Formula and preparation process of a kind of multi-color cabinet board

A cabinet and board technology, applied in the multi-color wood-plastic cabinet board and its preparation field, can solve the problems of easy decomposition of ammonium polyphosphate, easy moisture absorption of products, large amount of flame retardant, etc., and achieves good stability and surface structure. Hard-skinned, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

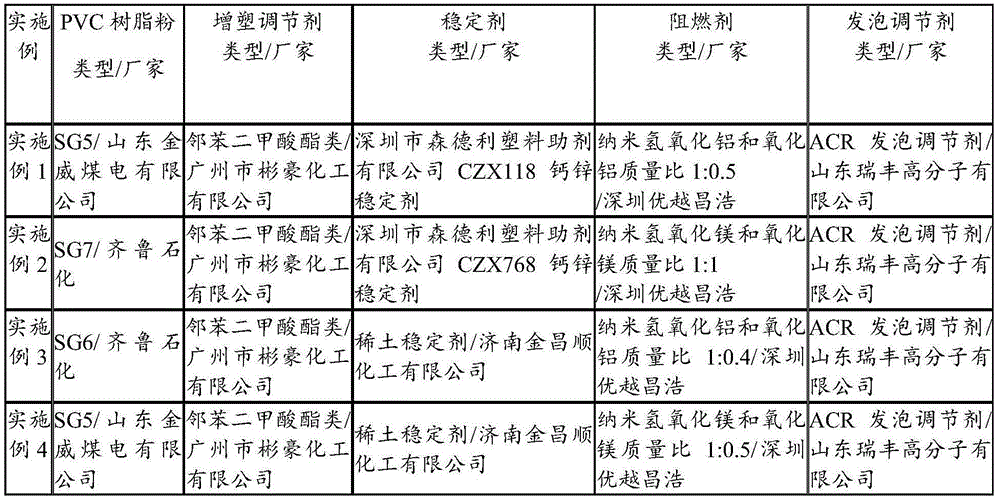

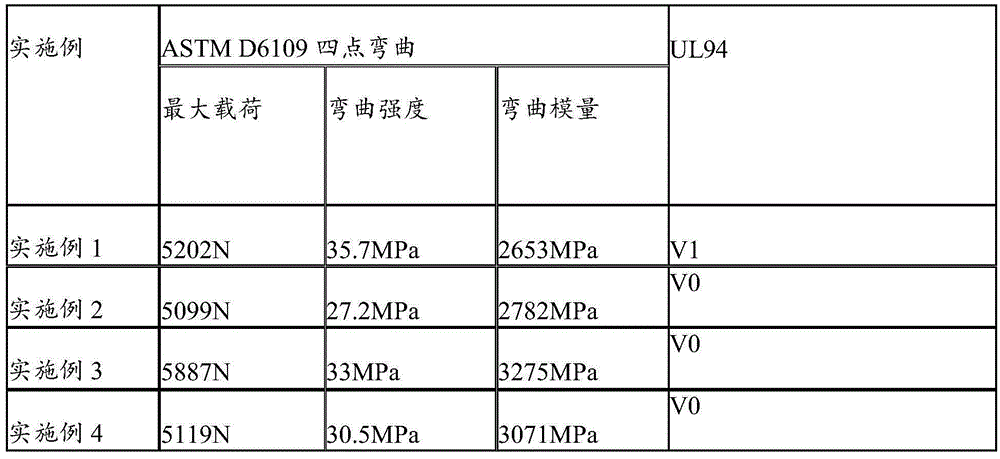

Embodiment 1

[0073] Weigh raw materials according to the following weight ratio:

[0074] PVC resin powder: 100 parts;

[0075] Wood fiber powder: 10 parts;

[0076] Calcium filler: 20 parts;

[0077] Plasticizing regulator: 15 parts;

[0078] Stabilizer: 6 parts;

[0079] Internal and external lubricant: 0.8 parts;

[0080] Stearic acid: 0.5 part;

[0081] Foaming agent: 0.5 part;

[0082] Foam regulator: 8 parts;

[0083] Flame retardant: 40 parts;

[0084] Pigment: 1.5 parts.

[0085] Then utilize the following methods to prepare wood-plastic cabinet panels:

[0086] 1) Mix the lignocellulosic powder with petroleum ether whose quality is 5% of the lignocellulosic powder, seal and keep for 30 minutes, then add a flame retardant to make the lignocellulosic powder completely covered by the flame retardant;

[0087] 2) The mixture prepared in step 1) was dried in a drying oven at 115° C. for 6 hours, degreased and dried, and mechanically ground into 800-mesh particles after drying...

Embodiment 2

[0091] Weigh raw materials according to the following weight ratio:

[0092] PVC resin powder: 100 parts;

[0093] Wood fiber powder: 15 parts;

[0094] Calcium filler: 30 parts;

[0095] Plasticizing regulator: 5 parts;

[0096] Stabilizer: 6 parts;

[0097] Internal and external lubricant: 1.5 parts;

[0098] Stearic acid: 0.7 parts;

[0099] Foaming agent: 1 part;

[0100] Foam regulator: 10 parts;

[0101] Flame retardant: 35 parts;

[0102] Pigment: 1 part.

[0103] Then utilize the following methods to prepare wood-plastic cabinet panels:

[0104] 1) First mix the wood fiber powder with ethanol or petroleum ether whose mass is 1% of the wood fiber powder, keep it sealed for 10 minutes, and then add a flame retardant to make the wood fiber powder completely covered by the flame retardant;

[0105] 2) The mixture prepared in step 1) was dried in a drying oven at 105° C. for 5 hours, degreased and dried, and mechanically ground into 500-mesh particles after drying...

Embodiment 3

[0109] Weigh raw materials according to the following weight ratio:

[0110] PVC resin powder: 100 parts;

[0111] Wood fiber powder: 15 parts;

[0112] Calcium filler: 20 parts;

[0113] Plasticizing regulator: 10 parts;

[0114] Stabilizer: 6 parts;

[0115] Internal and external lubricant: 1.5 parts;

[0116] Stearic acid: 0.7 parts;

[0117] Foaming agent: 1 part;

[0118] Foam regulator: 10 parts;

[0119]Flame retardant: 32 parts;

[0120] Pigment: 1 part.

[0121] Then utilize the following methods to prepare wood-plastic cabinet panels:

[0122] 1) First mix the wood fiber powder with ethanol or petroleum ether whose quality is 5% of the wood fiber powder, seal and keep for 5 minutes, then add a flame retardant, so that the wood fiber powder is completely covered by the flame retardant;

[0123] 2) The mixture prepared in step 1) was dried in a drying oven at 115° C. for 6 hours, degreased and dried, and mechanically ground into 800-mesh particles after dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com