Excircle surface rolling device

A technology of rolling device and outer circular surface, which is applied in the field of surface treatment equipment in mechanical processing, can solve the problems of long contact surface, difficult to achieve precise surface processing of rolling parts, and unstable adjustment of inner processing size of rollers, etc., to achieve Accurate dimensional processing and smooth torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

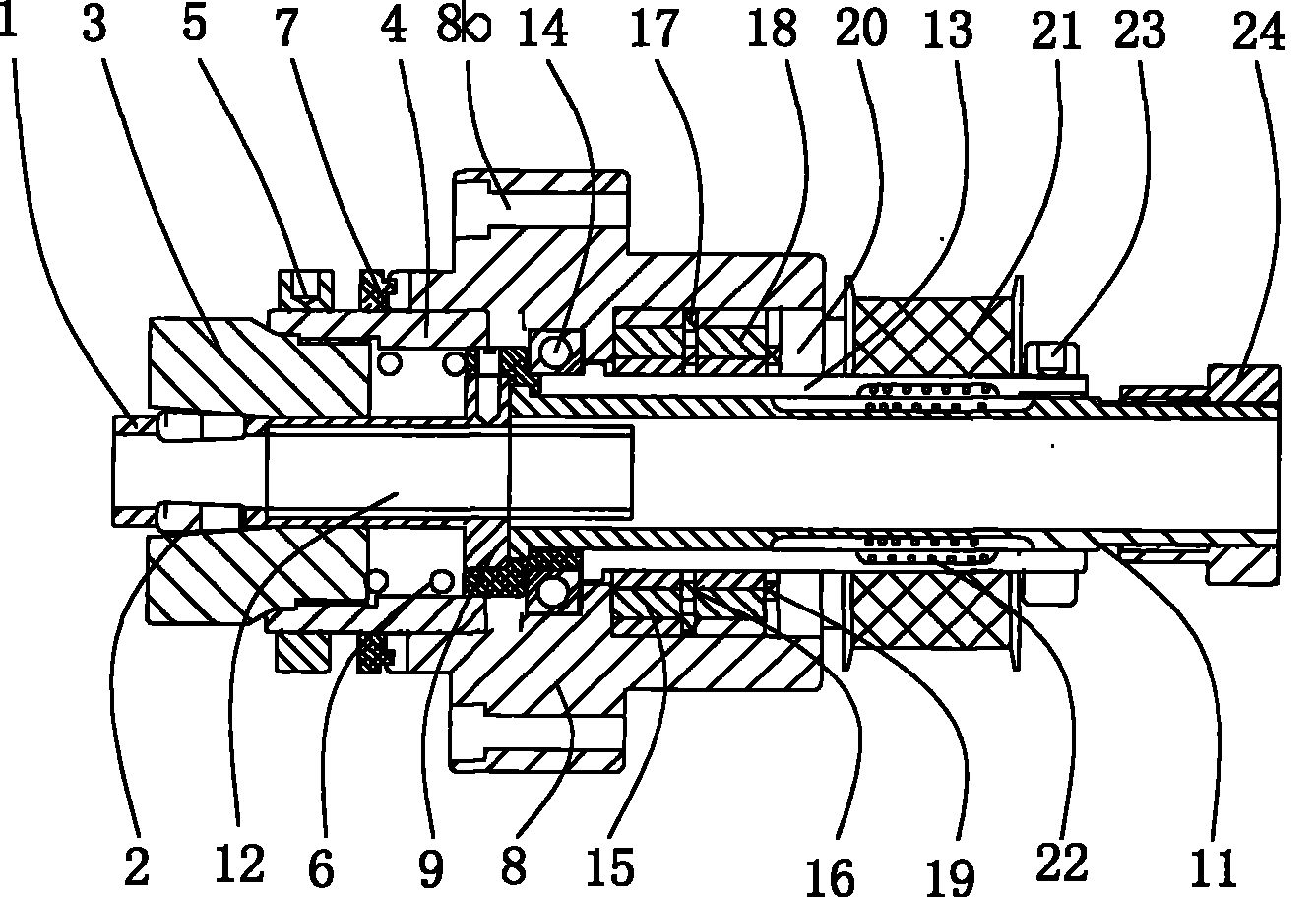

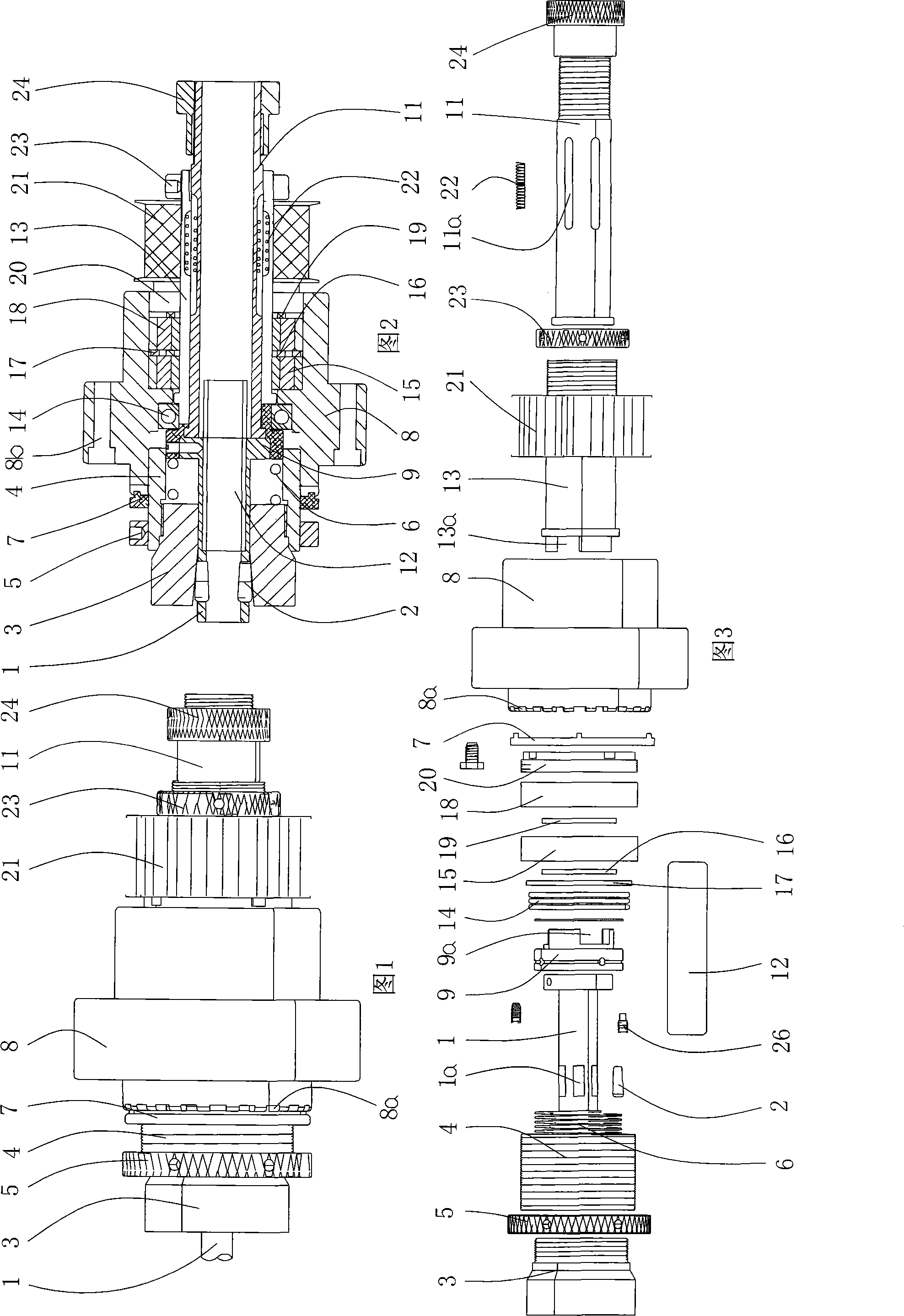

[0021] The embodiment shown in Fig. 1 to Fig. 3, the reference numbers explain: retaining sleeve 1, needle roller groove 1a, plastic transmission sleeve 11, first spring groove 11a, guide sleeve 12, steel transmission sleeve 13, first concave-convex tooth buckle 13a, thrust radial ball bearing 14, first bearing 15, first gasket 16, second gasket 17, second bearing 18, third gasket 19, needle roller 2, locking sleeve 20, synchronous pulley 21 , adjusting spring 22, locking ring 23, spring pressure sleeve 24, pin screw 26, mandrel 3, shell 4, locking ring 5, top pressure spring 6, size adjusting ring 7, fixed main body 8, adjusting teeth 8a, connection Hole 8b, separate transmission sleeve 9, second concave-convex toothed buckle 9a.

[0022] In the embodiment of the present invention, the outer circular surface rolling device includes a fixed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com