Vertical visual oil film power test device

A testing device and oil film technology, which is applied in the testing of machine gears/transmission mechanisms, etc., can solve problems such as excessive adjustment clearance, difficulty in ensuring accuracy, and slow progress in experimental research, and achieve uniform oil film thickness, good centering, and torque transmission stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

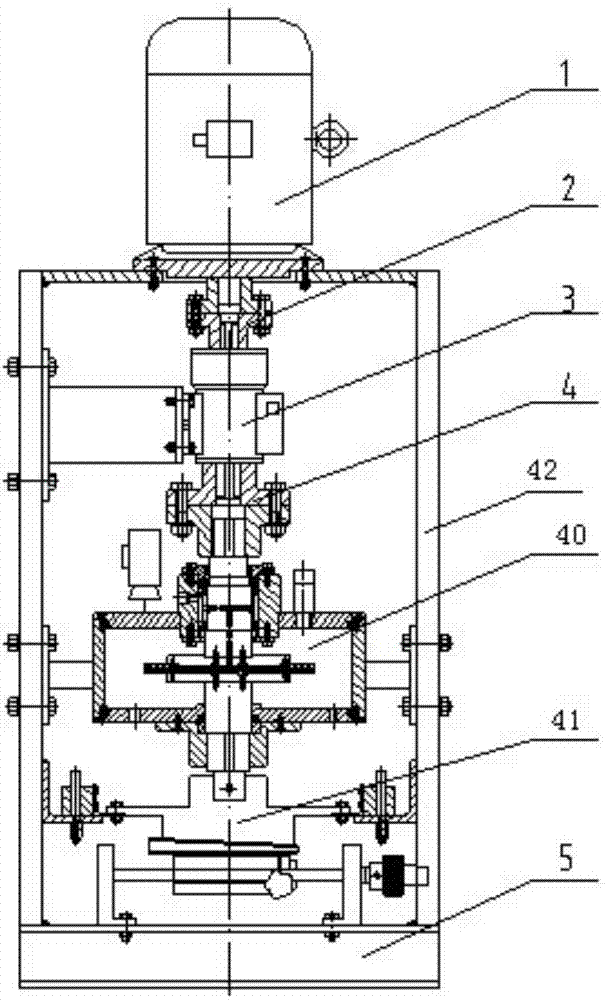

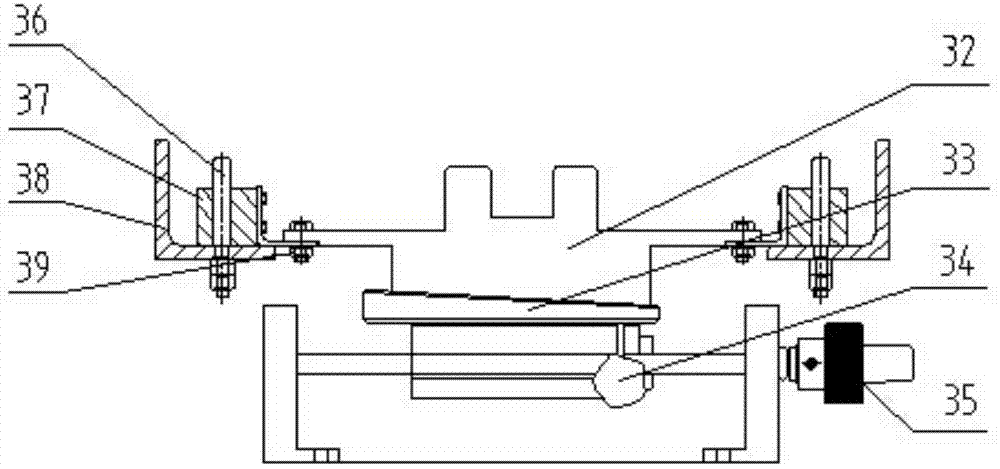

[0021] A vertical visual oil film power test device mainly includes a driving force part, a liquid viscous main engine, an oil film thickness adjustment device, a support, and the like.

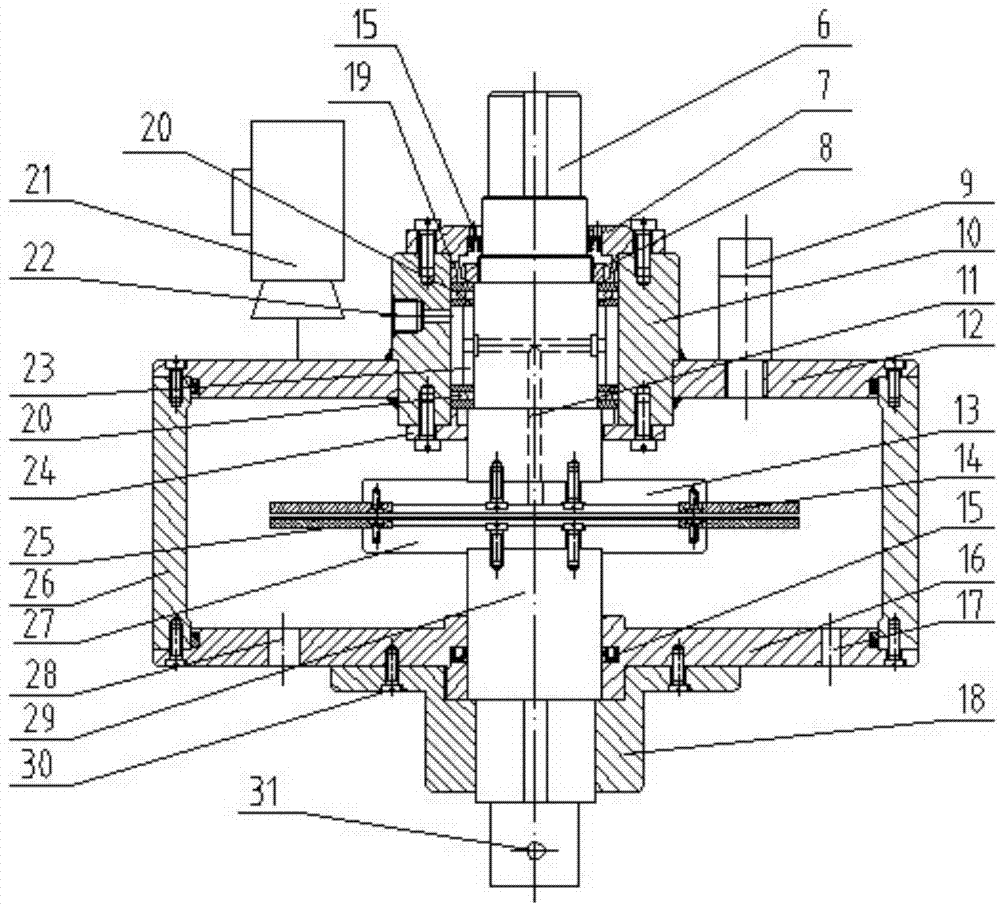

[0022] The motive force part mainly includes a motor, a first shaft coupling, a torque tachometer, a second shaft coupling, an input shaft of a hydraulic viscous main engine, and the like. The output end of the motor is connected to the input end of the torque tachometer through the first coupling, and the output end of the torque tachometer is connected to the input shaft of the hydraulic viscose main engine through the second coupling.

[0023] The liquid viscous main engine mainly includes an input shaft, an upper end cover of a bearing, a lock nut, a sleeve, a sleeve stopper, a plane thrust bearing, a bearing stopper, an upper case cover, an active plate support, an acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com