Porous composite bone plate with stiffness and gradient variation and preparation method thereof

A gradient change and stiffness technology, applied in the direction of outer plate, internal bone synthesis, medical science, etc., can solve the problems of stress shielding between prosthesis and human original bone, and cannot improve the stiffness of solid bone plate in a deeper level, so as to improve the stress shielding effect , improve the service life and reduce the weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

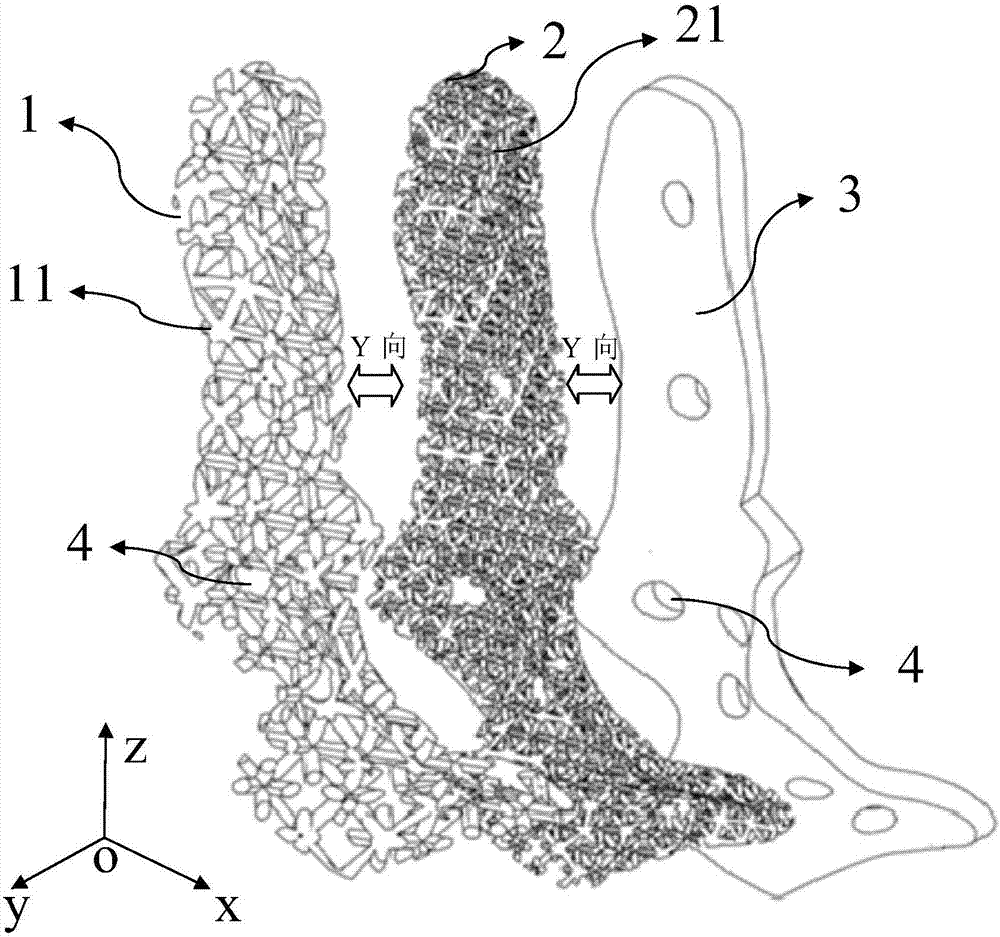

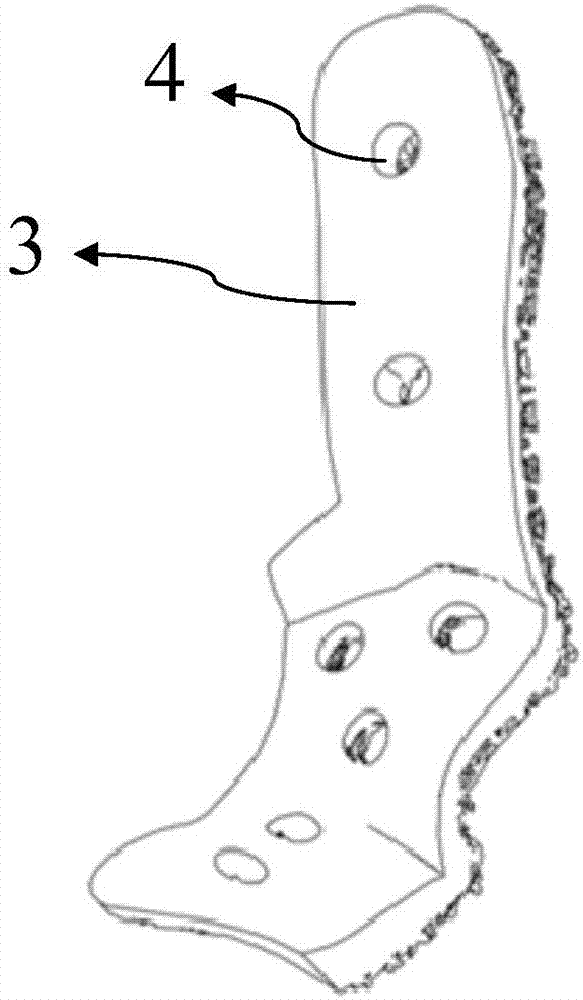

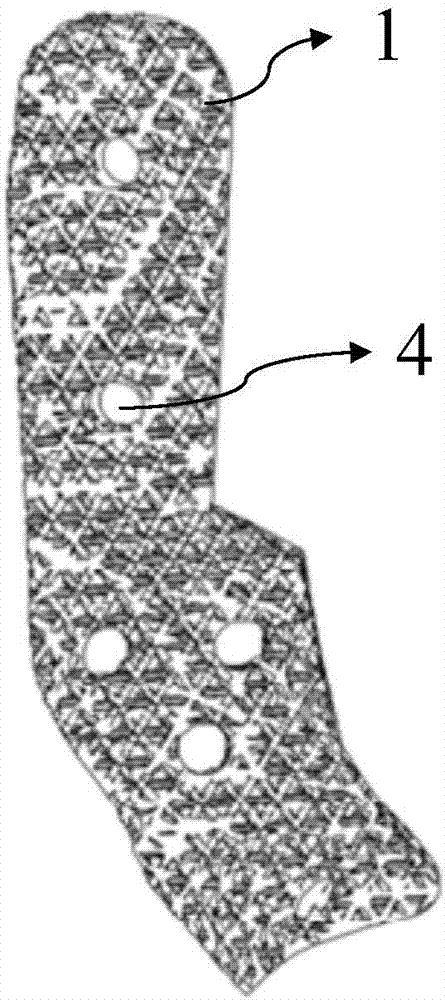

[0040] figure 1 It is a schematic diagram of the decomposition structure of the composite bone plate of the present invention, figure 2 is a schematic diagram of the overall structure of the composite bone plate of the present invention, image 3 It is a side view of the composite bone plate of the present invention on the XOZ plane, as Figure 1-3 As shown, the porous composite bone plate with varying stiffness disclosed in the present invention includes a fitting layer 1 , a transition layer 2 , and a solid layer 3 which are sequentially fitted and connected.

[0041] The bonding layer 1 has a first stiffness, the transition layer 2 has a second stiffness, and the solid layer 3 has a third stiffness, and the first stiffness is smaller than the second stiffness, and the second stiffness is smaller than the third stiffness. Specifically, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com