Control device for ensuring tight closure of gate of feed stirring tank

A feed mixing and control device technology, applied in feed, mixer accessories, transportation and packaging, etc., can solve the problems of raw materials entering the discharge device, production errors, etc., and achieve the effects of low procurement cost, rapid control and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

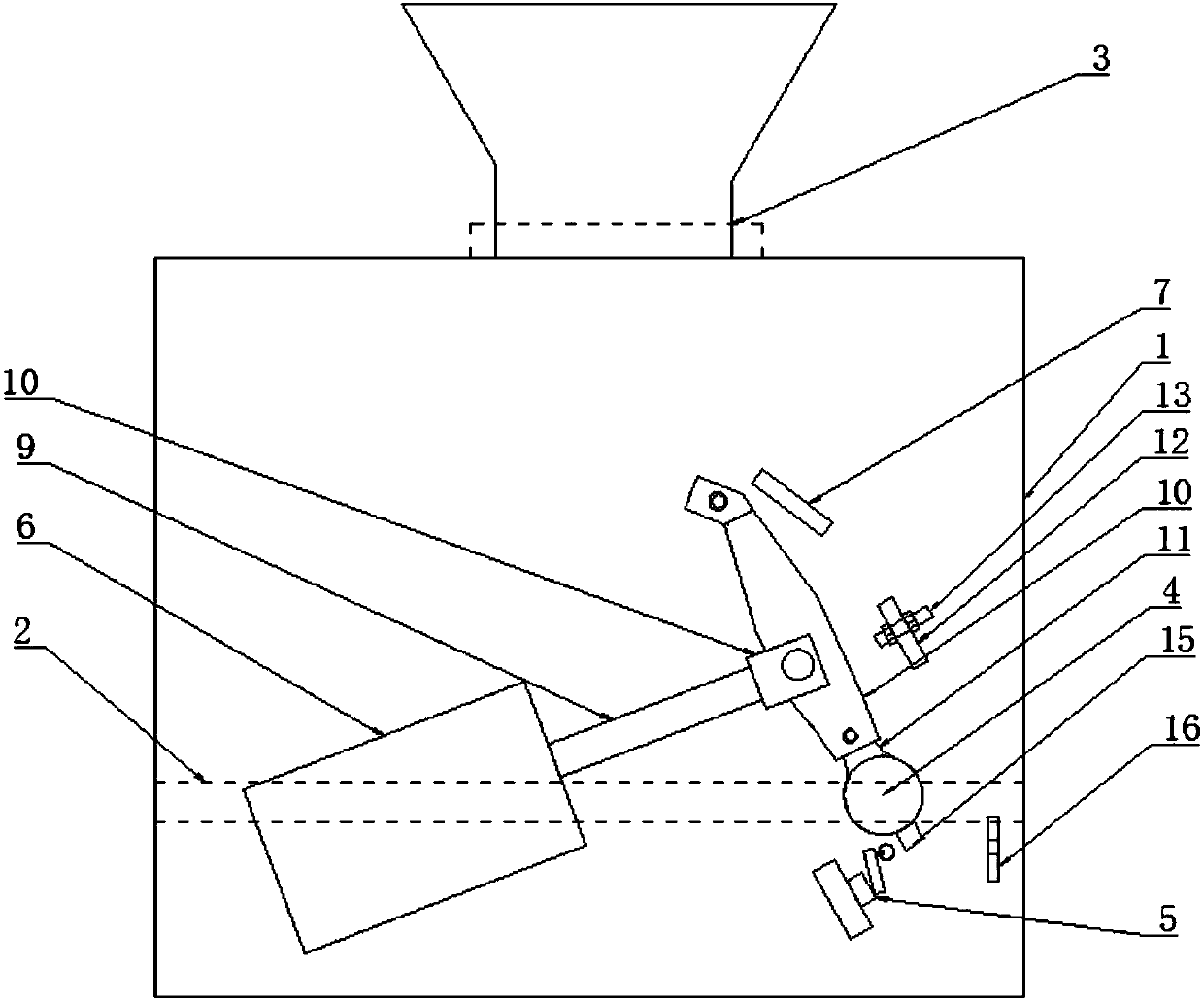

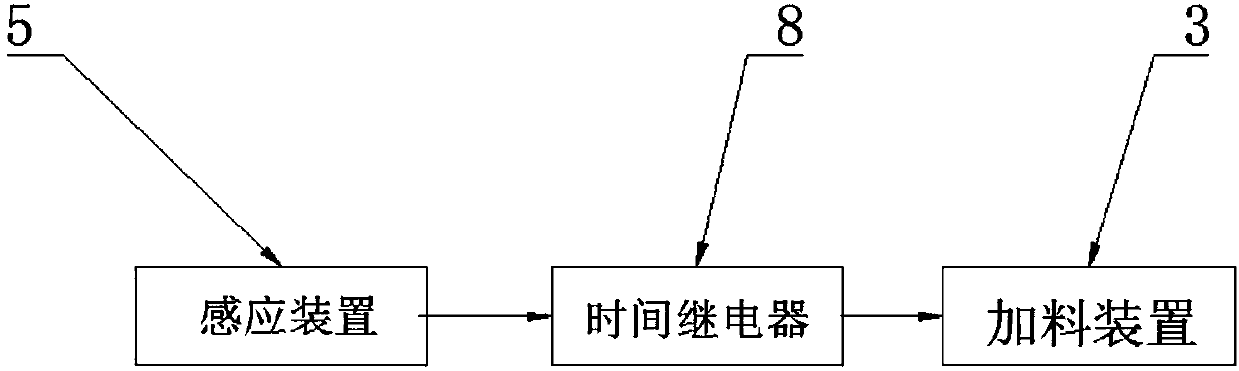

[0018] The specific embodiment of the present invention is like this: as Figure 1-2 As shown, a control device for ensuring that the gate of the feed mixing tank is closed tightly includes a mixing tank 1, a discharge gate 2 is provided at the lower end of the mixing tank 1, a feeding device 3 is provided at the top of the mixing tank 1, and a feeding device 3 is installed on the mixing tank 1. There is a drive shaft 4 connected to the discharge gate 2, the stirring tank 1 is provided with a drive device 6 for driving the drive shaft 4 to rotate, the stirring tank 1 is provided with an induction device 5 adapted to the end of the drive shaft 4, and also includes a The drive device 6 , the sensing device 5 and the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com