Formwork setting up method for floor post-cast strip

A formwork support method and post-casting belt technology are applied in the field preparation of formwork/formwork/working frame, building components, construction, etc., which can solve the problems of difficult formwork, formwork damage, and low service life, and achieve convenient support. Involving demolition, ensuring the effect of fixing strength and leak-proof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

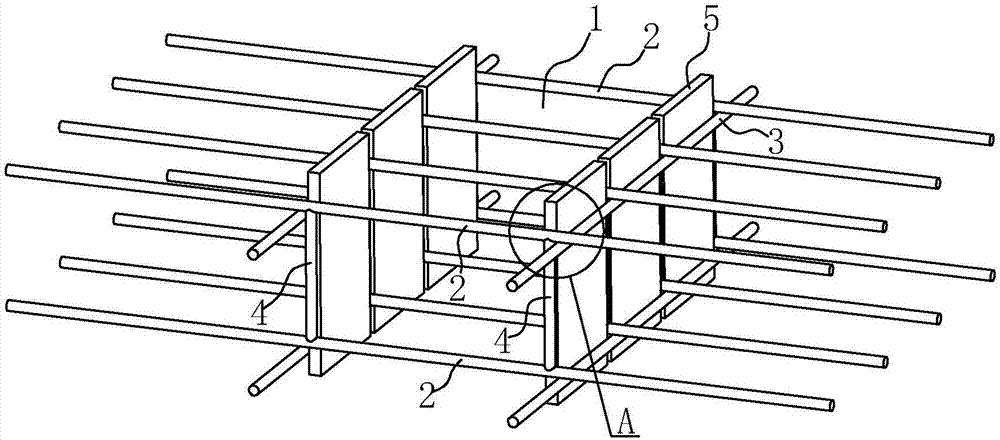

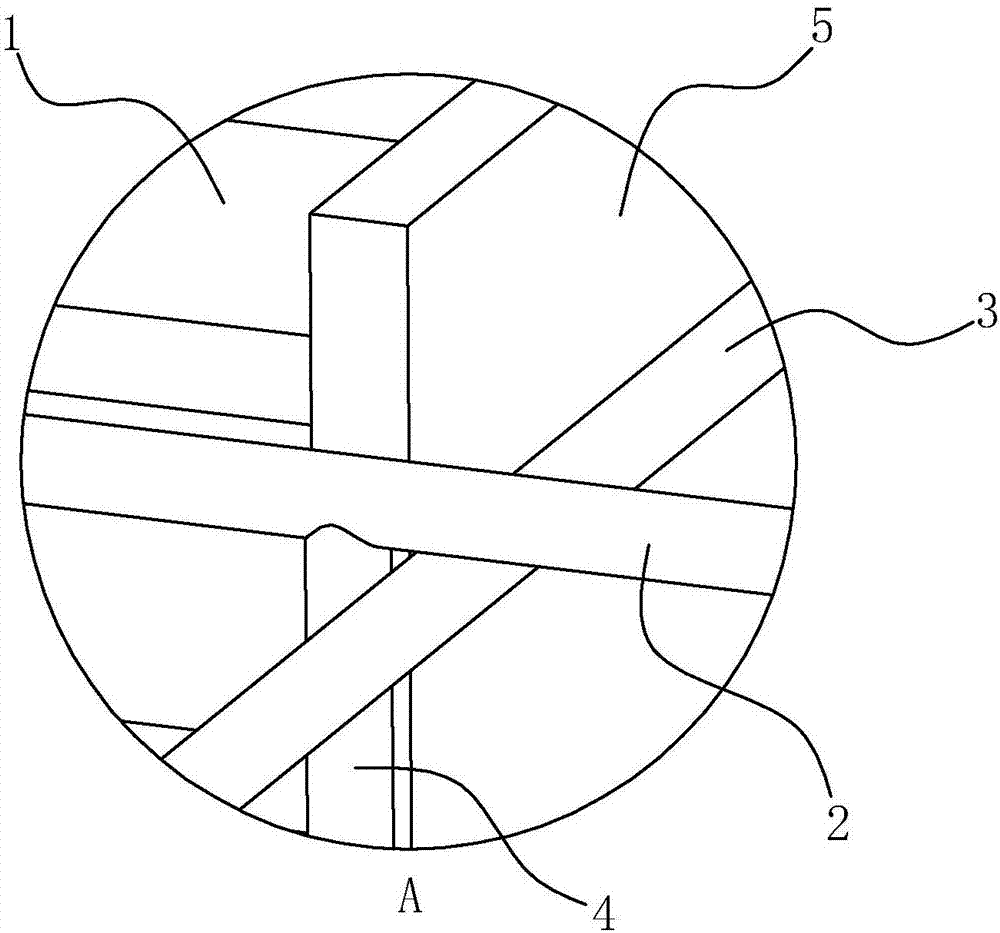

[0038] This embodiment discloses a formwork support method for the post-cast belt of the floor slab, such as figure 2 As shown, the part between the templates 5 on both sides is reserved for the post-casting tape part 1 .

[0039] The method mainly includes the following steps:

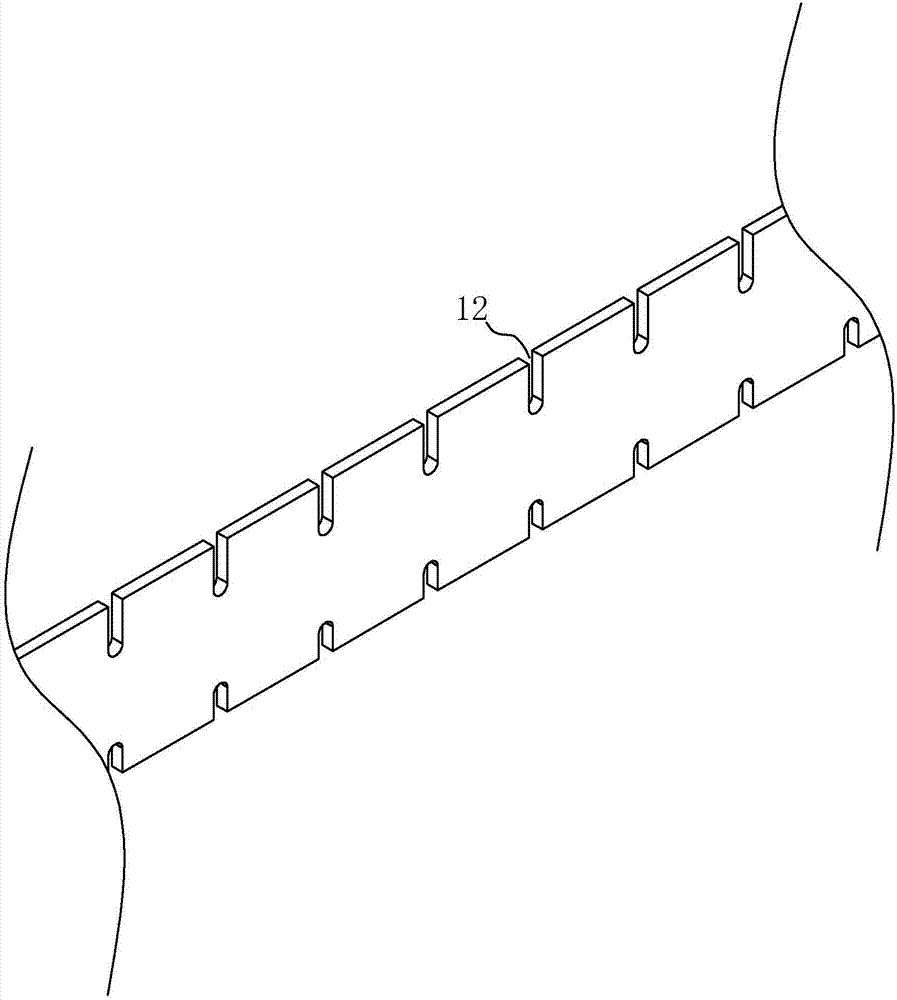

[0040] 1. According to the construction drawings, determine the reserved position of the post-casting belt part 1. When binding the floor steel bars, reserve the Y-axis steel bar 3 of the post-casting belt part 1 and do not bind it temporarily. After the concrete on both sides of the post-casting belt is solidified, proceed Binding; the X-axis steel bars 2 are set through the post-cast belt part 1, and a Y-axis steel bar 3 is respectively bound on the upper and lower X-axis steel bars 2 on both sides of the post-cast belt part 1, and the Y-axis steel bars 3 on both sides of the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com