Coaxial magnetic gear

A magnetic gear, coaxial technology, applied in electrical components, electromechanical devices, etc., can solve the problems of restricting the application of coaxial magnetic gears, reducing the mechanical bearing force of the rotor, and low torque density of magnetic gears, achieving convenient processing and manufacturing, improving The effect of high mechanical endurance and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

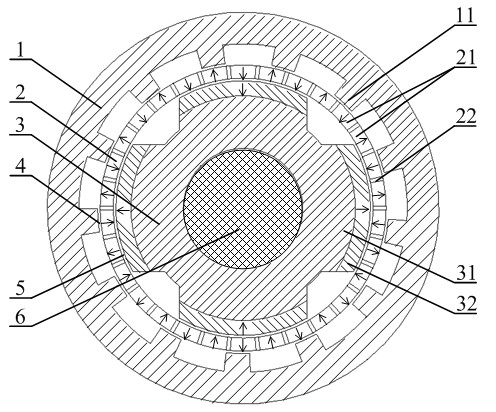

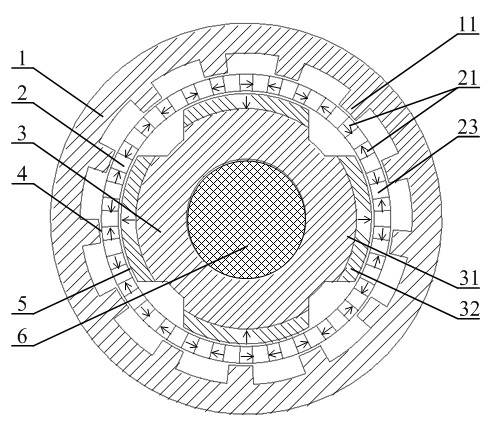

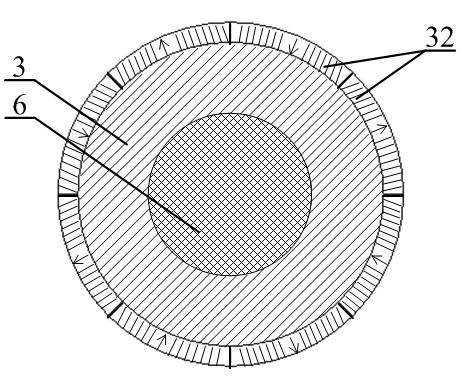

[0026] The coaxial magnetic gear of the present invention comprises an outer rotor 1, a stationary magnetic ring 2, an inner rotor 3 and a rotating shaft 6 arranged from outside to inside with a coaxial center; the outer rotor 1 is an annular magnetizer, and on its inner ring Equidistantly arranged outer rotor salient poles 11 are provided; the stationary magnetic ring 2 is an annular component composed of magnetic ring permanent magnets 21 arranged at equidistant intervals, and a non-conductive magnet is arranged between two adjacent magnetic ring permanent magnets 21. Block 22, the magnetic ring permanent magnet 21 is radially magnetized, and the magnetization direction of adjacent permanent magnets is opposite; the inner rotor 3 is fixed on the rotating shaft 6, and the outer ring of the inner rotor is provided with inner rotors arranged at equal intervals. The rotor permanent magnet 32 ; the outer air gap 4 is provided between the outer rotor salient pole 11 and the stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com