Spinning bobbin automatic replacing device for facilitating connection

A technology for automatic replacement and connection of devices, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of reducing production efficiency, increasing time costs, unable to meet production and processing needs, etc., to improve replacement. Efficiency, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

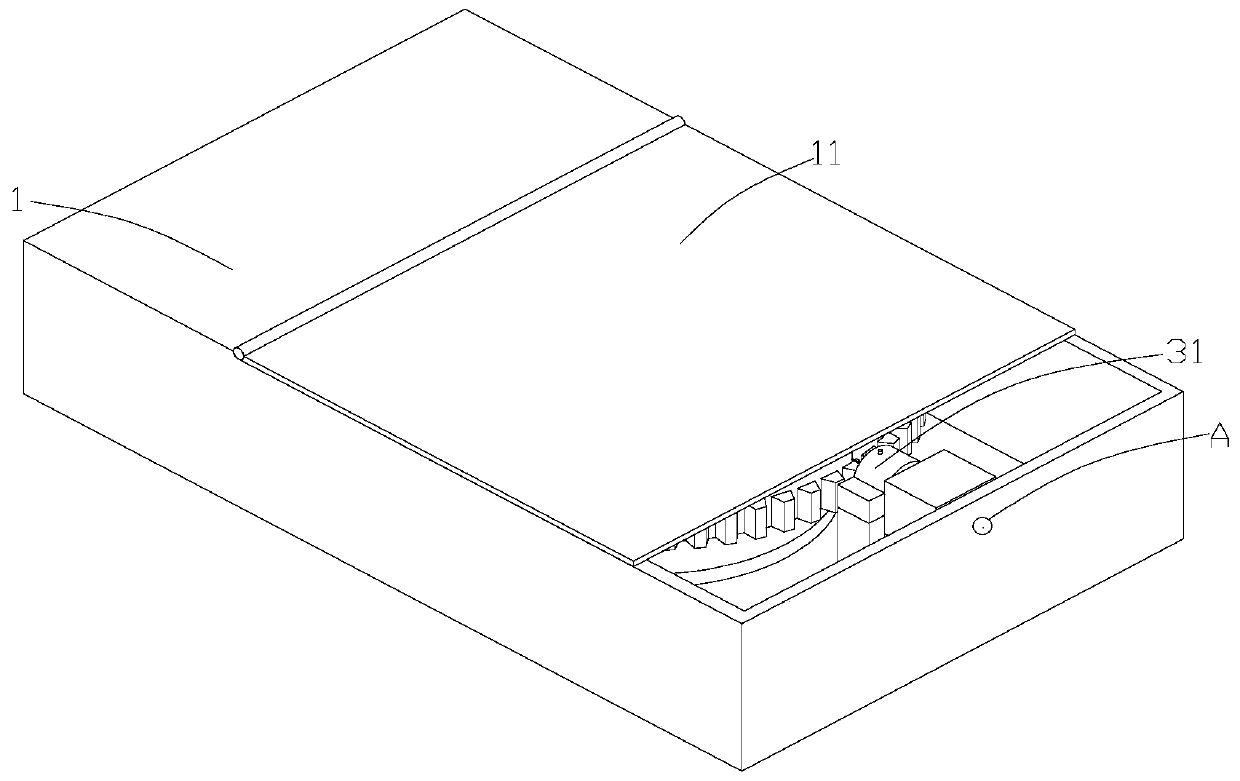

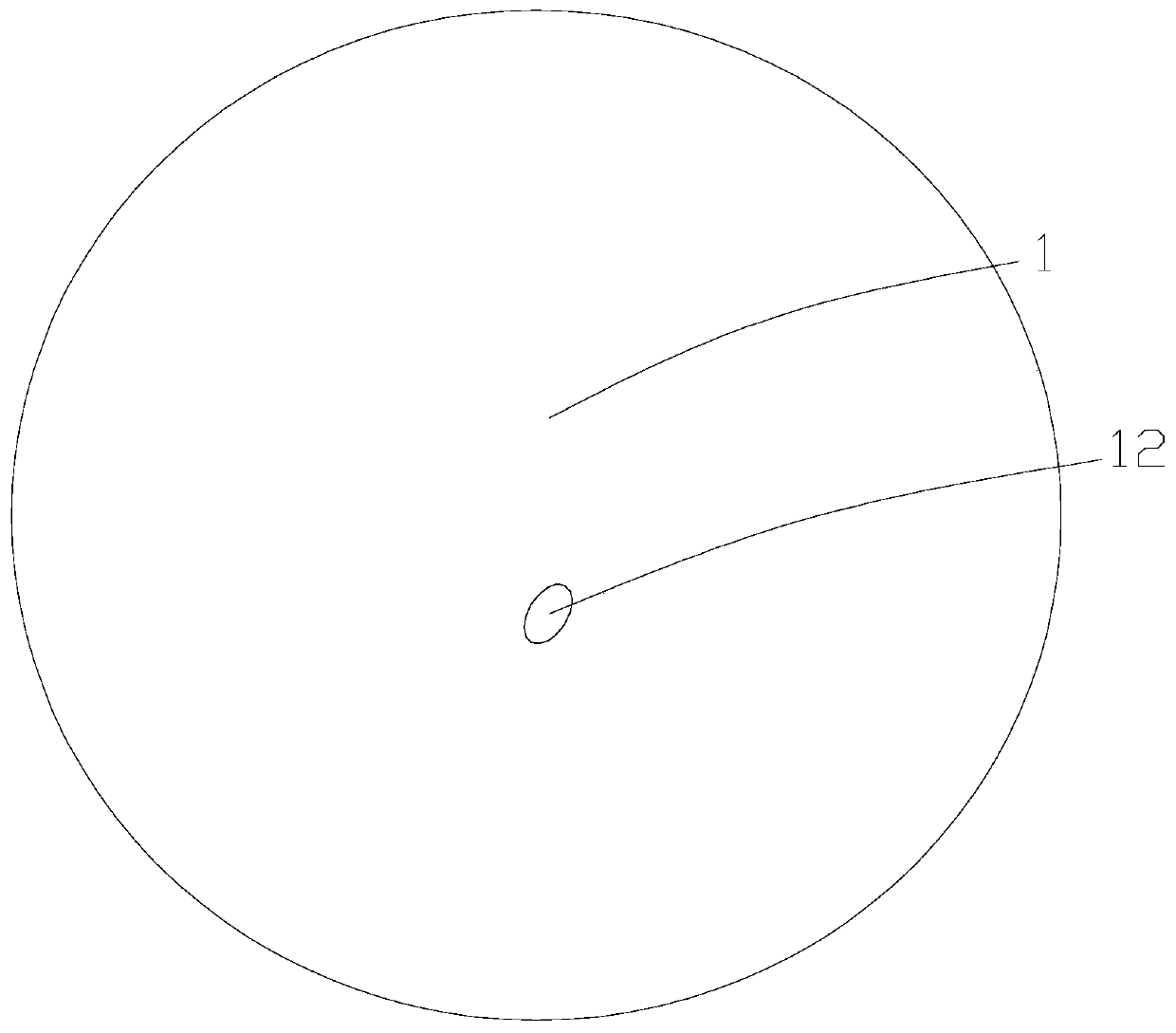

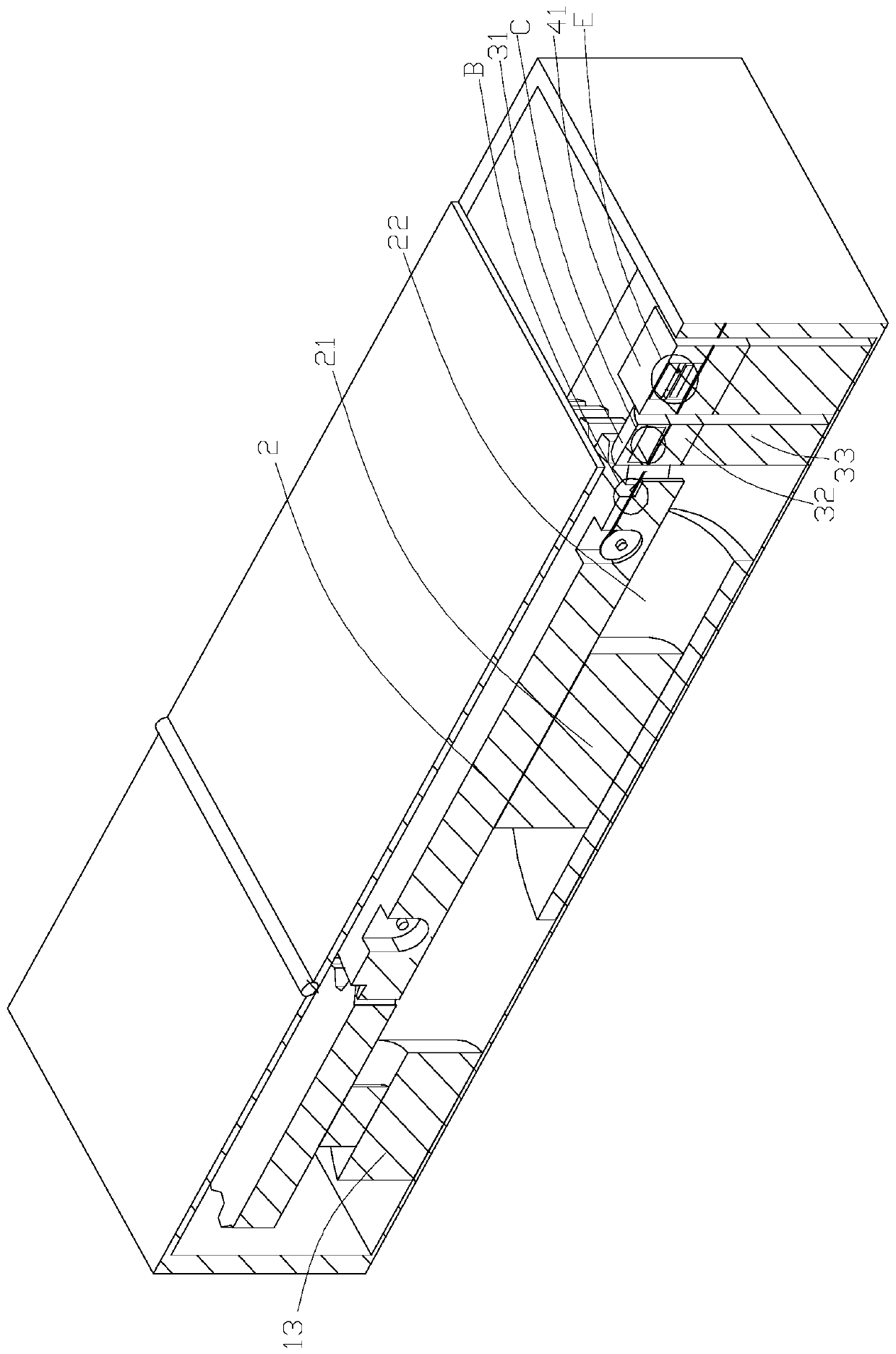

[0032] Such as Figure 1-18 As shown, a kind of textile thread bobbin automatic replacement device that is easy to connect includes a working box 1 for accommodating and protecting the device. The working box 1 is provided with a reversible cover plate 11 for protecting and closing the working box 1 and a In the first threading trough 12 for the textile thread to pass through, the working box 1 is provided with a placement tray 2 for placing and fixing the textile thread, a first driving member 13 for driving the placement tray 2 to rotate, and a first driver 13 for turning the broken thread. The connecting device for connecting the opened textile threads and the fixing device for fixing the ends of the disconnected textile threads, through the setting of the above structure, the effect of automatic replacement of the above-mentioned placing bobbin can be realized by the rotation of the placing plate, Therefore, through the cooperation of the connecting device and the fixing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com