Bearing device for wheel

A bearing device and wheel technology, applied in the directions of bearings, axles, wheels, etc., can solve the problems of a large number of components, poor component management, and poor workability, and achieve the effect of preventing rolling fatigue life, no noise, and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

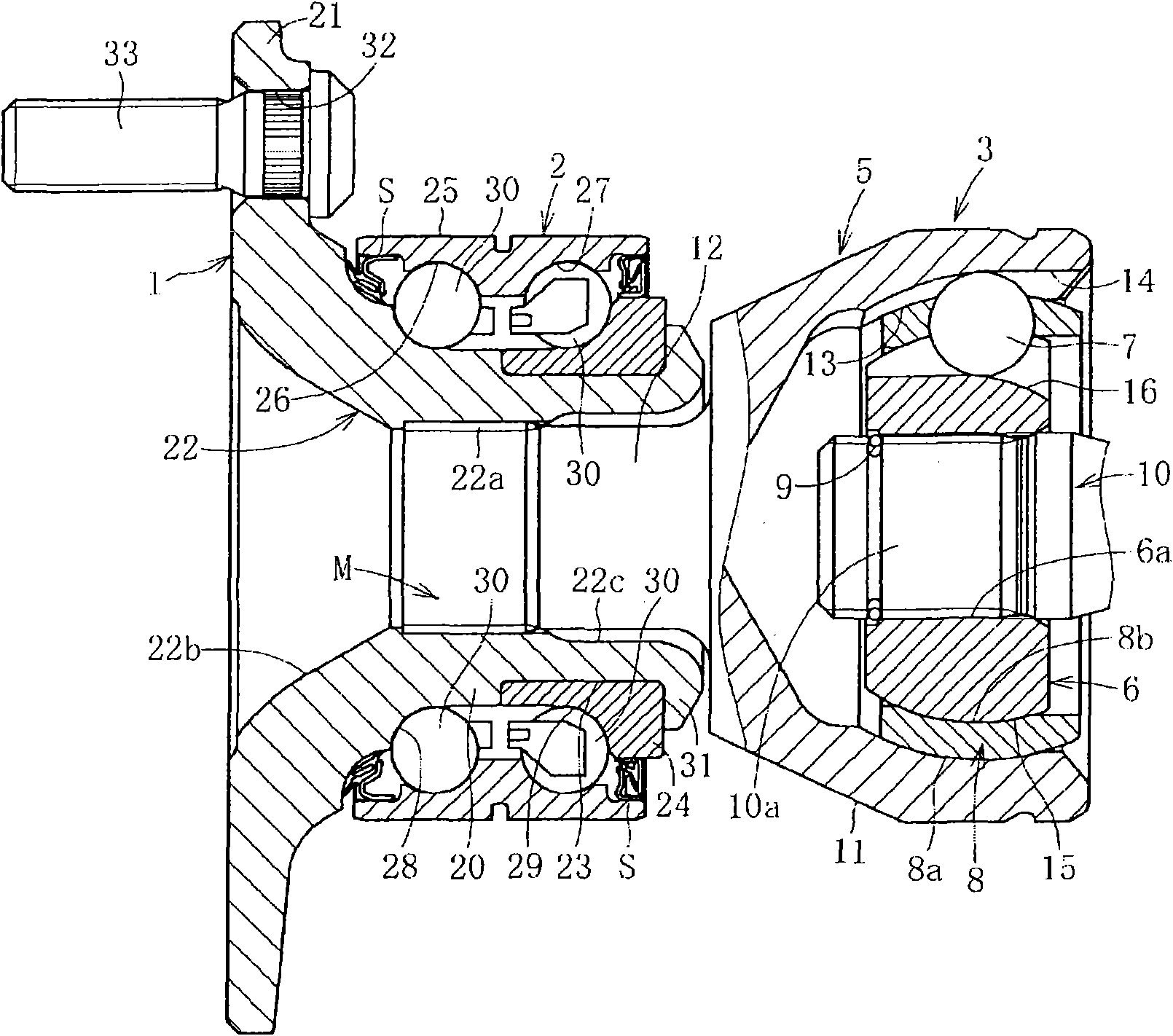

[0062] Below, based on Figure 1 to Figure 12 Embodiments of the present invention will be described. figure 1 A wheel bearing device according to a first embodiment is shown, in which a hub wheel 1 , a plurality of rows of rolling bearings 2 , and a constant velocity universal joint 3 are integrated.

[0063] The main components constituting the constant velocity universal joint 3 are: an outer ring 5 as an outer joint member; an inner ring 6 as an inner joint member arranged inside the outer ring 5; and a plurality of balls 7 for transmitting torque; and a cage 8 interposed between the outer ring 5 and the inner ring 6 to hold the balls 7 . The inner ring 6 is coupled to the shaft 10 by press-fitting the end portion 10a of the shaft 10 into the inner diameter 6a of the shaft hole 6a and spline-fitting, so that torque can be transmitted. In addition, an end portion 10a of the shaft 10 is fitted with a locking wheel 9 for shaft detachment prevention.

[0064] The outer rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com