Small-tooth-difference high-precision cycloid gear speed reducer

A cycloid gear and reducer technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of affecting the deceleration accuracy of the reducer, inability to achieve high transmission ratio, cycloid wheel and needle roller clearance, etc. problems, to achieve the effect of saving installation space, high transmission ratio, and realizing transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

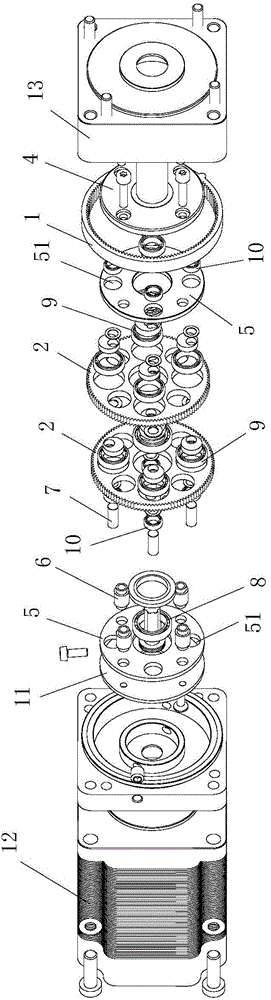

[0041] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

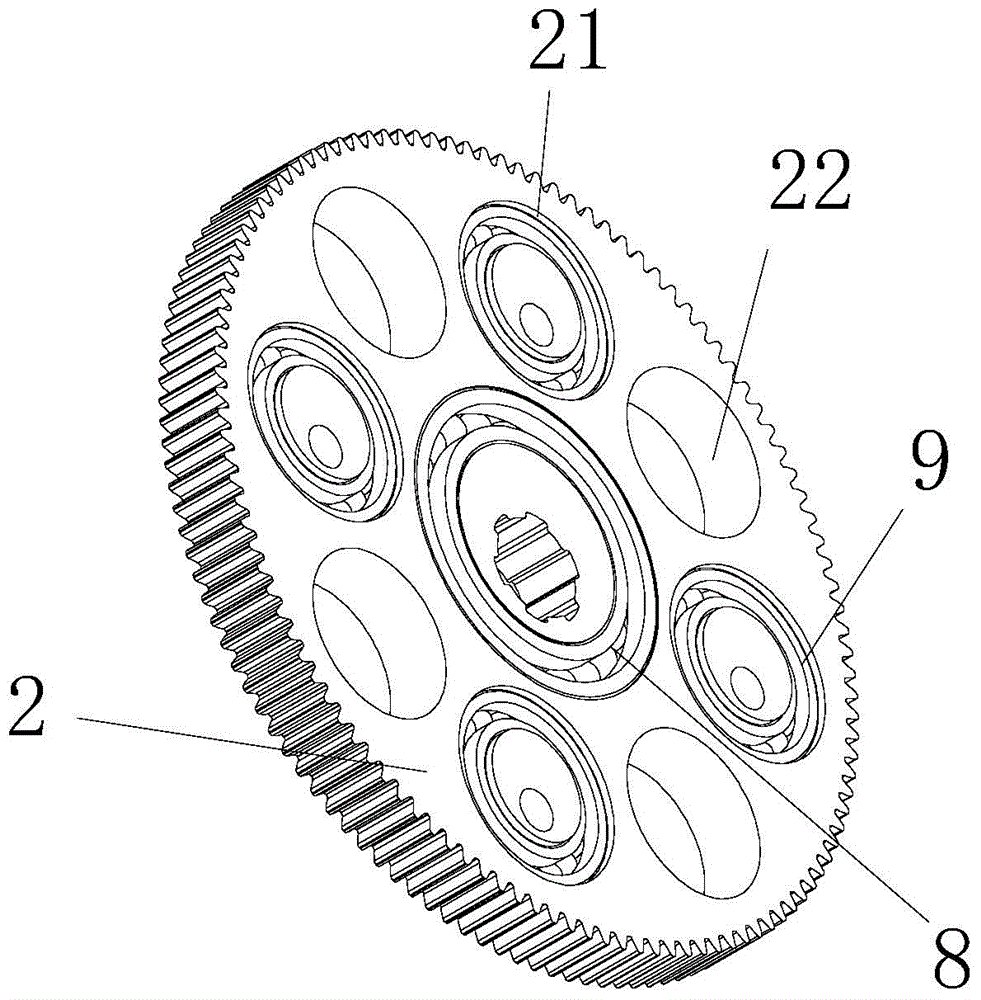

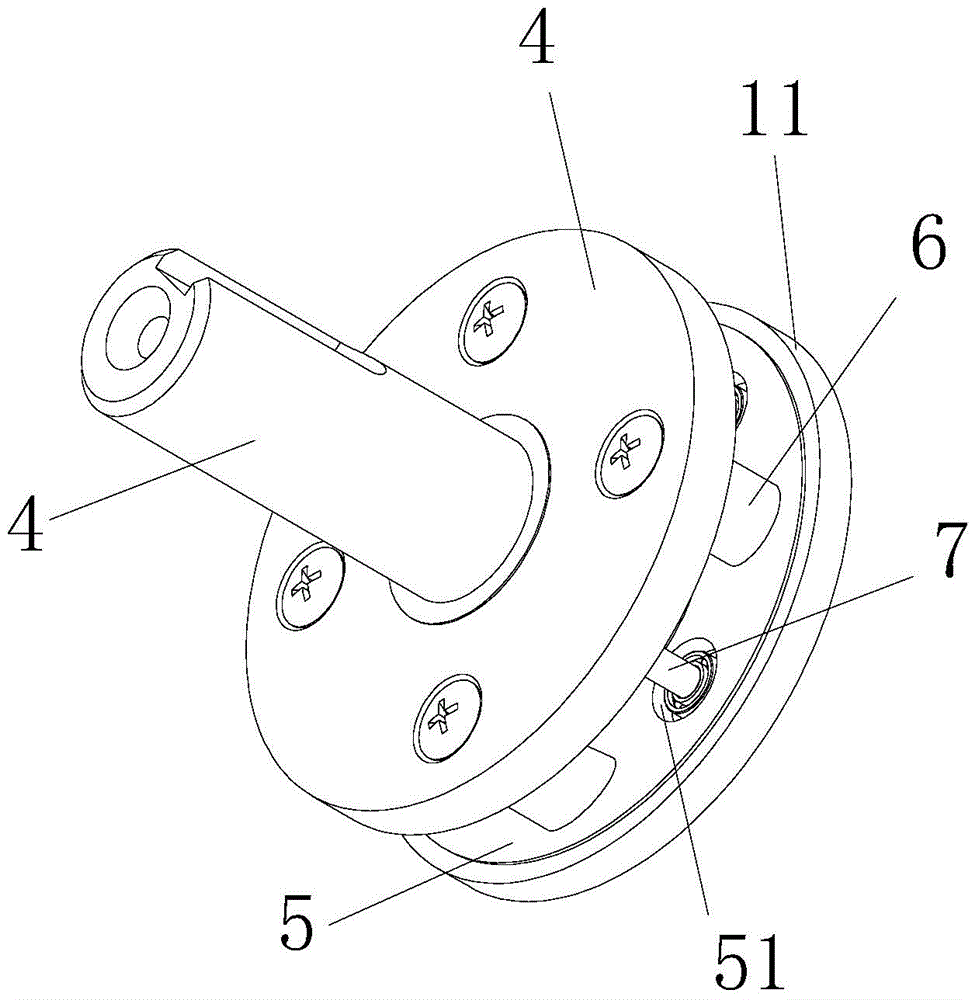

[0042] Such as Figure 1 to Figure 5 As shown, a high-precision cycloidal gear reducer with less tooth difference includes an input shaft 3, a reduction mechanism and an output shaft 4, and the reduction mechanism is respectively connected to the input shaft 3 and the output shaft 4; the reduction mechanism includes a ring gear 1, at least one The cycloid gear 2 located in the ring gear 1, the cage for rotation and at least one eccentric shaft 7 for cooperating with the cycloid gear 2 and driving the cage to rotate, the output shaft 4 is fixedly connected with the cage.

[0043]The cycloid tooth piece 2 is eccentrically arranged on the input shaft 3 through the first eccentric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com