Substrate cassette device

A substrate card and substrate technology, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve problems such as broken glass substrates, affecting the quality of conductive layers, barrier layer formation, and increasing the cost and difficulty of product preparation. Small contact area, improved heating uniformity, guaranteed flatness and dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

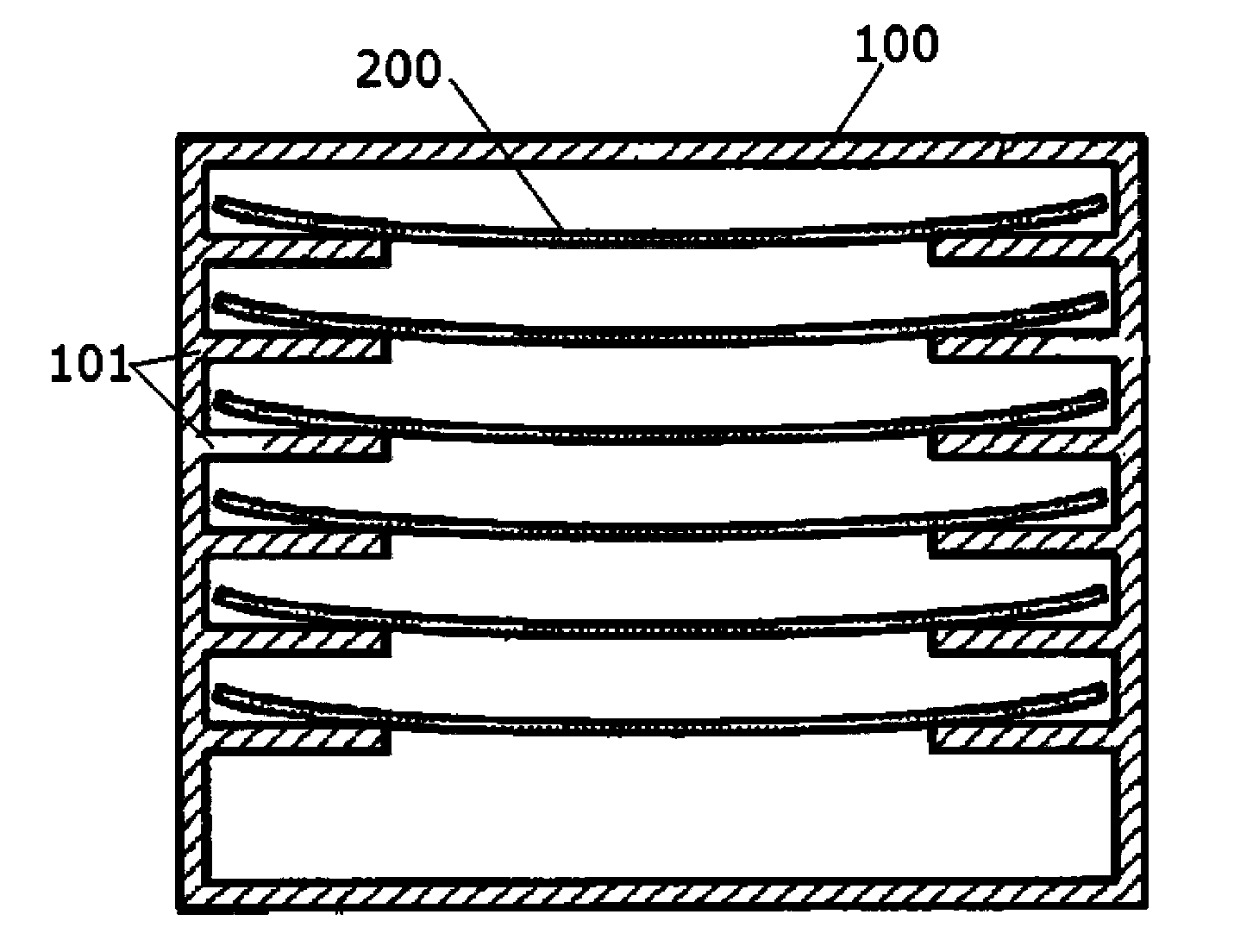

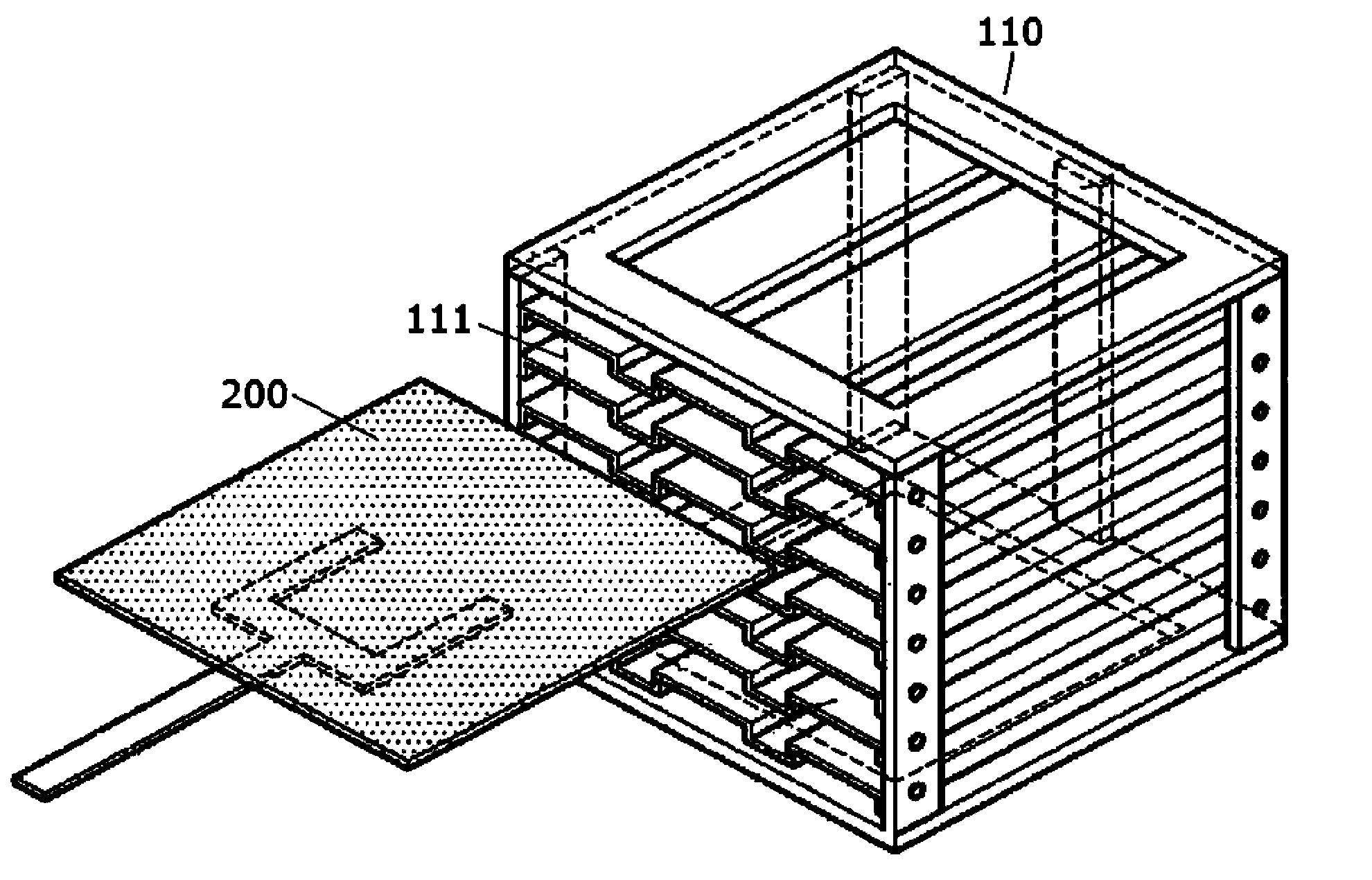

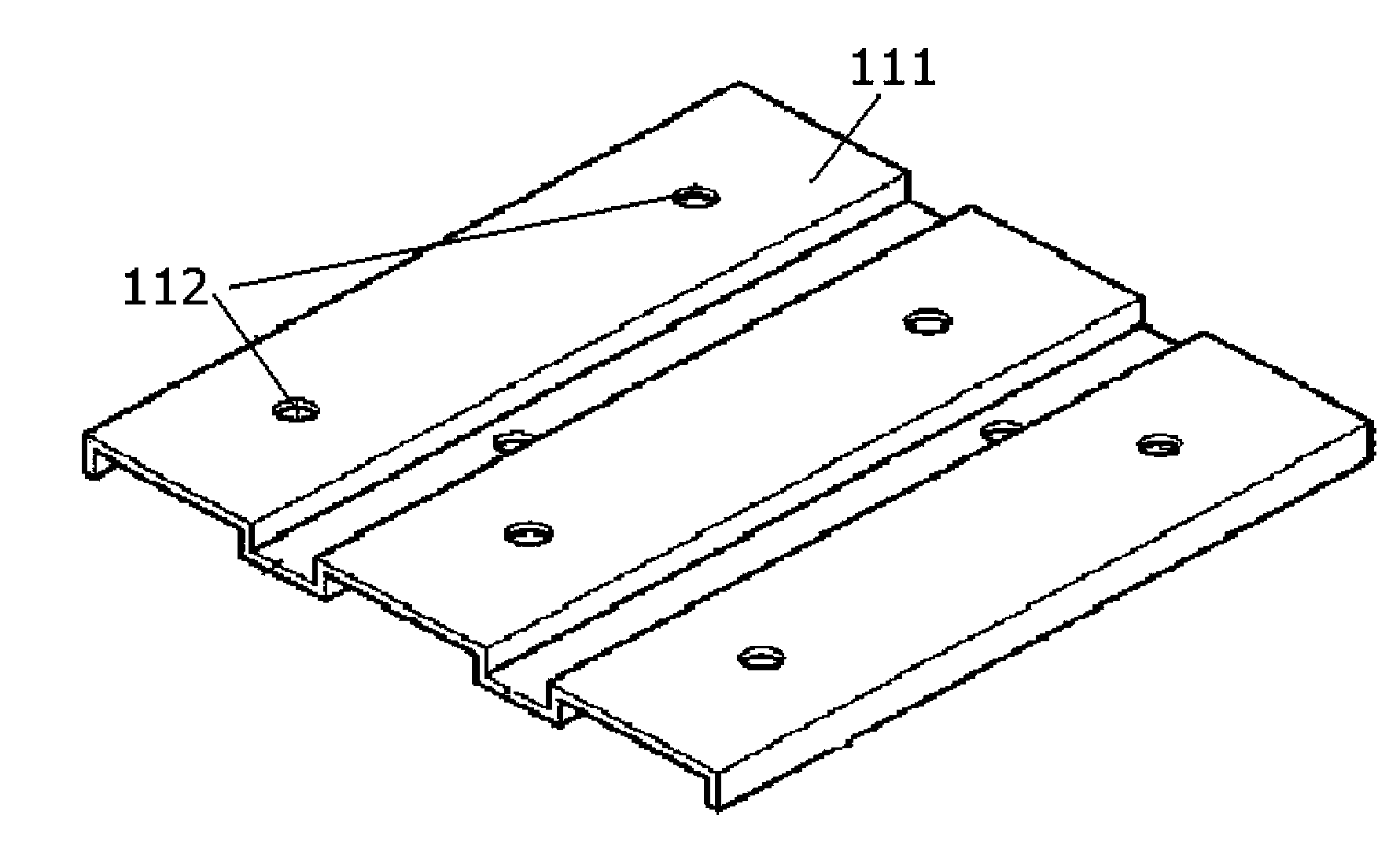

[0039] refer to Figure 4 As shown, a substrate cassette device provided by the present invention includes a cassette frame 1 and a frame overturning mechanism 2. The frame overturning mechanism 2 is fixedly connected to the cassette frame 1 and makes the cassette frame 1 overturn at multiple angles.

[0040] combined reference Figure 5 to Figure 7 As shown, the frame turning mechanism 2 includes two support frames 22 for supporting the cassette frame 1, and a pair of turning shafts 20 are arranged on opposite sides of the cassette frame 1, and are respectively connected with The two supporting frames 22 are fixedly connected. Thus, the cassette frame 1 is fixedly connected with the frame overturning mechanism 2, and the frame overturning mechanism 2 further includes a motor 21, and the motor 21 is fixedly connected with one of the overturning shafts 20, thereby driving the The cassette frame 1 is overturned around the pair of overturning axes 20 . The rotating shaft of th...

Embodiment 2

[0046] combined reference Figure 7 As shown, the design scheme of the substrate cassette device in this example is roughly the same as that of the substrate cassette device in Embodiment 1, the difference is that, on the basis of Embodiment 1, the substrate cassette device forms the corresponding opening 17 for the substrate cassette device. A detachable auxiliary support rod 18 is provided between the two adjacent support rods 13a and 13b; the upper and lower ends of the auxiliary support rod 18 are respectively connected to the upper frame 11 and the lower frame 12, thereby "blocking" the The substrate insertion opening 17 prevents the glass substrate 200 from sliding out through the insertion opening 17 during the flipping process. In addition, along the length direction of the auxiliary support bar 18, a plurality of finger-shaped gear bars 14b and fixed latches 15b are also provided as the substrate supporting part and the substrate fixing device, respectively. The mult...

Embodiment 3

[0048] combined reference Figure 8 As shown, in this example, a substrate protective layer is provided between the substrate placement layer of the cassette frame 1 and the glass substrate 200 , and at the contact portion between the substrate fixing device and the glass substrate 200 . combined reference Figure 8 , taking the connection structure between the support rod 13 and the fixed latch 15 on the support rod 13 and the glass substrate 200 as an example, on the inner side of the support rod 13, the auxiliary support rod 18, and each of the finger tooth rods 14 and the contact portion between the fixing latch 15 and the glass substrate 200 are provided with a substrate protection layer 19 . The substrate protection layer 19 can be made of elastic materials including various plastic materials. During the overturning process of the glass substrate 200, the glass substrate 200 is inevitably in contact with the cassette frame 1 to be stressed, and the glass substrate 200 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com