Bearing device for wheel, method of assembling bearing device for wheel, assembly constructed from bearing device for wheel and from drive shaft, and method of assembling assembly

A technology of a bearing device and an assembly method, which is applied in the direction of bearings, axles, wheels, etc., can solve the problems of not being able to press the outer joint parts, the difficulty of stable pressing, and the small area of the pressing part, so as to eliminate shaking and stably press in operation, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

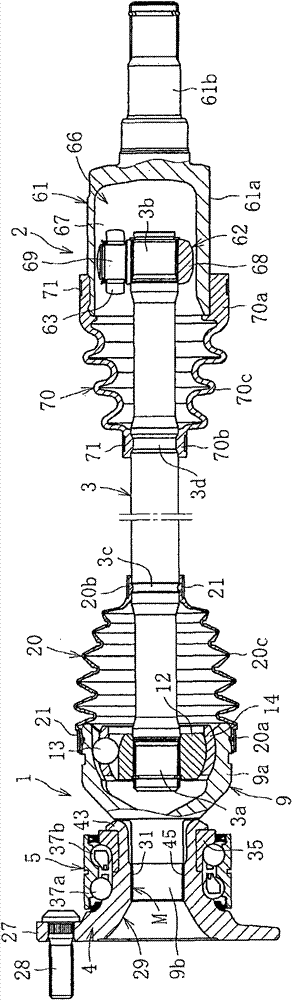

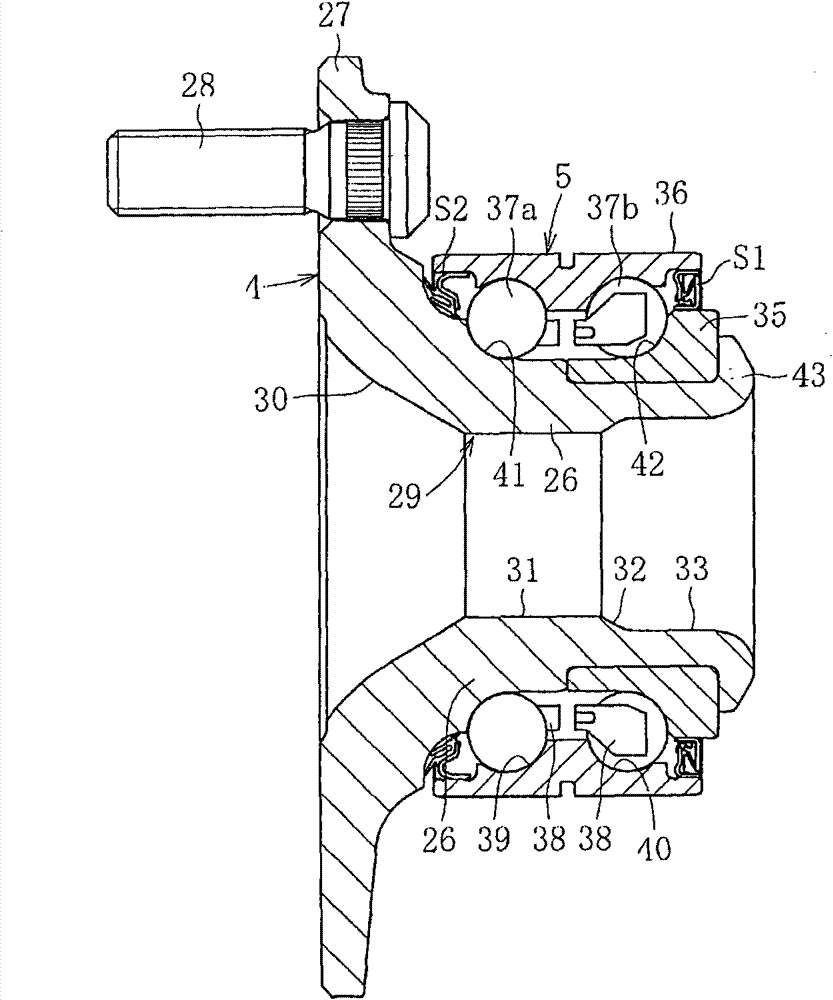

[0077] Below, according to Figure 1~Figure 10 The embodiment of the present invention is explained. figure 1 Represents a combination of a wheel bearing device and a drive shaft. The wheel bearing device has a constant velocity universal joint 1 on the outboard side, a constant velocity universal joint 2 on the inboard side, and these constant velocity universal joints 1, 2 Connected shaft 3. In this case, in the outboard side, the hub 4, the multi-row wheel bearing 5, and the constant velocity universal joint 1 are connected to form a wheel bearing device. When assembled on a car or other vehicle, the outer side of the vehicle is called the outboard (left side of the figure), and the one that constitutes the inner side of the vehicle when assembled on a car or other vehicle is called the inner side of the vehicle (right side of the figure) ).

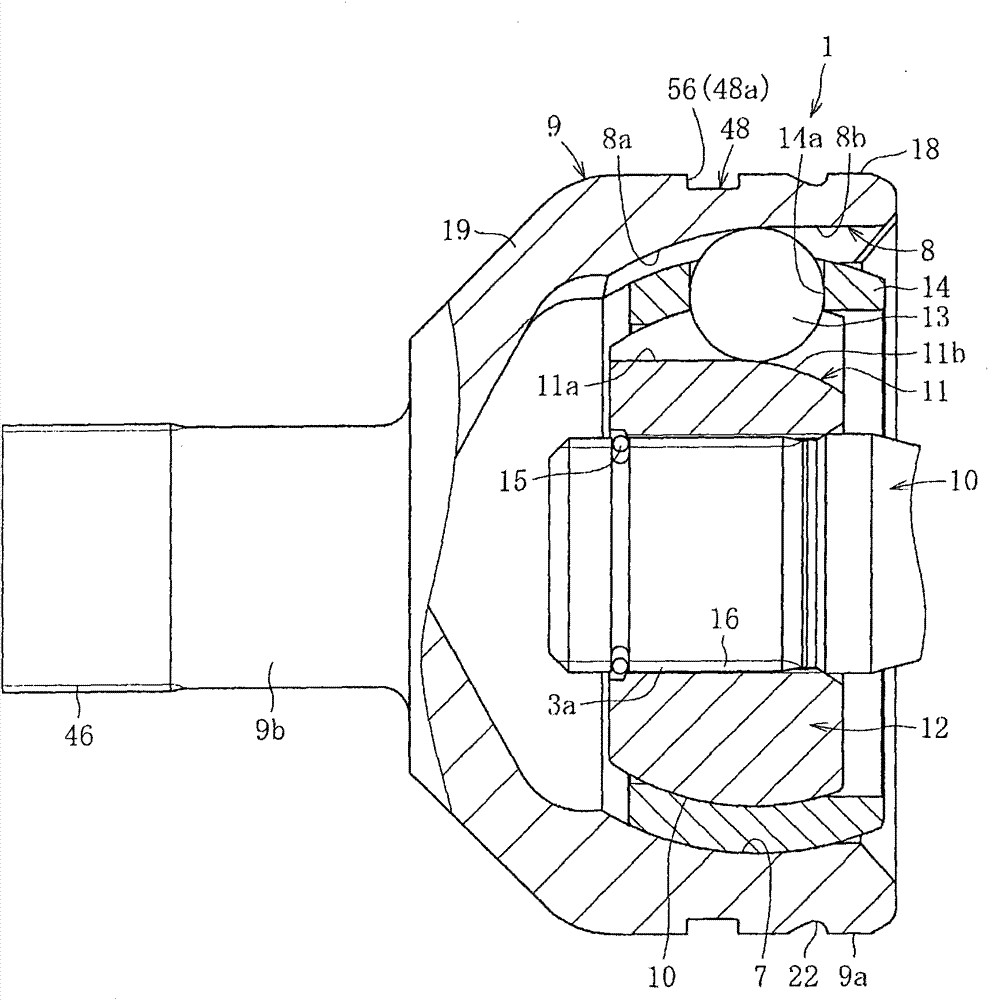

[0078] Constant velocity universal joint 1 on the outboard, such as figure 2 Shown are: the outer joint member 9 with a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com