Low-speed rotating original taste extrusion juicer

The technology of a juicer and a juicer is applied in the direction of household machinery, household appliances, and applications for filtering food, and can solve the problems of affecting the service life of the juicer, artificially exerting greater pressure, and the color of fruit and vegetable juices becoming darker, etc. Achieve the effect of light weight, low noise and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

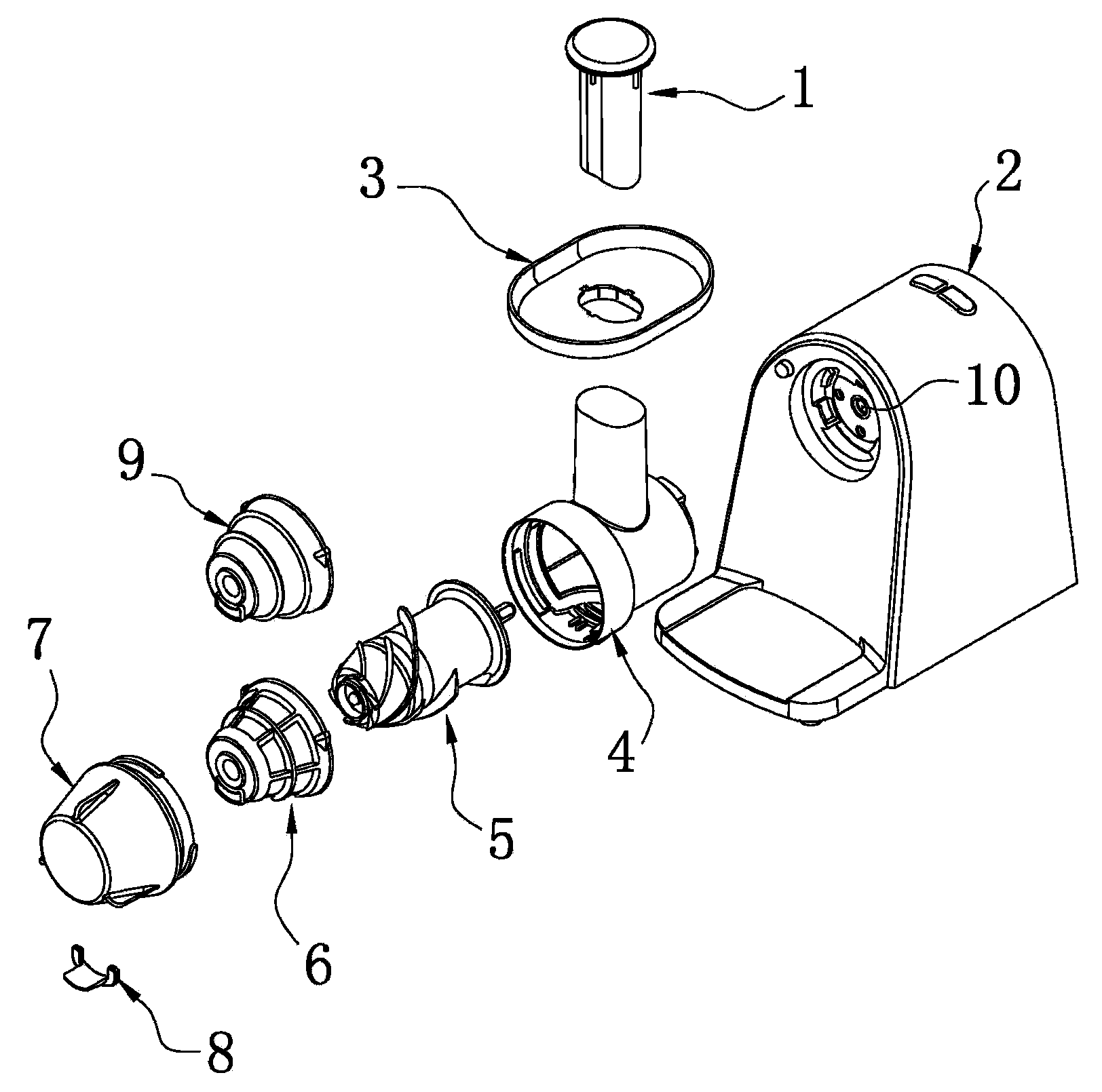

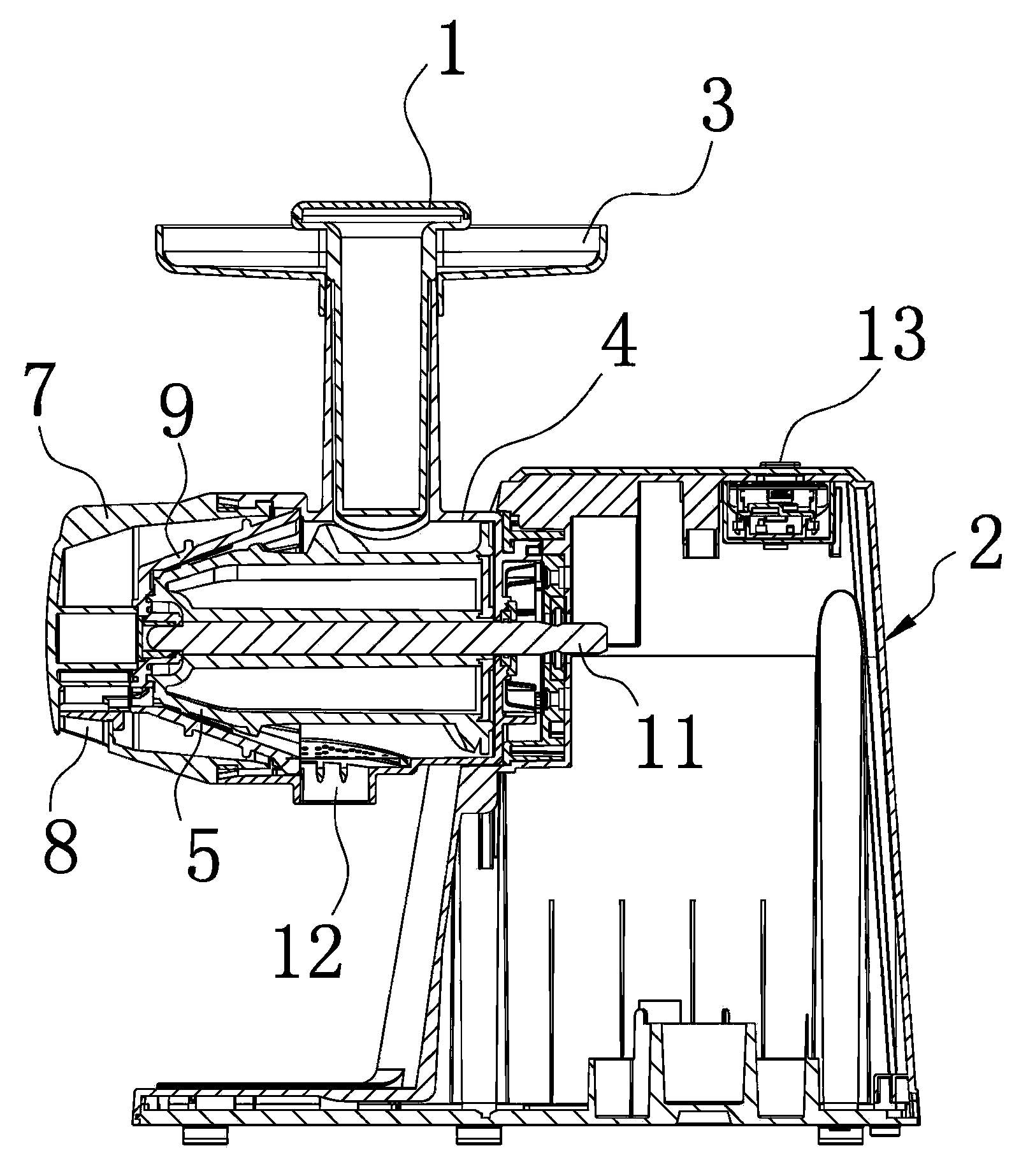

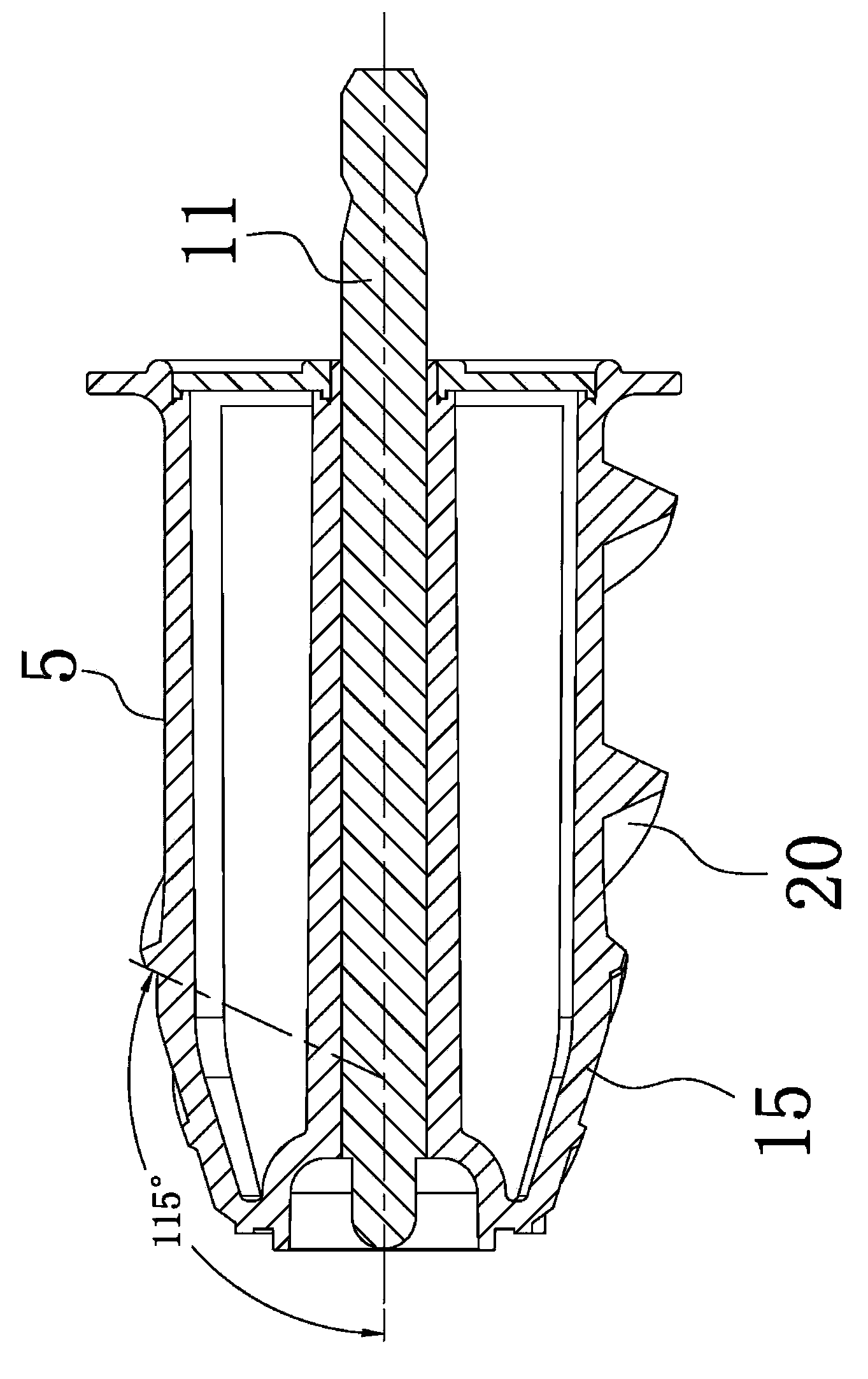

[0025] refer to Figure 1-Figure 4 . In the embodiment described below, the slow-rotating original-flavor squeeze juice extractor includes a screw propeller 5 and a juice separator assembled on the main shaft of the induction DC motor of the horizontal base pressing assembly 2 through the tray feeding cylinder. Wherein the push rod 1, the horizontal base power assembly 2, the tray feeding cylinder 3 and the fruit juice separator 6 are existing mature technologies, and will not be described in detail here. The tail end of the screw propeller 5 cylinder is formed with a flange, and the center is formed with a shaft hole. The motor connecting shaft 11 passes through the shaft hole and is inserted into the bearing of the motor rotation shaft hole 10 of the horizontal base press assembly 2 in a rotating manner. , connected to the induction DC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com