Instant testing platform clip

A test bench and fixture technology, which is applied in the field of instantaneous test bench fixtures, can solve problems such as unreliable workpiece compression, influence test results, and different contact resistances, and achieve stable pressing force, correct test data, and reliable workpiece positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

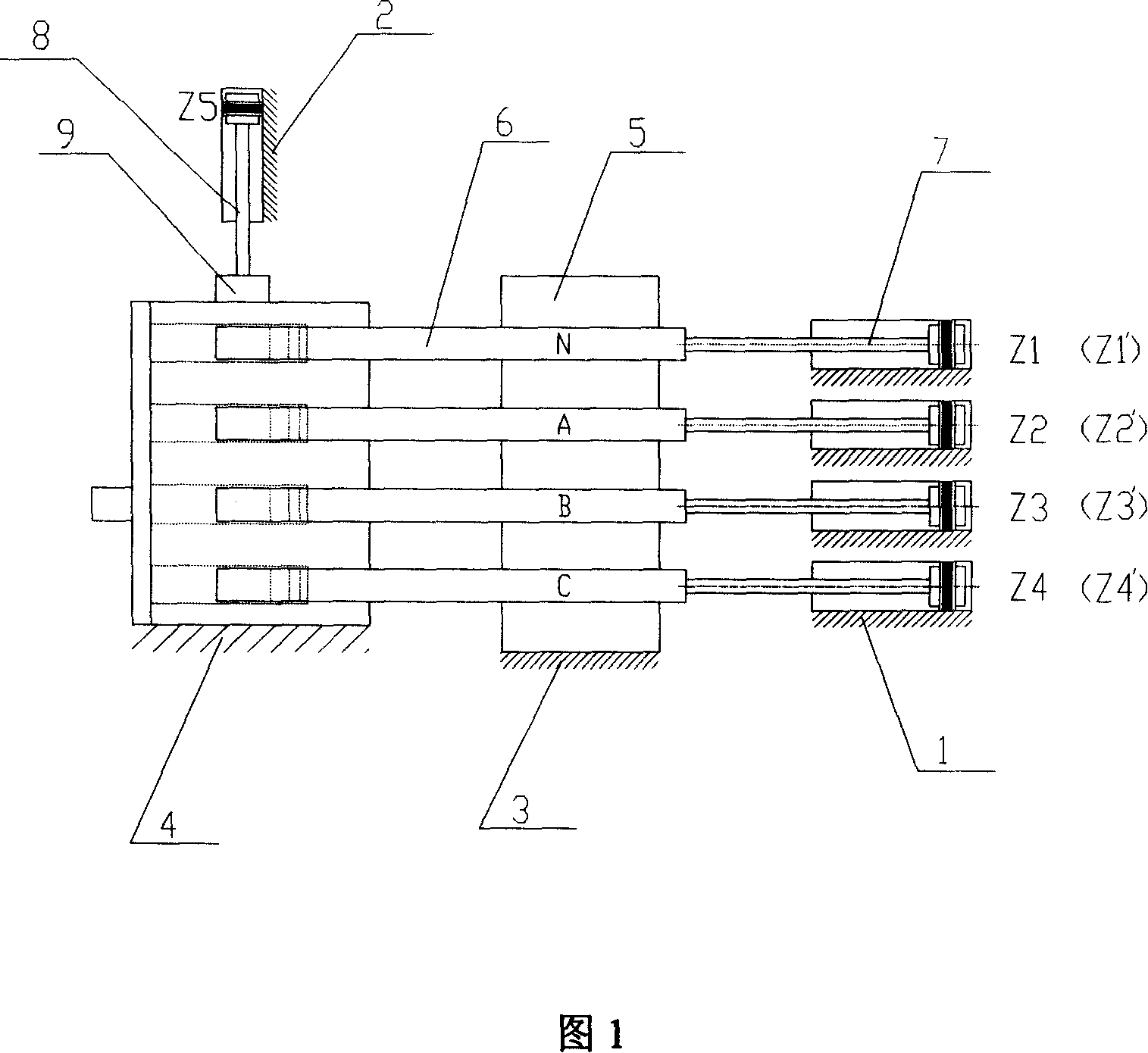

[0022] The present invention will be further described below in conjunction with accompanying drawing.

[0023] As shown in Figure 1, the instantaneous test bench fixture includes a fixture bracket, a guide rail body 5, at least two cylinders 7, four sets of contact claws 6, and a side pressure cylinder 8. The guide rail body 5, at least two cylinders 7, The four sets of contact claws 6 and the side pressure cylinders 8 are all arranged on the fixture bracket. The at least two cylinders 7 are connected to the four sets of contact claws 6 respectively, and the pressure blocks 9 are arranged on the side pressure cylinders 8 .

[0024] Described cylinder 7 is four, and these four cylinders 7 are respectively connected four groups of contact claws 6; Described fixture support comprises cylinder support one 1, cylinder support two 2, rail body support 3, workpiece support 4, described The cylinder support one 1, the guide rail body support 3, and the workpiece support 4 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com