Clutch with pressed-in drive ring

A clutch and tooth technology, applied in the field of clutches of motor vehicles, can solve problems such as reducing assembly complexity, and achieve the effects of reducing complexity, increasing operational reliability, and stabilizing torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

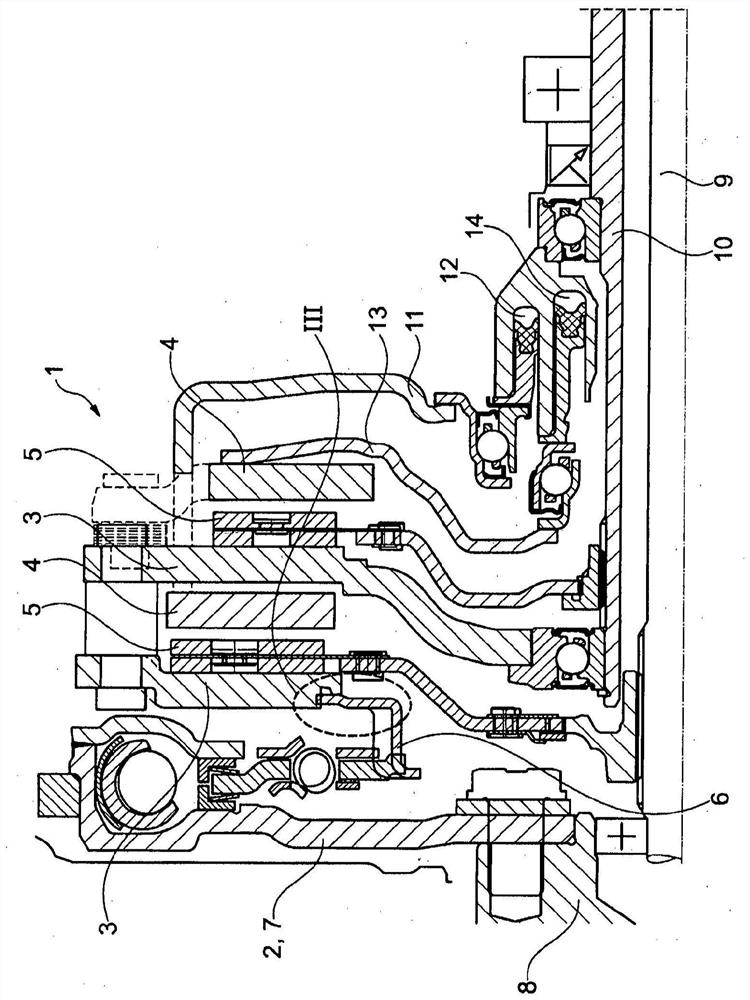

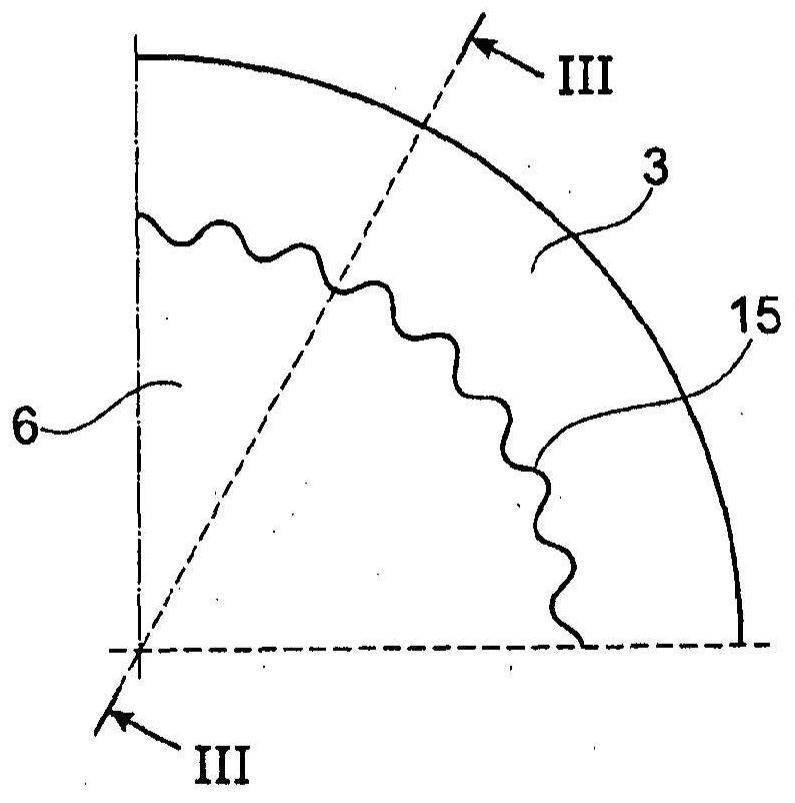

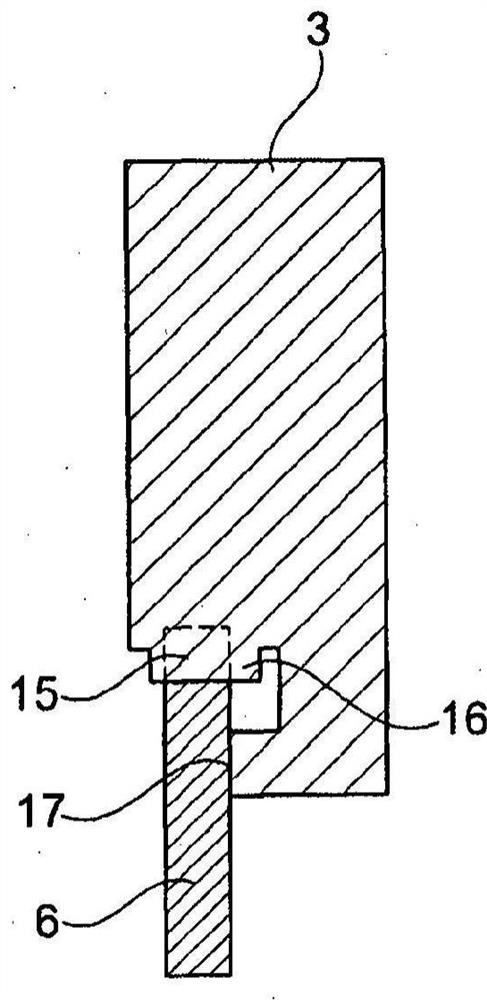

[0038] figure 1A clutch 1 for a motor vehicle is shown. In this case, the connection part 2 is connected to the counterplate 3 . The clutch 1 in the case of the present invention is designed as a double clutch and therefore has a plurality of counterplates 3 . By means of one or more pressure plates 4 (also referred to as pressure plates), an axial force is exerted on the clutch disc 5 such that torque can be transmitted. The drive toothed ring 6 is arranged between the interface part 2 and the counterplate 3 .

[0039] In this example, the interface part 2 is designed as a flywheel 7 on the engine side in the form of a dual-mass flywheel. A drive ring 6 is provided for accommodating the counterpressure disk 3 arranged on the transmission side next to the engine-side flywheel 7 between the engine-side flywheel 7 and the clutch plate.

[0040] The clutch 1 according to the invention transmits torque between the crankshaft-fixed part 8 and the transmission-fixed solid shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com