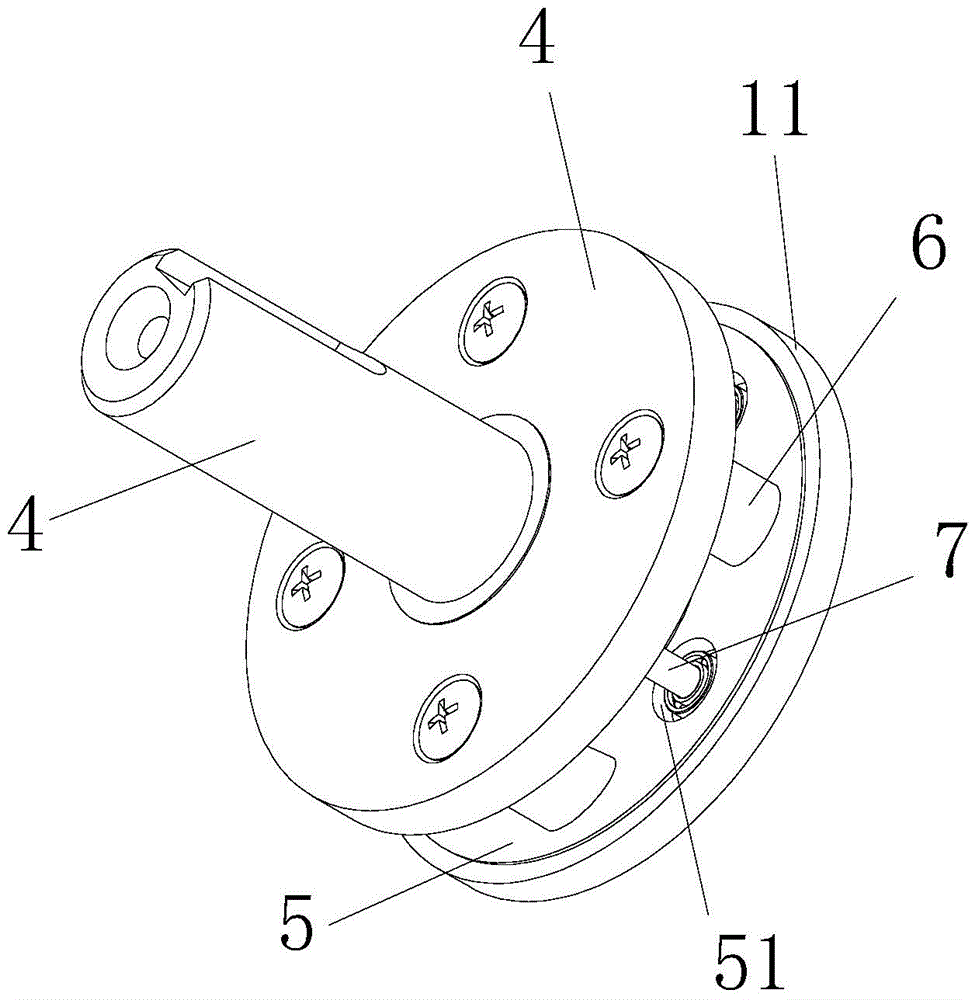

Small-tooth-difference high-precision cycloid gear speed reducer

The invention relates to a small-tooth-difference high-precision cycloid gear speed reducer which comprises an input shaft, a speed reduction mechanism and an output shaft. The speed reduction mechanism comprises a tooth ring, cycloid tooth pieces, a holder and eccentric shafts. The cycloid tooth pieces are eccentrically arranged on the input shaft through a first eccentric assembly. The holder comprises two holding end covers and connecting columns. The connecting columns are connected with and located on the holding end covers. The eccentric shafts penetrate through tooth penetrating shaft holes. A second eccentric assembly is arranged between the eccentric shafts and the tooth penetrating shaft holes of the cycloid tooth pieces. The two holding end covers are provided with cover penetrating shaft holes respectively. A third eccentric assembly is arranged between the two ends of the eccentric shafts and the cover penetrating shaft holes of the holding end covers. The cycloid gear speed reducer is small in size, all speed reduction parts can achieve close fitting, the precision of the whole speed reducer is improved, and the high transmission ratio can be achieved.

Owner:CHANGZHOU XINWEI ELECTRONICS CO LTD

Heat-dissipating system for clutch, heat-dissipating method for clutch and vehicle

InactiveCN110821982AStable pressing forceStable torque transmissionFriction clutchesCouplingsControl valvesClutch

The embodiment of the invention provides a heat-dissipating system for a clutch, a heat-dissipating method for the clutch and a vehicle and relates to the technical field of heat dissipation of clutches. The heat-dissipating system for the clutch is used for a clutch assembly provided with a fluid inlet. The heat-dissipating system for the clutch comprises a detector, a controller and a control valve assembly. The control valve assembly is connected to the fluid inlet and is used for controlling opening and closing of the fluid inlet. The controller is in communication connection to the detector and the control valve assembly. The detector is connected to a clutch pedal and is used for detecting whether the clutch pedal is pressed downward or not. When the detector detects that the clutchpedal is pressed downward, the controller controls the control valve assembly to open, so that a fluid flows to the clutch assembly through the fluid inlet. The heat-dissipating method comprises the steps of judging whether the clutch pedal is pressed downward or not; and controlling the fluid to flow through the clutch assembly when the clutch pedal is pressed downward. A purpose of active heat dissipation of the clutch assembly is achieved by means of the heat-dissipating system for the clutch, conditions such as starting shake of the vehicle and slip of the clutch are improved, the failurerate of the clutch assembly is reduced, and the user experience is enhanced.

Owner:湖南行必达网联科技有限公司

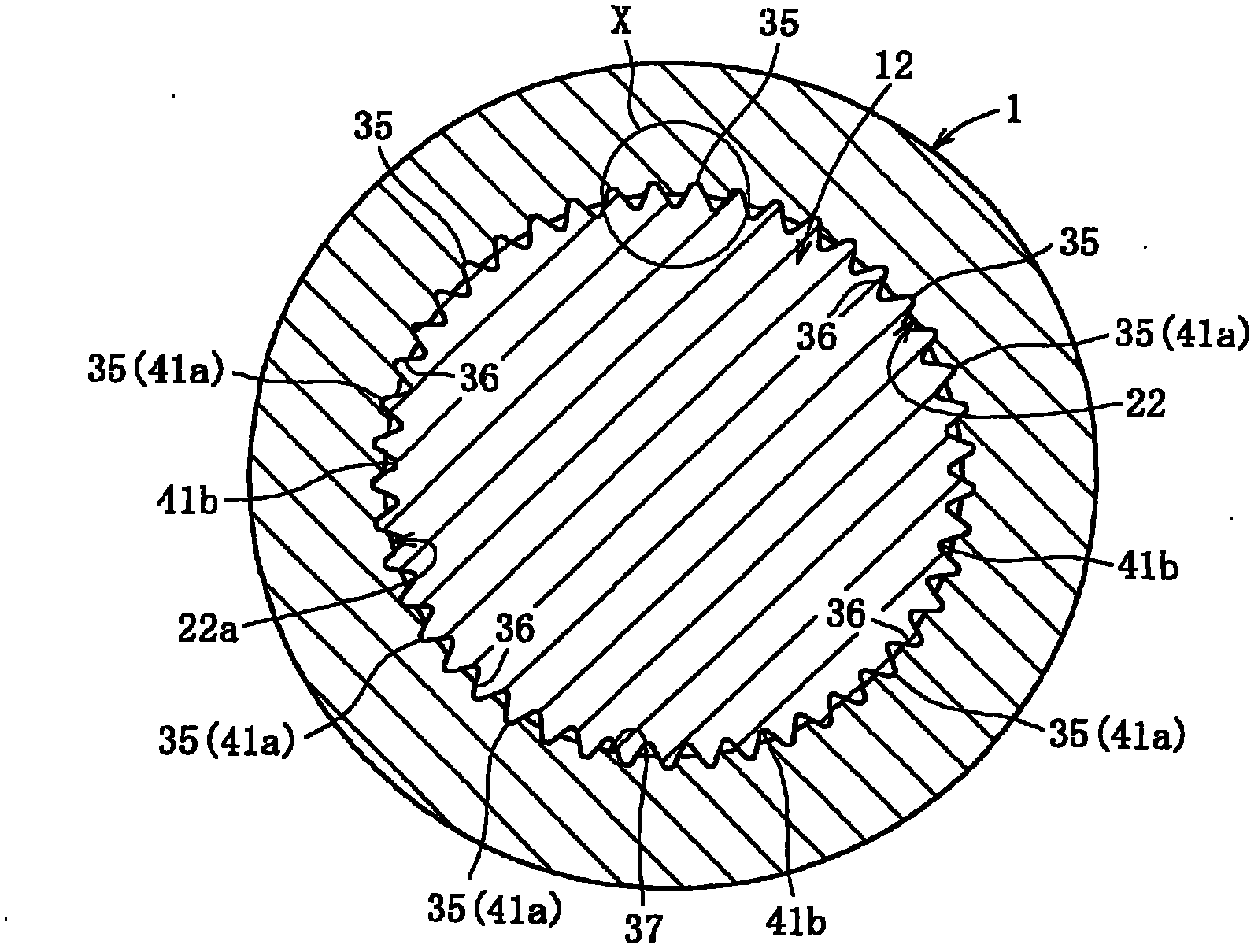

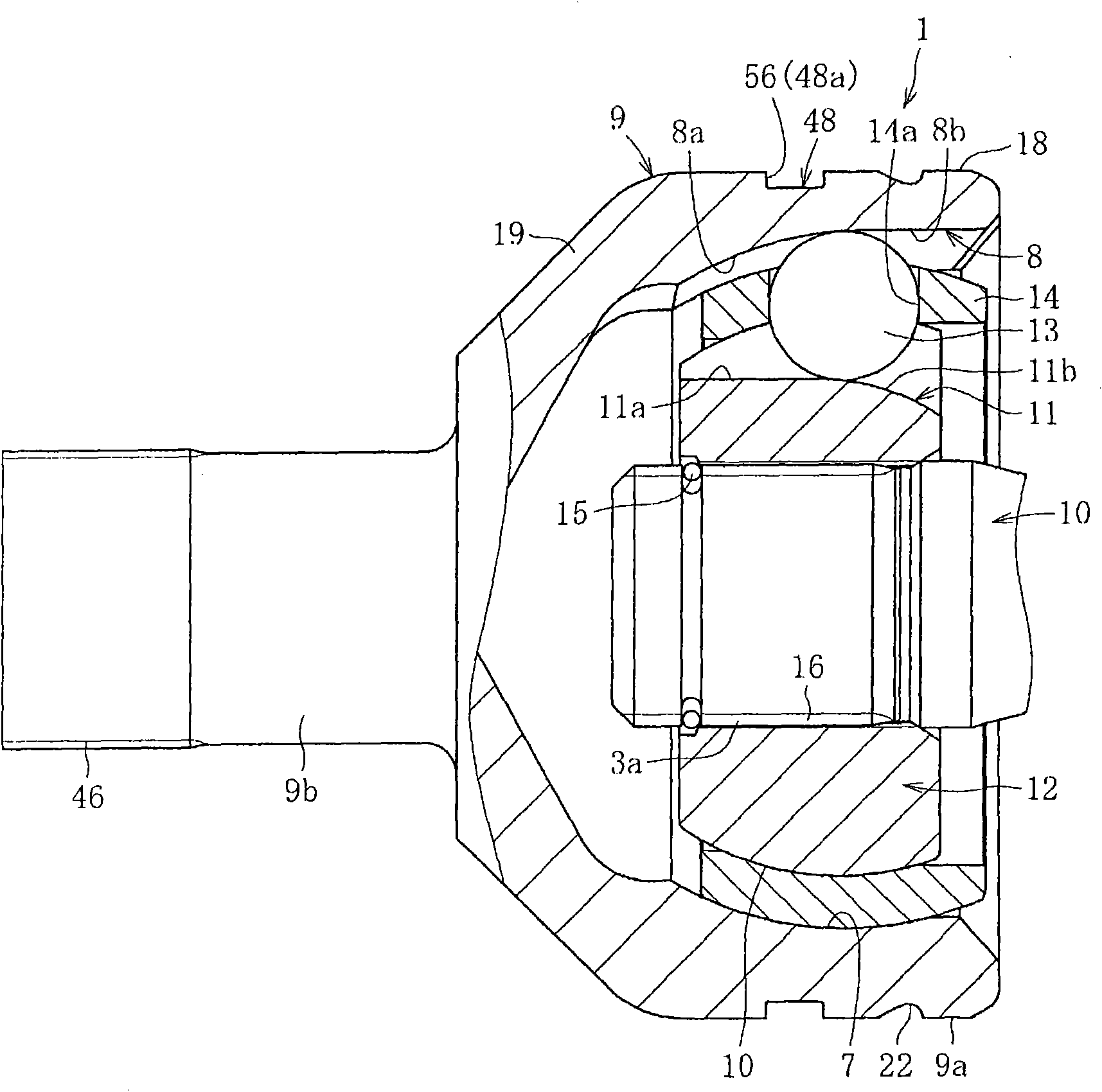

Bearing device for wheel

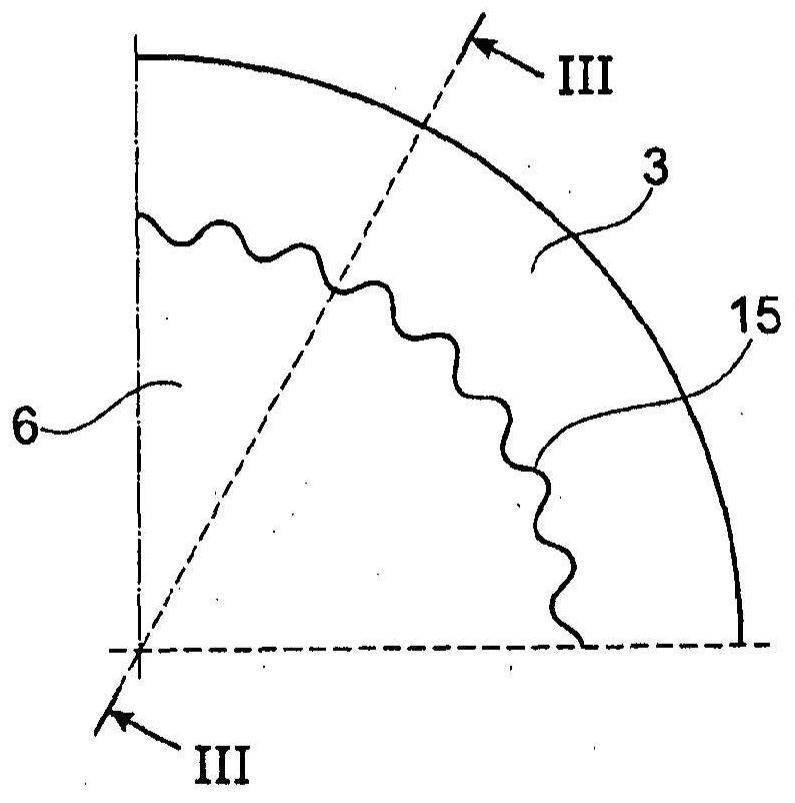

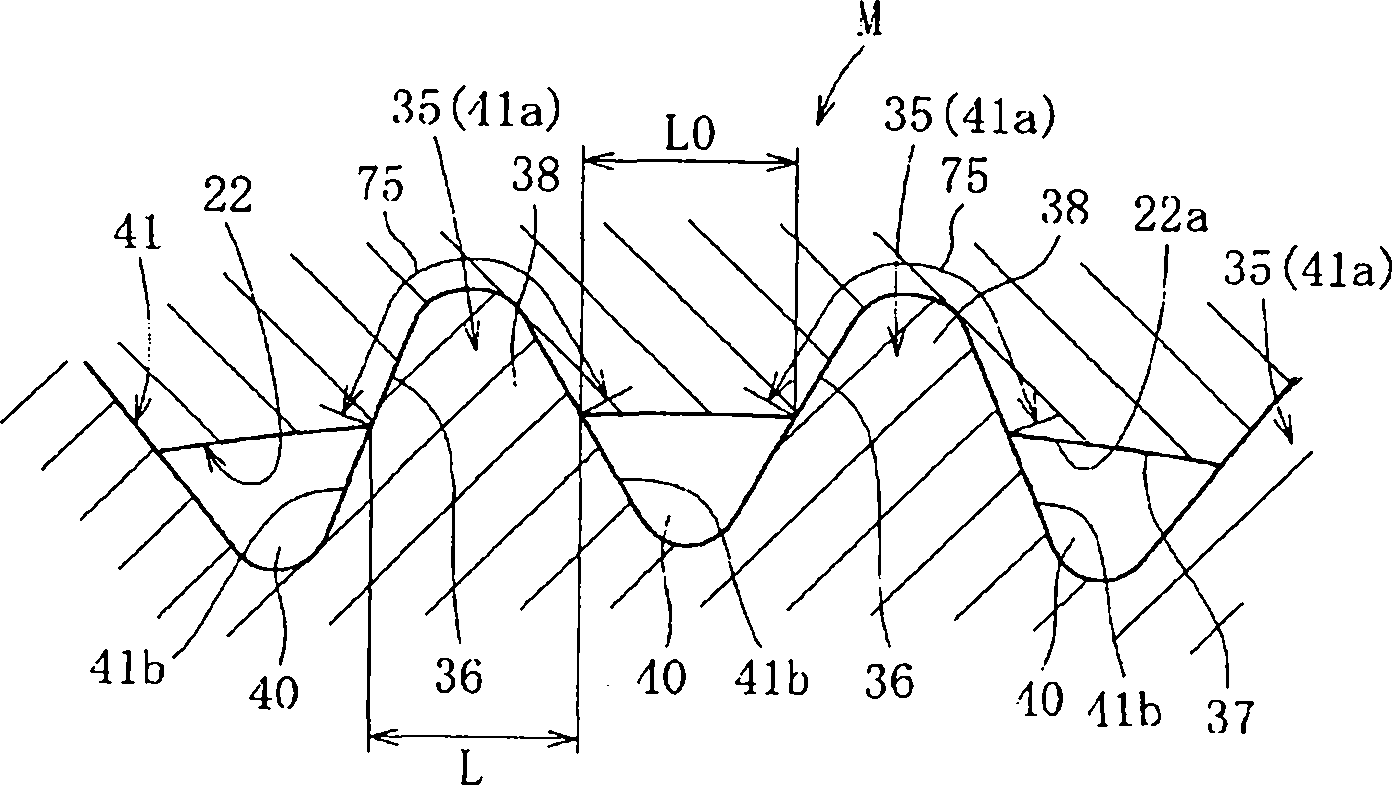

ActiveCN101802426AStable deliveryHigh strengthYielding couplingRolling contact bearingsUniversal jointEngineering

A bearing device for a wheel, in which circumferential play is suppressed and in which a hub ring and an outer ring of a constant velocity universal joint can be firmly and easily joined to each other. An axially extending projection (35) is formed on a shaft section (12) of the joint outer ring (5), and the shaft section (12) is press-fitted into a hole (22) of the hub ring (1). By this press-fitting, a recess (36) closely fitting on the projection (35) is formed in the inner diameter surface of the hub ring (1) to form a recess / projection fit structure (M) in which the entire regions of those portions of the projection (35) and the recess (36) at which they are fitted to each other are in close contact with each other. The bearing device satisfies the relationship of 0.3 < Deltad / 2h < 0.86, where Deltad is the press-fit interference of the projection (35) relative to the hub ring (1) and h is the height of the projection.

Owner:NTN CORP

Bearing device for wheel

ActiveCN101541560AEasy assemblyAchieve cost reductionRolling contact bearingsHubsConstant velocityUniversal joint

A bearing device for a wheel, in which circumferential play is suppressed and which has excellent workability of connection between a hub ring and an outer joint member of a constant velocity universal joint. In the bearing device for a wheel, a stem shaft (12), which is fitted in a hole (22) of the hub ring (1), of the outer joint member of the constant velocity universal joint (3) is integrated with a hub ring (1) via a depression / projection fitting structure (M). In the depression / projection fitting structure (M), the entire part of a portion (38) of a projection (35), which portion is to be fitted to a depression, is in intimate contact with a corresponding depression section (36).

Owner:NTN CORP

Excircle surface rolling device

The invention discloses an outer circle surface rolling device including a fixing main body. An inner ring at one end of the fixing body is rotatably cooperated with a steel drive sleeve that can drive power and the other end of the fixing body is screwedly connected with a shell. A screw thread in the shell is connected with a mandrel; the output end of the steel drive sleeve drives a protectingsleeve, a surrounding circle of which is embedded with a roller pin through a discrete drive sleeve and the protecting sleeve is inserted in a central hole located in the mandrel; a tip spring sleeved on an outer ring of the protecting sleeve is compressed between the inner end surface of the mandrel and the discrete drive sleeve; an inner hole of the steel drive sleeve is provided with a plasticdrive sleeve that can adjust and maintain the expansion amount of the sleeve and collocated with the dimension adjusting and locking functions of the mandrel and an adjusting spring as well as a spring pressure sleeve arranged n the plastic drive sleeve, thus realizing the coarse adjustment and micro-adjustment on the rolling parts with various dimensions; a through hole is arranged in the steel drive sleeve and the protecting sleeve and has no length depth position limiting; the processing length of the rolling parts are not restrained; a blocking connecting torque force is stably transferred; the invention adopts a diagonal roller pin structure and has accurate dimension processing.

Owner:宁波市精恒凯翔机械有限公司

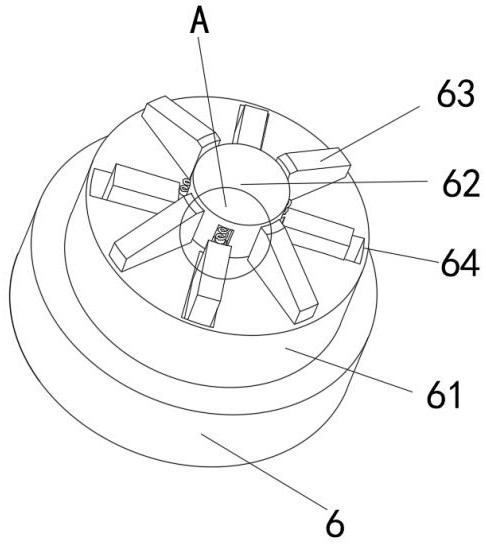

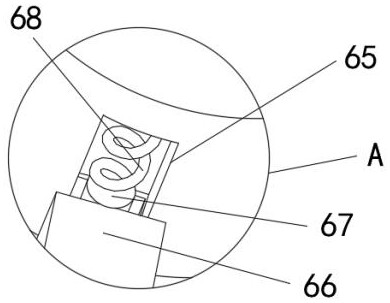

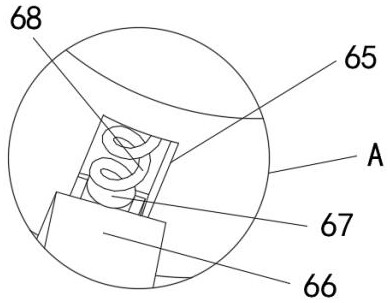

Wedge-block electromagnetic clutch

ActiveCN106678199AImprove carrying capacitySmall structure sizeMagnetically actuated clutchesElectromagnetic clutchCoupling

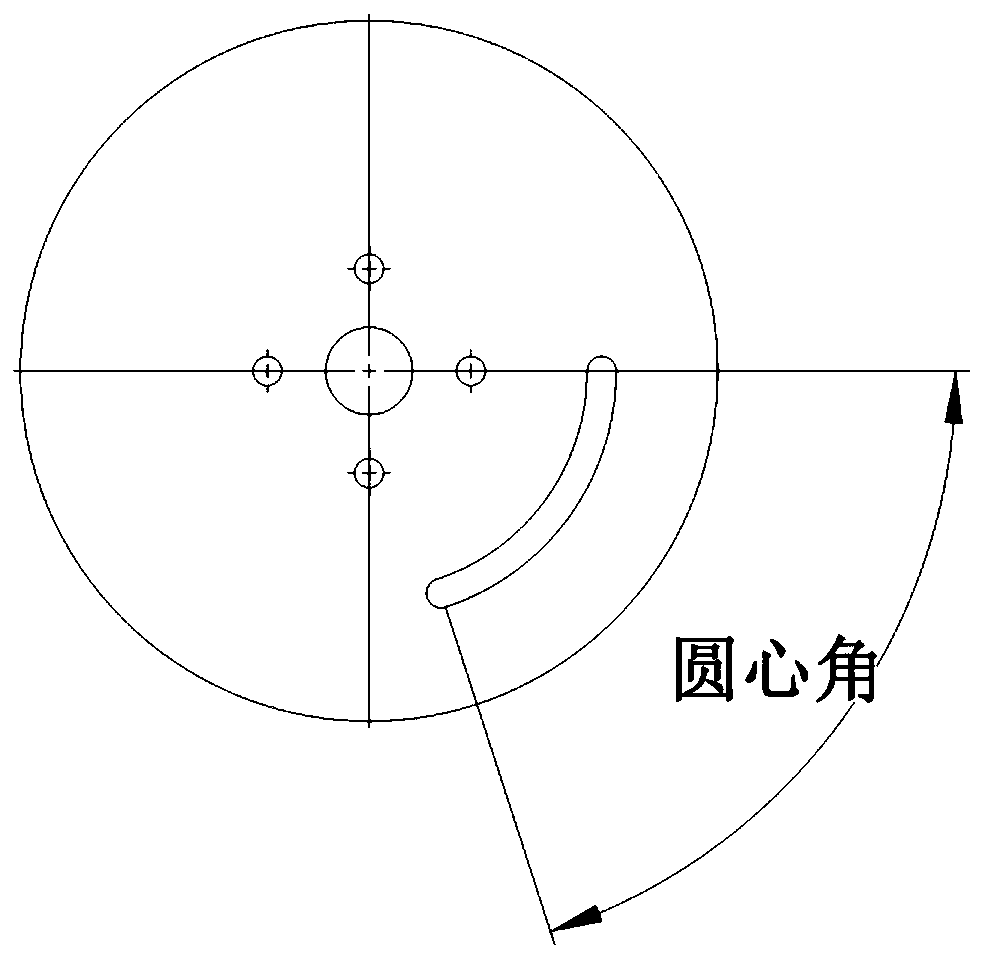

The invention provides a wedge-block electromagnetic clutch, and belongs to the technical field of mechanical transmission. The electromagnetic clutch comprises a half-coupling, a main shaft, wedge blocks, a retainer, torsion springs, isolation blocks, a compression spring, a clutch pin, an electromagnet and an armature, wherein the axes of the half-coupling and the main shaft are superposed, the retainer is located in an annular space formed by the shaft-diameter surface of the main shaft and the inner cylindrical surface of the half-coupling, a group of the torsion springs is uniformly distributed on the annular retainer, and splayed wedge block groups formed by the wedge blocks and the isolation blocks are also uniformly distributed on the circumference of the retainer; and the clutch pin provided with the compression spring at one end penetrates through the isolation blocks and is fixedly connected to the armature, and the electromagnet movably sleeves the main shaft and is fixed to a rack. The electromagnetic clutch provided by the invention is capable of increasing the transfer torque thereof, fast in engagement reaction, capable of reducing the power and energy consumption of operating the electromagnet, compact in structure, and convenient to install.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Bearing device for wheel, and axle module

InactiveCN101802425BPrevent intrusionAvoid deterioration of adhesionClutchesYielding couplingUniversal jointEngineering

Provided are a bearing device for a wheel, in which circumferential play is reduced, which provides excellent workability in connection between a hub ring and an outer joint member of a constant velocity universal joint, in which fitting between the hub ring and the outer joint member of the constant velocity universal joint is stable, and which has excellent strength, and an axle module using the bearing device. An axially extending projection is formed on either of the outer diameter surface of a shaft section of the outer joint member and the inner diameter surface of a hole of the hub ring. The projection is press-fitted to the other in the axial direction to form a recess in the other by the press-fitting. By this, a recess / projection fit structure is formed, in which the entire regions of those portions of the projection and the recess at which they are fitted to each other are in intimate contact with each other. The hardness of at least that portion of the projection at which the press-fit starts is higher than that of a portion where the recess is formed. The difference in hardness in HRC is 20 or more.

Owner:NTN CORP

Clutch with pressed-in drive ring

ActiveCN108291586BSmooth torque transmissionReduce complexityFluid actuated clutchesFriction clutchesInternal combustion engineFlywheel

Owner:SCHAEFFLER TECH AG & CO KG

Coaxial magnetic gear

ActiveCN102324821BIncreased torque densityHigh mechanical strengthDynamo-electric machinesGear wheelMagnetic poles

The invention discloses a coaxial magnetic gear comprising an external rotor, a static magnetic ring and an internal rotor which are lined from outside to inside and share the same axis. The external rotor is a circular magnetic conductor, and external rotor convex poles which are lined with equal spacing are arranged on the inner ring of the external rotor; the static magnetic ring is fixedly arranged between the internal rotor and the external rotor, and comprises permanent magnets and non-permanent magnets which are lined at intervals; internal rotor convex poles are lined on the outer ring of the internal rotor with equal spacing, and internal rotor permanent magnet bodies are arranged on the outer ring of the internal rotor; the internal rotor can be also in other structural forms capable of producing effective N-S magnetic poles; and in order to ensure the normal rotation of the internal rotor and the external rotor, air gaps are left between the three parts. Through the convex pole structure of the external rotor, the coaxial magnetic gear enables a static magnetic ring magnetic field to modulate a series of harmonic rotation magnetic fields on an inner air gap side, the number of the polar pairs of the selected internal rotor permanent magnet bodies is the same with that of the pole pairs of a required harmonic magnetic field, and the stable torque transmission is realized by the coupling action of the polar pairs of the selected internal rotor permanent magnet bodies and the pole pairs of a required harmonic magnetic field. The magnetic gear has the characteristics of high torque density, high mechanical strength of the external rotor, and convenience in processing and manufacturing.

Owner:SOUTHEAST UNIV

Bearing device for wheel

InactiveCN101641225BImprove qualityPrevent creepRolling contact bearingsAxle unitsUniversal jointEngineering

A bearing device for a wheel, in which circumferential play is suppressed, which facilitates connection between a hub ring and an outer coupling member, in which a reduction in NVH characteristics dueto play at a joint between the hub ring and the constant velocity universal joint and by play between a bearing outer member and a knuckle is prevented, and which performs highly accurate transmission of rotational torque. The bearing device has a groove-ridge fitting structure (M) by which the hub ring (1) and a shaft section (12) of the outer coupling member of the constant velocity universal joint (3) are integrated together, and the shaft section (12) is fitted in a hole (22) of the hub ring (1). In the groove-ridge fitting structure (M), ridges (35) on the outer diameter surface of the shaft section (12) and grooves (36) in the inner diameter surface (37) of the hub ring (1) are fitted to each other in a fitting contact portion (38), and the ridges (35) and the grooves (36) are in intimate contact with each other in the entire fitting contact portion (38).

Owner:NTN CORP

Bearing device for wheel

InactiveCN102152711BImprove qualityPrevent creepYielding couplingRolling contact bearingsUniversal jointTorque transmission

Owner:NTN CORP

A vertical visual oil film dynamic test device

InactiveCN104502092BNeutral goodUniform thicknessMachine gearing/transmission testingViscous liquidEngineering

The invention discloses a vertical visual oil film power testing device, which mainly includes a driving force part, a liquid viscous main machine, an oil film thickness adjusting device, a support and the like. The upper box cover, the lower box cover and the support plate of the liquid viscous main engine are connected by screws to form the liquid viscous main engine casing. The sleeve passes through the upper box cover and is welded and fixed with it. The input shaft passes through the sleeve and connects to the active plate support. The friction plate is fixed on the active plate support; the passive friction plate is fixed on the passive plate support, the passive plate support is connected to the output shaft, the output shaft is connected to the fixed block of the output shaft, and is fixed on the lower box cover to keep the output shaft not Rotate, while the output shaft and the groove block are fixed by pins, the groove block is placed on the wedge-shaped slider, and the wedge-shaped slider moves by adjusting the screw to realize the vertical rise and fall of the output shaft. The invention has the advantages of convenient operation, simple structure, and easy detection, and can realize functions such as large-scale adjustment of oil film thickness, fine adjustment, visible flow state of oil film, and the like.

Owner:JIANGSU UNIV

Bearing device for wheel

InactiveCN101802426BStable storagePrevent deviationYielding couplingRolling contact bearingsUniversal jointEngineering

Owner:NTN CORP

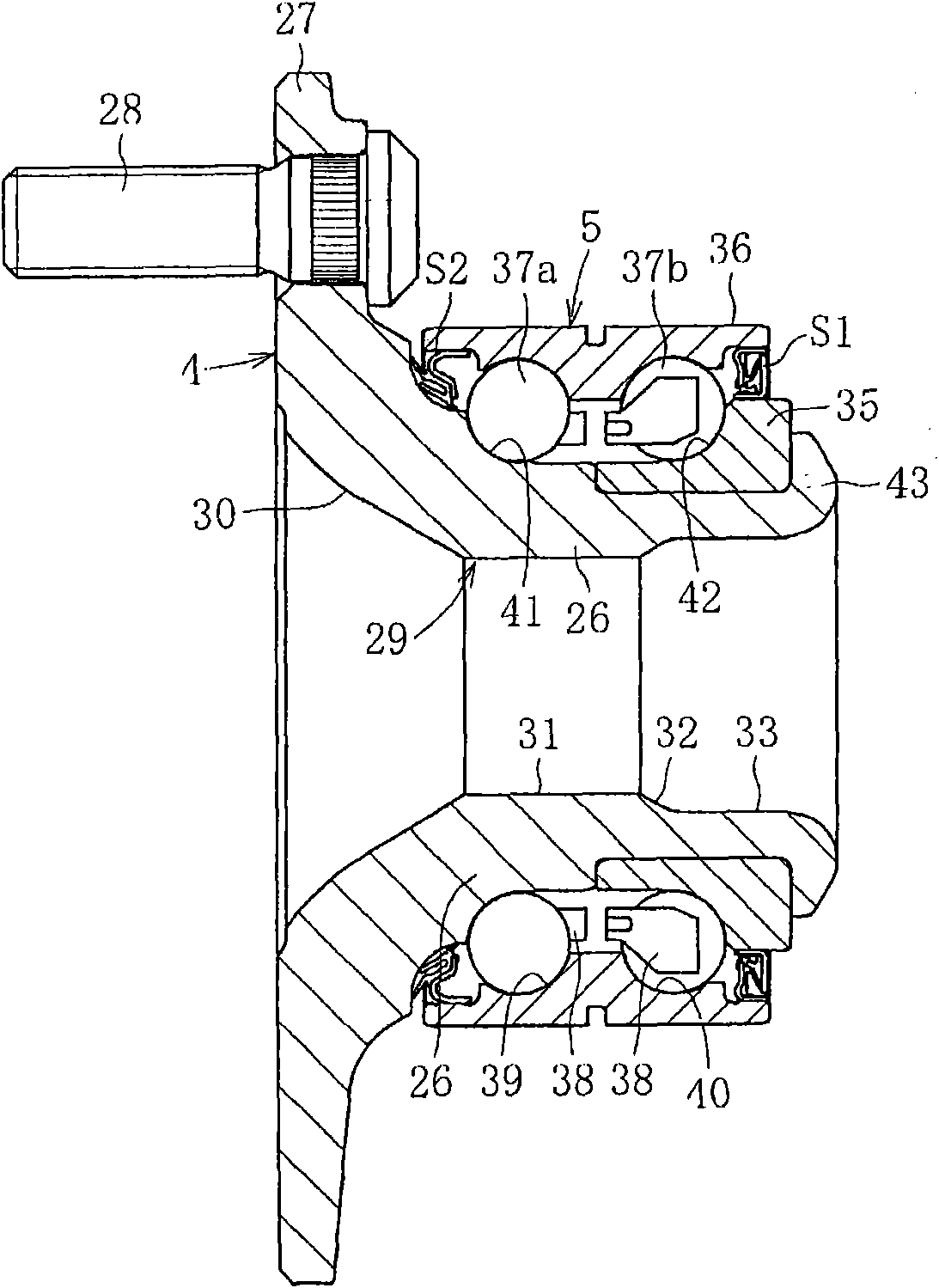

Vehicle Lamps

ActiveCN109237416BImprove reliabilityEasy to operateVehicle headlampsLighting support devicesOptical axisEngineering

Owner:KOITO MFG CO LTD

A method for combining a linkage trainer and a horseback riding with pedal turntable horseback riding

ActiveCN112999632BPlay a swinging effectHigh simulationGymnastic exercisingCircular discPhysical medicine and rehabilitation

The invention relates to a combined training device, which belongs to the field of fitness equipment, and in particular to a pedal turntable horse riding combined linkage training device and a horse riding method. The trainer comprises a riding seat (3); the riding seat (3) is divided into two parts: a riding seat plate (9) and a riding housing (10); two pedal circles are arranged at both ends of the upper front end of the frame (2) The disc (4) transmits the input force on the two pedal turntables through a plurality of torque changing devices through the transmission gear train structure, and finally plays the effect of making the saddle board swing. The riding seat plate is installed at the position of the connecting rod of the crank rocker mechanism, which can better simulate the posture of riding a horse, and the real effect is stronger. The power transmission is carried out through the synchronous belt transmission wheel system, the transmission torque is stable, the rotation is not lost, the swing speed is stable, and the transmission efficiency is high.

Owner:SANHE GUIYUXING SPORTS GOODS

A device for measuring instantaneous heat flow at stagnation point of high-temperature plasma wind tunnel

The application discloses a measuring device for an instantaneous heat flow of a high temperature plasma wind tunnel stagnation point. The measuring device comprises a graphite baffle, a connecting fixing seat, a motor bracket, a low speed motor, a rib plate, a support base, a coaxial thermocouple, a clamping base, and a stable bottom plate. According to the invention, the time and interval of aninstantaneous airflow flowing through the coaxial thermocouple can be controlled by different speeds of the low speed motor, thereby protecting the coaxial thermocouple from being damaged by long-timeablation and thus realizing instantaneous heat flow measurement.

Owner:星焓科技(北京)有限公司

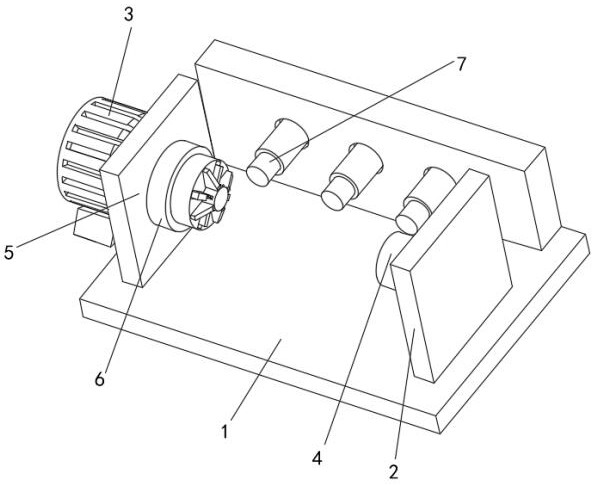

Numerical control machine tool with clamping tip

ActiveCN114101722AStable and enhanced clamping forceStable torque transmissionTailstocks/centresLarge fixed membersElectric machineryLeft lateral wall

The invention relates to the technical field of intelligent manufacturing, and discloses a numerical control machine tool with a clamping tip, the numerical control machine tool comprises a base, a first support, a second support, a motor and a grinding piece, a shaft sleeve is fixedly connected to the right side of the second support and located at the tail end of an output shaft of the motor, and a limiting column is fixedly connected to the left side wall of the first support; a center sleeve is fixedly connected to the right side wall of the shaft sleeve, a rotating column is fixedly connected to the center of the top wall of the center sleeve, a first protrusion is fixedly connected to the rotating column in the circumferential direction, and a permanent magnet is slidably connected to the interior of a limiting groove. Clamping of a part to be machined is achieved through the first protrusion on the tip, multi-stage switching of the protection mechanism is achieved through centrifugal force changes at different rotating speeds in the part machining process, the automation degree is high, torque is kept to be stably transmitted according to increase of the rotating speeds, multi-stage protection of the part is achieved, the machining efficiency is high, and the machining cost is low. The service life of the center is prolonged, and the defect rate of products is effectively reduced.

Owner:南通永锠数控机械科技有限公司

Bearing device for wheel, method of assembling bearing device for wheel, assembly constructed from bearing device for wheel and from drive shaft, and method of assembling assembly

The present invention provides a wheel bearing device, a method of assembling the wheel bearing device, an assembly configured by the wheel bearing device and a drive shaft, and a method of assembling the assembly, in which the wheel bearing device eliminates a nut tightening operation, is capable of reducing costs, and has a projection and recess mating structure that can firmly connect an outer joint member and a hub. Axial direction load is applied to a stepped surface 56 provided on an outer diameter surface of an outer joint member. A projection that extends in the axial direction and is provided on one of a stem shaft 9b of the outer joint member and an inner diameter surface of a hole section 29 of a hub 4 is press-fitted into a partner member along the axial direction, As a result, a recess that is in close contact with the projection over an overall mating contact area 45 is formed in the partner member, thereby configuring a projection and recess mating structure M.

Owner:NTN CORP

A CNC machine tool with clamping top

ActiveCN114101722BSmooth torque transmissionStable and enhanced clamping forceTailstocks/centresLarge fixed membersNumerical controlElectric machine

The invention relates to the technical field of intelligent manufacturing, and discloses a CNC machine tool with a clamping top, including a base, a first bracket, a second bracket, a motor, and a grinding piece. The second bracket is located on the right side of the motor The end of the output shaft of the first bracket is fixedly connected with a shaft sleeve, the left side wall of the first bracket is fixedly connected with a limit column, the right side wall of the shaft sleeve is fixedly connected with a top sleeve, and the center of the top wall of the top sleeve is fixedly connected with a The rotation column, the circumference of the rotation column is fixedly connected with the first protrusion, and the inside of the limiting groove is slidably connected with the permanent magnet. The present invention realizes the clamping of the parts to be processed through the first protrusion on the top, realizes the multi-level switching of the protection mechanism through the centrifugal force changes at different speeds during the processing of the parts, has a high degree of automation, and keeps the torque stable according to the increase of the speed Transmission, to achieve multi-level protection of parts, high processing efficiency, improve the service life of the top, so that the defective rate of the product is effectively reduced.

Owner:南通永锠数控机械科技有限公司

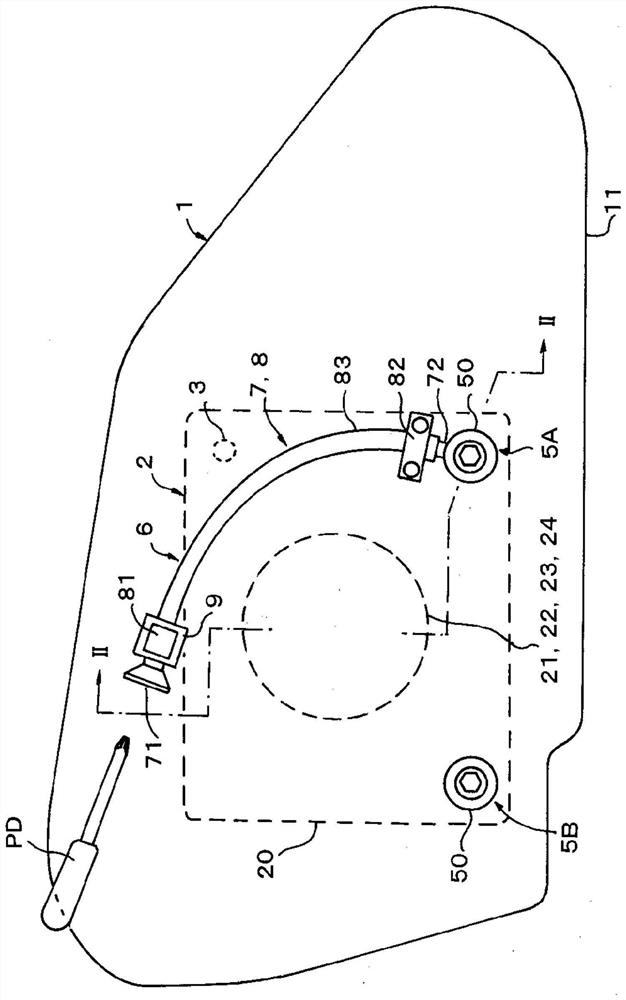

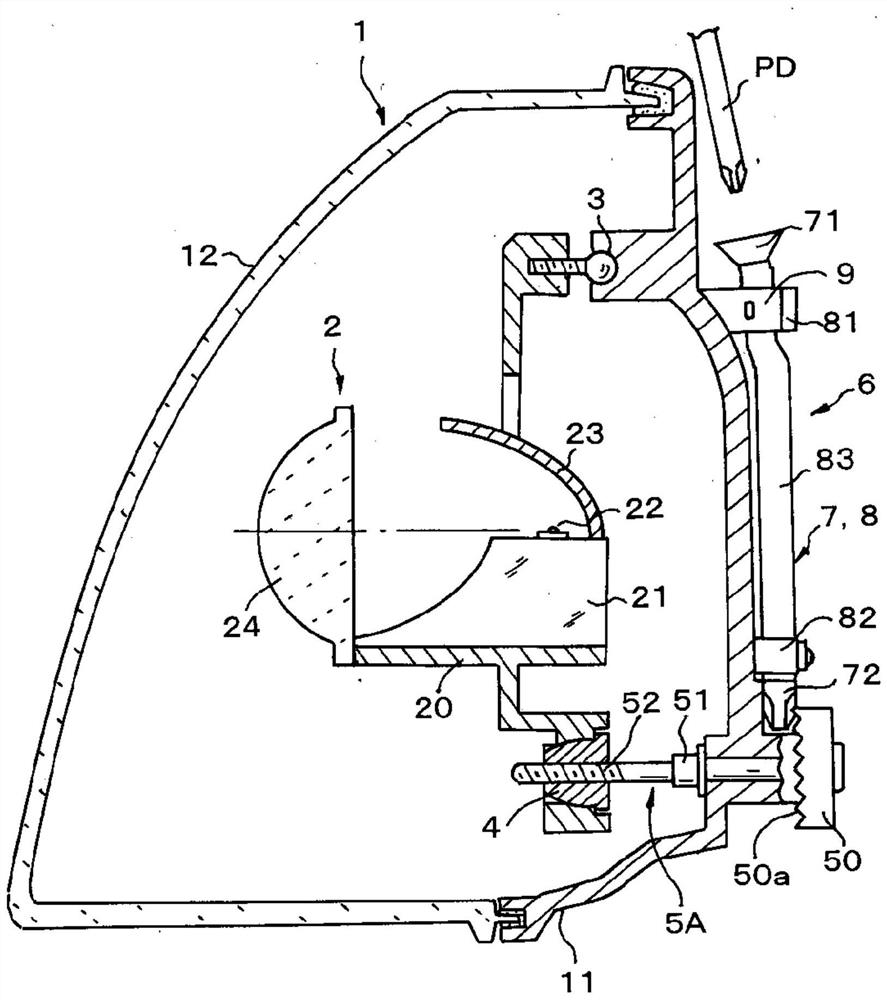

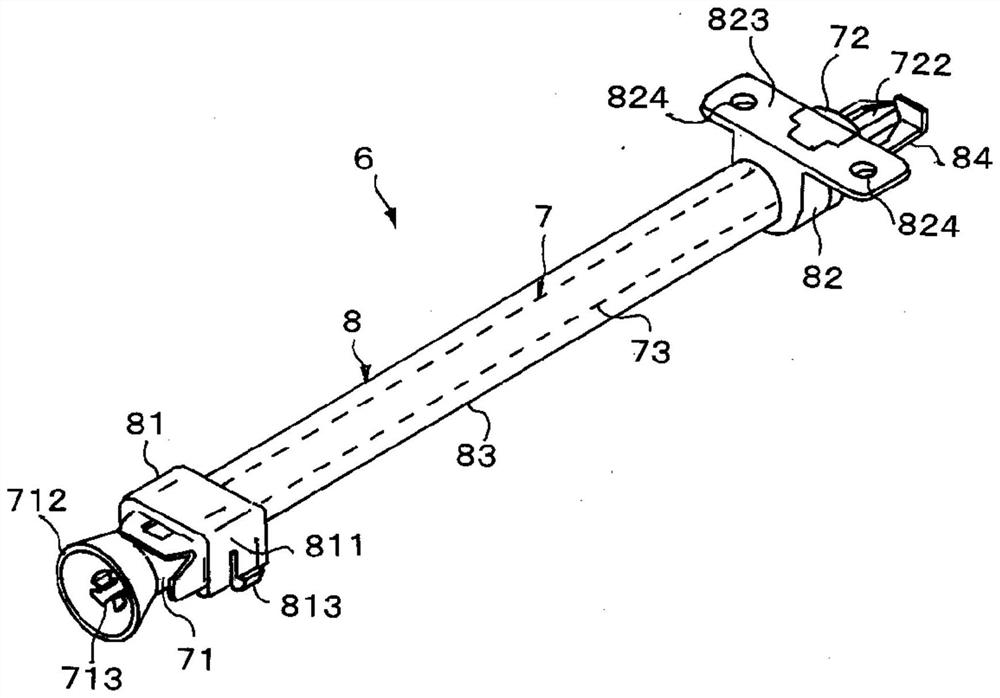

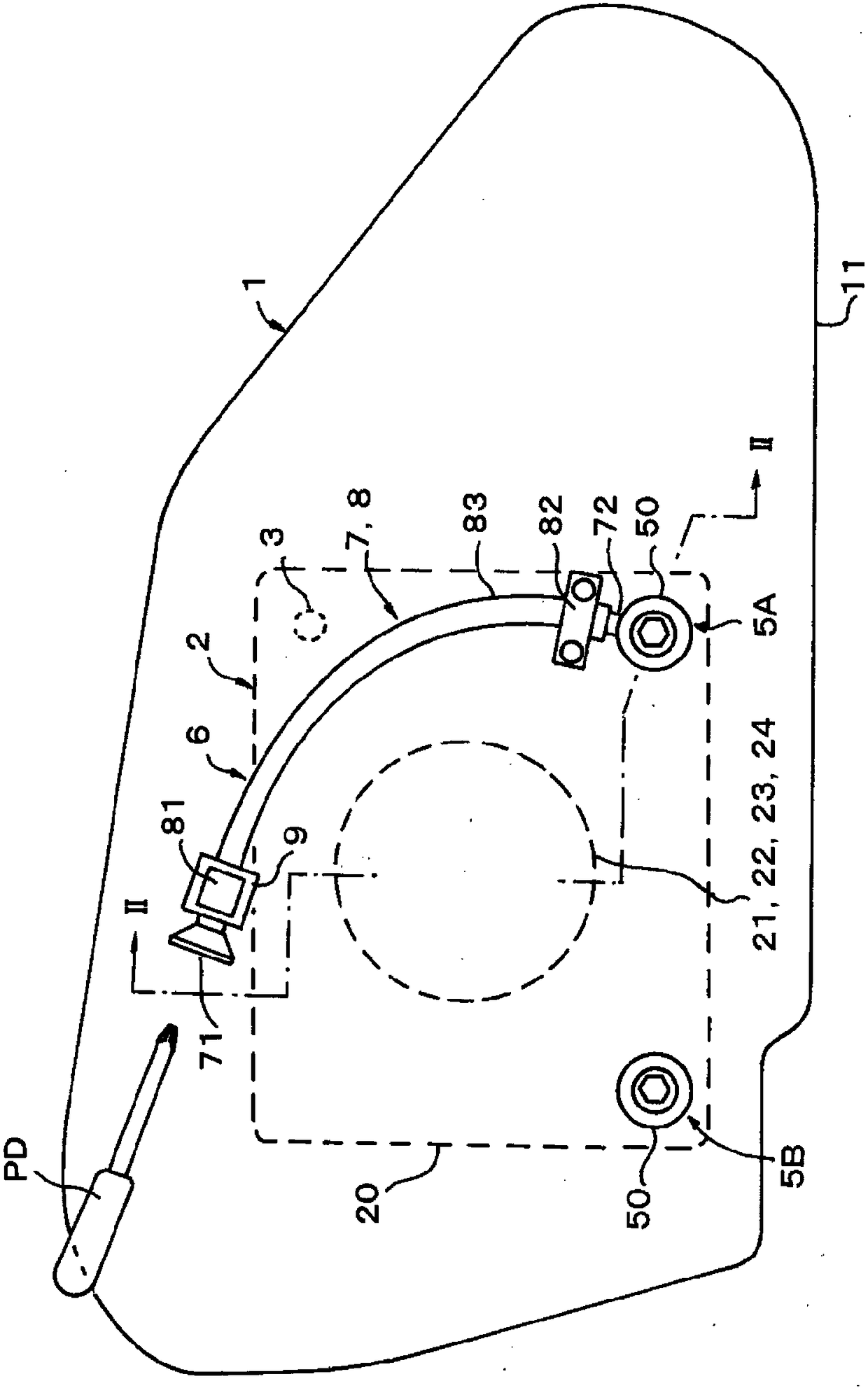

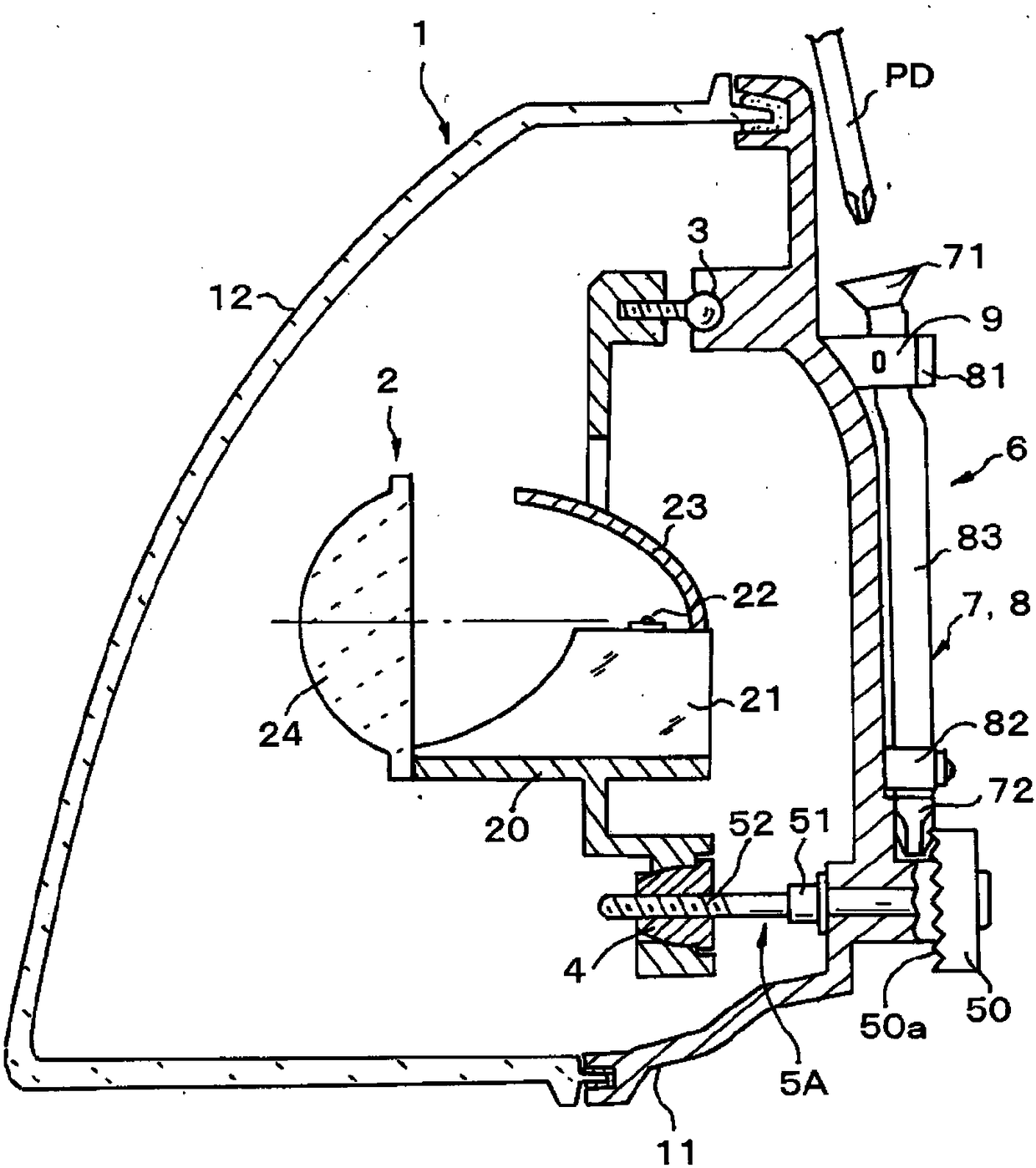

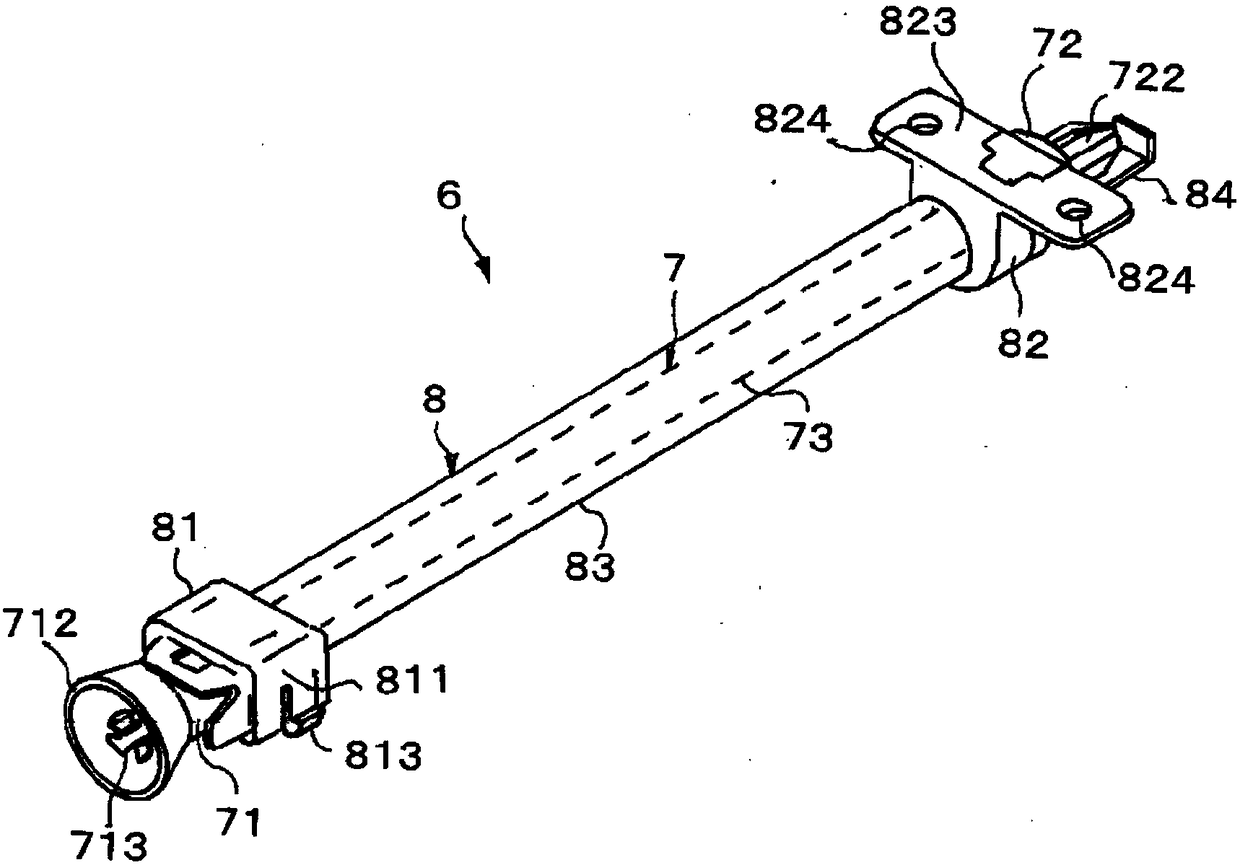

Vehicle lamp

ActiveCN109237416AImprove reliabilityPrevent wearVehicle headlampsLighting support devicesEngineeringOptical axis

The present invention relates to a vehicle lamp. An object of the present invention is to improve the reliability of an operation unit that performs illumination adjustment of a lamp and to improve the operability of the operation unit. The vehicle lamp includes an operation unit (6) for operating a bevel gear (50) for adjusting the optical axis of the lamp (1) in a shaft driving manner. A shaft driving force transmitting body (7) of the operation unit (6) includes an operating lever (71) for shaft driving operation, a driving rod (72) that meshes with the bevel gear (50), and a metal wire (73) that connects the operating lever (71) and the driving rod (72) in the shaft driving direction, and the driving rod (72) is formed of a metal that is difficult to rust. The driving rod is formed bya metal injection molding process. A support member (84) extends between the driving rod (72) and the lamp.

Owner:KOITO MFG CO LTD

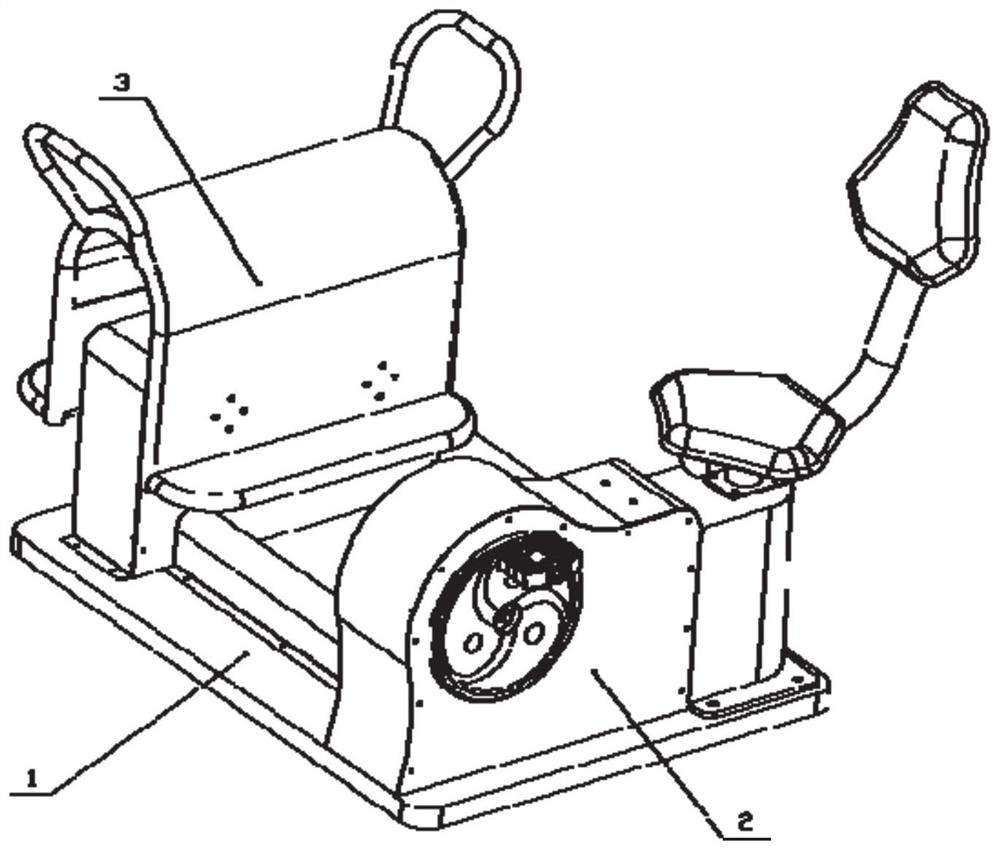

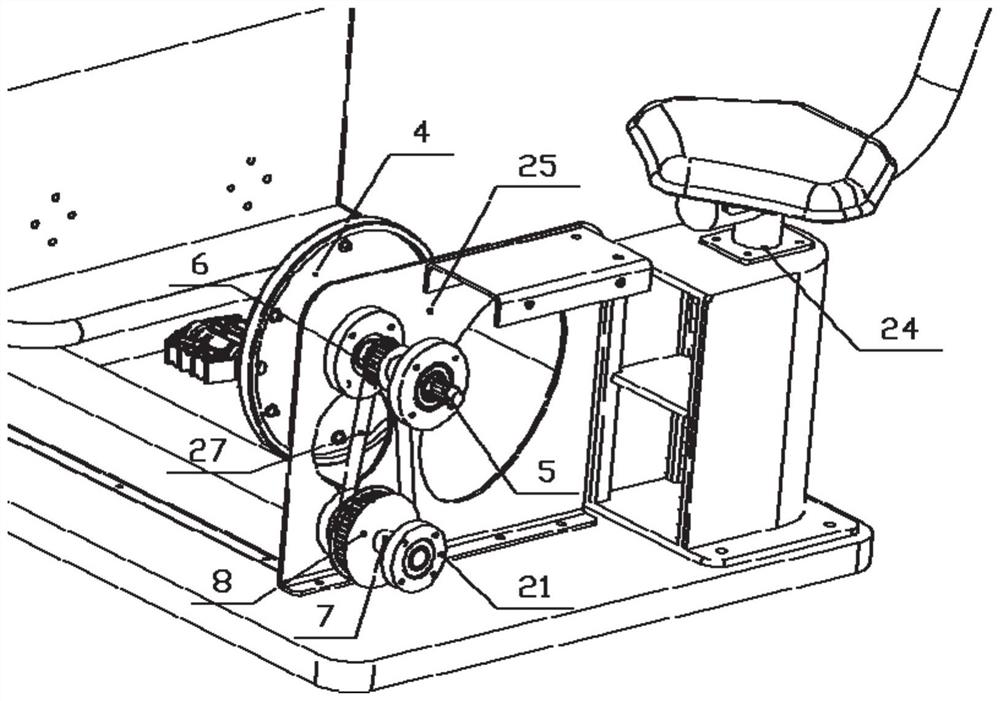

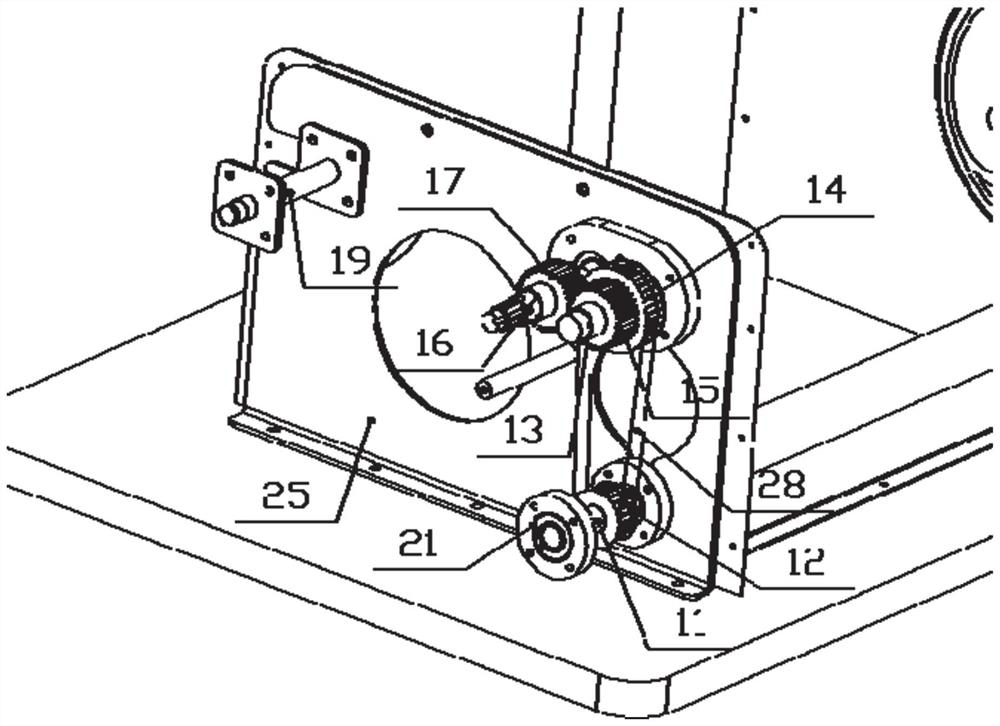

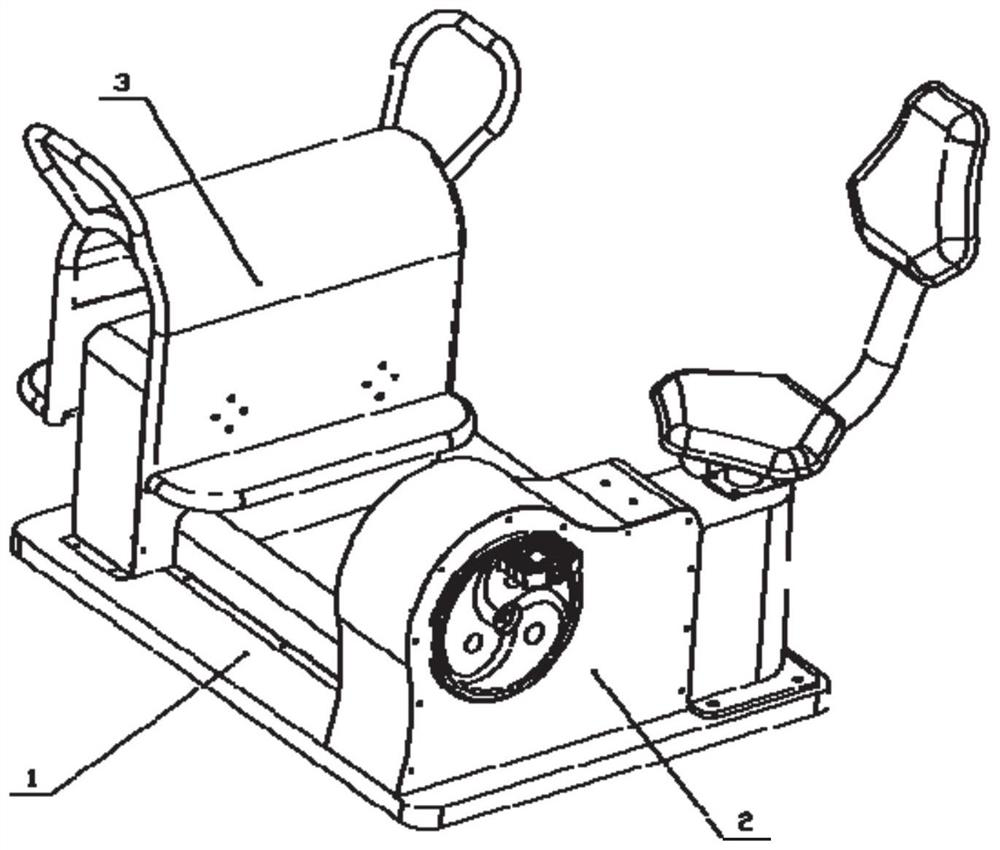

Pedal turntable horse riding combined linkage trainer and horse riding method

ActiveCN112999632APlay a swinging effectHigh simulationGymnastic exercisingCircular discPhysical medicine and rehabilitation

The invention relates to a combined training device, belongs to the field of fitness equipment, and particularly relates to a pedal turntable horse riding combined linkage training device and a horse riding method. The trainer comprises a riding seat (3); the horse riding seat (3) is divided into a horse riding seat plate (9) and a horse riding shell (10); two pedal discs (4) are arranged at the two ends of the upper portion of the front end of the machine frame (2), input force on the two pedal discs is transmitted through a transmission wheel train structure through a plurality of torque changing devices, and finally the effect that a riding seat plate swings is achieved. The horse riding seat plate is installed at the position of the connecting rod of the crank rocker mechanism, the posture of horse riding movement can be better simulated, and the real effect is higher. Power transmission is carried out through the synchronous belt transmission wheel train, torque transmission is stable, rotation loss is avoided, the swing speed is stable, and transmission efficiency is high.

Owner:SANHE GUIYUXING SPORTS GOODS

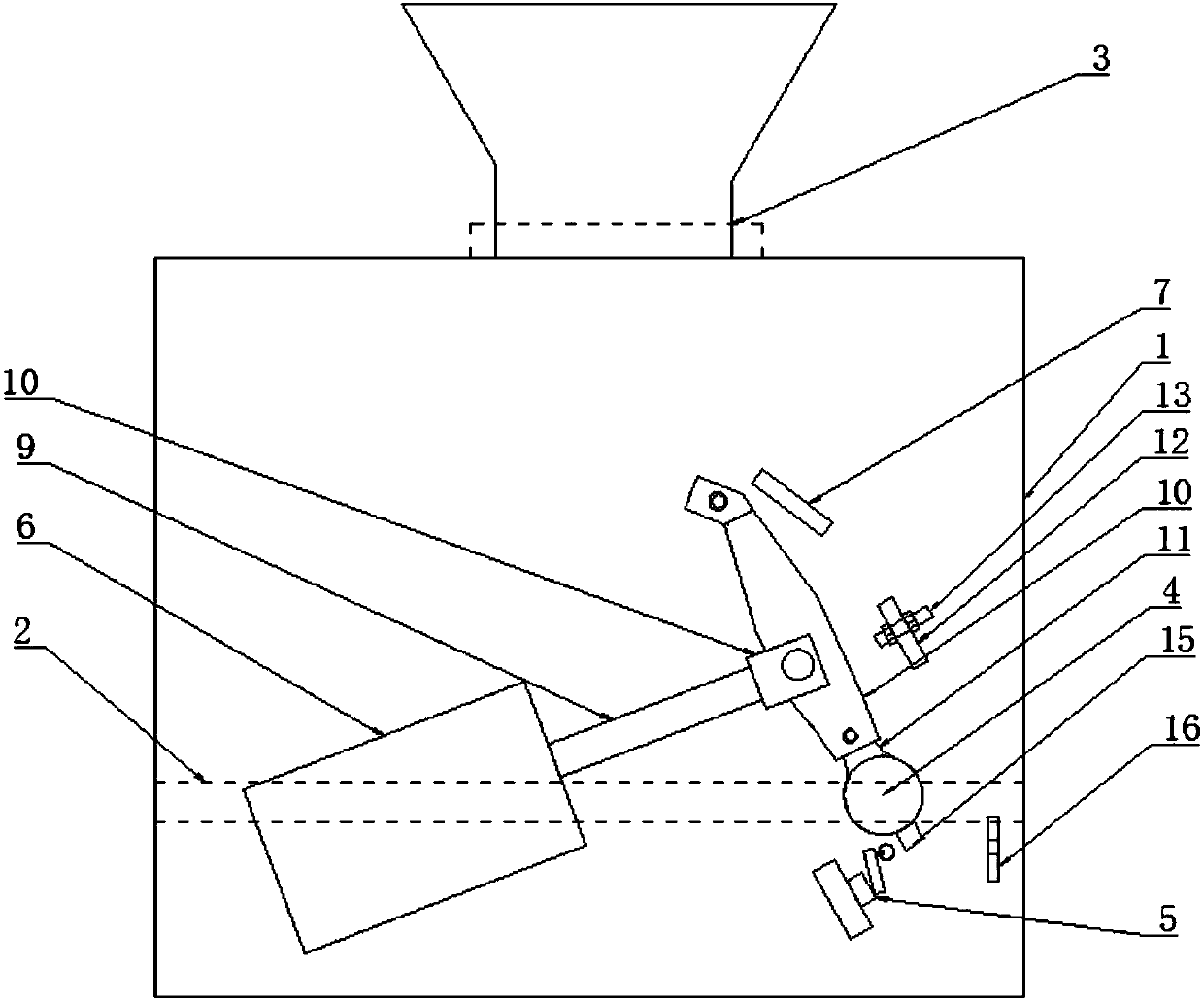

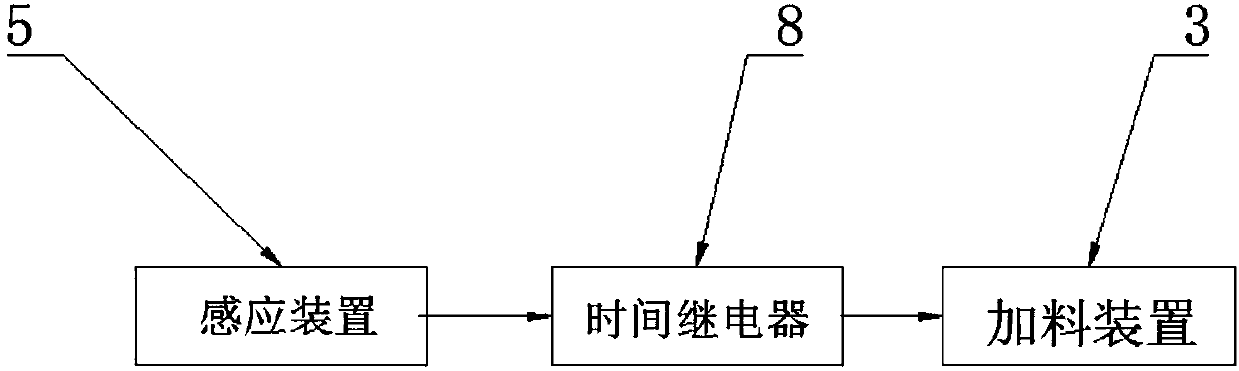

Control device for ensuring tight closure of gate of feed stirring tank

PendingCN107715786AReduce procurement costsEasy to controlFeeding-stuffTransportation and packagingBiochemical engineering

The invention discloses a control device for ensuring tight closure of a gate of a feed stirring tank. The control device comprises the stirring tank; a discharging gate is arranged at the lower end of the stirring tank; a feeding device is arranged at the top end of the stirring tank; a driving shaft connected with the discharging gate is arranged into the stirring tank in a penetrating manner; adriving device for driving the driving shaft to rotate is arranged on the stirring tank; a sensing device adapted to the end part of the driving shaft is arranged on the stirring tank; the control device further comprises a control cabinet connected with the driving device, the sensing device and the feeding device; and a time relay is arranged between the control cabinet and the feeding device.The control device for ensuring the tight closure of the gate of the feed stirring tank can ensure the tight closure of the discharging gate, and is convenient to control, easy to manufacture and easyto implement; and the purchase cost of control equipment is low.

Owner:广西鸿光农牧有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com