A wood-plastic building formwork produced by recycling waste materials and its preparation method

A construction formwork and wood-plastic technology, which is applied in the field of wood-plastic materials, can solve the problems that the high strength of composite materials cannot be maintained continuously, the short service life of building formwork, and the reduction of plastic usage, etc., to achieve easy realization, high toughness, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The preparation of the lignocellulosic powder of embodiment 1 rubber-modified clay coating

[0068] Take the following raw materials according to the various weight ratios of Table 2: the ultrafine clay adopts the ultrafine white clay of Hebei Jianhui Mining Industry; the vulcanized rubber adopts the nitrile powder rubber P-6387 (group 1 and Group 2) and nitrile rubber NBR P8300 (with acrylonitrile content of 33% and 26% respectively) (group 3 and group 4); the wood fiber powders were respectively wood fiber powders from Longzheng Fiber Co., Ltd., Yuncheng County, Shandong Province.

[0069] Table 2 Preparation of rubber-modified clay-coated lignocellulosic powder

[0070]

[0071] Then prepare modified wood fiber powder according to the following steps:

[0072] 1) first superfine clay is mixed with wood fiber powder;

[0073] 2) adding vulcanized rubber powder, and further mixing evenly to make rubber-modified wood fiber powder.

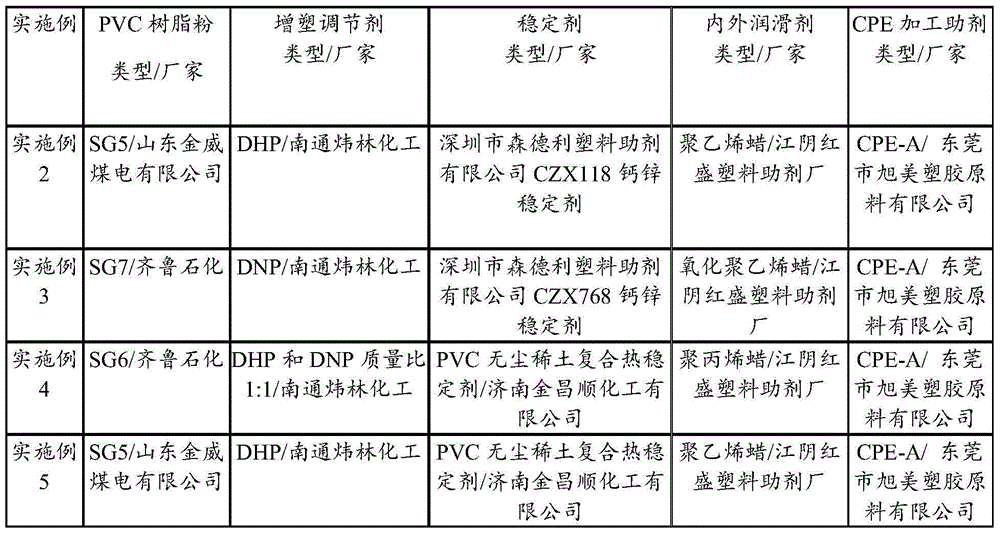

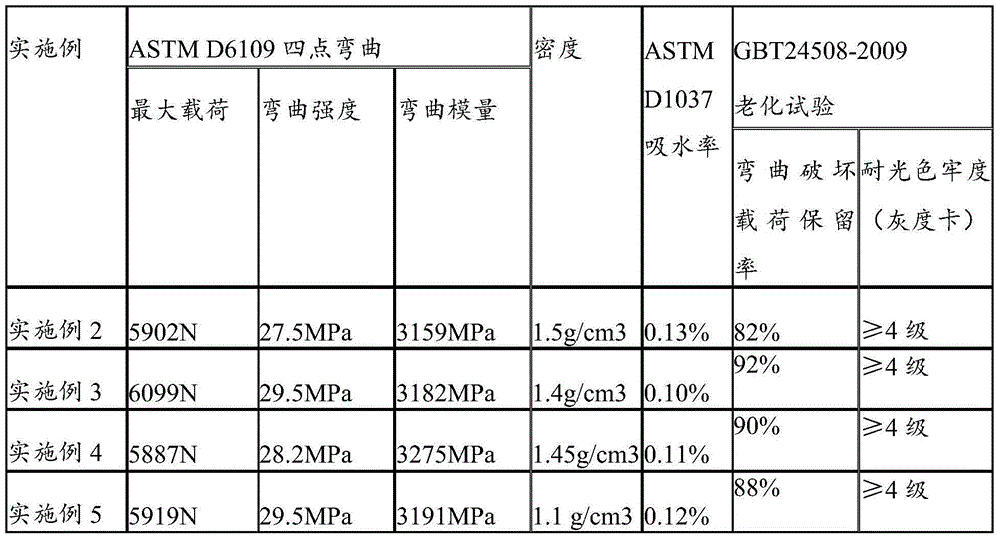

Embodiment 2

[0075] The modified wood fiber powder prepared by Group 1 in Example 1 was used. Weigh raw materials according to the following weight ratio:

[0076] PVC resin powder: 100 parts;

[0077] Modified wood fiber powder: 20 parts;

[0078] Calcium filler: 50 parts;

[0079] Plasticizing regulator: 12 parts;

[0080] Stabilizer: 4 parts;

[0081] Internal and external lubricant: 1 part;

[0082] CPE anti-impact agent: 8 parts;

[0083] Foaming agent: 1.0 parts.

[0084] PVC resin powder: 100 parts;

[0085] Then utilize the following methods to prepare wood-plastic building formwork:

[0086] a) taking modified wood fiber powder and various raw materials;

[0087] b) Add the above-mentioned raw materials into the stirring mixer according to the ratio of parts and mix them, heat to 130°C, then cool to 80°C and release;

[0088] c) Put the mixed raw materials into the extruder, heat them to 180°C and extrude them, shape them with abrasive tools, cool them, draw them, cut th...

Embodiment 3

[0090] The modified wood fiber powder prepared by Group 2 in Example 1 was used. Weigh raw materials according to the following weight ratio:

[0091] PVC resin powder: 100 parts;

[0092] Modified wood fiber powder: 15 parts;

[0093] Calcium filler: 60 parts;

[0094] Plasticizing regulator: 10 parts;

[0095] Stabilizer: 3 parts;

[0096] Internal and external lubricant: 1 part;

[0097] CPE anti-impact agent: 6 parts;

[0098] Foaming agent: 0.8 parts.

[0099] Then utilize the following methods to prepare wood-plastic building formwork:

[0100] a) taking modified wood fiber powder and various raw materials;

[0101] b) Add the above-mentioned raw materials into the stirring mixer according to the ratio of parts and mix them, heat to 150°C, then cool to 80°C and release;

[0102] c) Put the mixed raw materials into the extruder, heat to 140°C to extrude, shape by abrasive tools, cool, draw, cut to length, and cut into plates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com