Patents

Literature

138results about How to "Guaranteed fixed strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

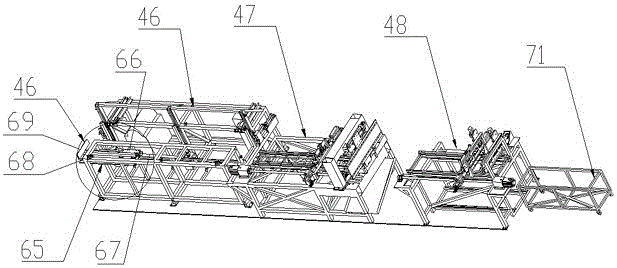

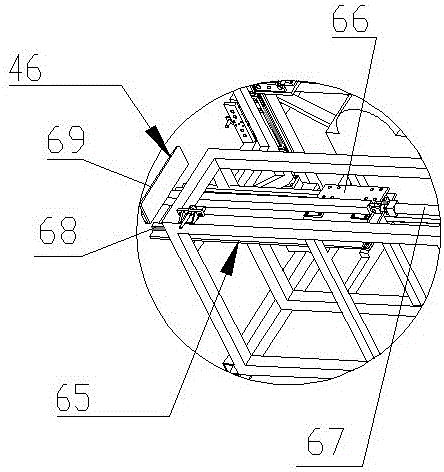

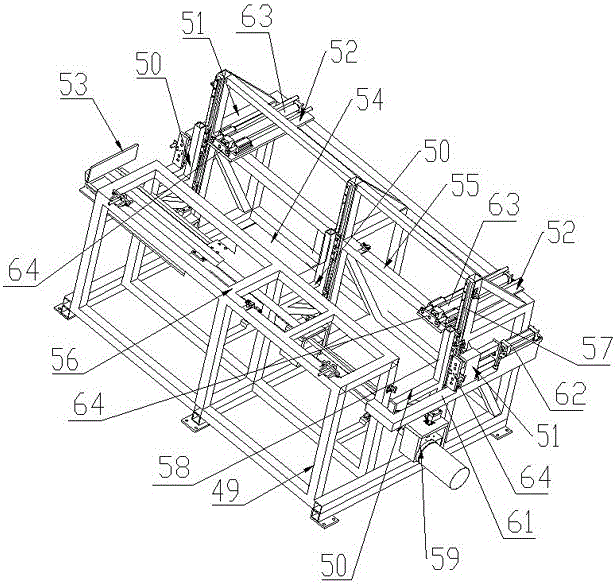

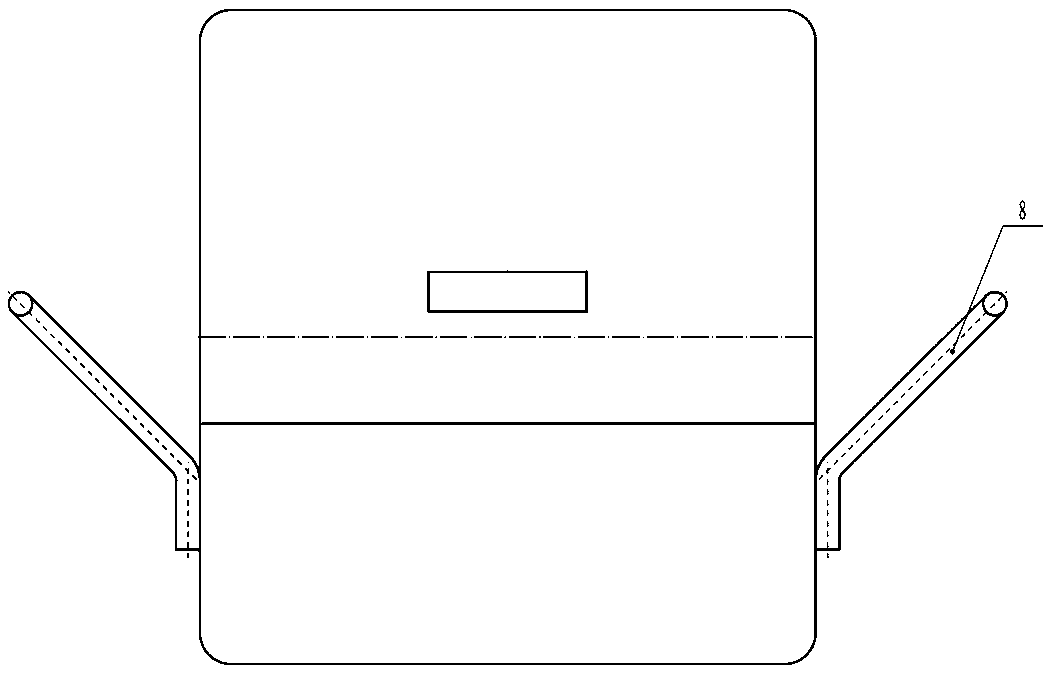

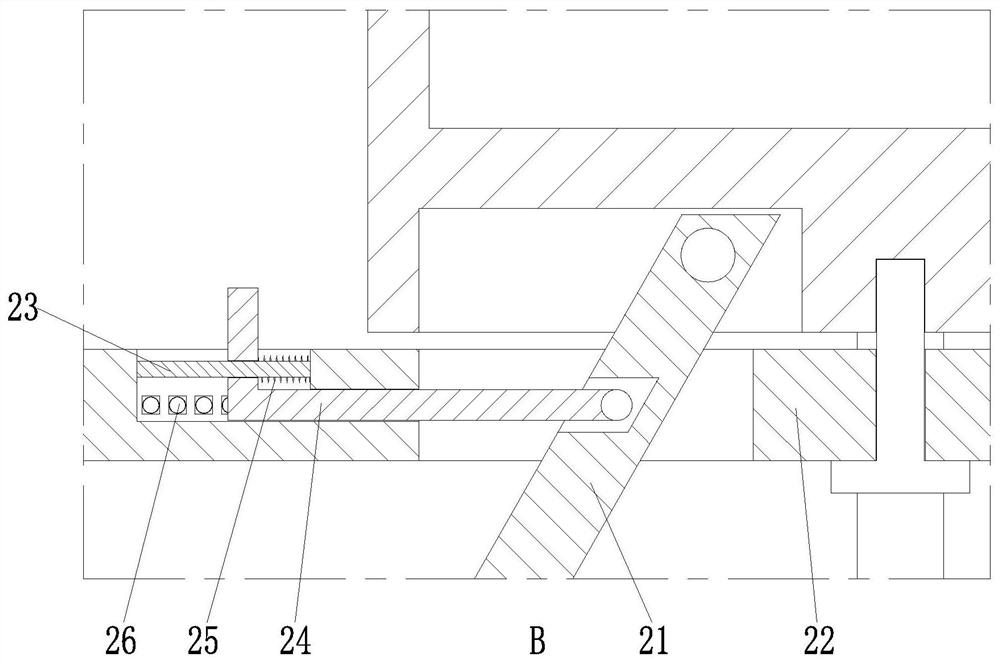

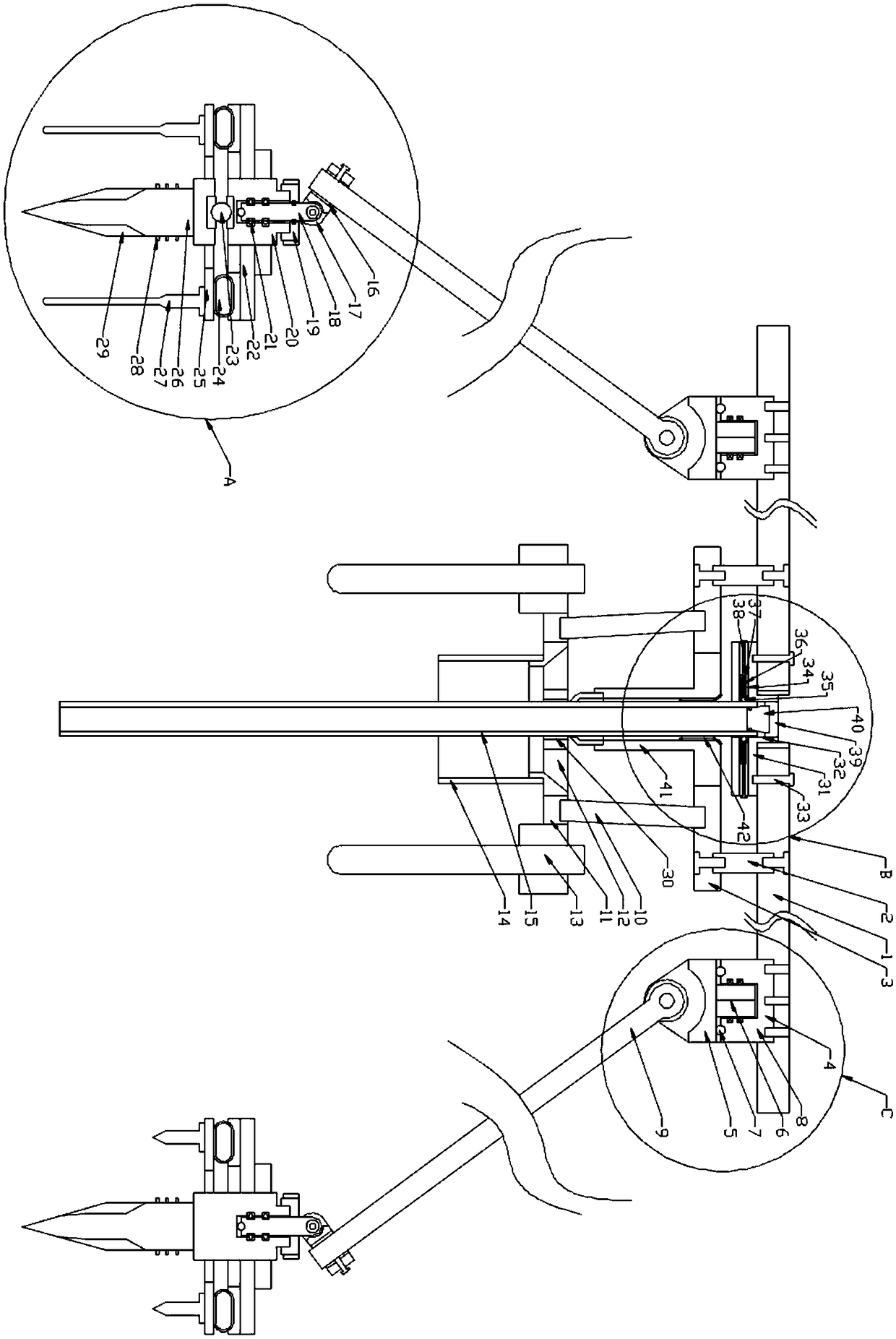

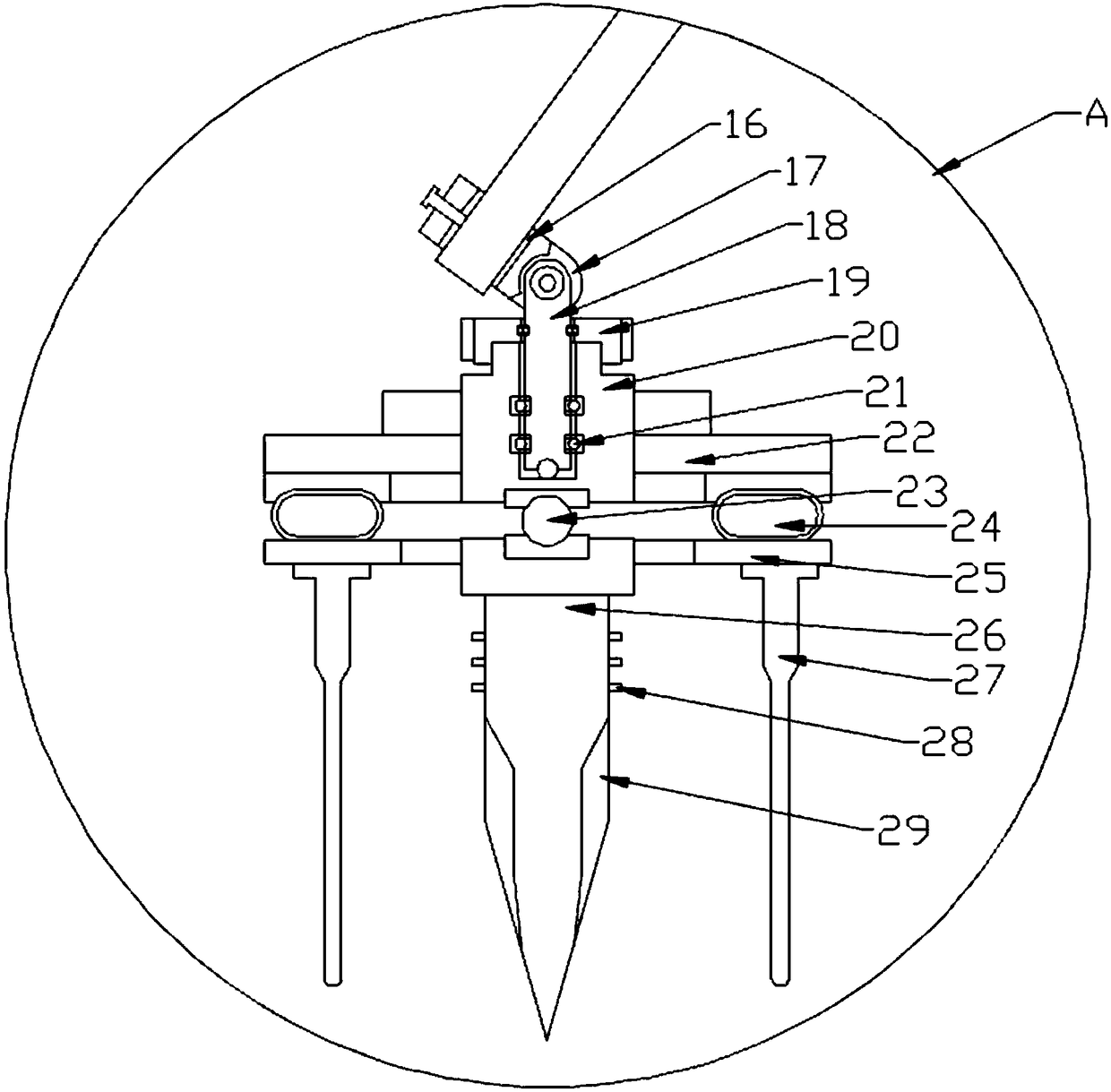

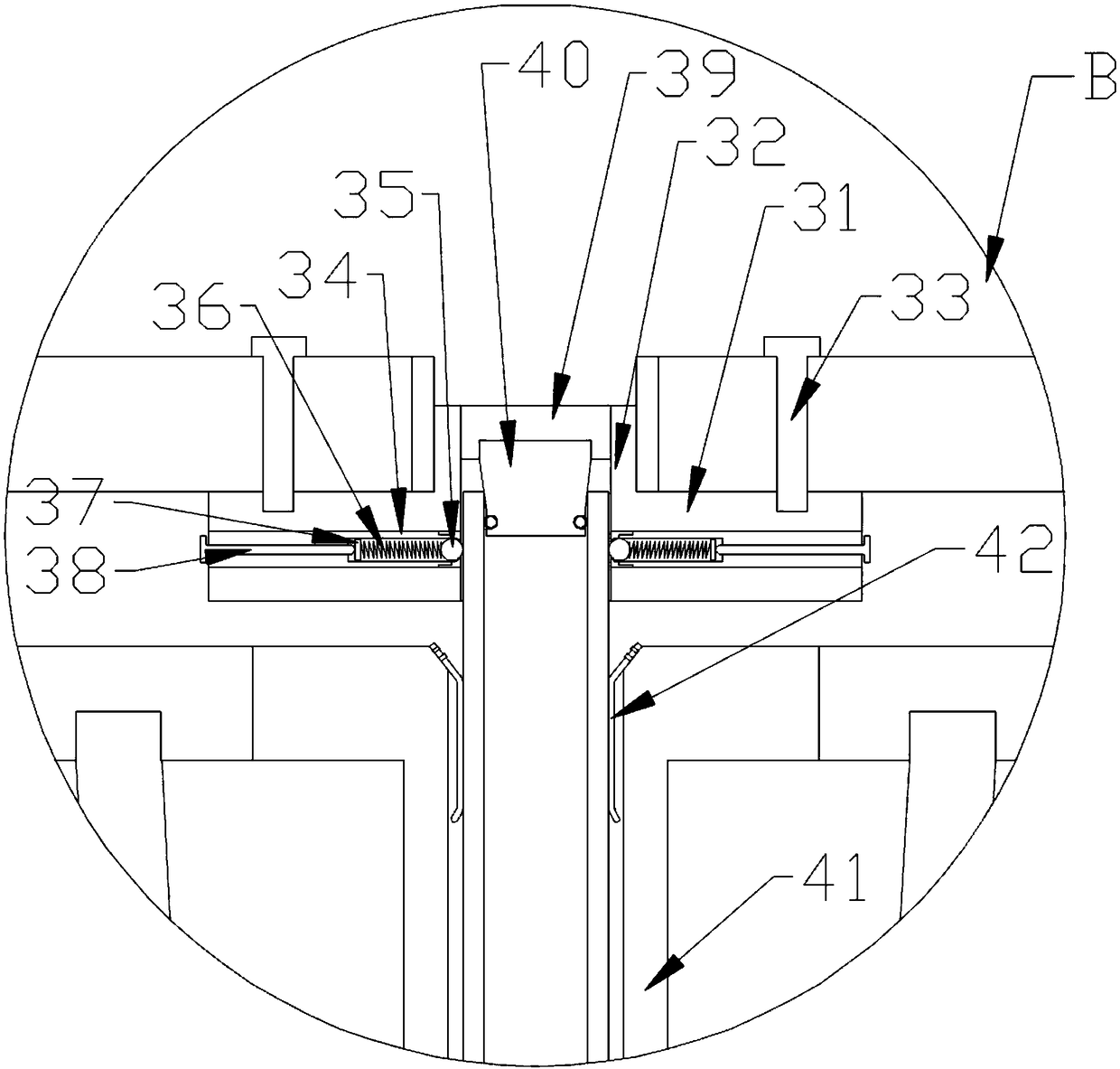

Automatic assembly line for feeding, cutting and punching pipe automatically

ActiveCN106271629AHigh degree of automationImprove cutting efficiencyMetal sawing devicesOther manufacturing equipments/toolsPunchingAssembly line

The invention discloses an automatic assembly line for feeding, cutting and punching a pipe automatically. The automatic assembly line comprises a front feeding mechanism, a middle feeding and cutting mechanism and an automatic punching and unloading mechanism which are arranged in sequence from left to right; the front feeding mechanism comprises a first supporting frame, a lifting mechanism, a pipe clamping mechanism, a transverse pushing mechanism and a longitudinal pushing mechanism; the middle feeding and cutting mechanism comprises a second supporting frame, a first clamping conveying mechanism, an automatic cutting mechanism and an automatic clamping mechanism; the automatic punching and unloading mechanism comprises a third supporting frame, a second clamping conveying mechanism, a drilling clamping mechanism and two sliding drilling mechanisms which are positioned on the right side of the second clamping conveying mechanism and are arranged at an interval. The automatic assembly line can realize automatic feeding, and is low in labour intensity and high in work efficiency; the pipe can be cut automatically; the cutting quality is good; high-efficiency cutting operation of one or more pipes can be realized synchronously; the punching operation can be performed on the two ends of the pipe simultaneously; the function of clamping a plurality of pipes at one time and punching the pipes in sequence can be realized.

Owner:JIANGSU JINPENG VEHICLE CO LTD

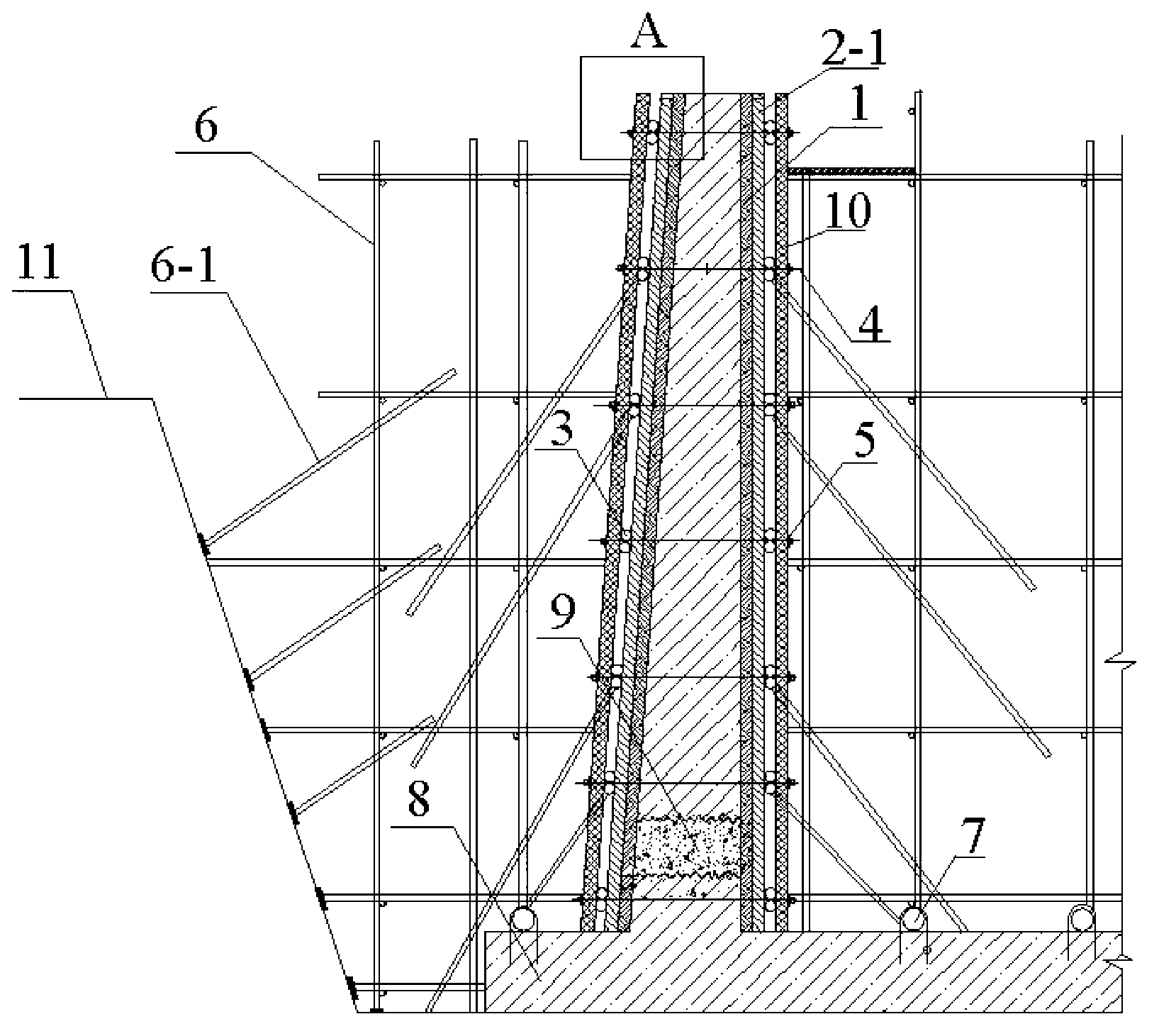

Construction method for one-time formation of concrete pool wall

ActiveCN103321421AGood structural integrityEnsure integrity and compactnessBuilding material handlingBulk storage containerWater leakageSupport system

The invention discloses a construction method for one-time formation of a concrete pool wall. The method includes the steps of erection of a pool wall reinforced frame, mounting of pool wall forms, mounting of a support system, and casting of the concrete pool wall. The method has the advantages that the problems of large pool wall height and large form side pressure are solved by the use of the solid side forms and a reinforcing support system; the pool wall forms are erected to the top once, and the appearance quality of the pool wall is easily guaranteed; pool concrete is cast once, structure integrity is good, and the potential water leakage problem of the pool wall caused by reservation of multiple horizontal construction joints; construction process is greatly quickened, construction period is shortened, labor cost and materials cost are saved, and engineering cost is lowered; the method is especially applicable to construction of concrete pool walls 9m in height and 300mm-1100mm in thickness.

Owner:河北省第二建筑工程有限公司

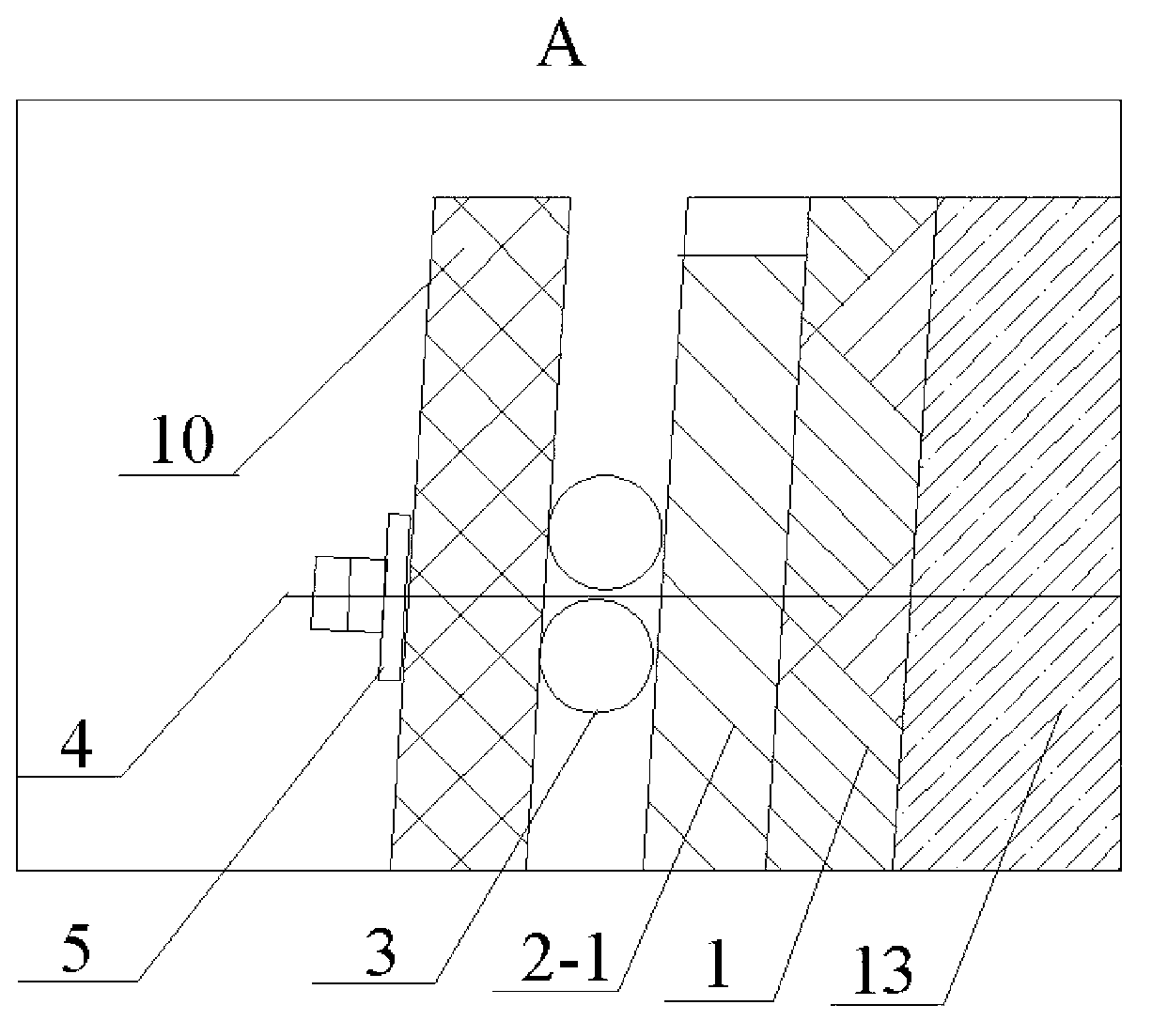

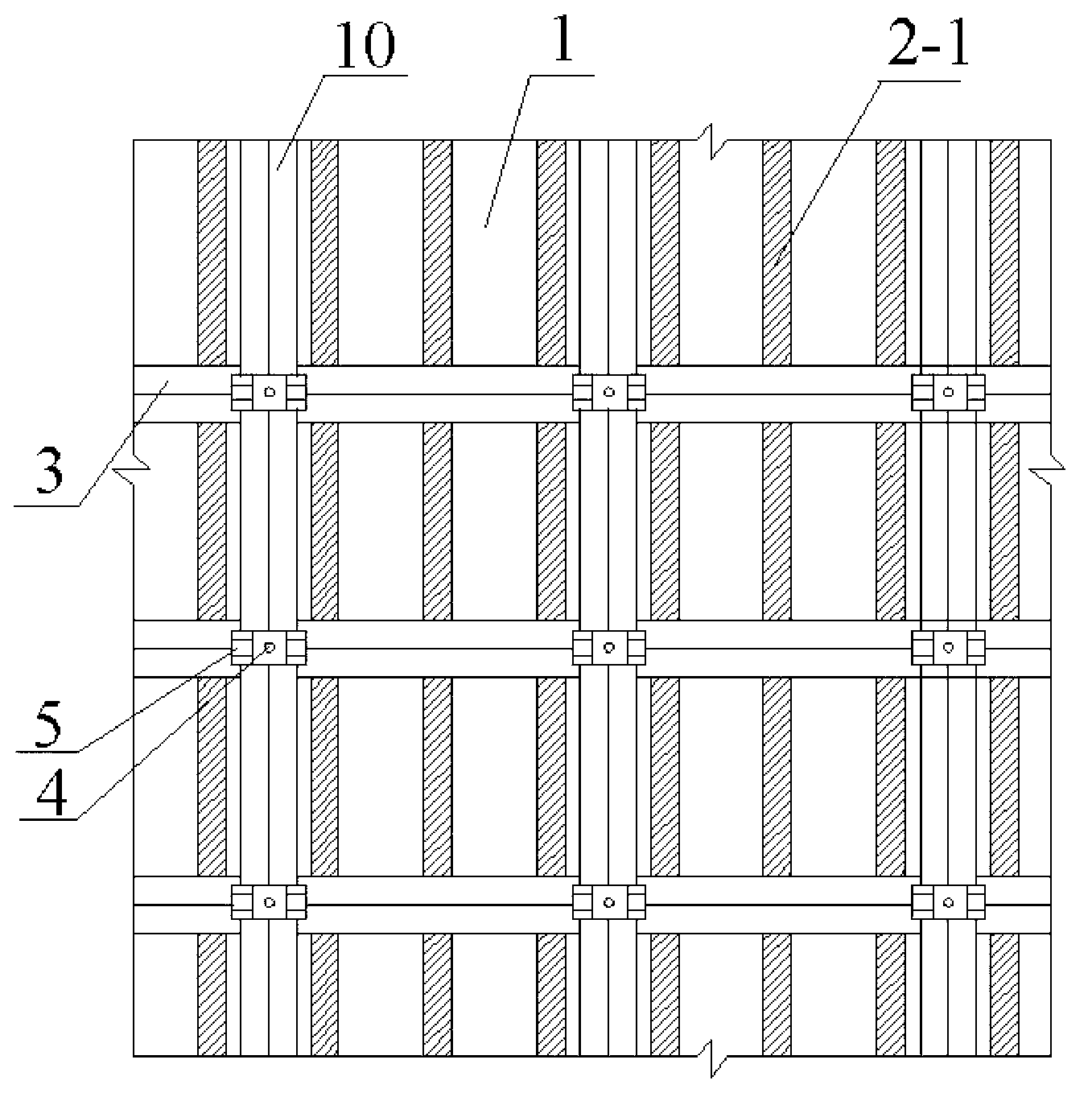

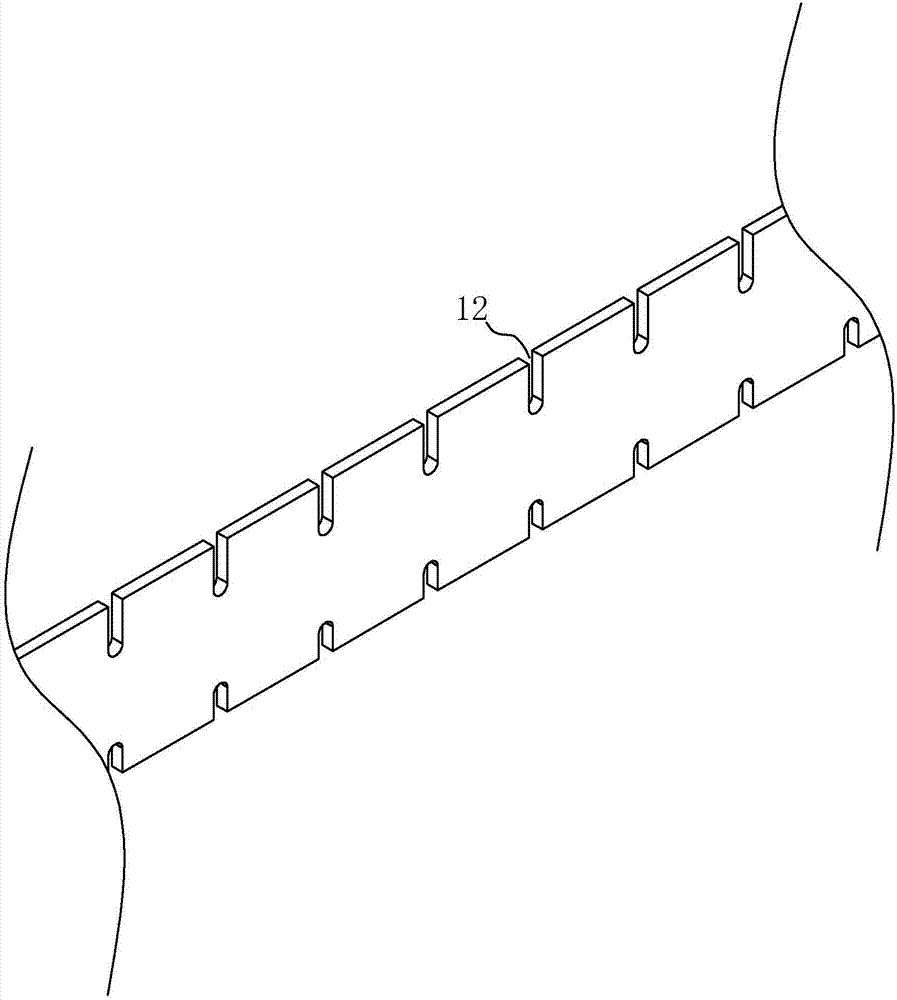

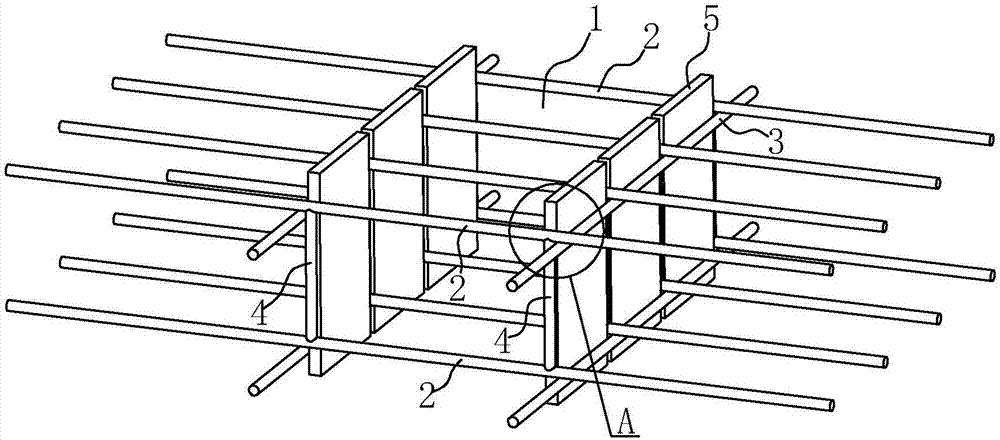

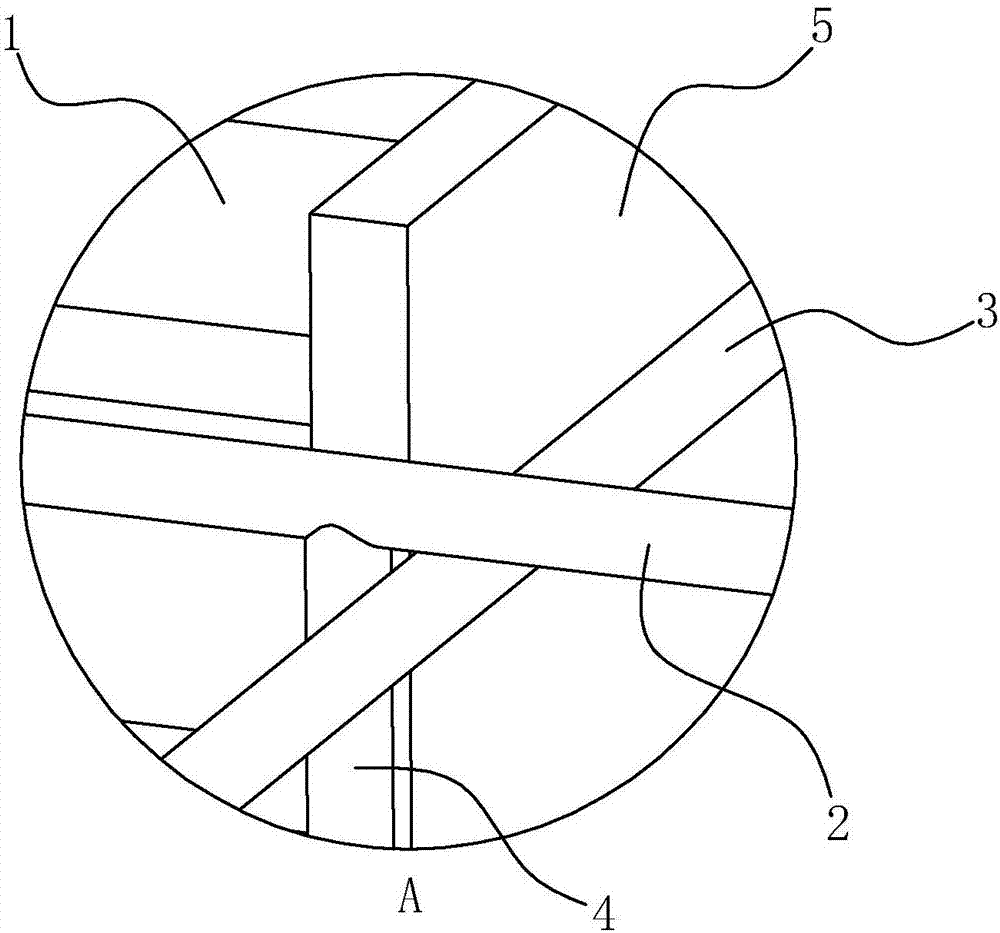

Formwork setting up method for floor post-cast strip

ActiveCN107035141ANot easily oxidizedPlay a rainproof roleForms/shuttering/falseworksFloor slabRebar

The invention discloses a formwork setting up method for a floor post-cast strip. The formwork setting up method comprises the following steps that step one, positioning and line drawing are conducted; step two, floor steel bars are bound; step three, Z-axis steel bars are welded to the upper layer X-axis steel bars and the lower layer X-axis steel bars on the two sides of the post-cost strip, and the welding positions of the Z-axis steel bars are on the opposite sides of the upper layer X-axis steel bars and the lower layer X-axis steel bars; step four, formworks are mounted on the two sides of a post-cast strip part and connected between the adjacent X-shaft steel bars in a clamped mode and abut against the Y-axis steel bars, and the Z-axis steel bars are connected with the side walls of the formworks in an abutting mode; step five, battens are mounted on the sides, facing the post-cast strip part, of the upper sides and the lower sides of the formworks, attach to the formworks in an abutting mode and close the gaps of the connecting positions of the upper sides and the lower sides of the adjacent formworks; and step six, detachable supporting components are mounted between the battens of the two sides of the post-cast strip part to fix the battens and the formwork. By adoption of the formwork setting up method, formwork setting up and dismantling are facilitated, and meanwhile, the fixing strength and the anti-leakage capacity of the formworks are effectively guaranteed.

Owner:温州神光建设工程有限公司

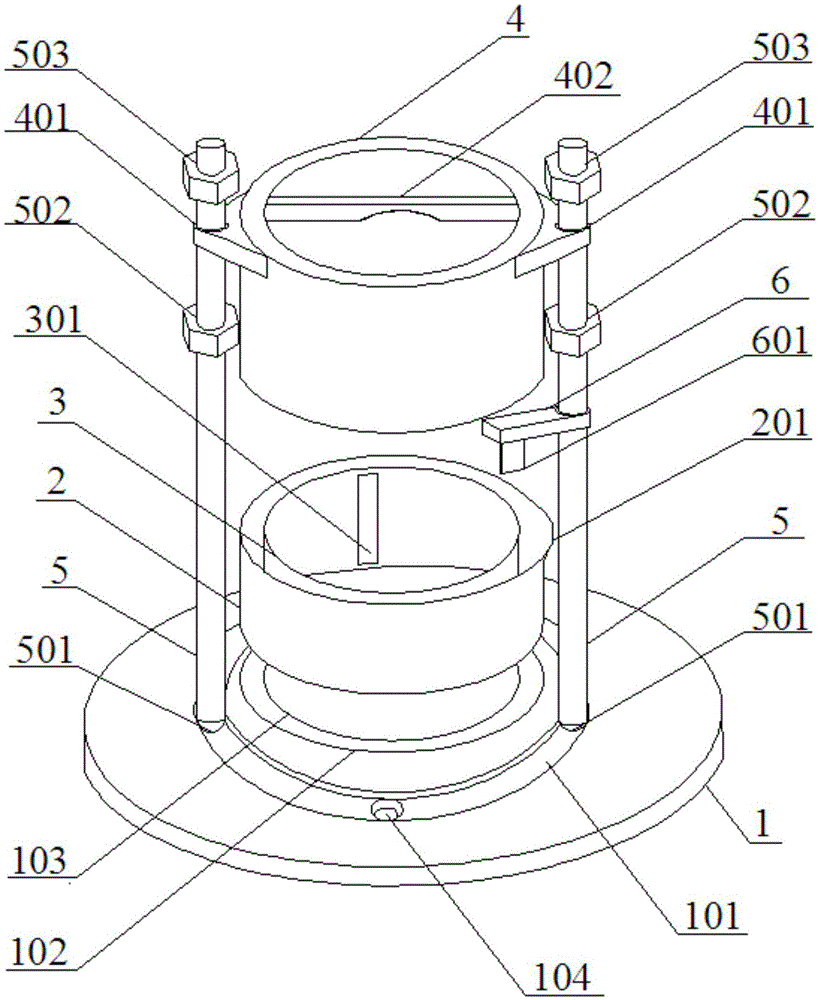

Ring type sample preparation device for ring shear tests

ActiveCN105571919AStable compaction effectStable and even impact forcePreparing sample for investigationTesting equipmentRing type

The invention belongs to the technical field of geotechnical engineering testing equipment, and discloses a ring type sample preparation device for ring shear tests. The device comprises a base, an inner barrel, an outer barrel, a supporting column and a compaction barrel. The base is provided with two concentric circular grooves. The inner barrel and the outer barrel are embedded into the two concentric circular grooves respectively. The inner barrel, the outer barrel and the top wall of the base form a sample groove. One end of the supporting column is perpendicularly fixed to the base. The compaction barrel is arranged over the sample groove and supported by the supporting column. The compaction barrel is of a barrel structure, and the barrel wall can be embedded into the sample groove. The compaction barrel is provided with a supporting lug and is movably connected with the supporting column through the supporting lug. On the condition that sample compaction and compression operation is executed, the compaction barrel slides along the supporting column to get close to or away from the sample groove, and the barrel wall is embedded into or disengaged from the sample groove. The sample preparation device is high in structure precision, and the sample leveling and compaction operation effect is good.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

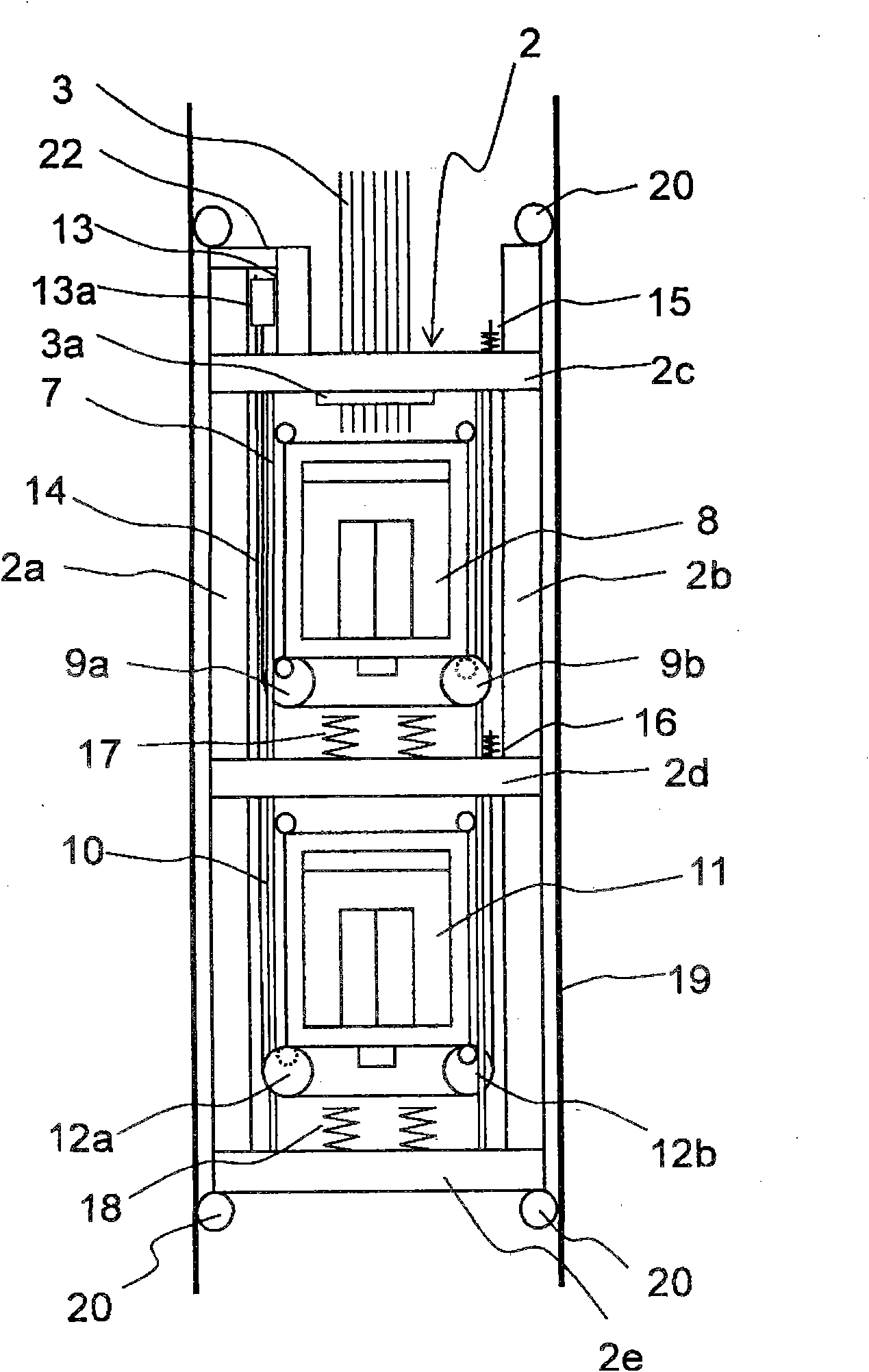

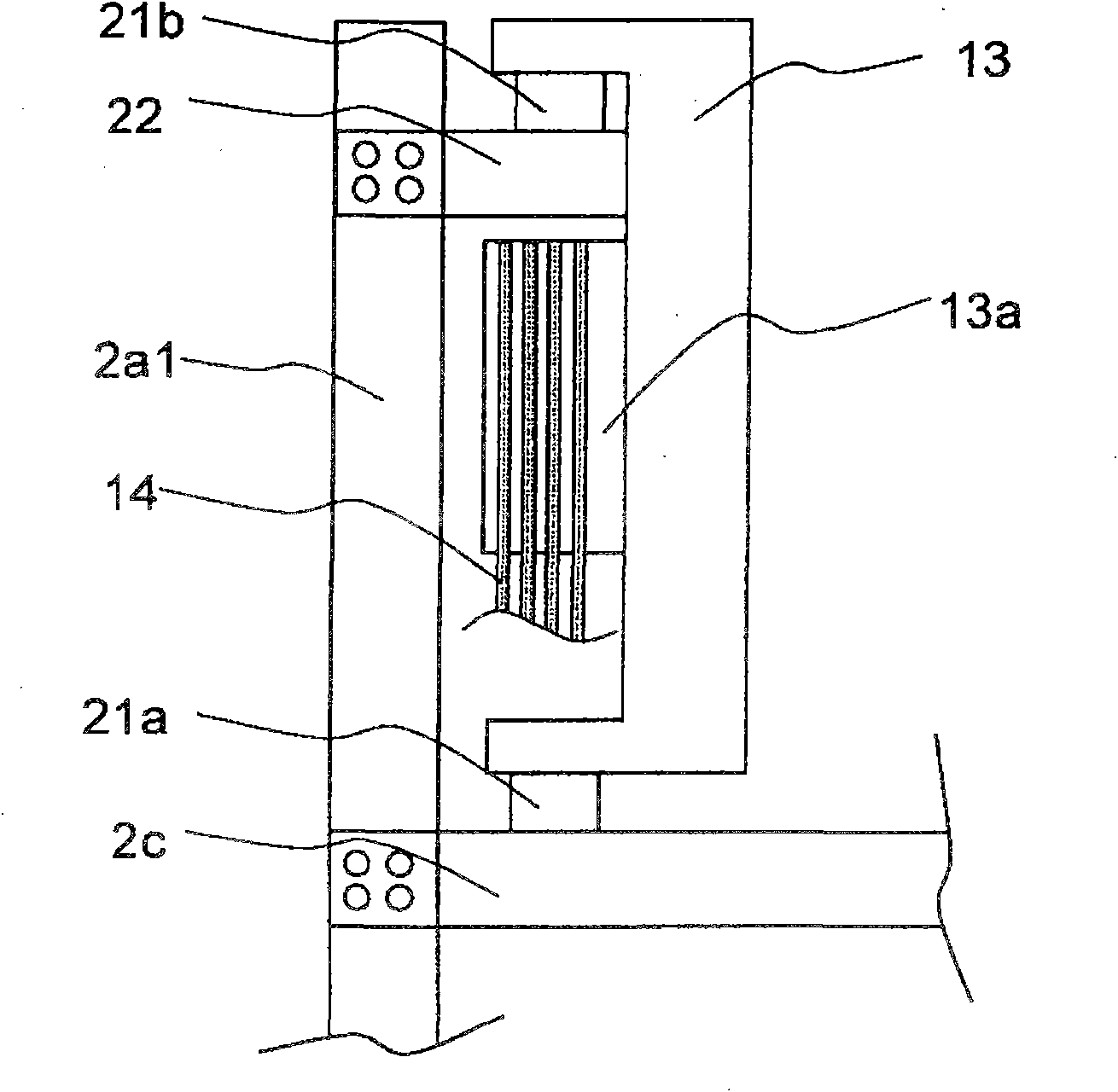

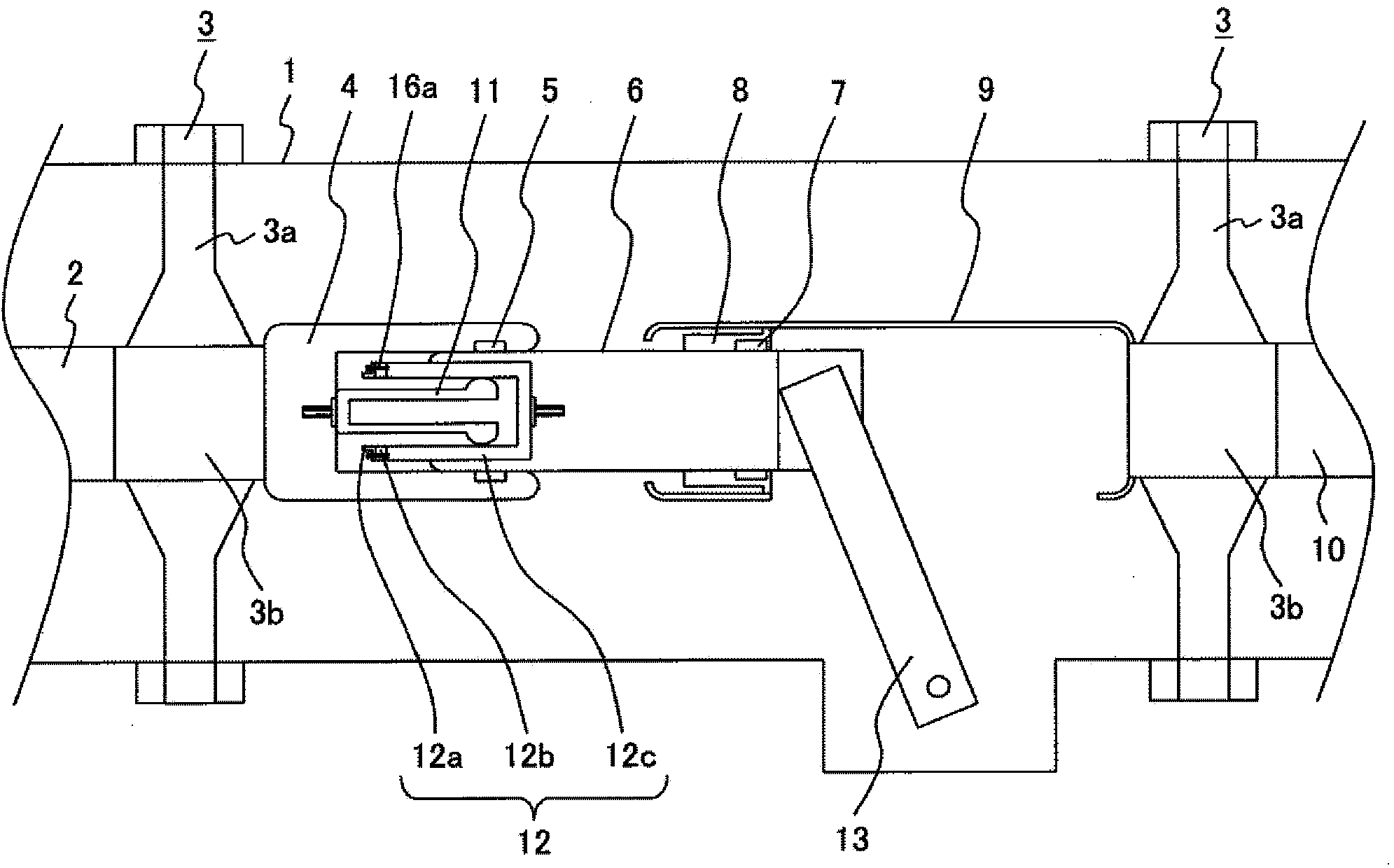

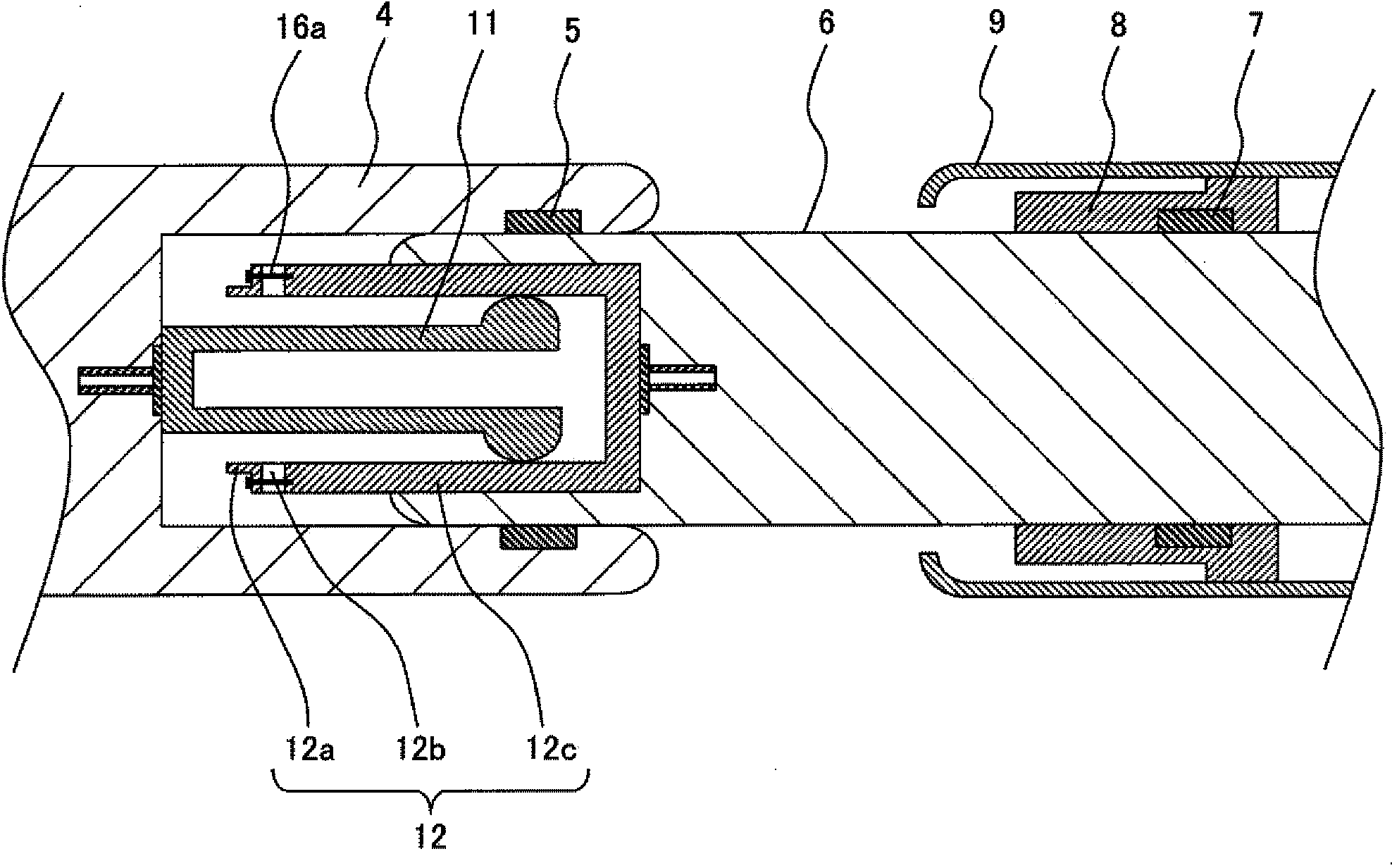

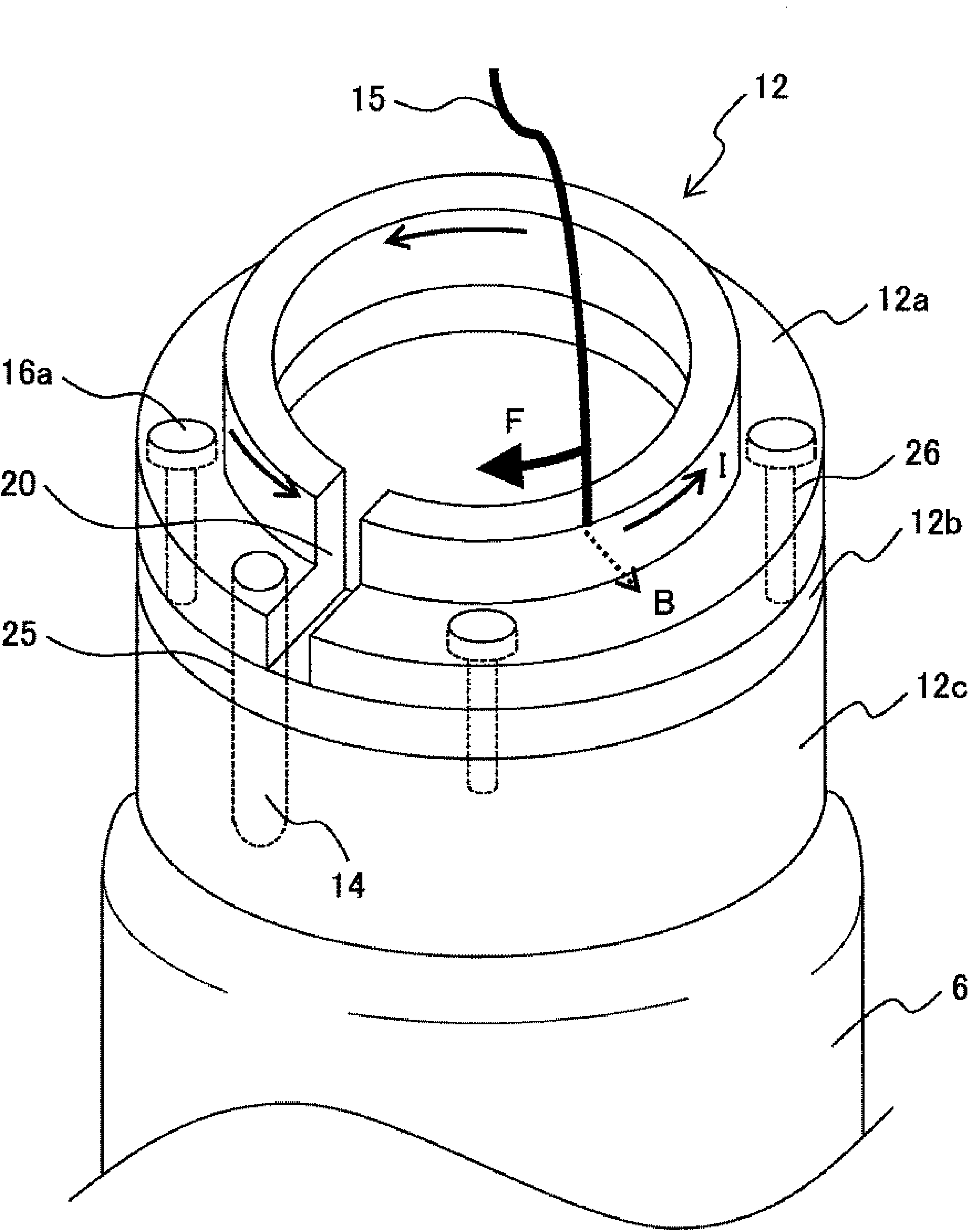

Double-deck elevator

The invention provides a double-deck elevator, wherein the installation position of a drive device for regulating the position of the elevator car is optimized. The double-deck elevator comprises a main frame (2) lifting in the elevating passage, an upper elevator car (8) arranged inside the main frame (2) capable of moving in a vertical direction, a lower elevator car (11) arranged inside the main frame (2) below the upper elevator car (8) capable of moving in a vertical direction and a drive device (13) for regulating the position of the elevator car arranged on the main frame (2) and equipped with a drive rope (13a) for regulating the position of the elevator car. The main frame (2) is formed by longitudinal frames (2a, 2b), an upper frame (2c), a middle frame (2d) and a lower frame (2e). The interval between the upper elevator car (8) and the lower elevator car (11) is adjusted by the up-down movement of the two elevator cars driven by an elevator car position adjusting rope (14). The drive device (13) for regulating the position of the elevator car is arranged above the upper frame (2c).

Owner:HITACHI LTD

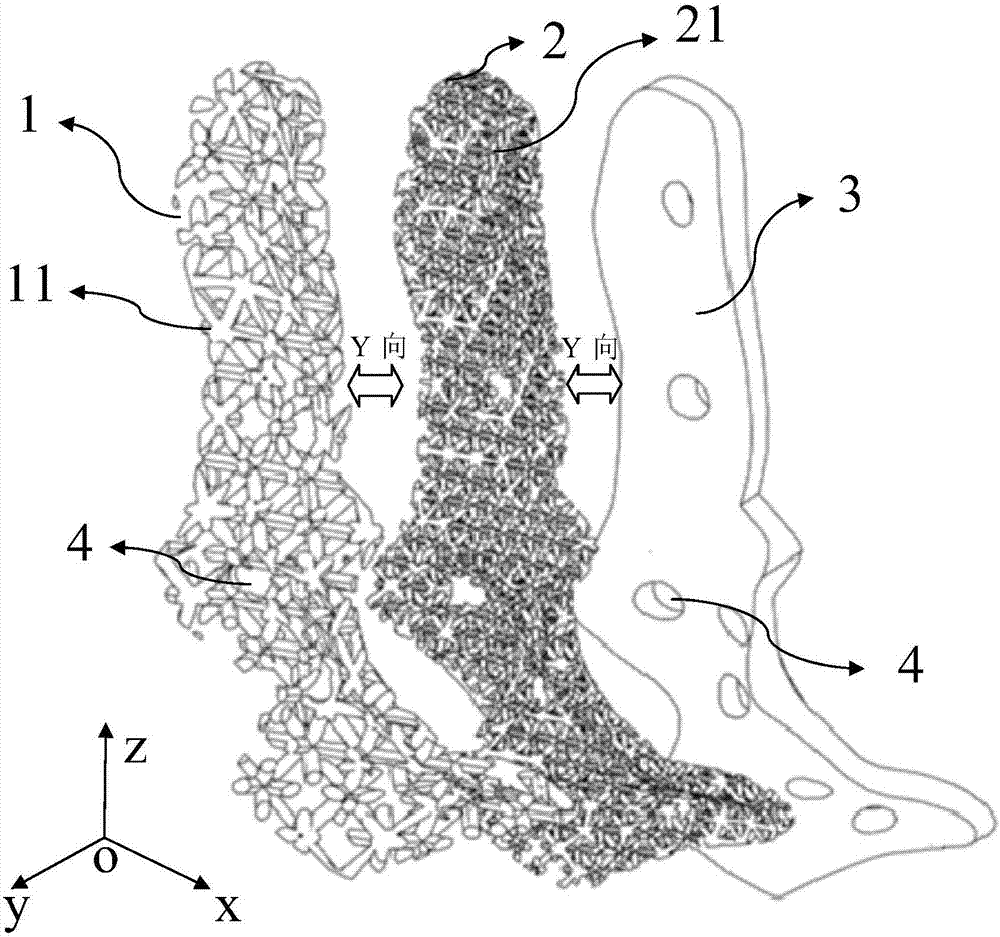

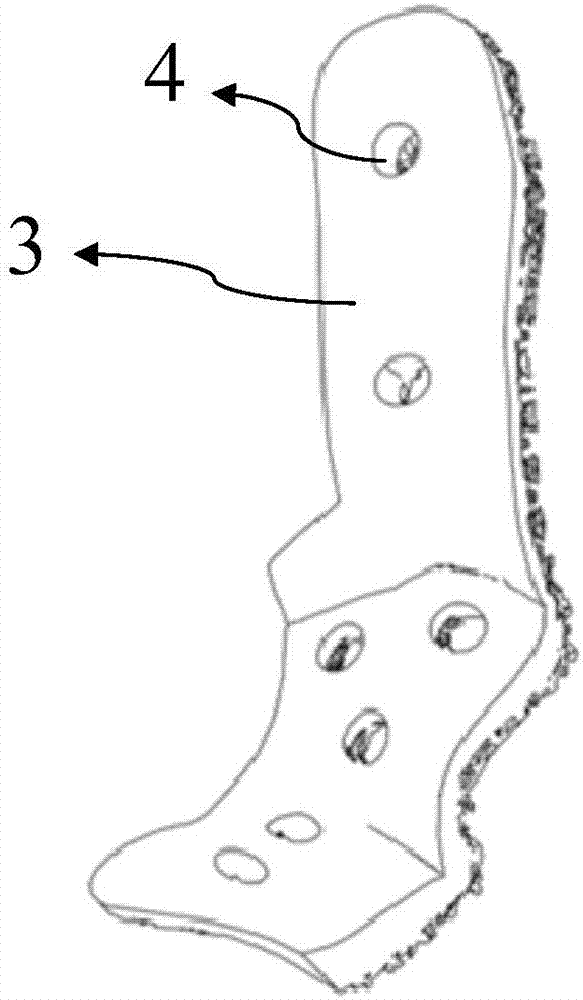

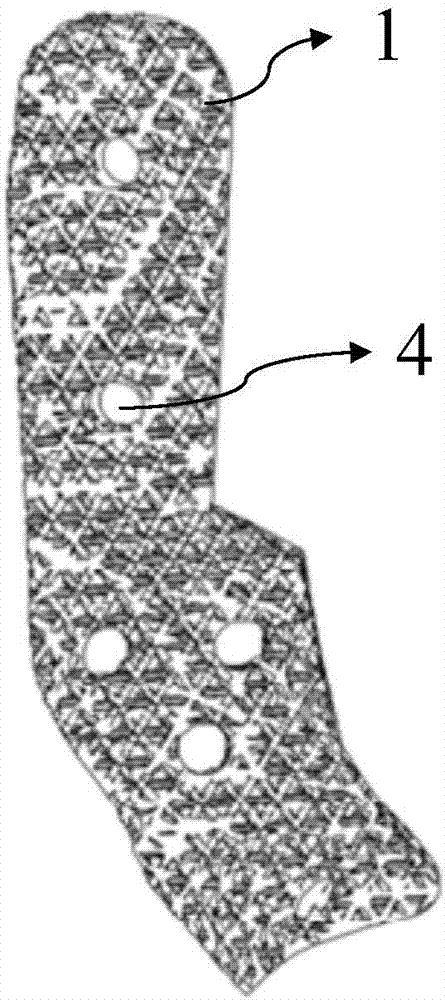

Porous composite bone plate with stiffness and gradient variation and preparation method thereof

ActiveCN106983551AReduce stiffnessImproved stress shielding effectBone platesBiocompatibility TestingStress shielding

The invention provides a porous composite bone plate with stiffness and gradient variation and a preparation method thereof. The bone plate is formed by sequentially connecting a bonding layer, a transition layer and a physical layer, wherein the bonding layer, transition layer and physical layer are successively increased in stiffness. The corresponding position of the layers is provided with a positioning hole in a penetrating mode. The bonding layer with smaller stiffness is in contact with the original bone, therefore the stiffness of the contact surface of the bone plate can be reduced and the stress shielding effect is improved; the physical layer with larger stiffness achieves the fixed connection; a porous structure is arranged on the bonding layer and the transition layer respectively, thereby promoting the adhesion growth of cells, forming the more solid biological fixation, and being conducive to the long-term effective service of the bone plate. The bone plate overall structure uses 3D printing to be molded integrally, thus the natural transition and convergence from the porous structure of the bonding layer and transition layer to the physical structure of the physical layer can be achieved; the bone plate possesses obvious heterogeneous mechanical properties. According to the porous composite bone plate with the stiffness and gradient variation and the preparation method thereof, an individualized composite bone plate with stiffness and gradient variation and multi-directional gradient structures can be designed for different parts according to the individual difference, thereby improving the adaptability and biocompatibility of the bone plate.

Owner:国家康复辅具研究中心

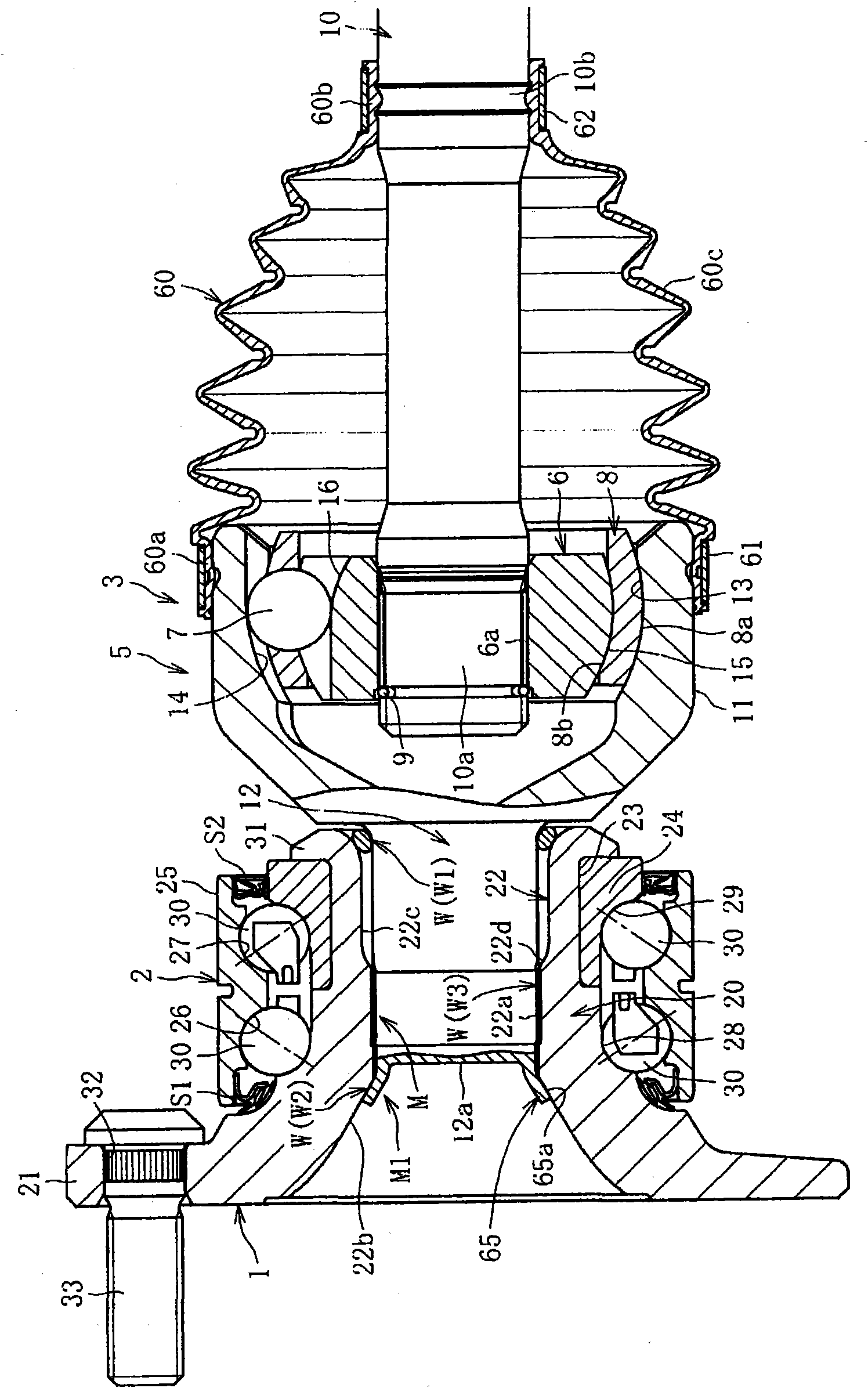

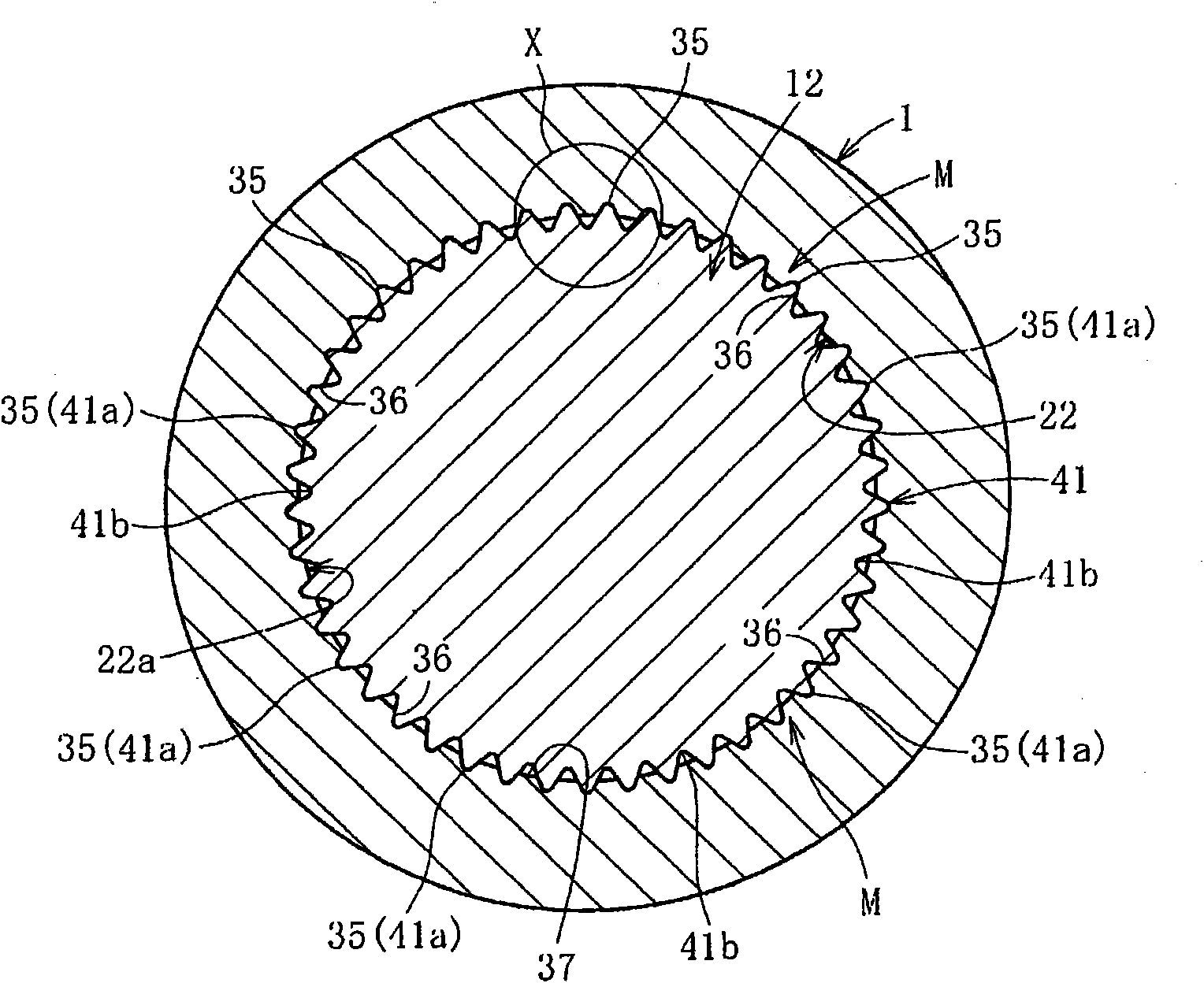

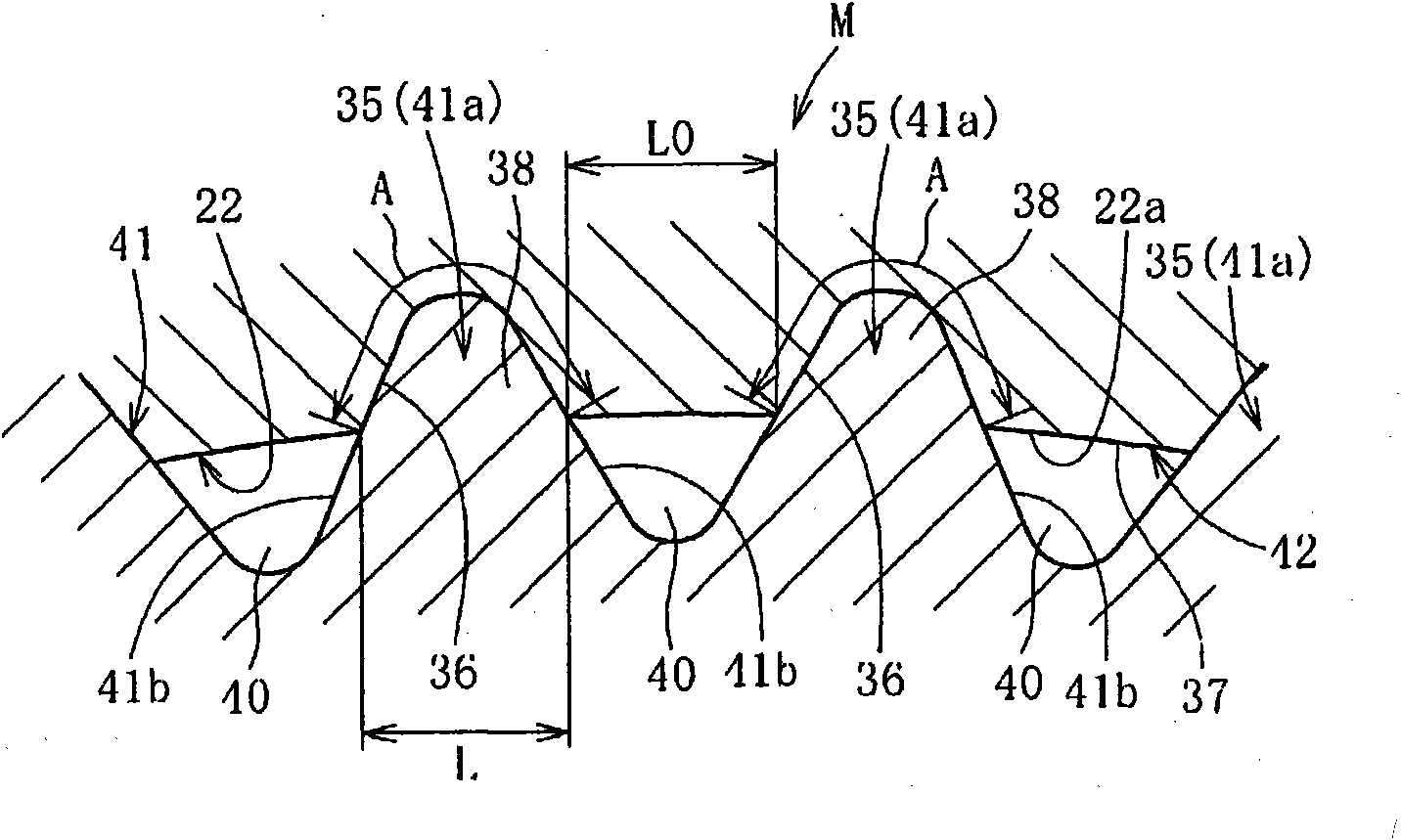

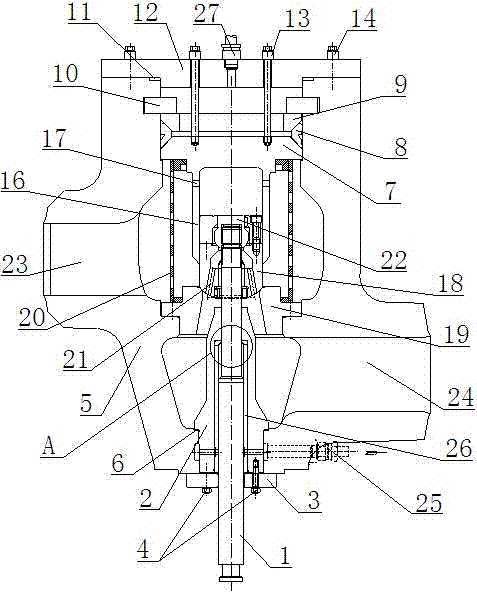

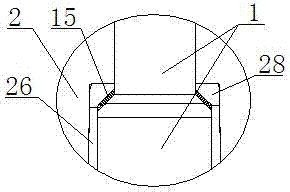

Bearing device for wheel, and axle module

Provided are a bearing device for a wheel, in which circumferential play is reduced, which provides excellent workability in connection between a hub ring and an outer joint member of a constant velocity universal joint, in which fitting between the hub ring and the outer joint member of the constant velocity universal joint is stable, and which has excellent strength, and an axle module using the bearing device. An axially extending projection is formed on either of the outer diameter surface of a shaft section of the outer joint member and the inner diameter surface of a hole of the hub ring. The projection is press-fitted to the other in the axial direction to form a recess in the other by the press-fitting. By this, a recess / projection fit structure is formed, in which the entire regions of those portions of the projection and the recess at which they are fitted to each other are in intimate contact with each other. The hardness of at least that portion of the projection at which the press-fit starts is higher than that of a portion where the recess is formed. The difference in hardness in HRC is 20 or more.

Owner:NTN CORP

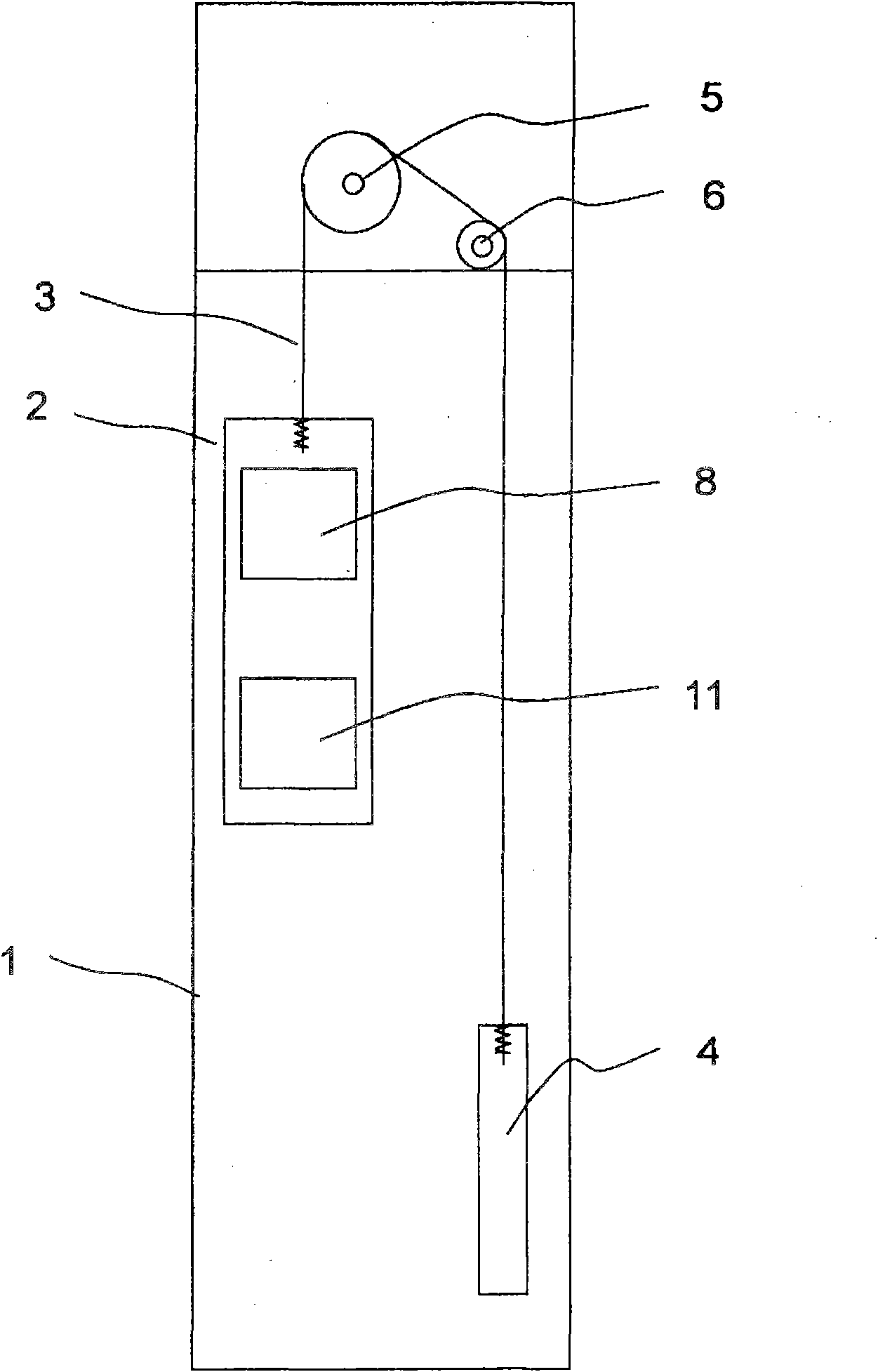

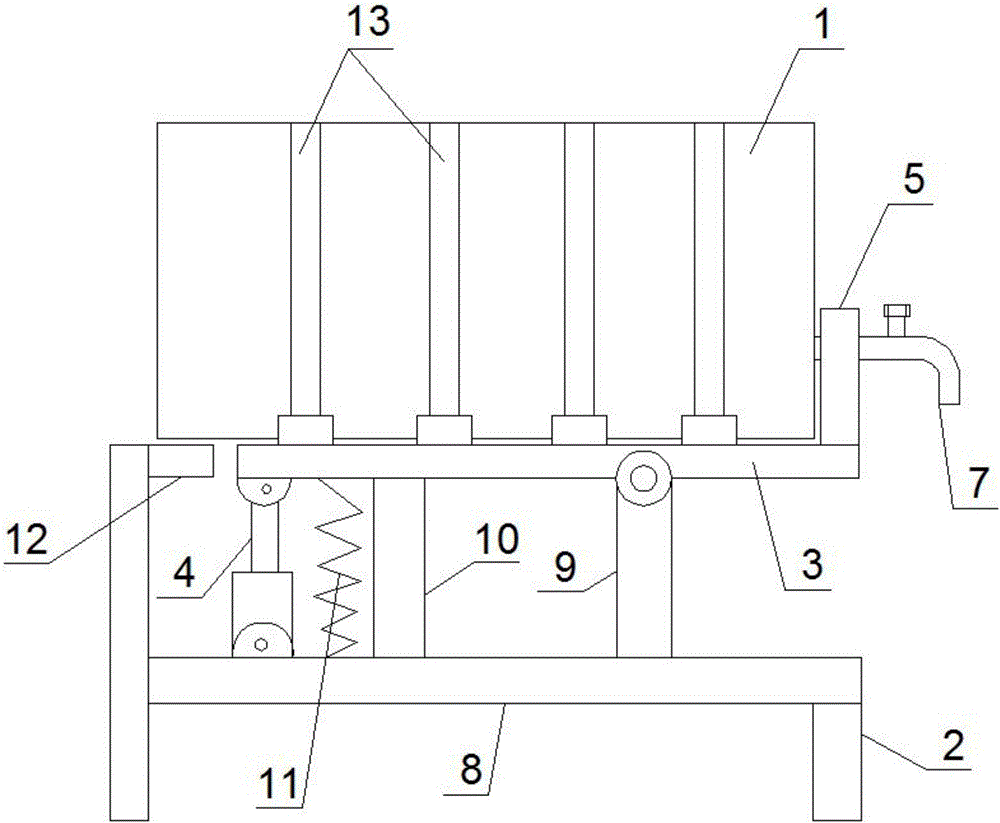

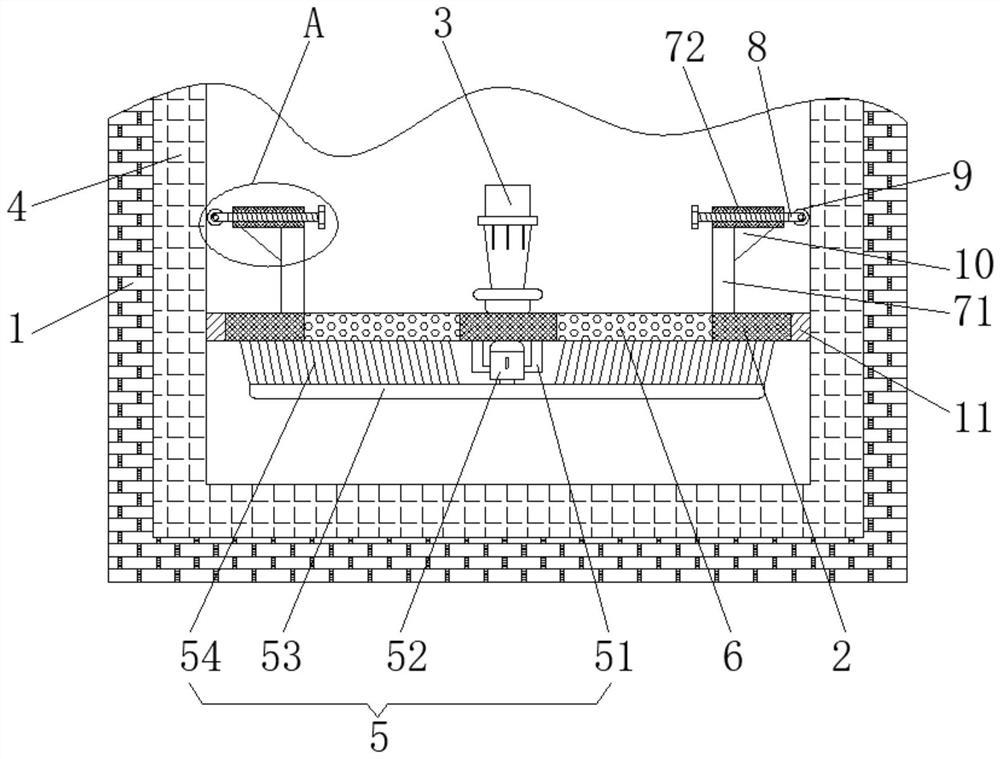

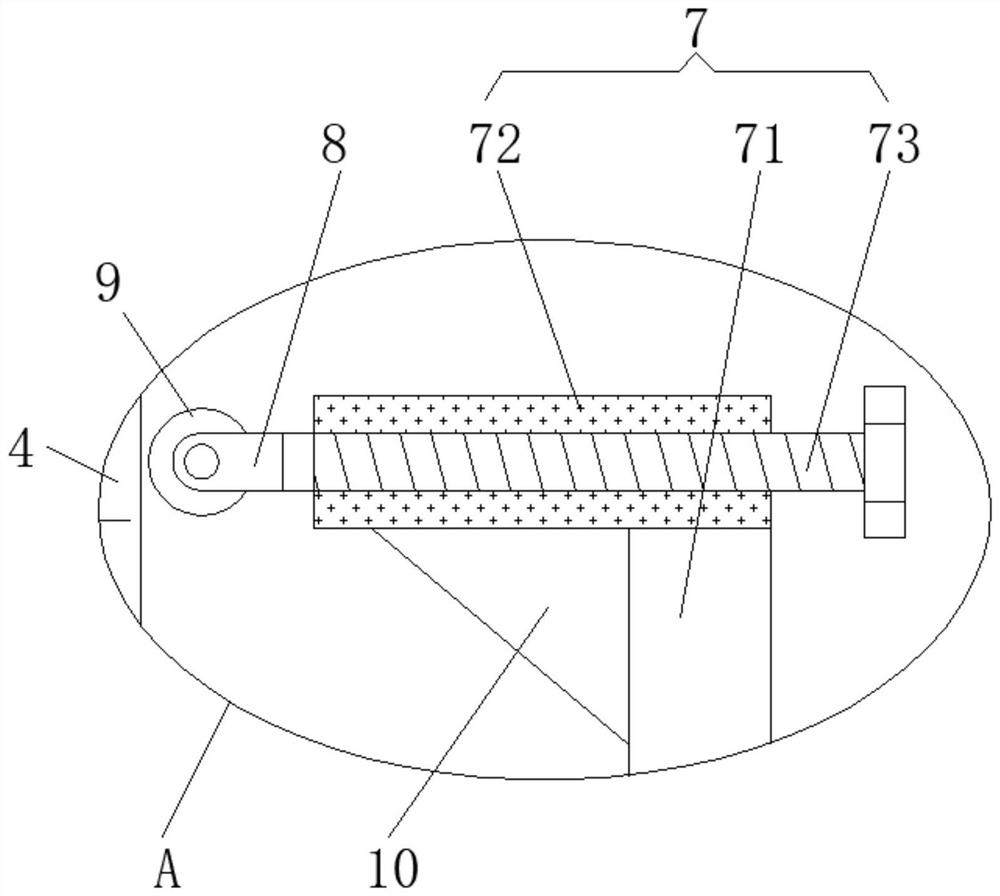

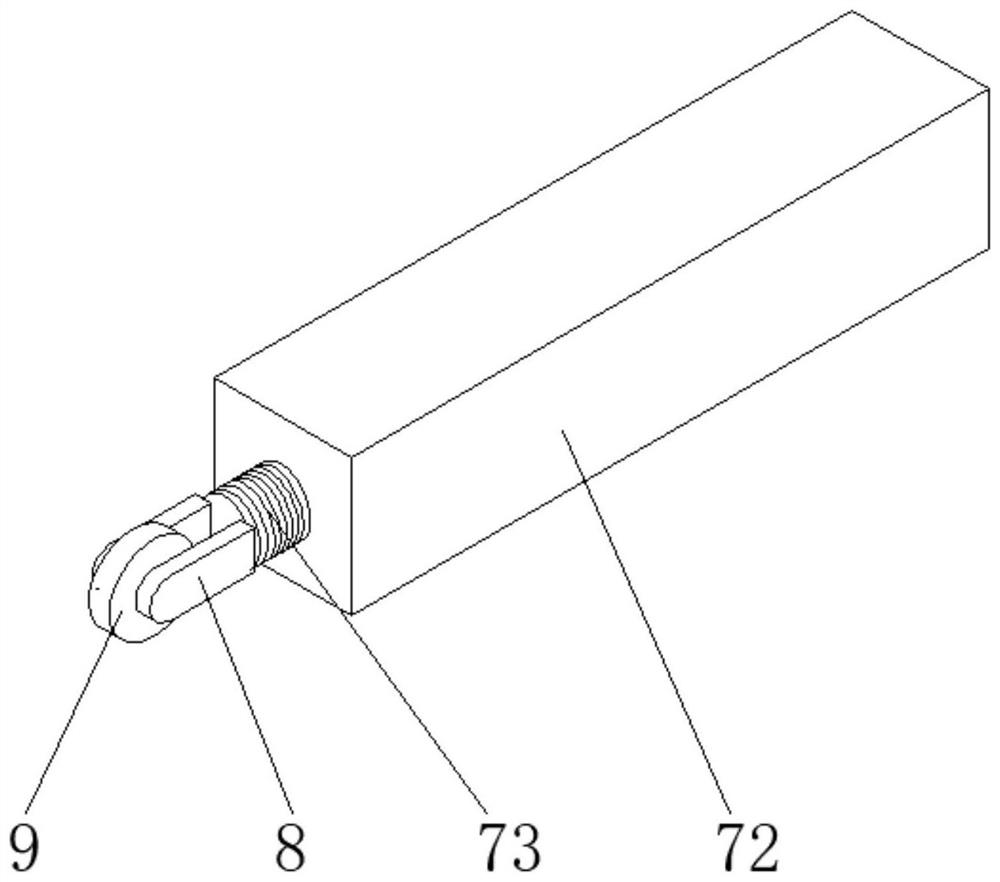

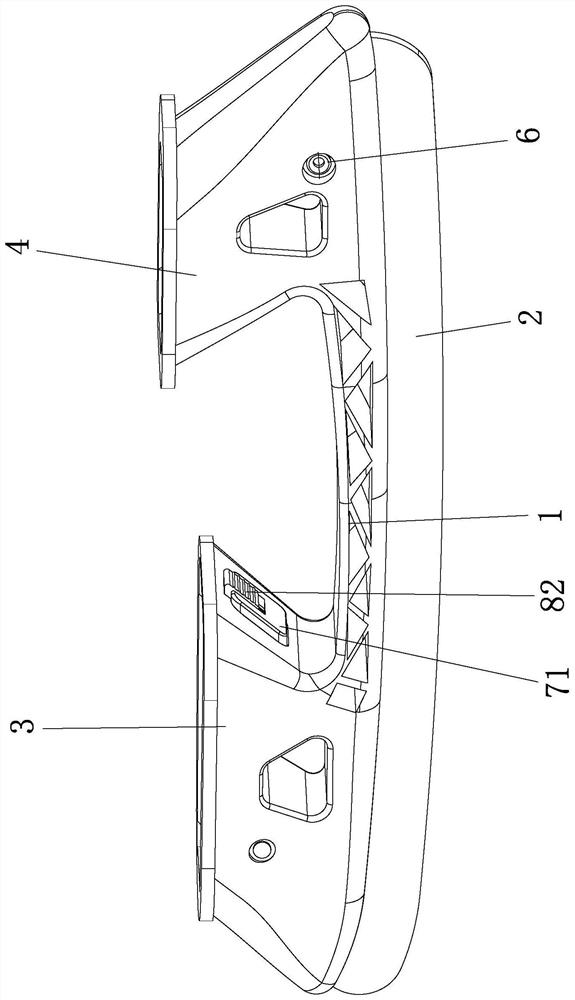

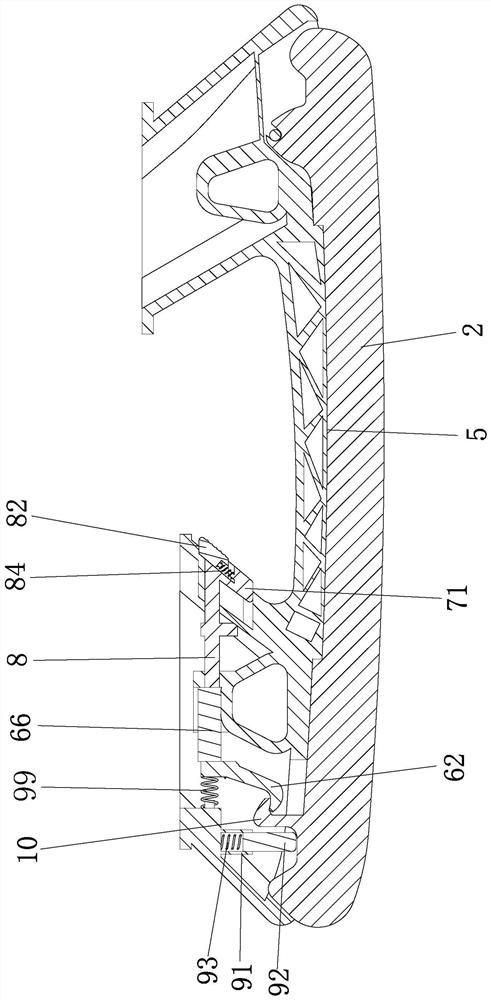

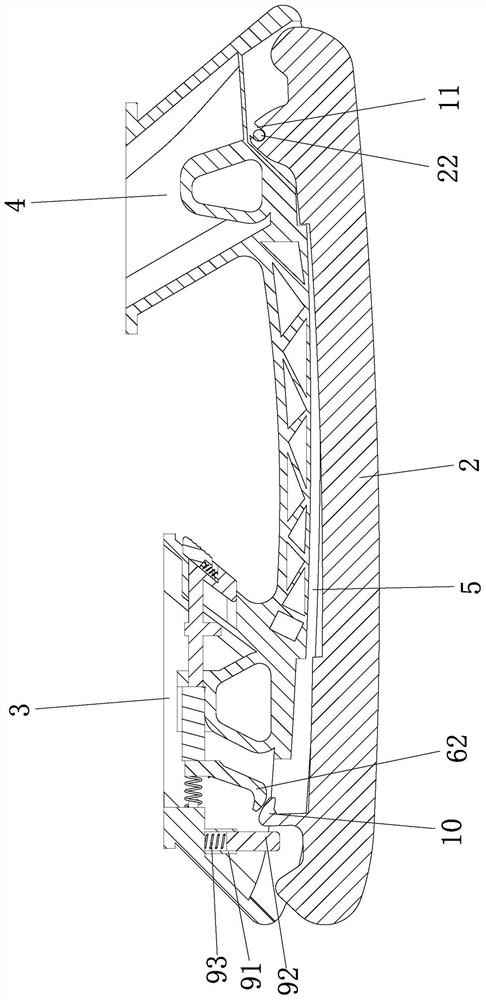

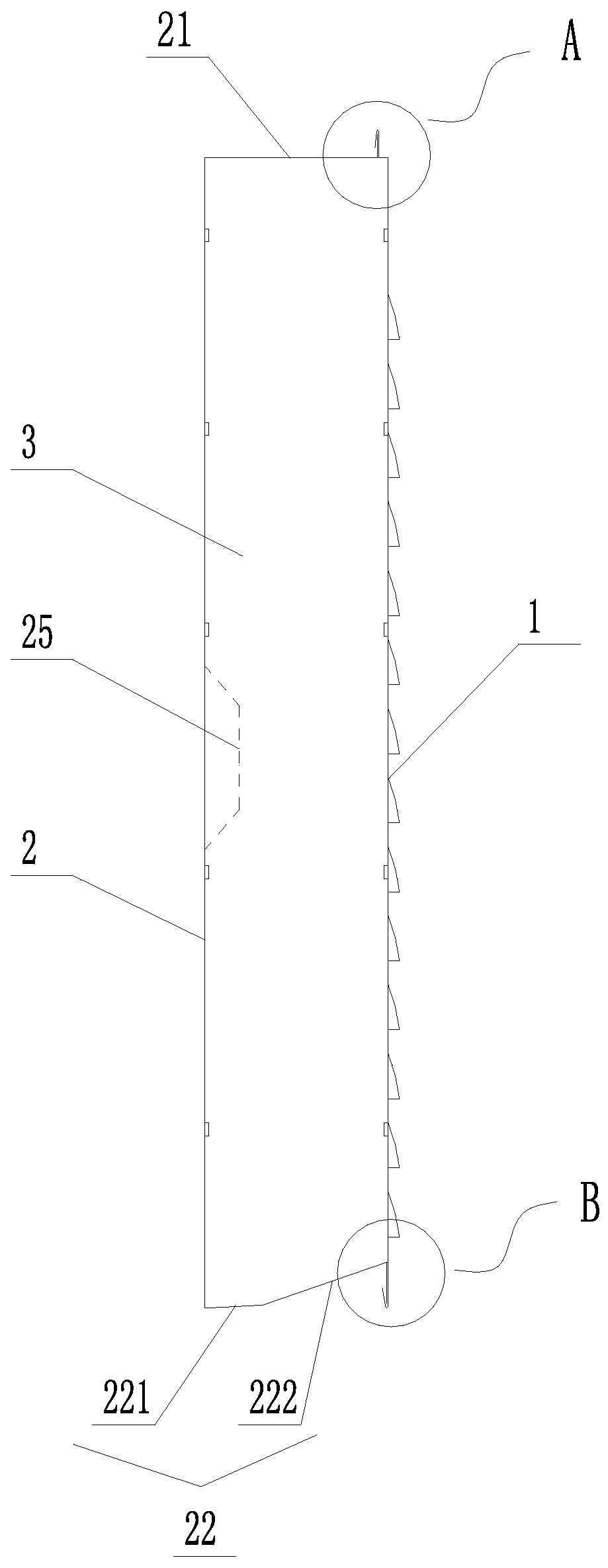

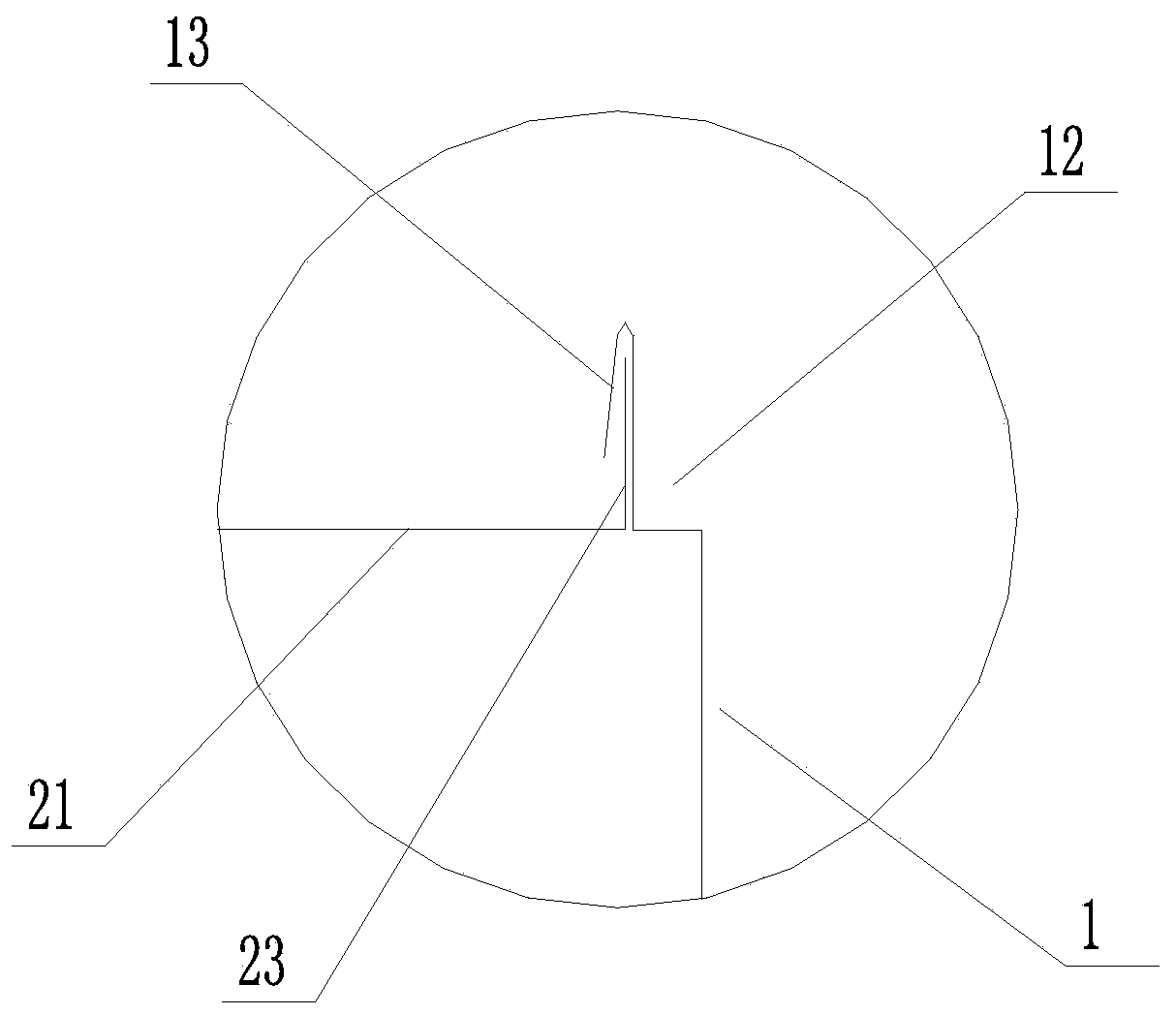

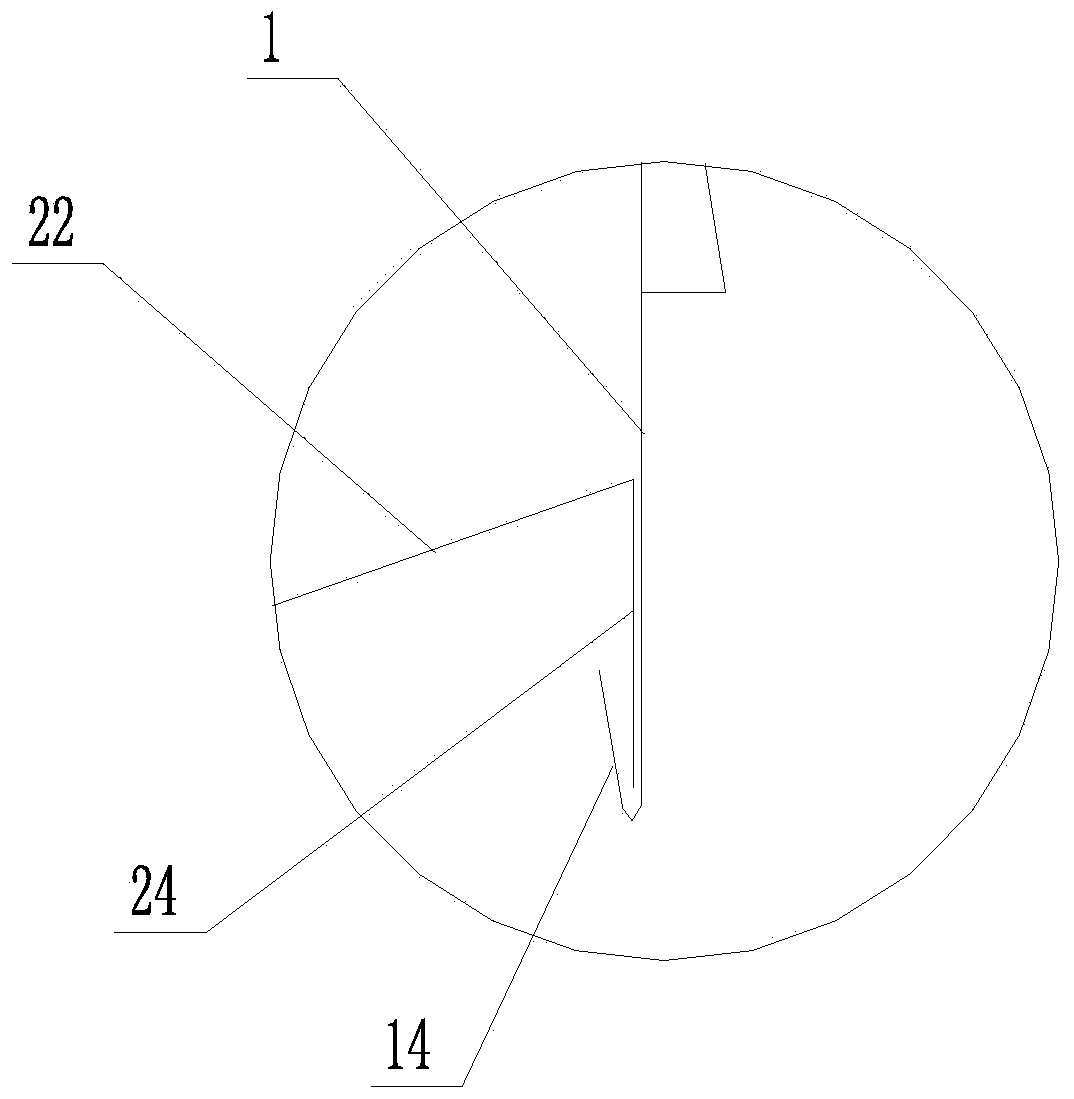

Mining oil drum oil drainage device

InactiveCN105667988AGuaranteed fixed strengthLarge containersExternal framesHydraulic cylinderOil can

The invention discloses an oil discharge device for mine oil barrels. An oil outlet pipeline (7) with a valve is arranged on the barrel cover of the oil barrel (1), and the oil barrel (1) is horizontally and fixedly arranged on a placement frame (3 ), the right end of the shelf (3) is provided with a baffle (5), the upper part of the baffle (5) is provided with a vertical groove (6), and the oil outlet pipeline (7) protrudes from the vertical groove (6) to the baffle ( the right part of 5); the support frame (2) top is provided with a horizontal support plate (8), and the right side of the support plate (8) top is fixedly provided with an upright beam (9) perpendicular to it, and the upper end of the upright beam (9) Hinged with the bottom right side of the placement frame (3), the left end of the placement frame (3) is hinged with the piston rod head of the hydraulic cylinder (4), and the cylinder seat of the hydraulic cylinder (4) is hinged with the left side of the support plate (8) top. The device is easy to operate, does not require additional pumping equipment such as an additional oil pump, and can conveniently realize frequent supply of oil.

Owner:徐州途远精密设备有限公司

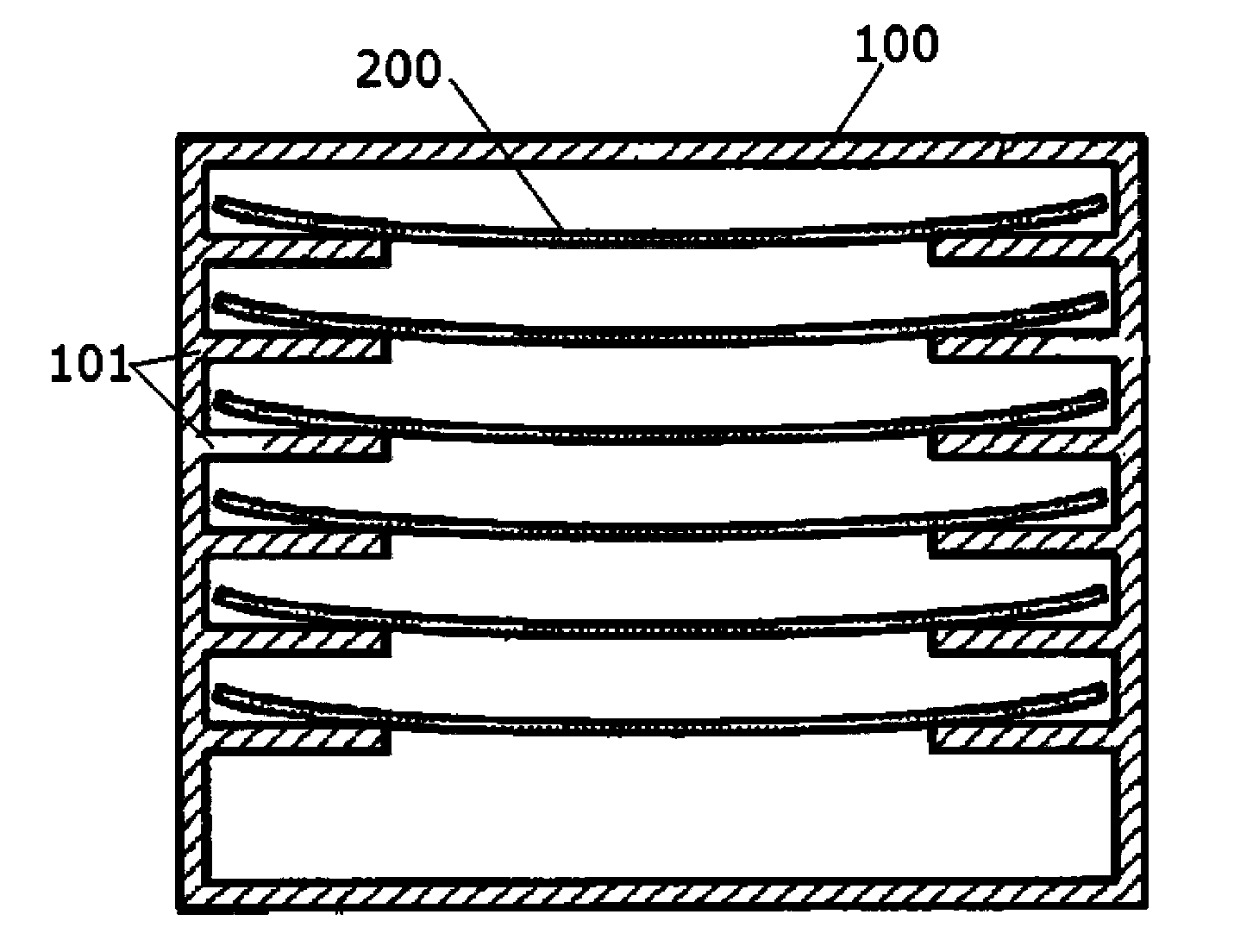

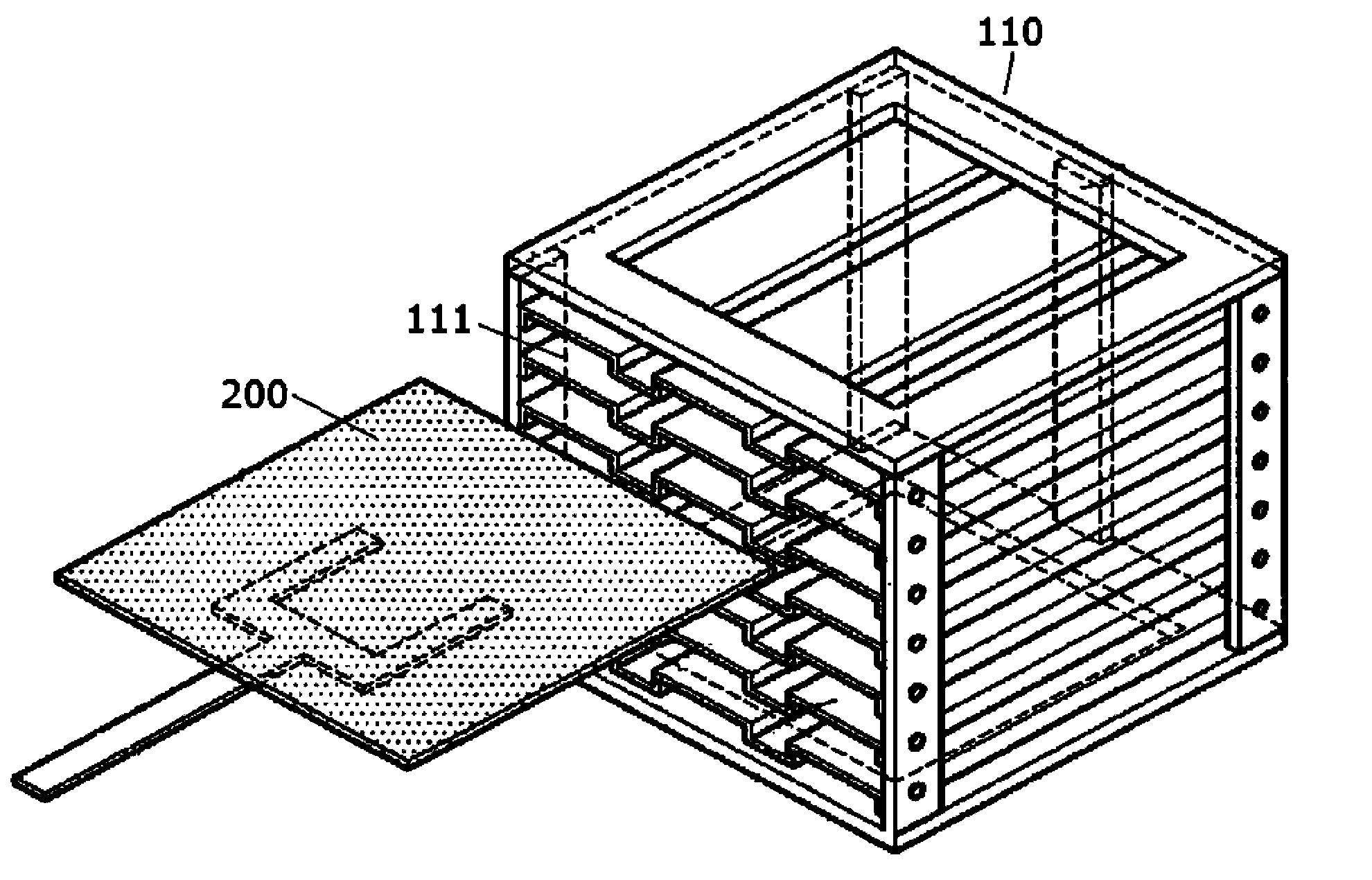

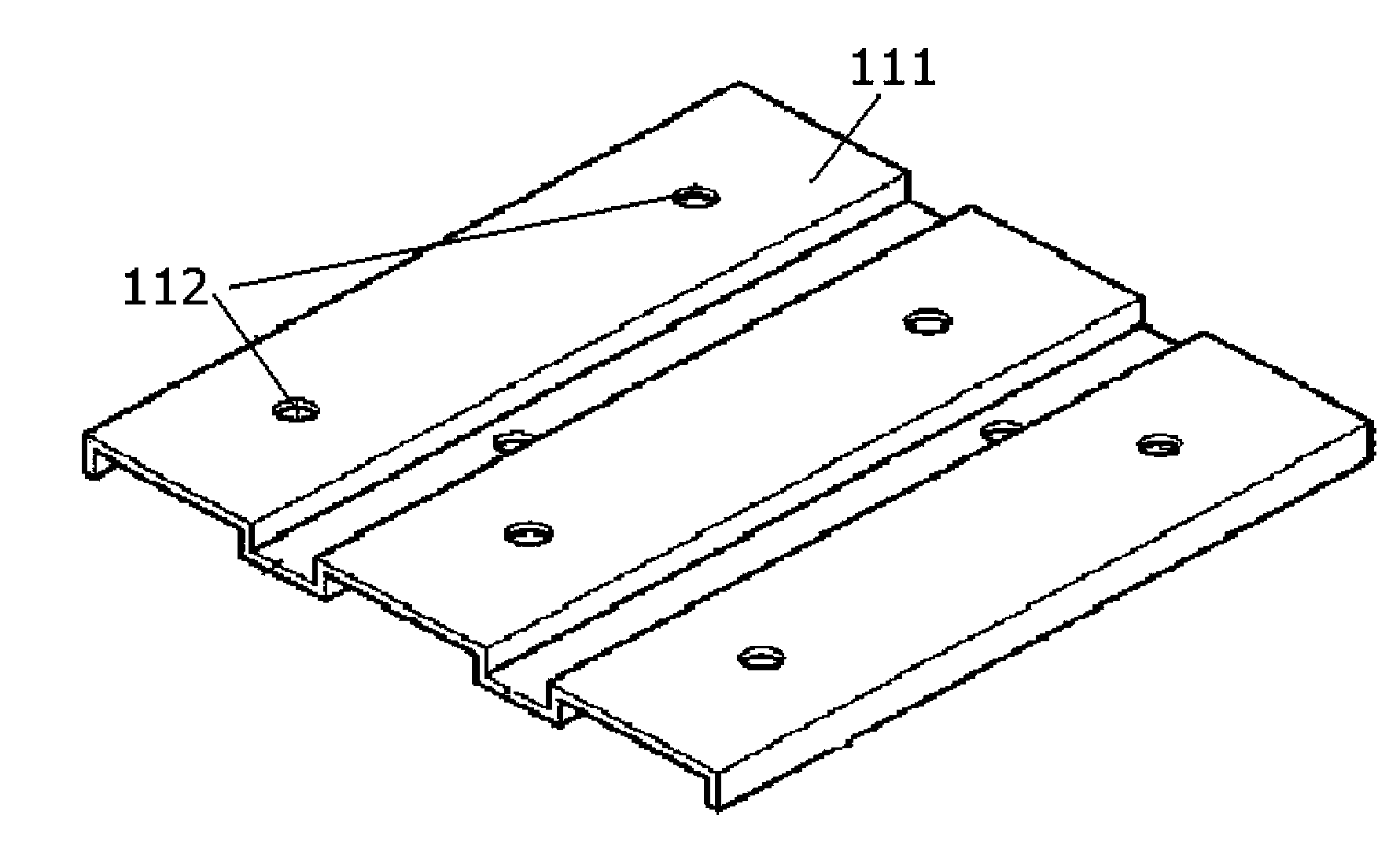

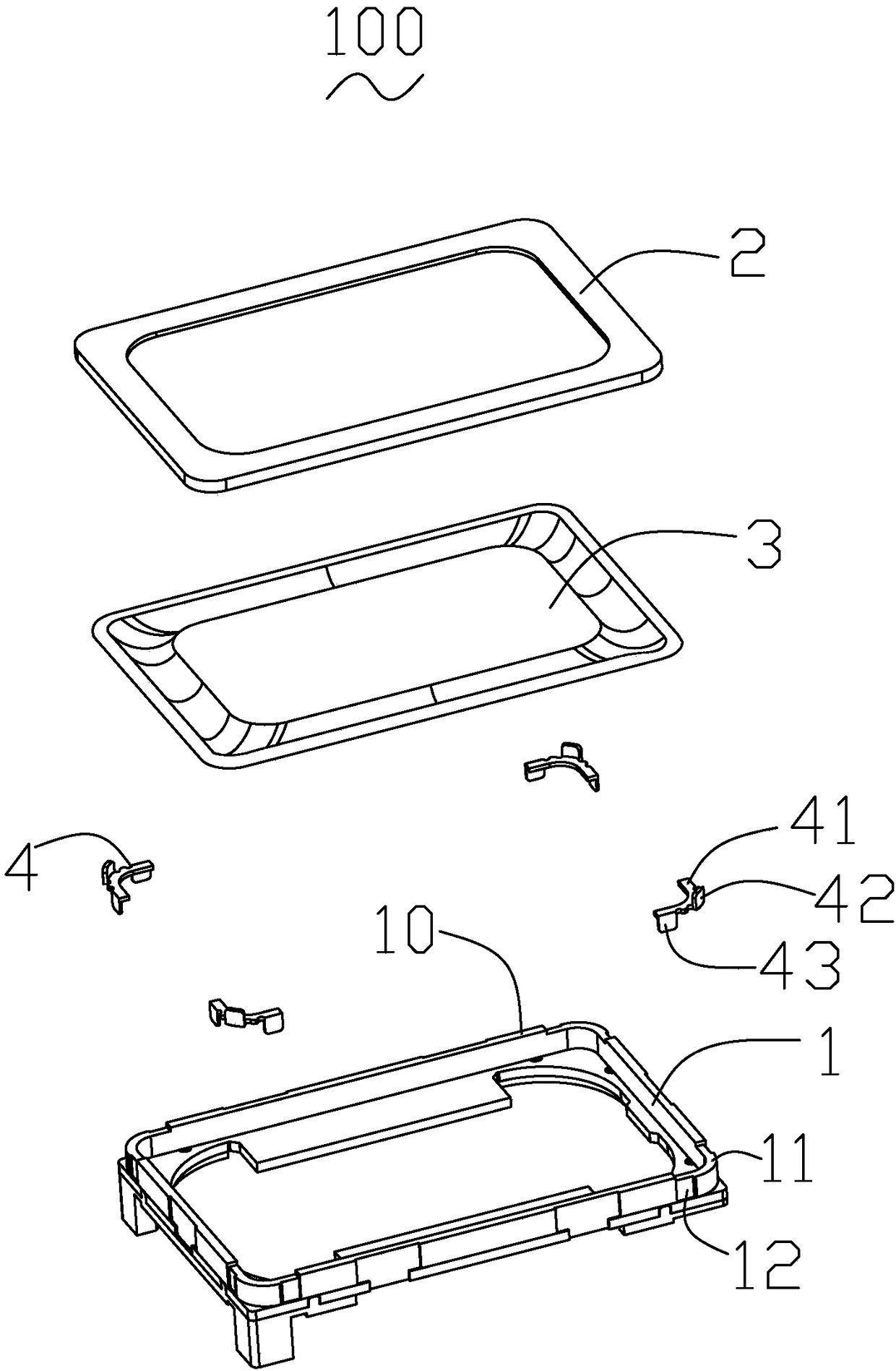

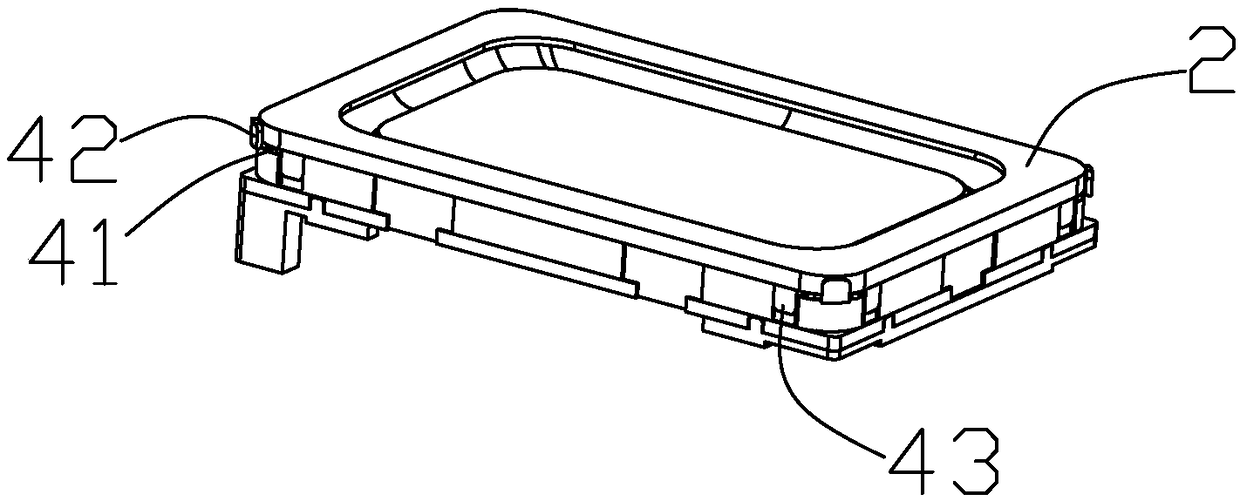

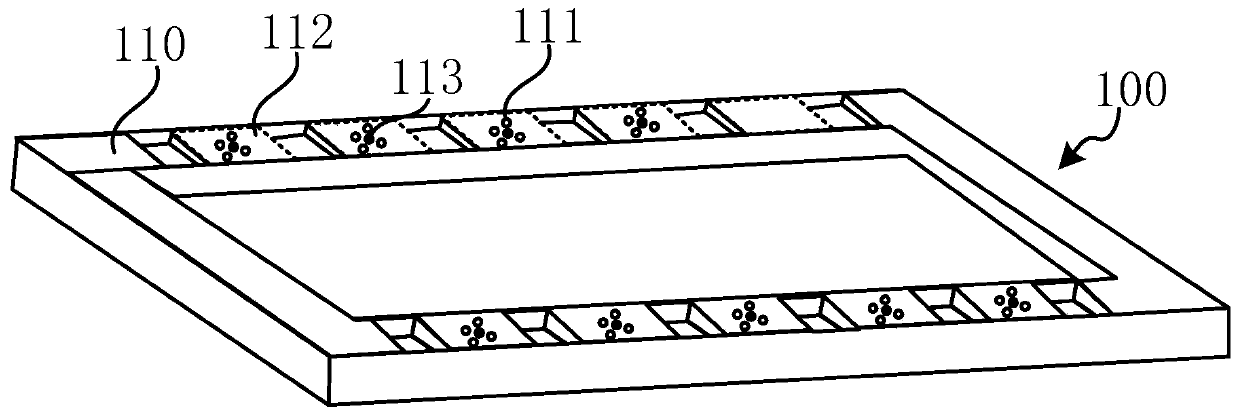

Substrate cassette device

InactiveCN103387333AAvoid structural slackImprove heating uniformityGlass tempering apparatusEngineering

Owner:DU PONT APOLLO

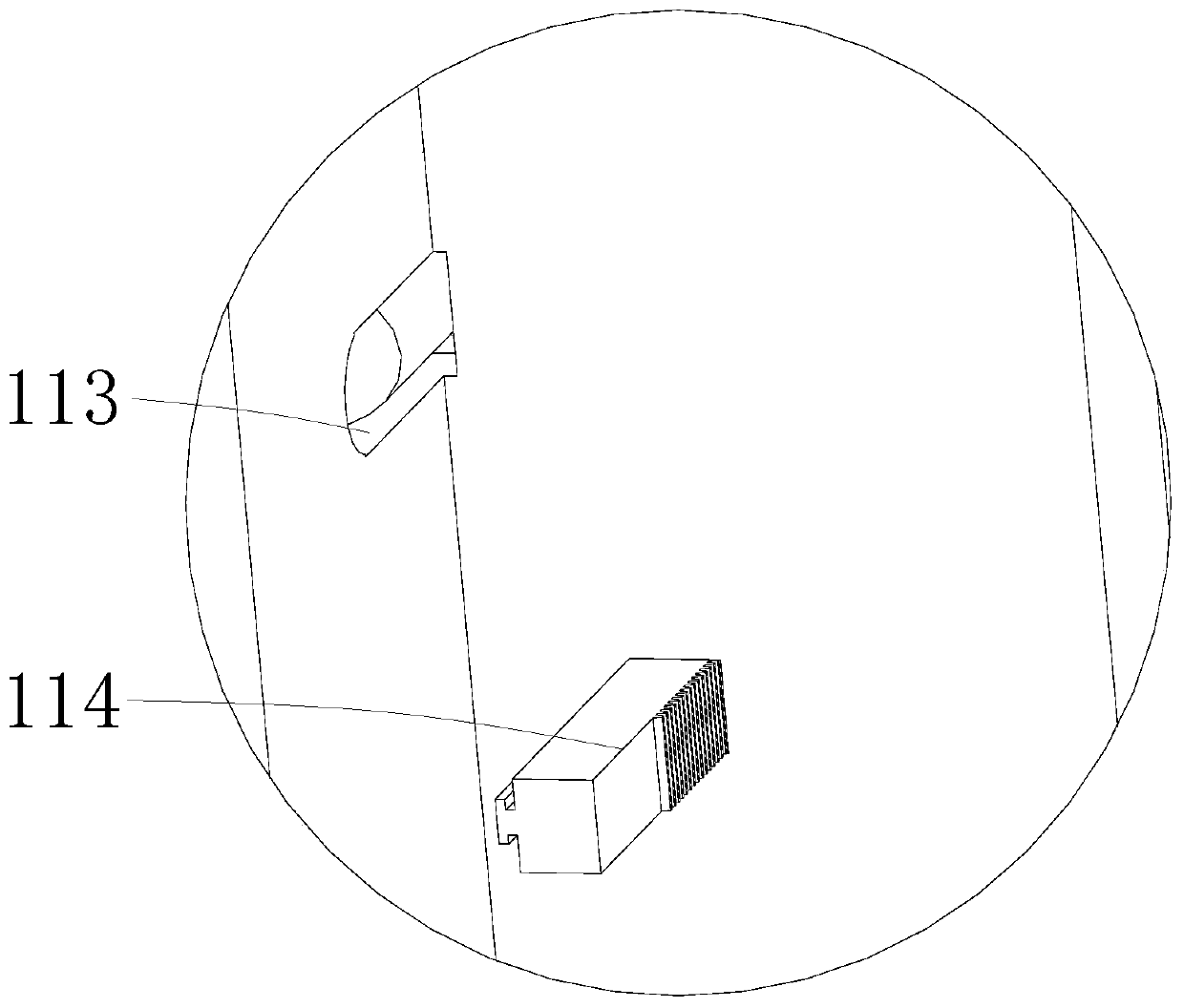

Sounding device and mounting method thereof

InactiveCN108235194AGuaranteed assembly accuracyGuaranteed fixed strengthElectrical transducersLoudspeakersEngineeringSpot welding

The invention provides a sounding device and a mounting method thereof. The sounding device includes a metal basin frame, a metal front cover that is attached to the basin frame, and a diaphragm sandwiched between the front cover and the basin frame. The sounding device further includes a metal connector that is fixed to the basin frame by laser spot welding. The front cover and the connector arefixed by the laser spot welding. The sounding device provided by the invention is capable of ensuring assembly precision as well as fixing strength, and improving product stability.

Owner:AAC TECH PTE LTD

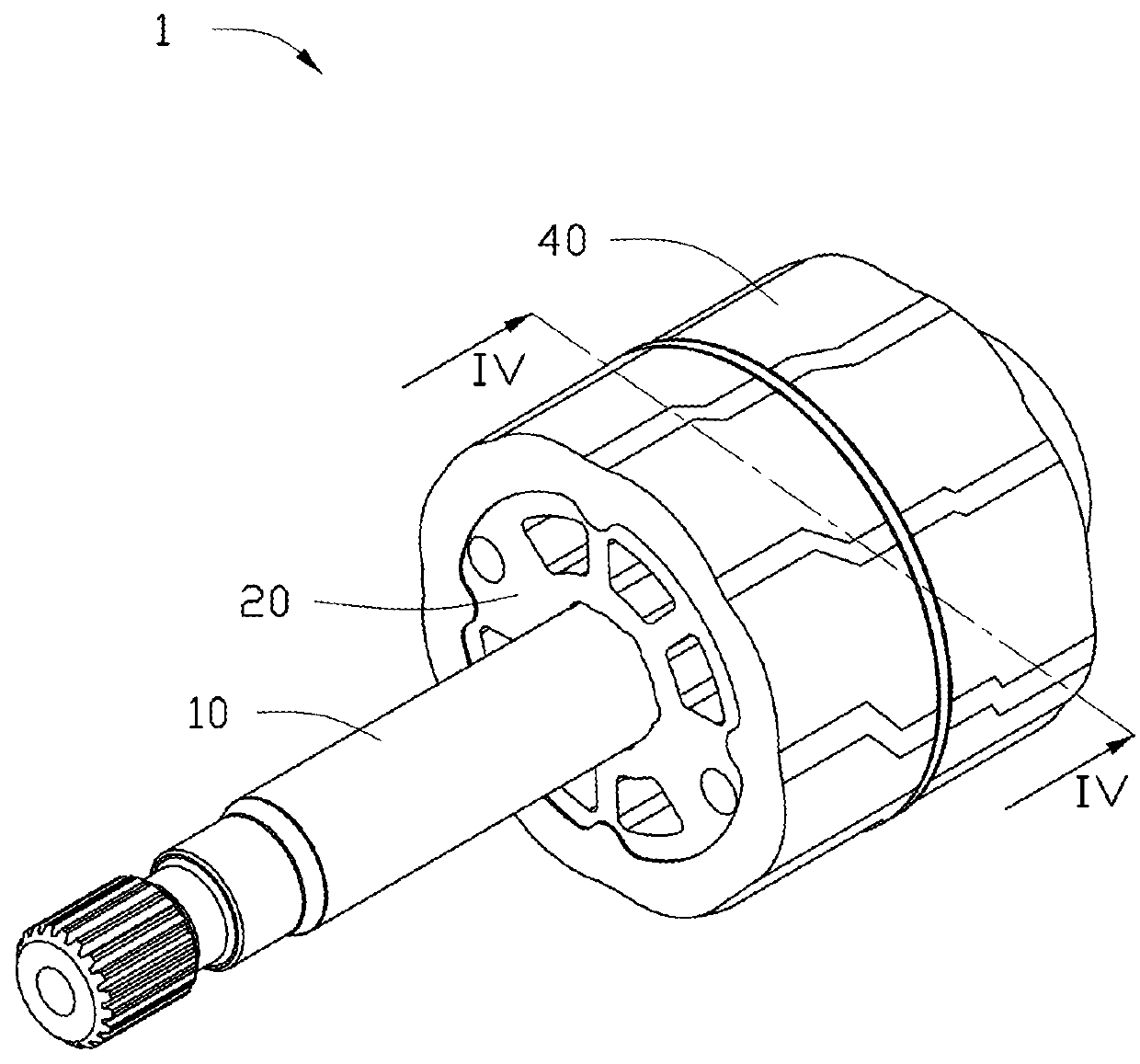

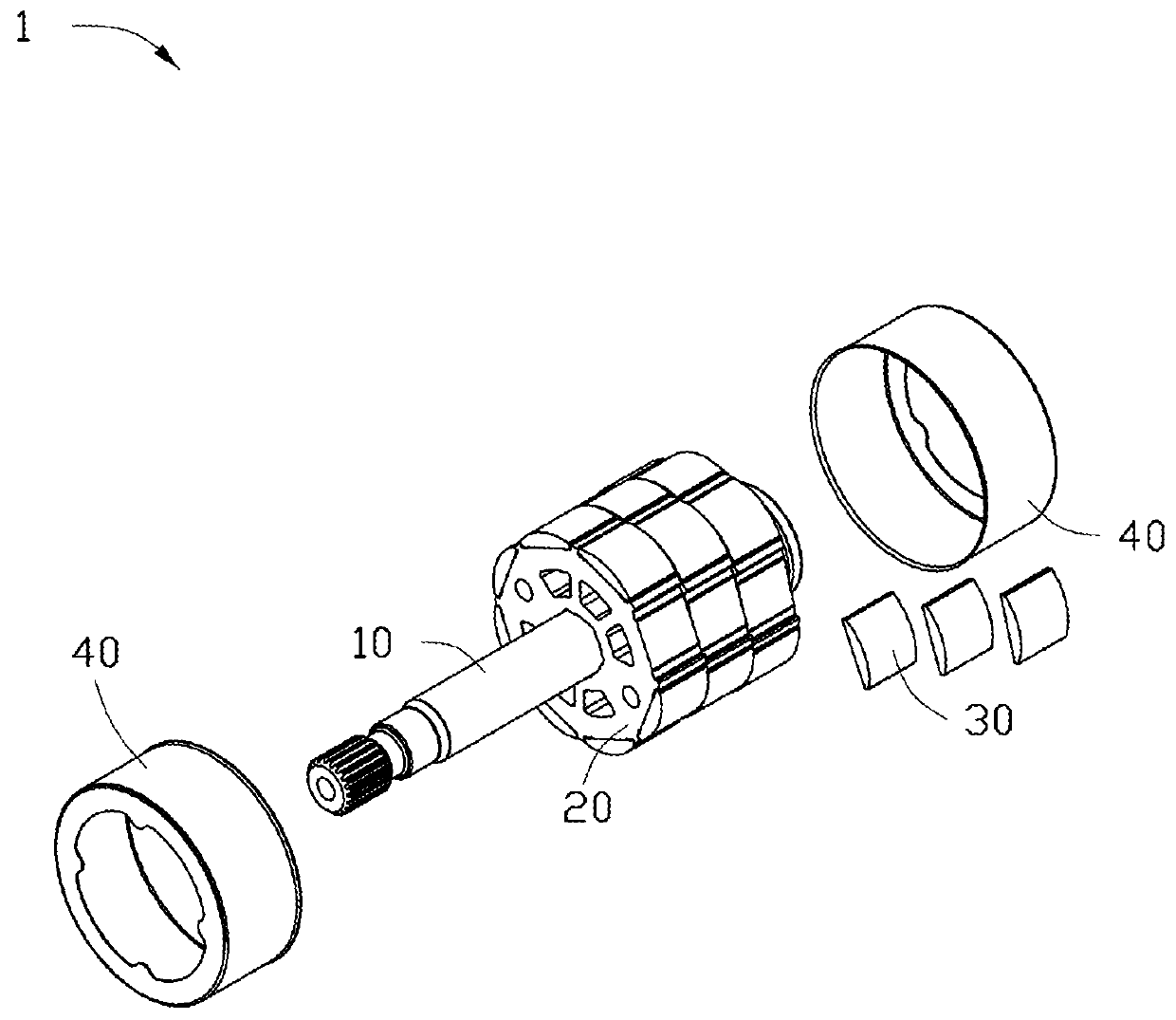

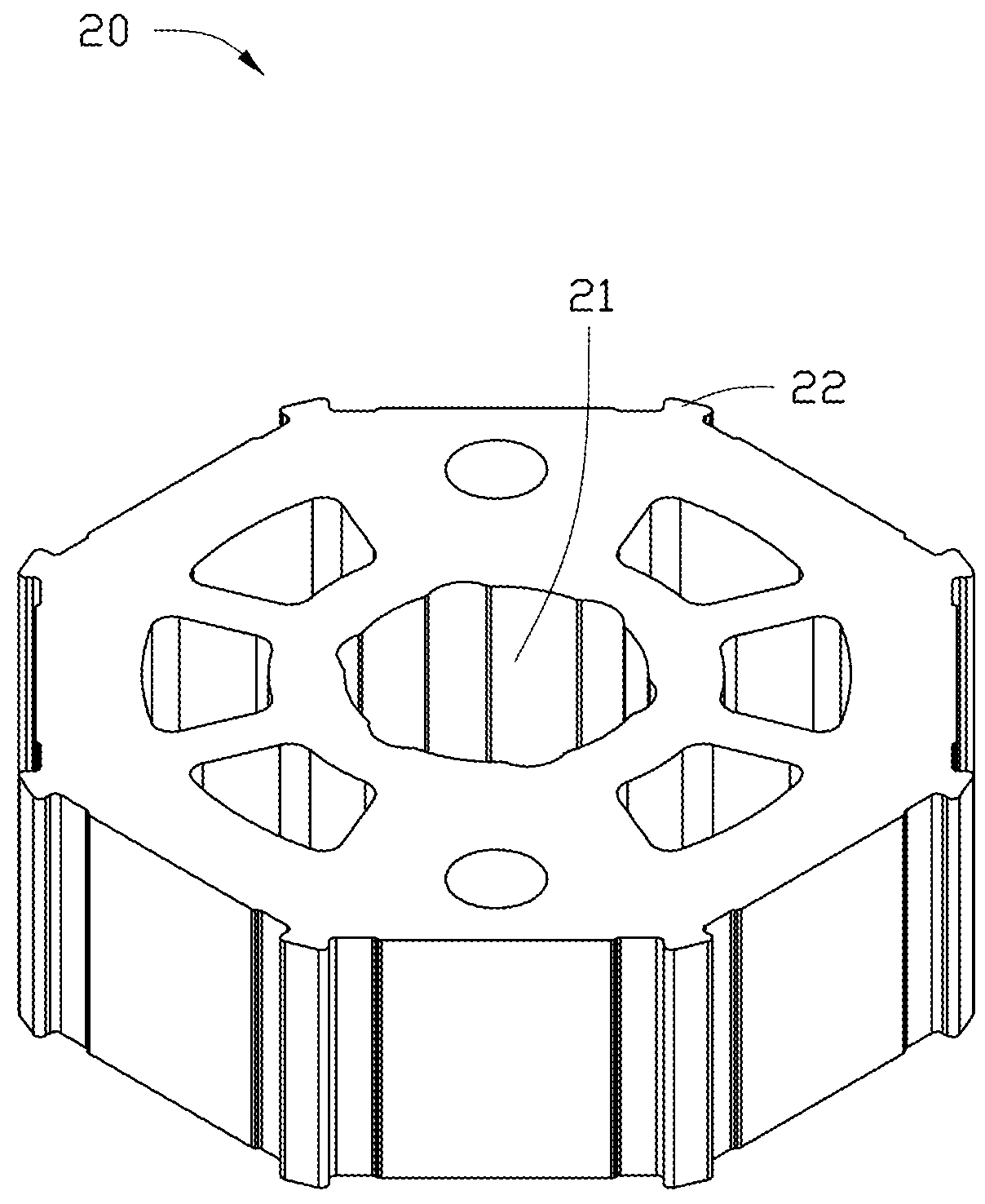

Motor and rotor thereof

InactiveUS20180097413A1Guaranteed fixed strengthPreventing the magnets from breakingMagnetic circuit rotating partsSupports/enclosures/casingsMagnetElectric motor

Owner:JOHNSON ELECTRIC SA

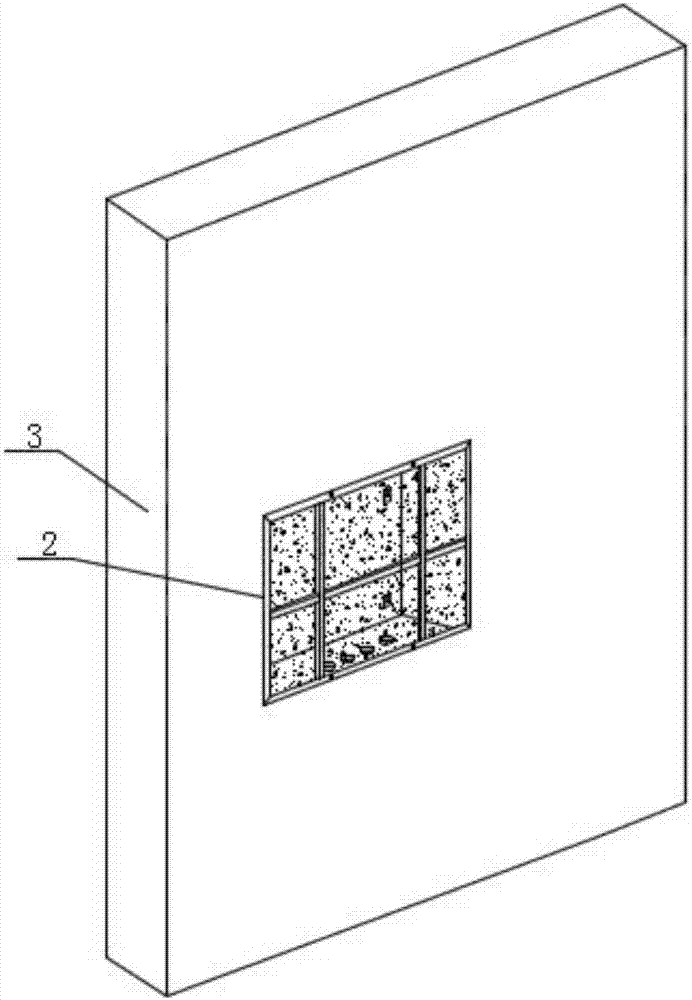

Overall keel lifted glass curtain wall

The invention discloses an overall keel lifted glass curtain wall. The overall keel lifted glass curtain wall comprises two curtain wall stand columns and two curtain wall cross beams; the curtain wall stand columns are provided with first fixed grooves for inserting in glass; the curtain wall cross beams are provided with second fixed grooves for inserting in the glass; and suckers for fixing theglass and driving devices for driving the suckers to fix the glass are arranged on the two sides of the curtain wall stand columns. Through arrangement of the structures, the glass can be directly inserted in the first fixed grooves and the second fixed grooves for primary fixation; and through direct insertion of the glass, the movement control of the suckers by the driving devices is realized,so that the suckers are conveniently controlled to reliably fix the glass, the crushing of the glass caused by punching fixation of the glass can be prevented, the completeness of the glass is guaranteed, and the cost output is reduced.

Owner:HANJIA DESIGN GRP CO LTD

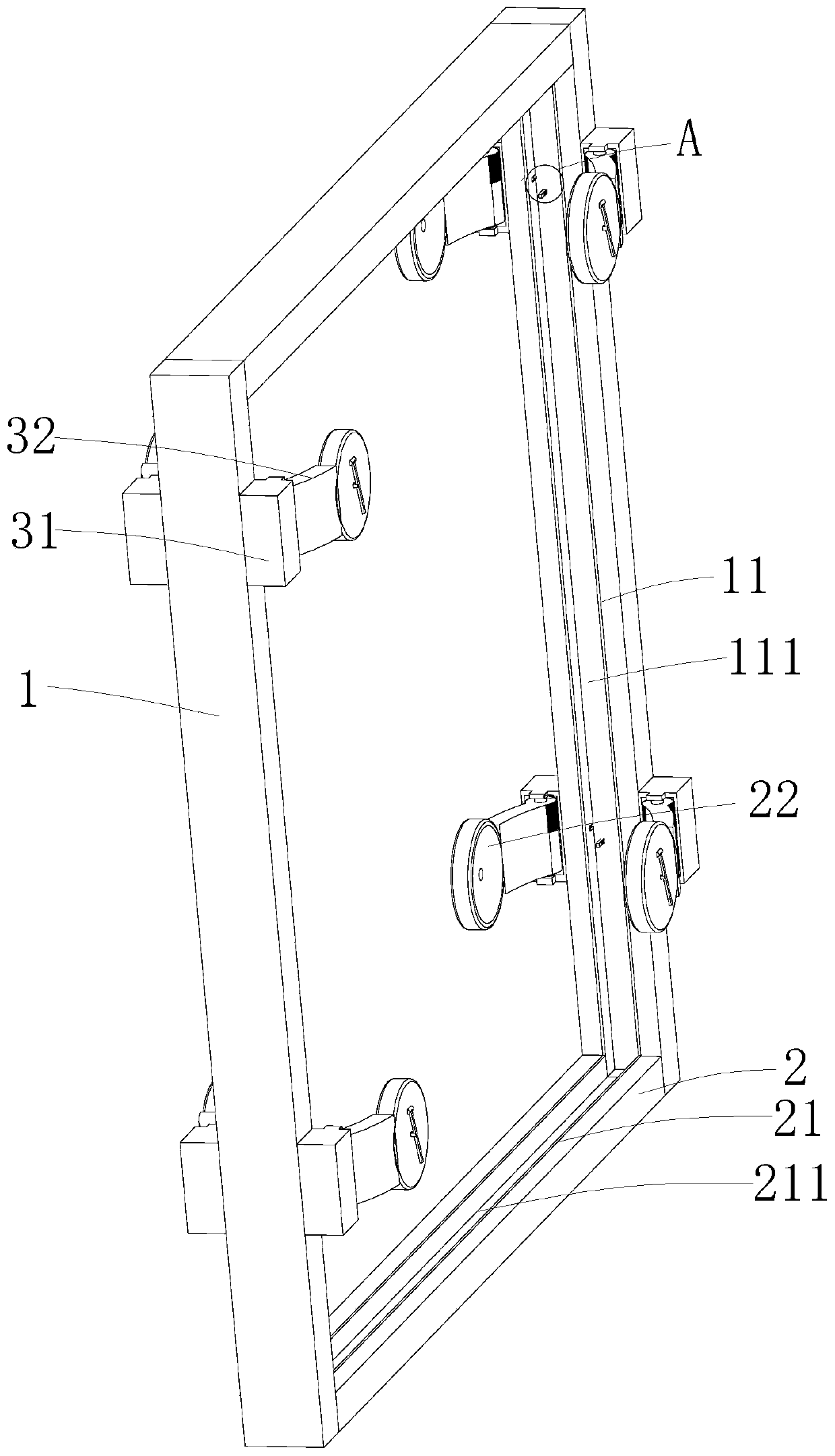

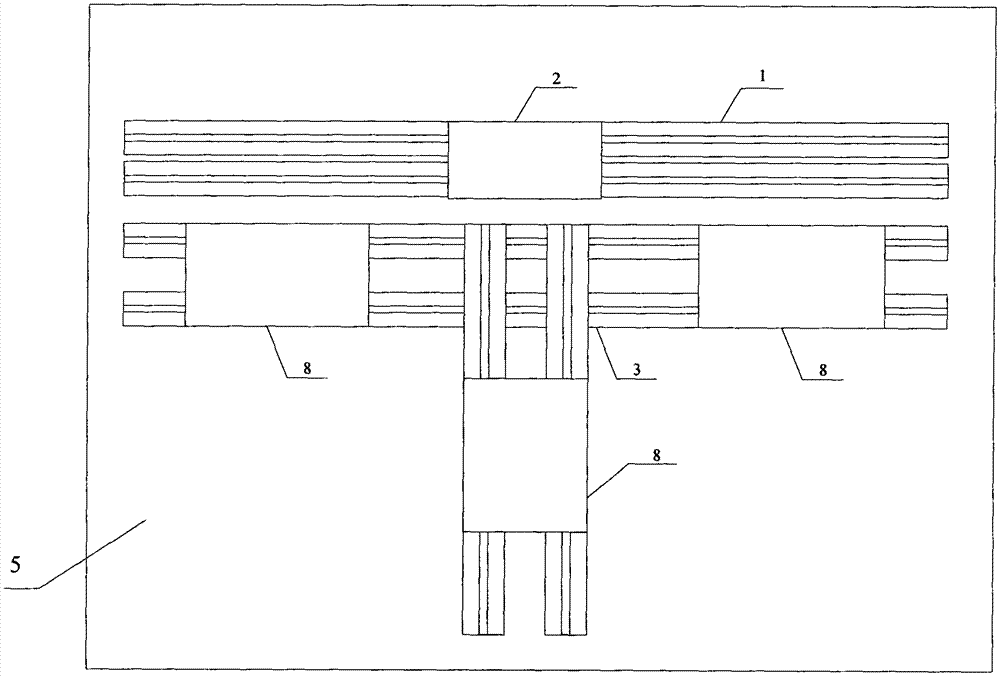

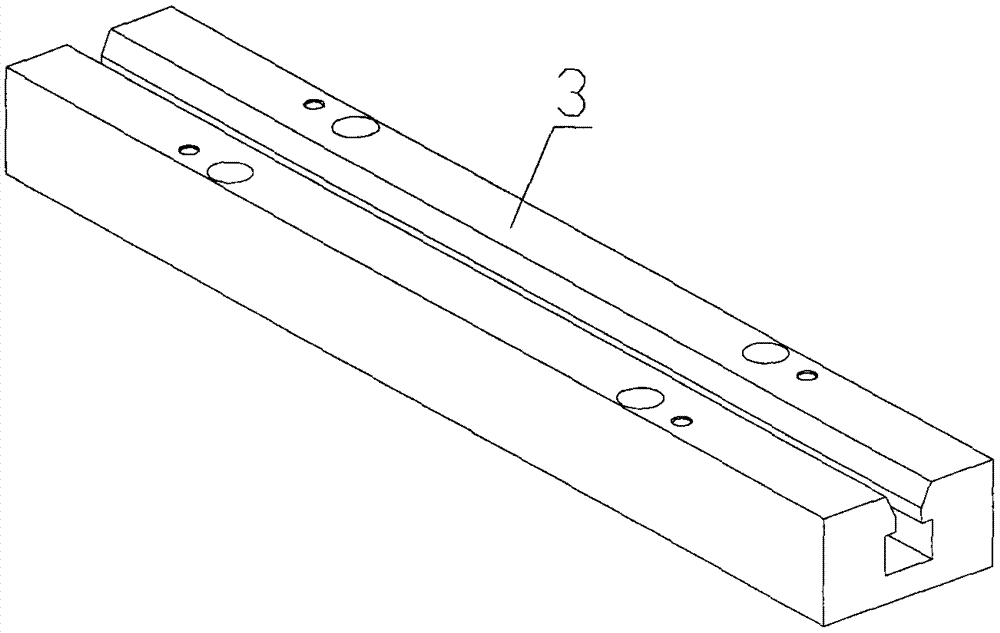

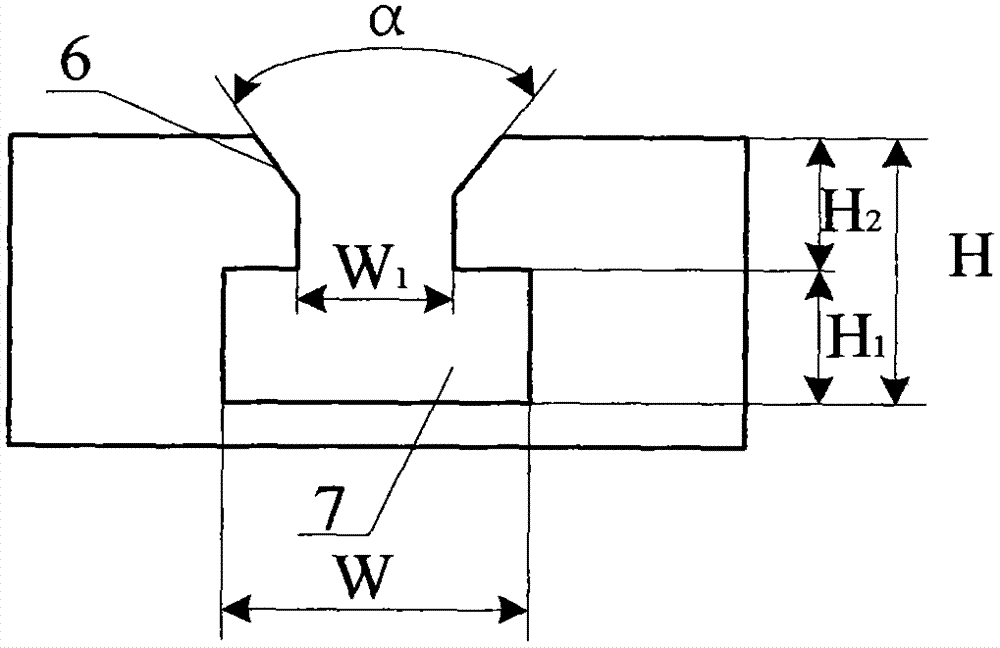

Moving mechanism

ActiveCN103776606AVarious formsGuaranteed movement accuracyVibration testingSheet steelPre embedding

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

Gas insulated switchgear

InactiveCN104241016AGuaranteed fixed strengthSmall operating forceHigh-tension/heavy-dress switchesAir-break switchesOperating energyHigh resistivity

Compact lightweight gas insulated switchgear which assures sufficient electrode fixing strength equivalent to the fixing strength given by brazing and is structurally simple and enables efficient arc rotation with low operating energy. In the switchgear, a movable arcing contact is located on a movable element, opposite to a fixed arcing contact and electrically connected to, or disconnected from, the fixed arcing contact as the movable element moves. The movable arcing contact includes, in order from its tip opposite to the fixed arcing contact, a first electrode as a convex hollow coaxial cylindrical electrode, hollow coaxial cylindrical first spacer, and second electrode as a hollow coaxial cylindrical electrode and has electric conduction means to connect the first and second electrodes electrically through the first spacer. The first and second electrodes are fixed through the first spacer by a fixing member having higher resistivity than the first and second electrodes.

Owner:HITACHI LTD

Mask fixing device, mask plate, and manufacturing method of mask plate

InactiveCN110359011AImprove fitReduce wrinklesVacuum evaporation coatingSputtering coatingEngineeringColor mixing

The invention discloses a mask fixing device, a mask plate and a manufacturing method of the mask plate. The mask fixing device comprises a bearing part, wherein one or more adsorption air holes for adsorbing the mask are arranged on the bearing part. Through arranging one or more adsorption air holes for adsorbing the mask on the bearing part, the adsorption air holes generate adsorption force toadsorb the mask in the process of mask attaching; the mask is better attached to the bearing part; folding risk of the mask is reduced; attaching tightness of the mask and the bearing part is improved; and fixing strength of the mask is guaranteed. In addition, the reduced folding risk of the mask can improve alignment precision of the mask and further improve precision of the mask plate. According to the device, when the mask plate is used for evaporating luminous materials with different colors of the display panel; and risks like color deviation and color mixing of the display panel can bereduced.

Owner:YUNGU GUAN TECH CO LTD

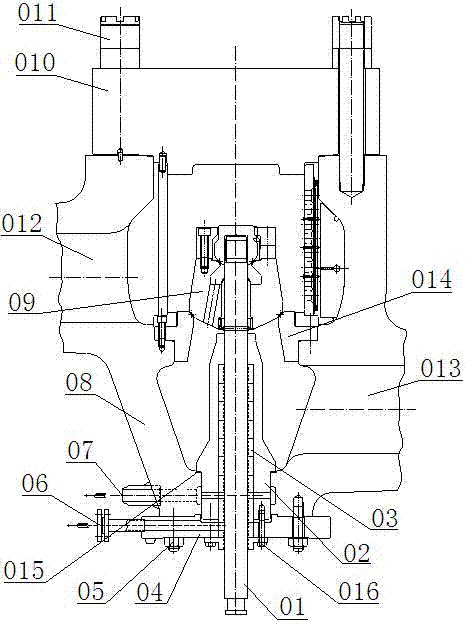

Main steam valve of steam turbine

ActiveCN102787871AImprove efficiencyReduce operating costsMachines/enginesLift valveValve stemVALVE PORT

The invention discloses a main steam valve of a steam turbine. The main steam valve comprises a valve body, a bonnet and a valve stem, wherein an upstream steam passage, a downstream steam passage, a valve stem assembly hole, a bonnet assembly hole and a valve seat are formed on the valve body. The bonnet mainly comprises an inner bonnet, an elastic sealing ring, a hold-down ring and a locating ring which are arranged in the bonnet assembly hole from the bottom up in sequence, and an outer bonnet which is fixed at the outer end of the bonnet assembly hole through fixing bolts, wherein the inner bonnet is subjected to self-tightening seal and bears most pressure, the outer bonnet bears less pressure, and the sealing effect is good. The upper end of the valve stem passes through a sleeve and is connected with a valve disc, and under the operation of the valve stem, the valve disc is matched with the valve seat to close or open the upstream steam passage and the downstream steam passage on the valve body. A sealing cartridge is arranged on the sleeve, and a sealing cone is arranged on the valve stem. When the valve disc and the valve seat are open, the valve stem is sealed with the sealing cartridge through the sealing cone, and the opening of the valve disc is limited by the sealing cone. The main steam valve has the characteristics that the main steam valve is good in sealing performance, low in production cost, high in practicability and capable of bearing high parameter steam.

Owner:DONGFANG TURBINE CO LTD

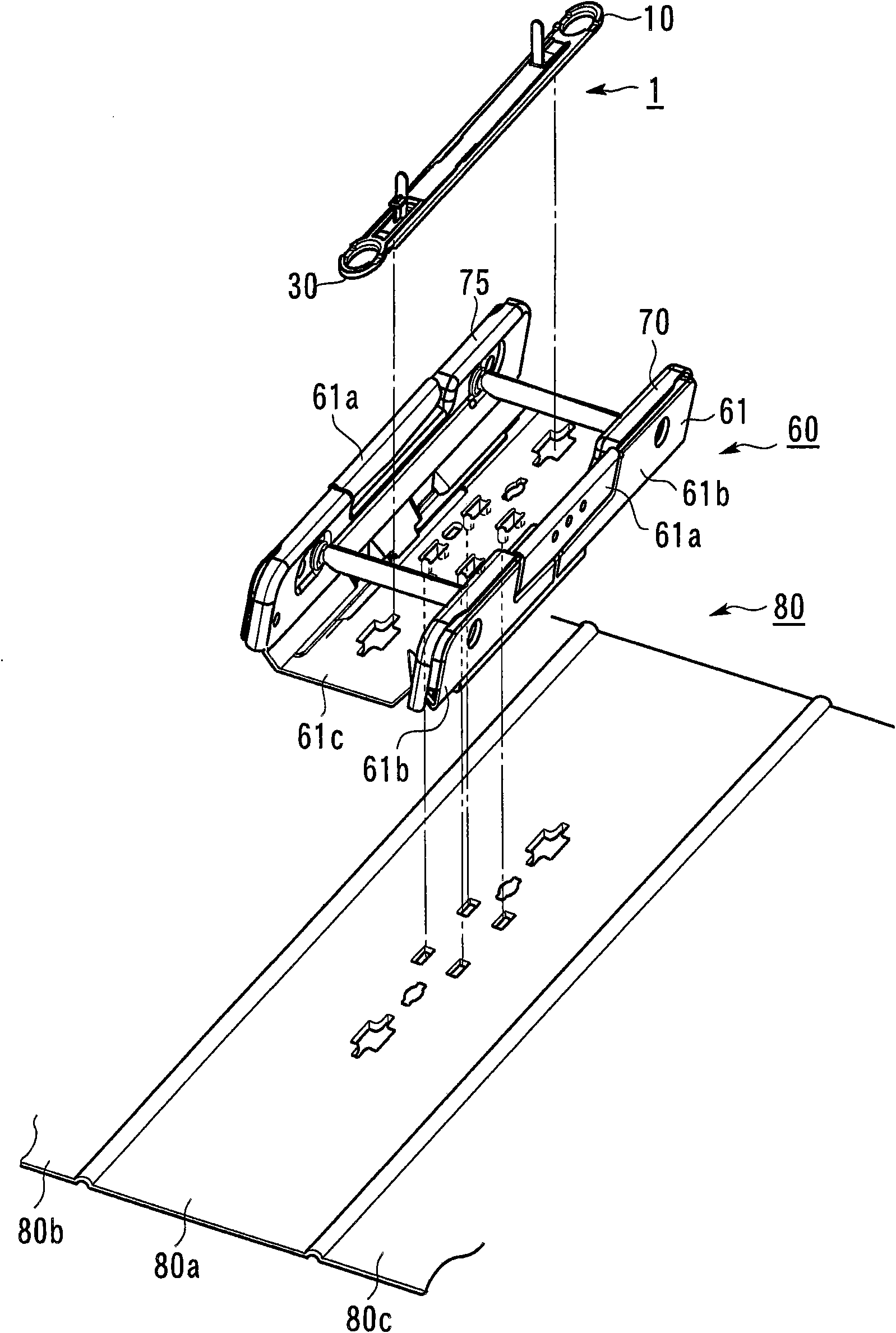

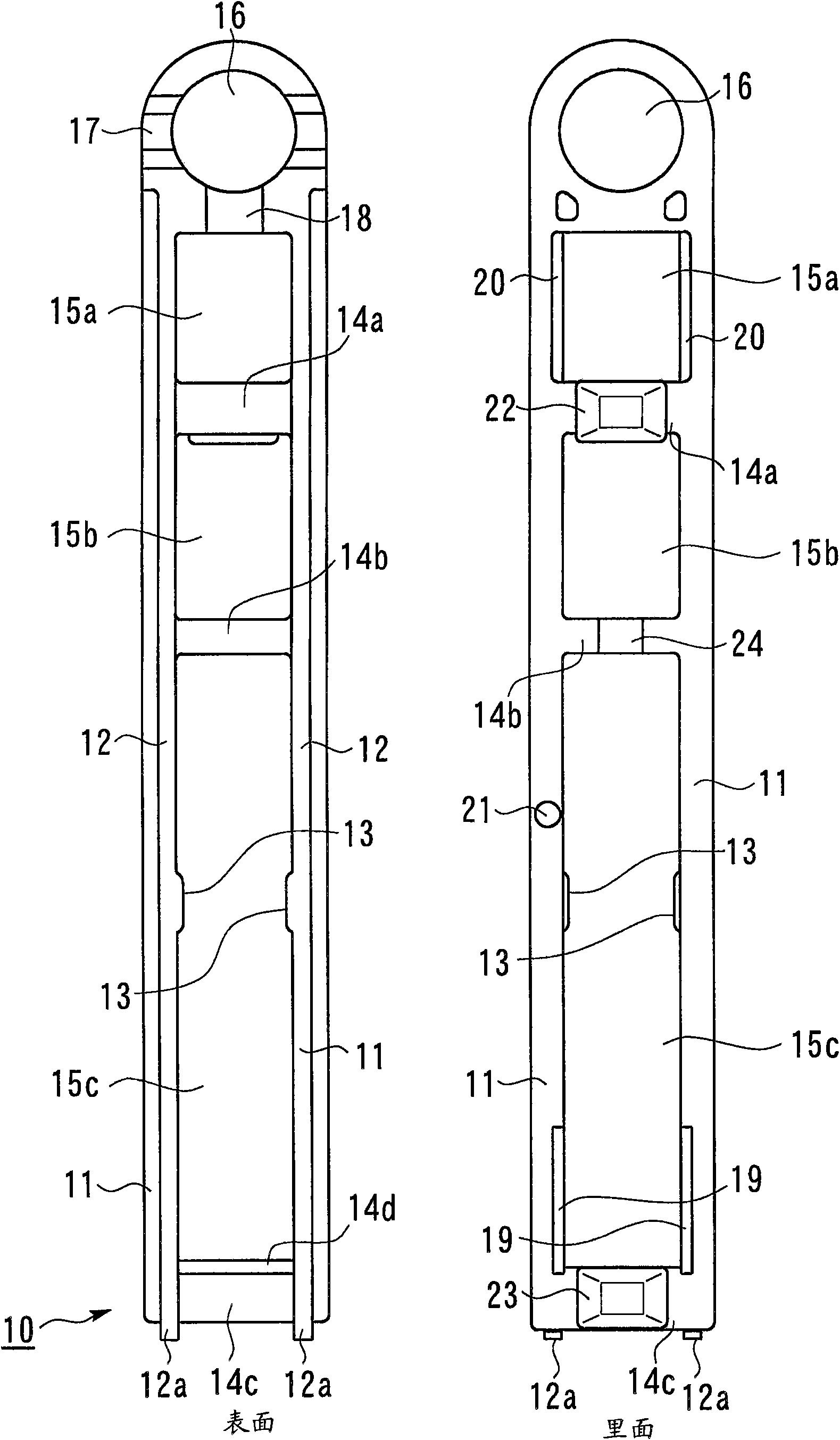

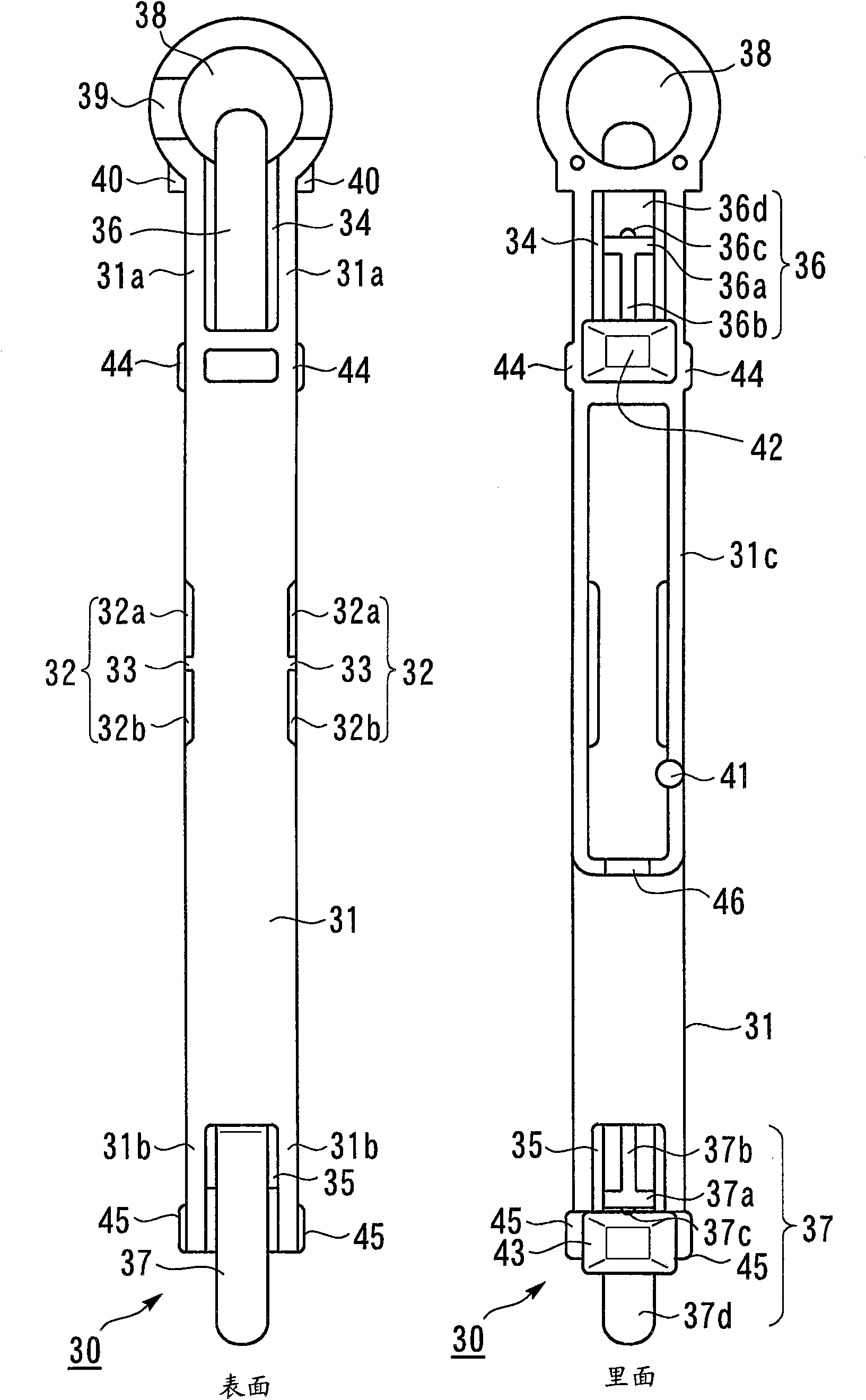

Loose leaf binding fixture attachment device, cover, and loose leaf binding fixture affixing method

InactiveCN101983134AEasy to fixGuaranteed fixed strengthFiling appliancesEngineeringMechanical engineering

The invention concerns a device for fixing a loose leaf binding fixture used to bind books, etc., to a cover body by manipulating only one side and which provides the required attachment strength. Disclosed is a loose leaf binding fixture attachment device that affixes a loose leaf binding fixture to a cover body and is equipped with an attachment device main body part arranged on the cover body, a pair of insertion parts provided on the attachment device main body for insertion into connection holes formed with hole parts for attachment and hole parts on the cover side that overlay each other, and a first engagement part and a second engagement part provided for one of the two insertion parts so that the engaged member can be engaged or disengaged, where said engaged member is the member, either the cover body or the loose leaf binding fixture, at the inside part of the insertion parts in the insertion direction, when the pair of insertion parts is inserted into the connection holes. The first engagement direction, which is the engagement direction of the engaged member that is engaged by the first engagement part, is set to be different from the second engagement direction, which is the engagement direction of the engaged member that is engaged by the second engagement part.

Owner:KING JIM CO LTD

Spinning bobbin automatic replacing device for facilitating connection

The invention discloses a spinning bobbin automatic replacing device for facilitating connection. The spinning bobbin automatic replacing device comprises a working box for containing and protecting the device, the working box is internally provided with a placing tray for placing and fixing spinning threads, a first driving piece used for driving the placing tray to rotate and a connecting devicefor connecting the broken spinning threads together, a spinning bobbin placing device for placing spinning bobbins is further included, and the spinning bobbin placing device comprises a placing box,a placing column used for placing a plurality of spinning bobbins and a control handle for controlling the rotation of the placing column. Through the arrangement of the above structure, the spinningbobbins can realize the storage and standby effect through the above-mentioned placing column and a placing rod, so that more spinning bobbins are conveniently stored and placed for waiting to be used, the storage capacity of the spinning bobbins is effectively increased, and the spinning bobbin automatic replacing device is simple in structure and easy to operate.

Owner:安吉万洲电气有限公司

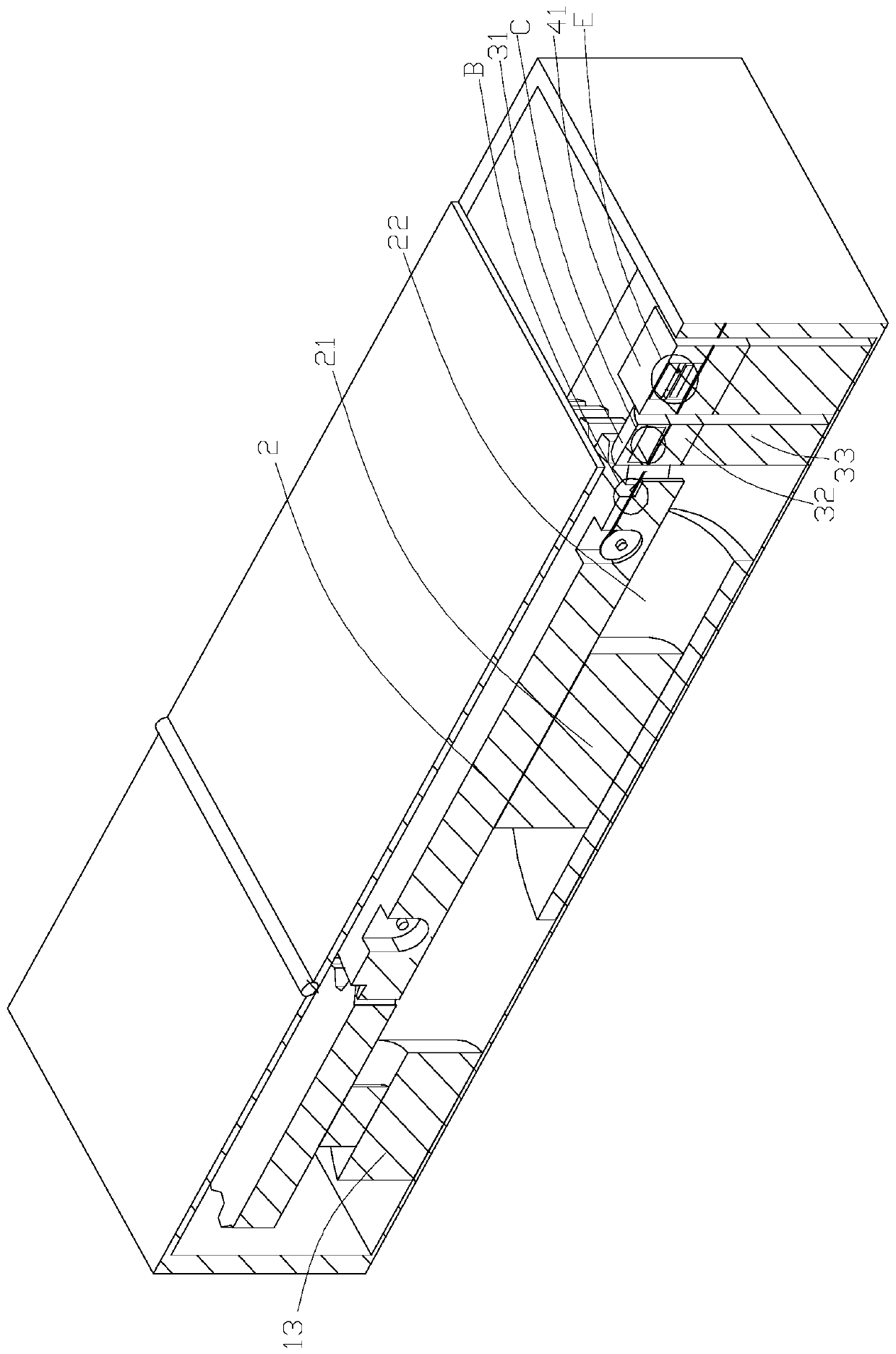

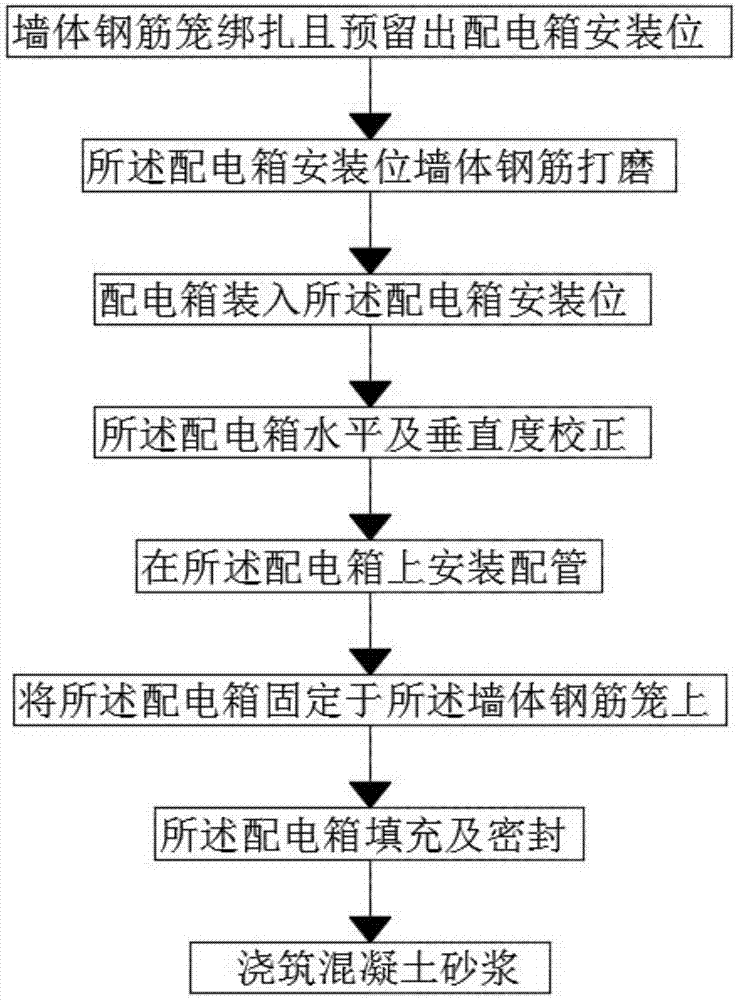

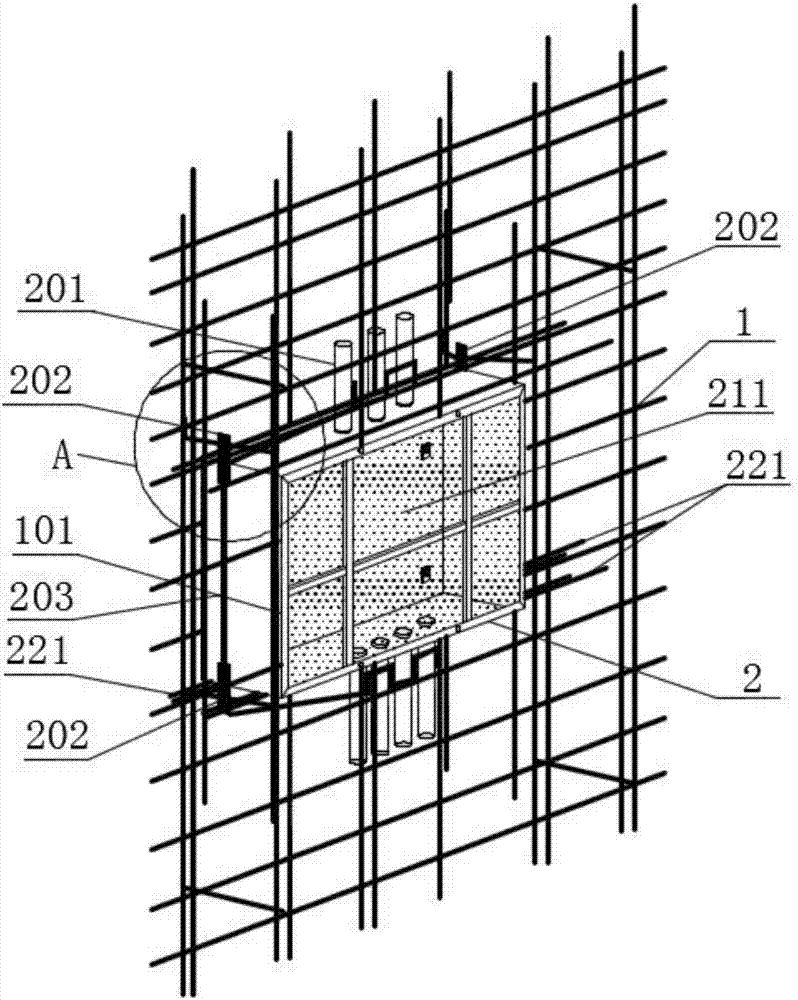

Construction method for integral pouring of concealed-mounting distribution box along with concrete wall structure

InactiveCN107269001AContact stabilityAvoid crackingElectrical apparatusBuilding material handlingRebarPiping

The invention relates to the technical field of building distribution box mounting, in particular to a construction method for integral pouring of a concealed-mounting distribution box along with a concrete wall structure. The construction method comprises the steps that a wall steel reinforcement cage is bound, and a distribution box mounting position is reserved; the distribution box is mounted in the distribution box mounting position; pieces of piping are mounted on the distribution box; the distribution box is fixed to the wall steel reinforcement cage; the distribution box is filled and sealed; and concrete mortar is poured. The distribution box is fixed to the wall steel reinforcement cage, and then the concrete mortar is poured, so that the problems that in the prior art, cracks are prone to forming in a gap between a distribution box and an original wall structure, hollowing is prone to being generated in the distribution box, the technological process has multiple steps, the large number of materials and a large amount of labor are invested, resources are wasted, and the consumed time is long are solved.

Owner:北京城建远东建设投资集团有限公司

Closed type dewatering environment-friendly energy-saving device for deep foundation pit and construction process thereof

InactiveCN112081126AWith energy saving and environmental protectionGuaranteed running stabilityExcavationsElectric machineArchitectural engineering

The invention discloses a closed type dewatering environment-friendly energy-saving device for a deep foundation pit and a construction process thereof, and relates to the technical field of deep foundation pit dewatering. The closed type dewatering environment-friendly energy-saving device for the deep foundation pit comprises a dewatering well, wherein a sliding plate is arranged inside the dewatering well, the top of the sliding plate is fixedly connected with a submersible pump, the inner wall of the dewatering well is sleeved with a retaining ring pipe, the bottom of the sliding plate isfixedly connected with a filtering and cleaning mechanism, and the left side and the right side of the top of the sliding plate are fixedly connected with filter screens. According to the closed typedewatering environment-friendly energy-saving device for the deep foundation pit and the construction process thereof, the problems that the dewatering well is not environment-friendly and energy-saving enough during existing deep foundation pit construction, blocking objects are easy to pump out during well water pumping during dewatering, the construction environment is influenced, the filteringeffect is poor, so that impurities permeate the filter screens and are pumped out by the submersible pump after blocking, meanwhile, the submersible pump consumes more electric energy during blocking, and a motor is easy to damage are solved, and the advantages of energy conservation and environmental protection are achieved.

Owner:ZHEJIANG GUANGDA CONSTR GRP

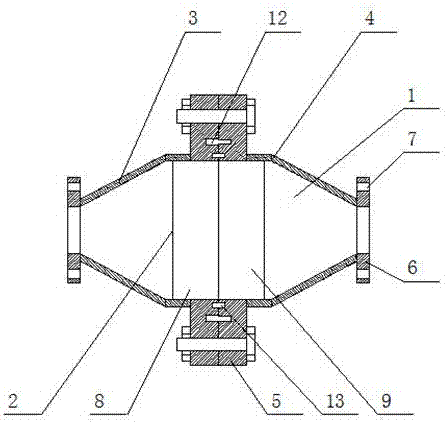

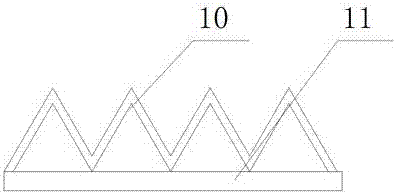

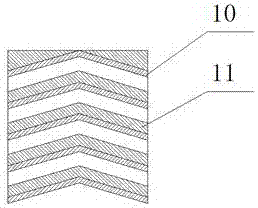

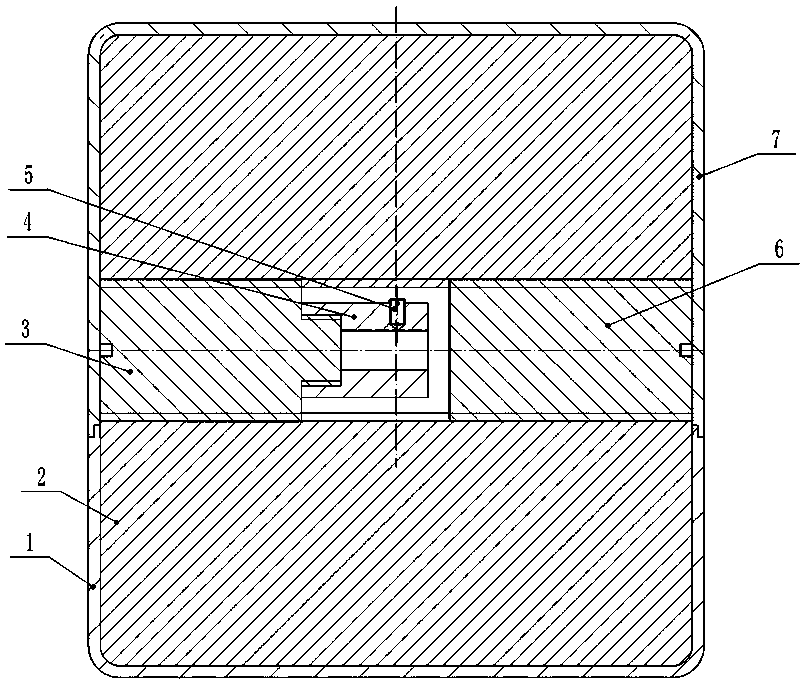

Pipeline fire barrier

The invention discloses a pipeline fire barrier. The pipeline fire barrier comprises a valve and a fire blockage device; the valve comprises a first valve body, a second valve body, large flange discs and small flange discs, the first valve body and the second valve body are conical, the large flange discs and the small flange discs are fixed to the two ends of the first valve body and the second valve body correspondingly, the large flange discs and the small flange discs are each evenly provided with four connecting holes, the small flange discs are fixedly connected with a pipeline through bolts, and the positions, between the large flange discs, on the first valve body and the second valve body are fixedly connected through bolts. The fire blockage device comprises a first fire blockage plate and a second fire blockage plate. The first fire blockage plate is fixedly connected with the inner wall of the first valve body, and the second fire blockage plate is fixed to the inner wall of the second valve body. According to the pipeline fire barrier, due to the fact that a corrugated steel strip and a flat steel strip are both in a V shape, the length of the pipeline can be increased, the contact area can be increased, and the better fire blockage aim is achieved.

Owner:YANCHENG OURUN PETROCHEMICAL EQUIP MFG CO LTD

Shielding device for high-reflective material and application of device

ActiveCN108182982AReduce radiation doseReduce penetrationShieldingPortable shielded containersNuclear reactorReflective layer

The invention discloses a shielding device for a high-reflective material and application of the device. The problem that an RPV steel sample obtained after being irradiated with a nuclear reactor hasextremely high harm, and no perfect shielding method or device exists is solved. The high-reflective material is an RPV steel experimental sample obtained after being treated and irradiated with thenuclear reactor for a long time, in other words, the invention provides the shielding device aiming at RPV steel obtained after being irradiated with the nuclear reactor and a processing method and application of the device, and relates to a ray shielding technology and method for the high-reflective material in the long process transportation and processing processes. Accordingly, on the basis ofthe ray shielding theory and the material characteristics of depleted uranium, a novel portable shielding container is designed and made, harmful ray release of the PRV steel in the processes such aslong process turnover and machining can be effectively lowered, the safety in the transportation and machining processes is guaranteed, and the influence of the high-reflective material on the environment is lowered to the maximum extent.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

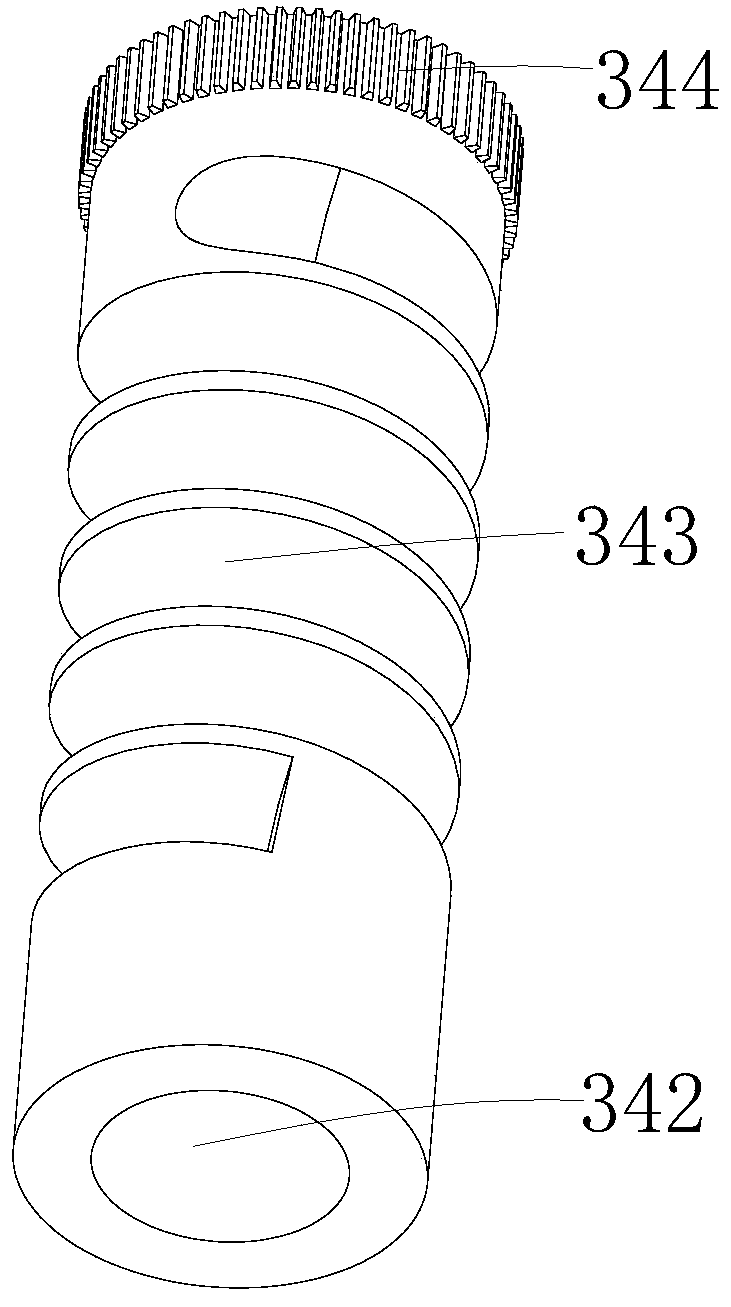

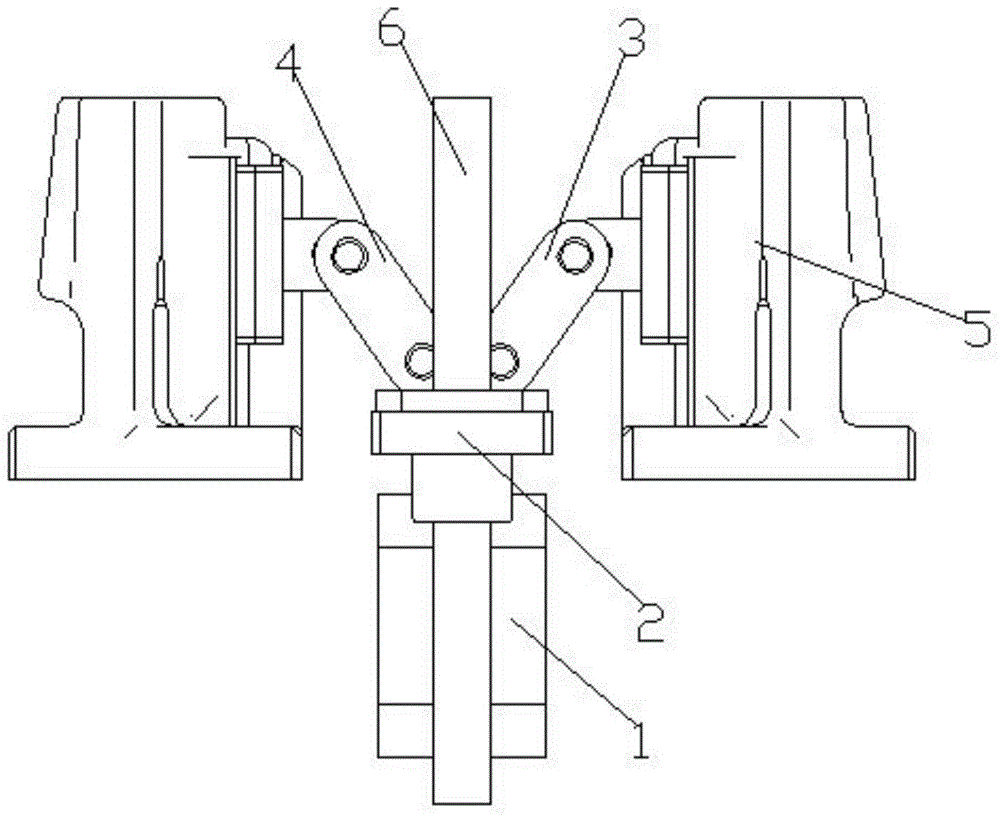

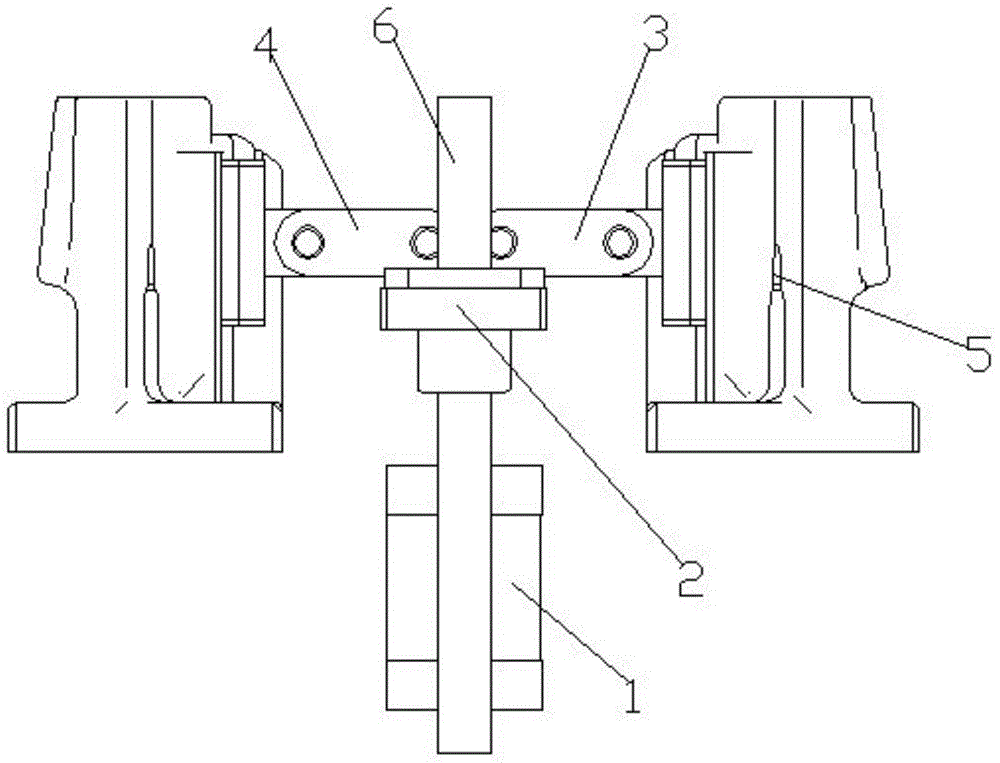

Internal supporting jig

InactiveCN104607842AGuaranteed fixed strengthWill not harmWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringPiston

The invention relates to an internal supporting jig. The internal supporting jig comprises a telescopic cylinder, a guide base, a first connecting plate, a second connecting plate and two supporting heads, wherein the guide base is fixed to the piston end of the cylinder, one end of the first connecting plate and one end of the second connecting plate are connected with the guide base in a pivoting mode, the other end of the first connecting plate and the other end of the second connecting plate are fixedly connected with the supporting heads respectively, and the shape of each supporting head is matched with that of the inner wall of the workpiece. According to the internal supporting jig, the telescopic cylinder works to drive the guide base to push one end of the first connecting plate and one end of the second connecting plate upwards, the supporting heads are pushed by the other end of the first connecting plate and the other end of the second connecting plate to expand outwards to achieve firm supporting, the shapes of the supporting heads are matched with the shape of the inner wall of the workpiece, the supporting heads tightly support the inner wall of the workpiece, the structure is simple, operation is convenient, the workpiece fixing strength is guaranteed, the workpiece is prevented from being damaged, operation difficulty is lowered, and product quality is guaranteed.

Owner:SUZHOU KEBER PRECISION MACHINERY

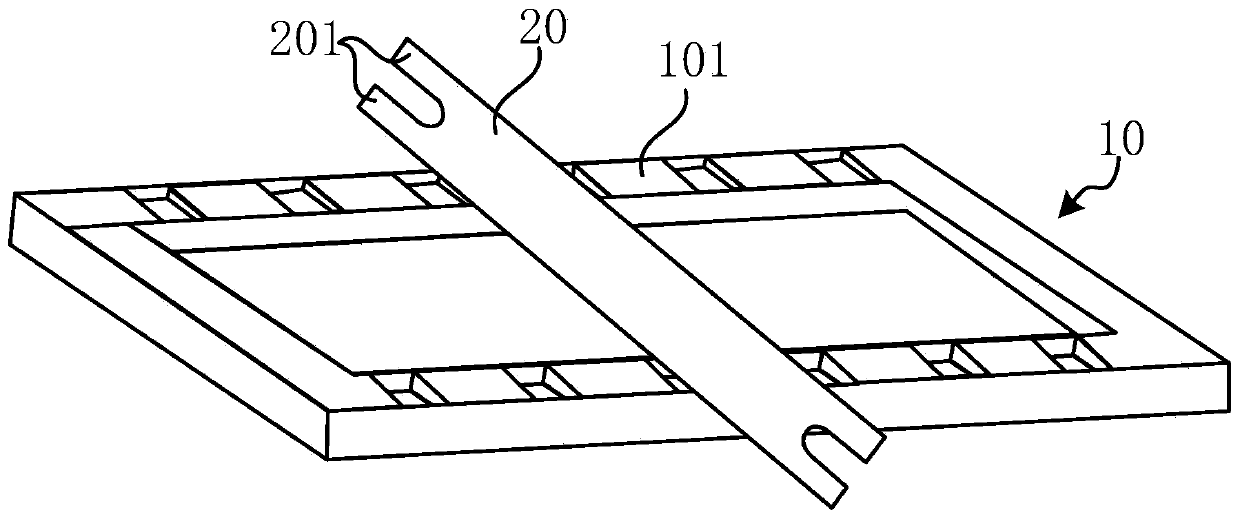

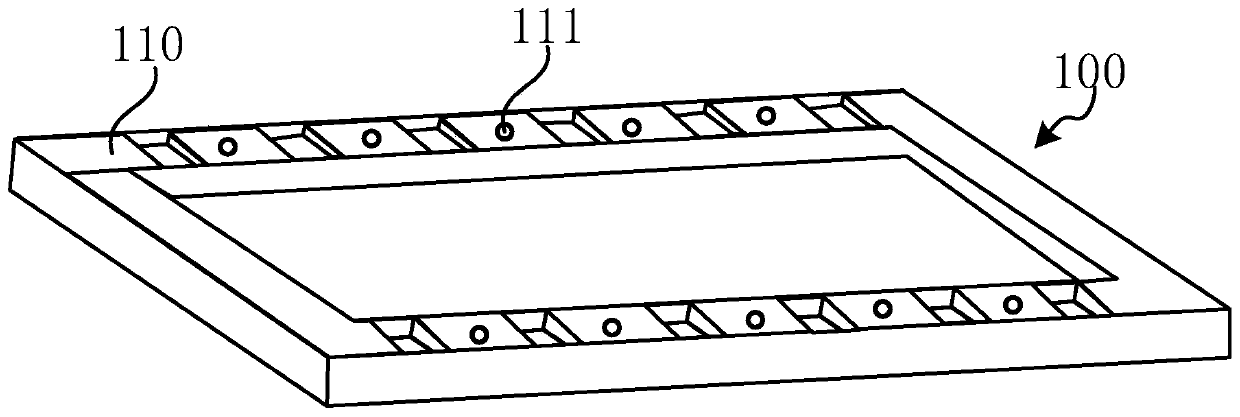

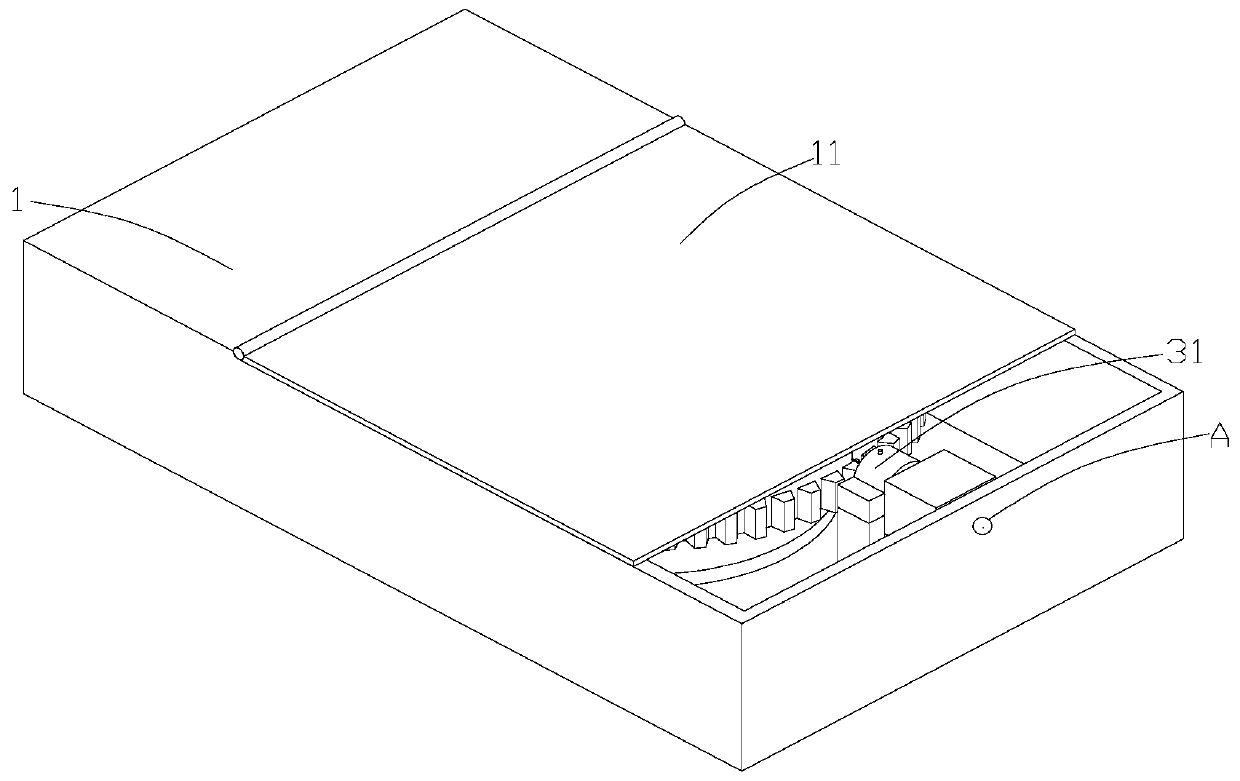

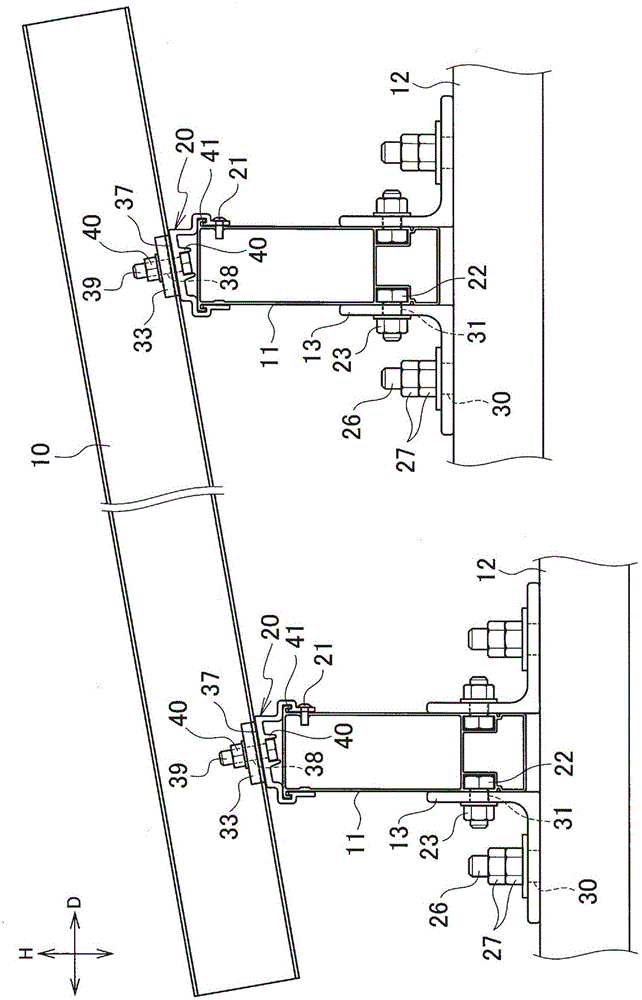

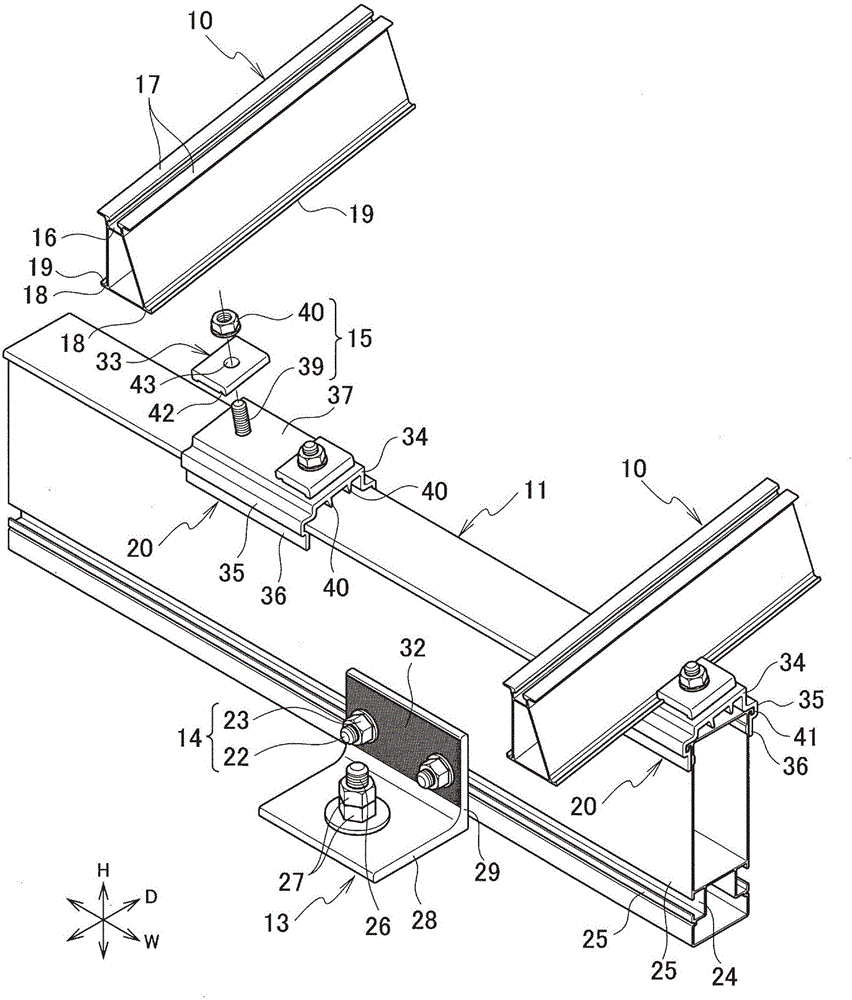

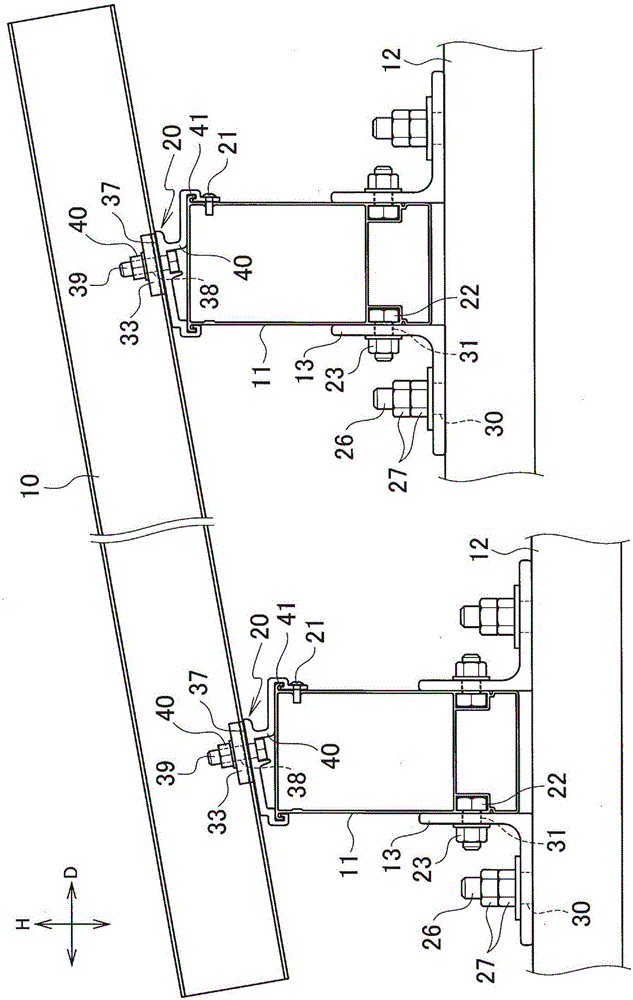

Solar panel stand

InactiveCN106330078AReduce the number of partsEasy to set up jobsPhotovoltaicsPhotovoltaic energy generationEngineeringStructural engineering

Owner:NIKKEIKIN ALUMINUM CORE TECH +6

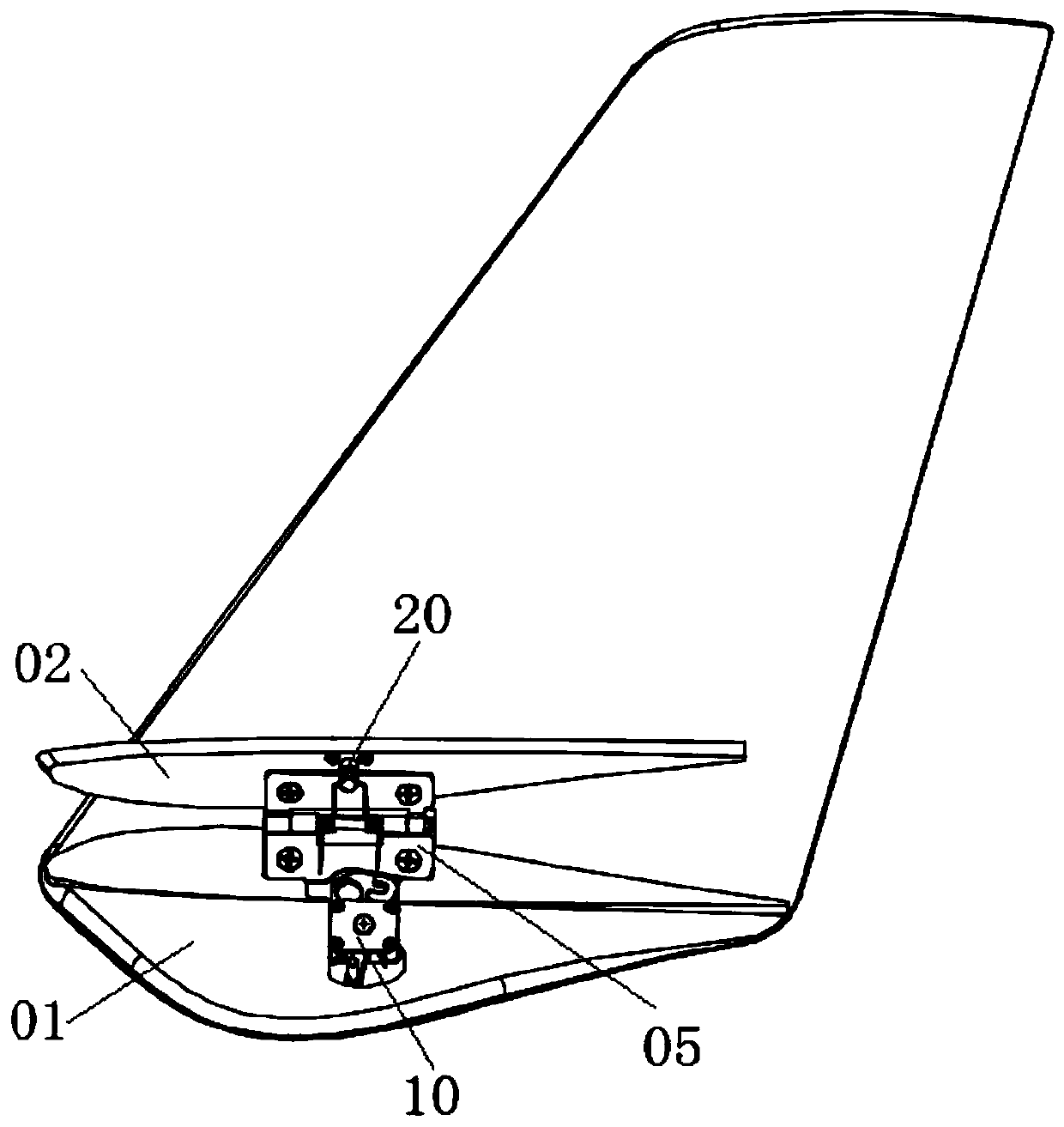

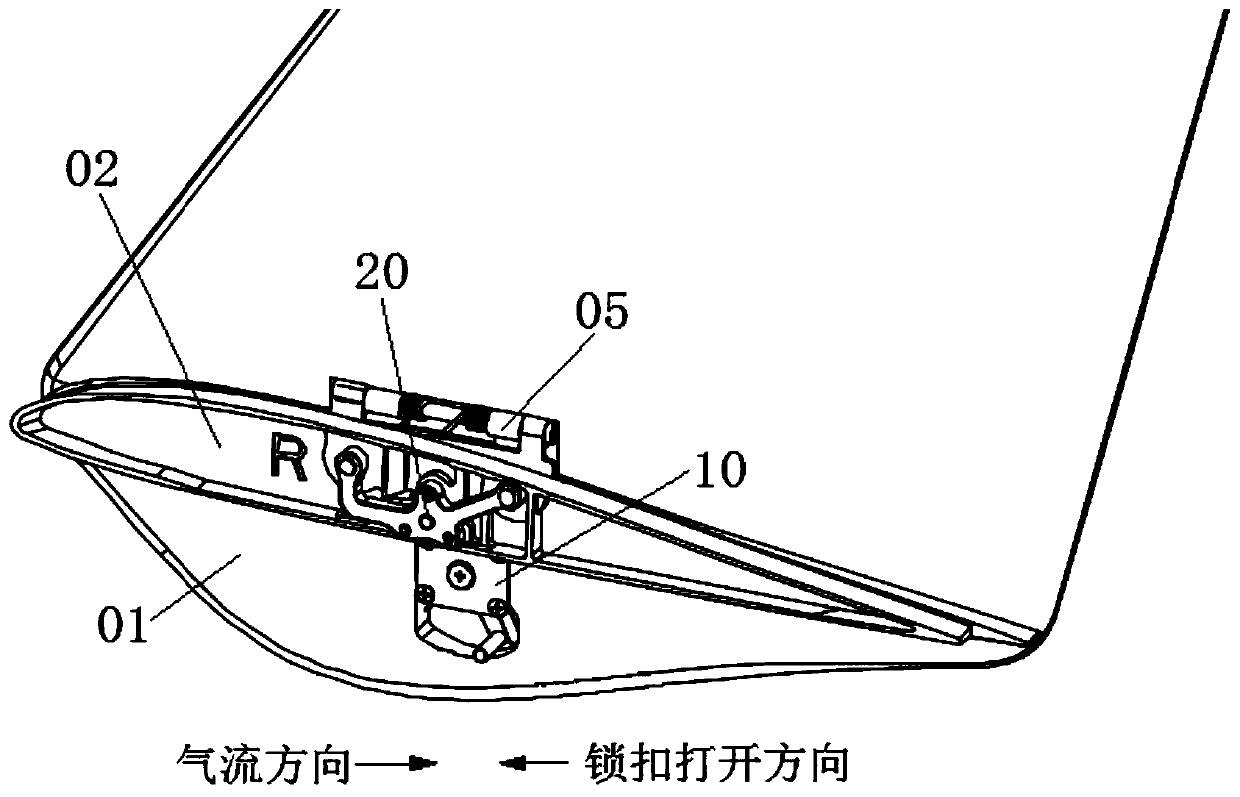

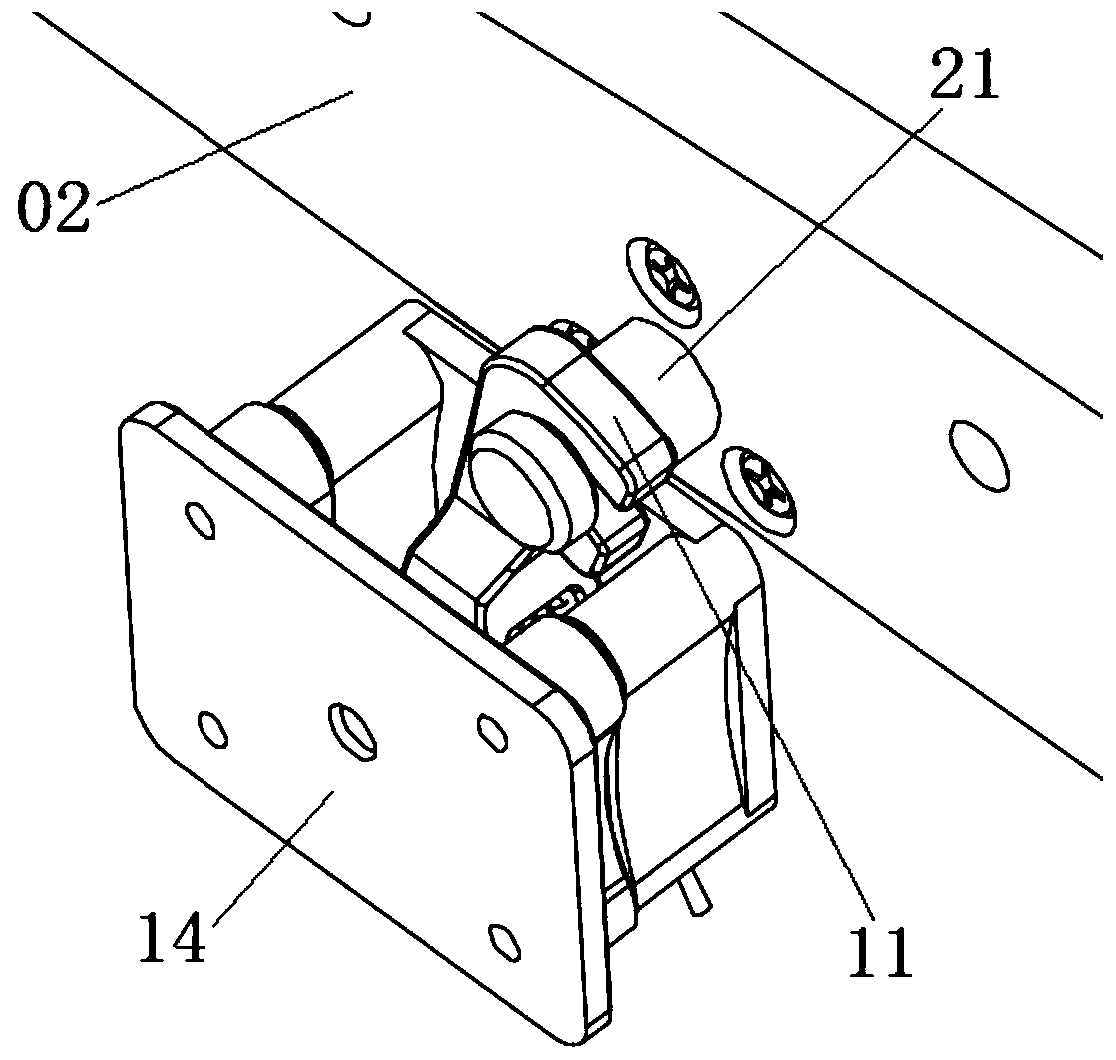

Locking structure and unmanned aerial vehicle

PendingCN111332456AImprovement is not easy to installImprove the problem that the user is easy to tilt and lock inWing adjustmentsAircraftsMarine engineeringUncrewed vehicle

The embodiment of the invention provides a locking structure and an unmanned aerial vehicle, and relates to the technical field of unmanned aerial vehicles. The locking structure is used for fixedly locking and connecting a first part and a second part which are hinged to each other in the unmanned aerial vehicle. The locking structure comprises a hook assembly and a lock pin assembly, the hook assembly comprises a lock catch, and the lock pin assembly comprises a bayonet lock. The hook assembly is used for being installed on the first part, and the lock pin assembly is used for being installed on the second part. And one part of the bayonet lock is positioned between the first part and the second part and is clamped with or separated from the lock catch. When the lock catch is clamped with the bayonet lock, the first part can be fixed relative to the second part, and when the lock catch is separated from the bayonet lock, the first part can move relative to the second part. When the locking structure is used for connecting a winglet and a wing, the locking or unlocking of the winglet and the wing on the unmanned aerial vehicle can be realized through the clamping or separation ofthe lock catch and the bayonet lock, so that the locking difficulty of the winglet is greatly reduced, the operation time of unfolding and folding the winglet relative to the wing is shortened, and the maneuverability of whole machine assembly is improved.

Owner:ZEROTECH (SHENZHEN) INTELLIGENCE ROBOT CO LTD

Centrifugal pump

The invention provides a centrifugal pump. The centrifugal pump comprises a pump body, an auxiliary ground inserting device, a water inlet unit and a water outlet unit, wherein the water inlet unit isinstalled on the side wall of the left end of the pump body, the water outlet unit is installed on the side wall of the right end of the pump body, and the auxiliary ground inserting device is installed at the lower end of the pump body through bolts. According to the centrifugal pump, the problems that when the centrifugal pump is placed in water or oil liquid, vibration is generated in the working process, so that the pump body is inclined and inclined, and then the work of the pump body is influenced can be solved; the problems that when the pump body is placed in the water or the oil liquid, a large number of fixed particles and the like existing in the pump body are adsorbed into the pump body, then normal operation of the pump body is influenced, and rotation of an impeller in the pump body is influenced after long-time use are solved; and the problems that when a water outlet of the pump body is connected with a guide pipe, a water guide pipe is prone to falling off due to thewater spraying pressure generated by the pump body, and then the work of the pump body is influenced are solved.

Owner:百鸿国际机械(上海)有限公司

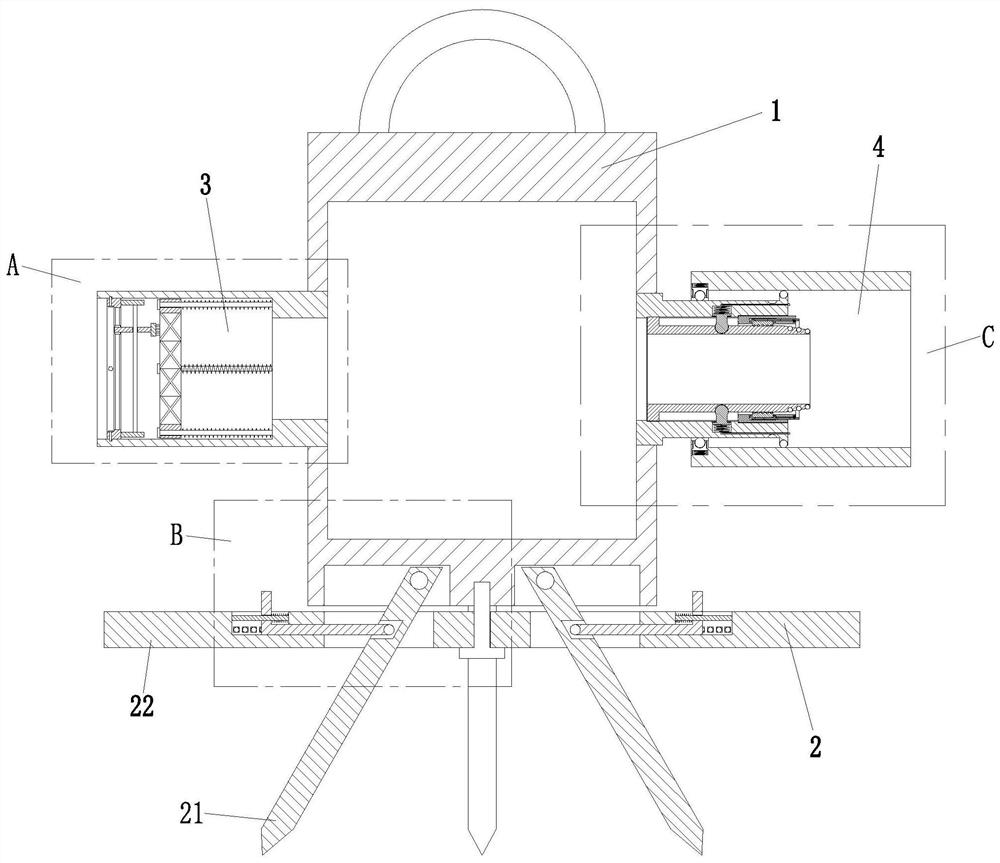

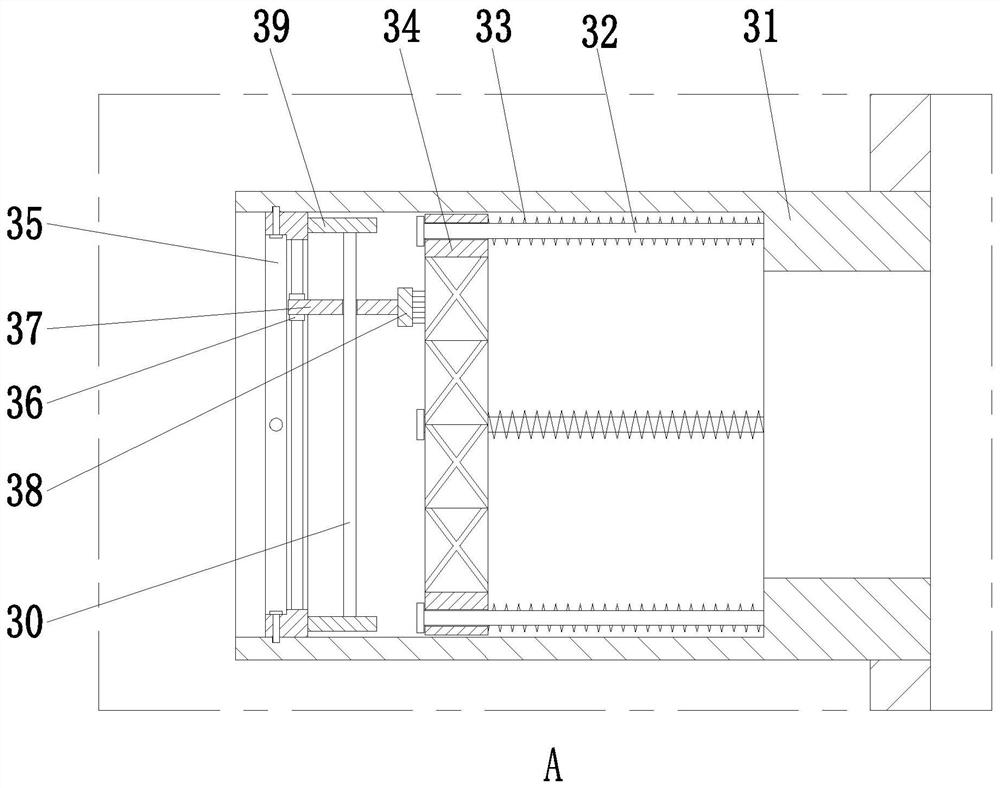

Accurate automatic filling pile centralizing equipment and application method thereof

The invention relates to accurate automatic filling pile centralizing equipment and an application method thereof. The accurate automatic filling pile centralizing equipment comprises supporting legs,a connecting frame, a connecting pile, a pile filler and other components, wherein the connecting frame comprises a connecting plate, and the lower portion of the connecting plate is connected with aguide frame; the connecting pile is connected to the connecting plate and the guide frame; the supporting legs are connected to the edge of the connecting plate through connecting rods; the pile filler is connected to the bottom of the guide frame; the middle of the connecting plate is provided with an embedment hole; the inner wall of the embedment hole is provided with a connecting pile squeezer; the connecting pile squeezer is internally connected with the connecting pile; the connecting plate and the supporting legs are connected through the connecting rods; gyroscope sensors are arrangedat the joints of the connecting plate and the connecting rods; supporting leg supporting plates, floating plates and supporting airbags are arranged in an annular cavity between the floating plates and the supporting plates in an arrayed mode. The application method comprises the steps of conducting filling on a standard pile through the pile filler, pushing the connecting rods through the supporting airbags, accordingly, righting the connecting plate and then righting the connecting pile.

Owner:南京江宁区上峰国银标准件厂

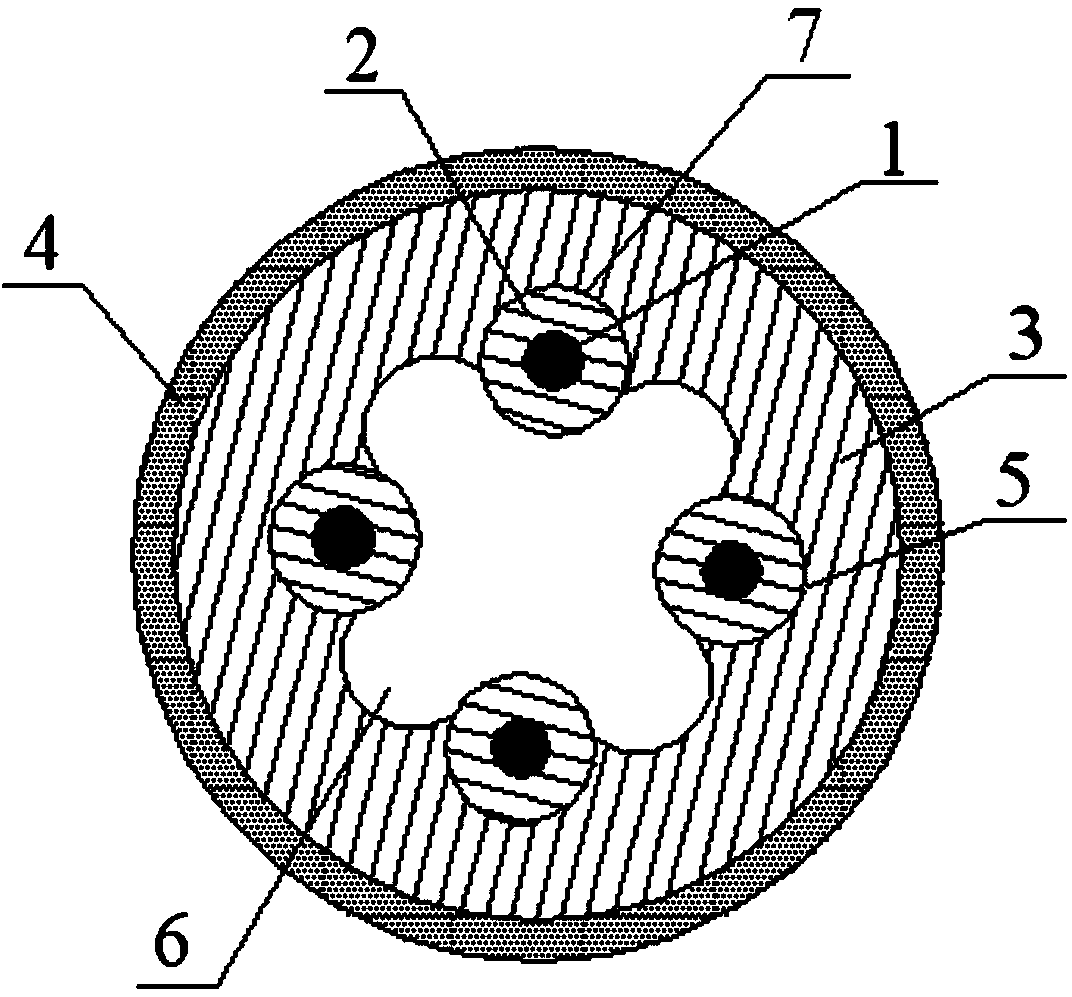

Squeezing trigger type signal line

InactiveCN104252750AAvoid monitoring blind spotsImprove monitoring accuracyBurglar alarm mechanical actuationVIT signalsEngineering

The invention discloses a squeezing trigger type signal line. The squeezing trigger type signal line comprises an elastic insulation sleeve; two or more than two electric conductors are arranged inside the insulation sleeve; the electric conductors are fixed on the inner wall of the insulation sleeve along the axial direction of the insulation sleeve in a spiral shape; the electric conductors are mutually separated. According to the squeezing trigger type signal line, monitoring signals can be generated when the signal line is stressed from all directions by the electric conductors which are arranged in a spiral mode, monitoring dead angles are avoided, installation angles are not required, and the monitoring accuracy is improved; the electric conductors are fixed through a spiral trunking which is formed in the inner wall of the insulation sleeve, the fixing intensity between the electric conductors and the inner wall of the insulation sleeve is improved, and the service life of the signal line is guaranteed.

Owner:绍兴金创意塑化电器有限公司

Ice skate blade quick replacement structure

Owner:HONG WEI SPORTS MFG (ZHANGJIAKOU) CO LTD

Sound screen board and sound barrier using same

PendingCN110042773ANo connection requiredThe strength of large expansionNoise reduction constructionRear quarterLap joint

The invention discloses a sound screen board and a sound barrier using the same. A sound screen board comprises a rectangular outer shell body and a sound absorbing body, wherein the rectangular outershell is composed of a panel, a back board, and a side board, and the sound absorbing bodyfillsthe interior of the outer shell body;in the assembly process of the sound screen board, the use of rivets is omitted, the appearance is more aesthetic, automatic continuous production can be realized, using of manpower is reduced, production efficiency is greatly improved, and finished products are decreased;in terms of using performance, the corrosion of riveting joints can be avoided, and the overall fixing strength can be ensured. In the assembly structure of the sound screen board, the top of the outer shell body is in the structural form of an upper flanging groove covering an upper clamping part, and an overlap joint slit is vertically formed, and a vertical upper clamping part is arrangedon the inner side of the lap joint slit for protection, so that rainwater does not enter into the outer shell body, thus the problemsof corrosion of the sound screen board and uneven filling caused by sinking of the sound absorbing body are avoided, the service life of the sound screen board is prolonged, and the sound absorption and noise reduction effects are further improved.A sound barrier has the using and producing advantages of the sound screen board.

Owner:HEBEI JINBIAO CONSTR MATERIALS TECH CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com