Heat-dissipating system for clutch, heat-dissipating method for clutch and vehicle

A technology of heat dissipation system and heat dissipation method, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve problems such as easy occurrence of abnormality and affect user experience, and achieve the effect of reducing failure rate, improving good experience, and slowing down thermal recession.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

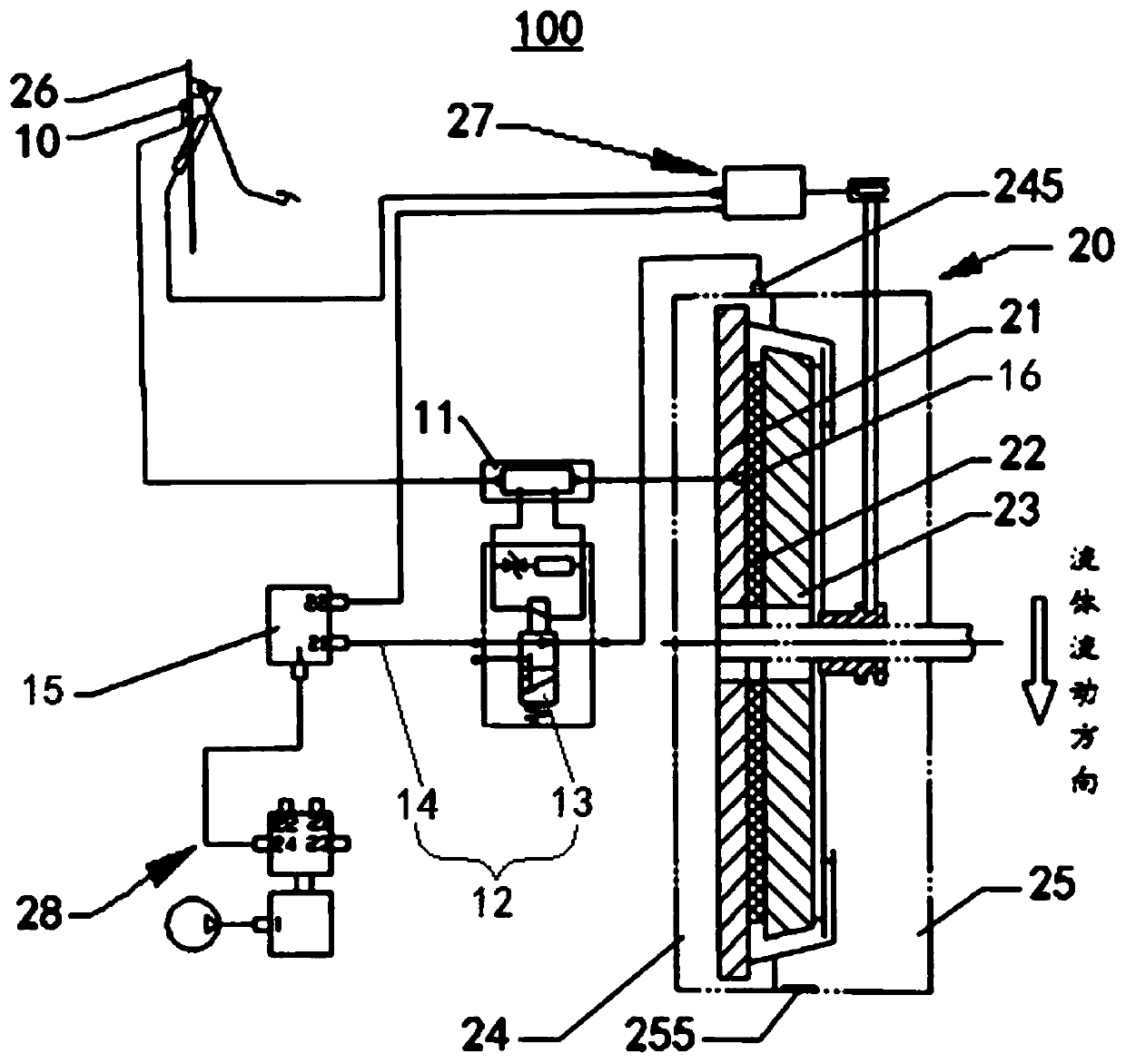

[0040] The embodiment of the present application provides a vehicle, which includes a clutch cooling system 100 , through which the clutch assembly 20 can be automatically cooled.

[0041] The vehicle in this embodiment refers to a heavy vehicle. Of course, it can be understood that the vehicle may also be other vehicles except the heavy vehicle, for example, a truck, a passenger car, etc., and there is no specific limitation.

[0042] The heavy-duty vehicle is matched with a high-pressure clutch. Because the high-pressure clutch will generate more heat when the vehicle starts or shifts gears, the friction material of the clutch will exceed the critical temperature value and the friction coefficient will decrease; In addition, due to the heavy load of the vehicle and bad operating habits, such as high-end starting, etc., the ineffective slippage of the clutch will be aggravated. If the temperature is too high, the pressing force of the clutch will decline thermally and the torq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com