Moving mechanism

A technology of moving mechanism and moving wheel, which is applied in the field of machinery, can solve problems such as single vibration items, and achieve the effects of simple and reliable assembly, guaranteed movement accuracy, and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

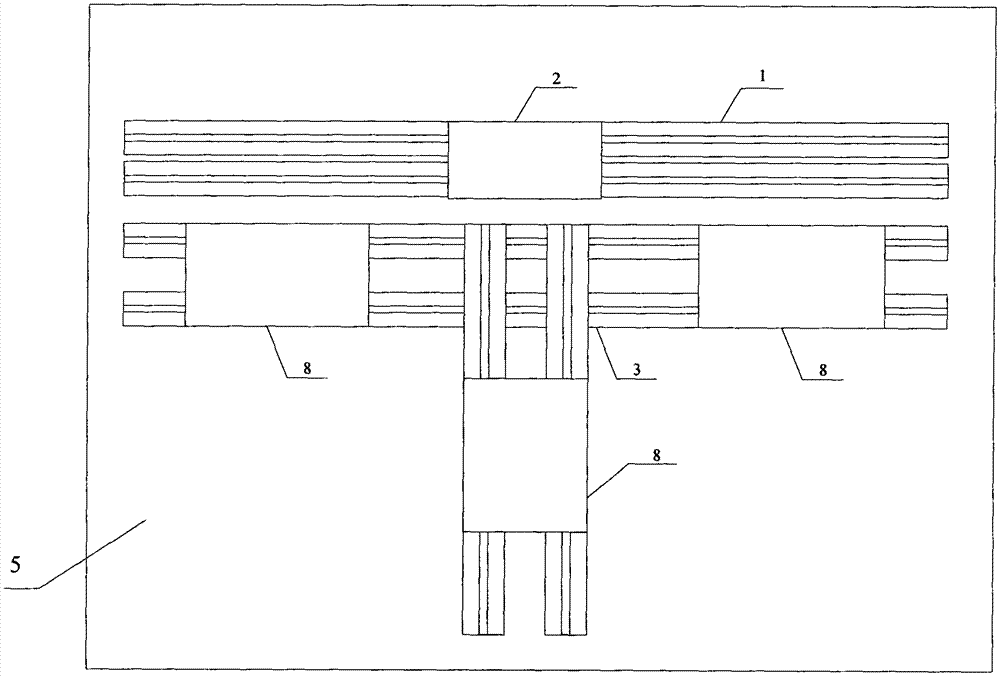

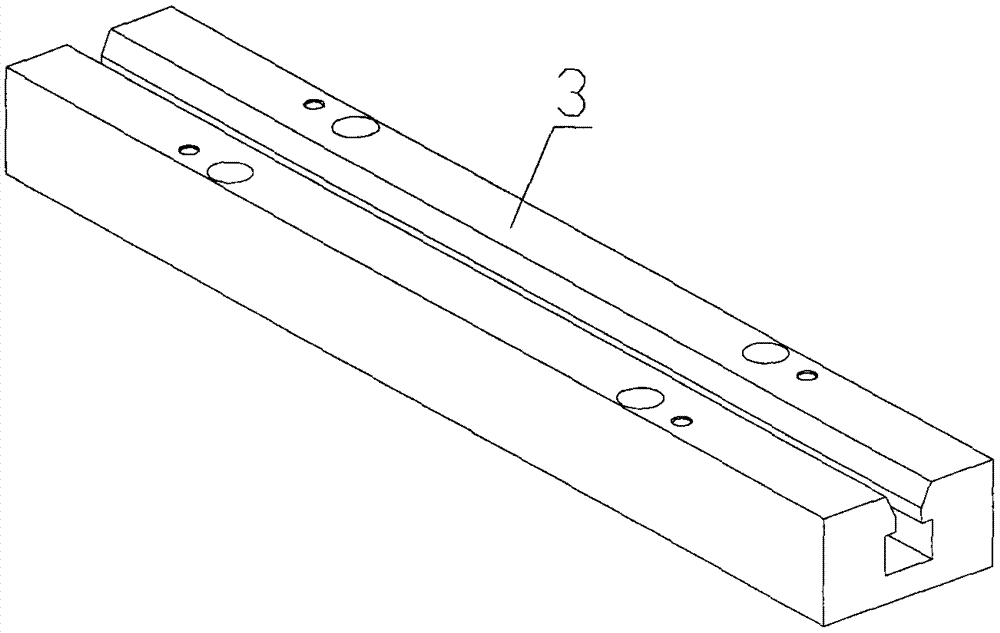

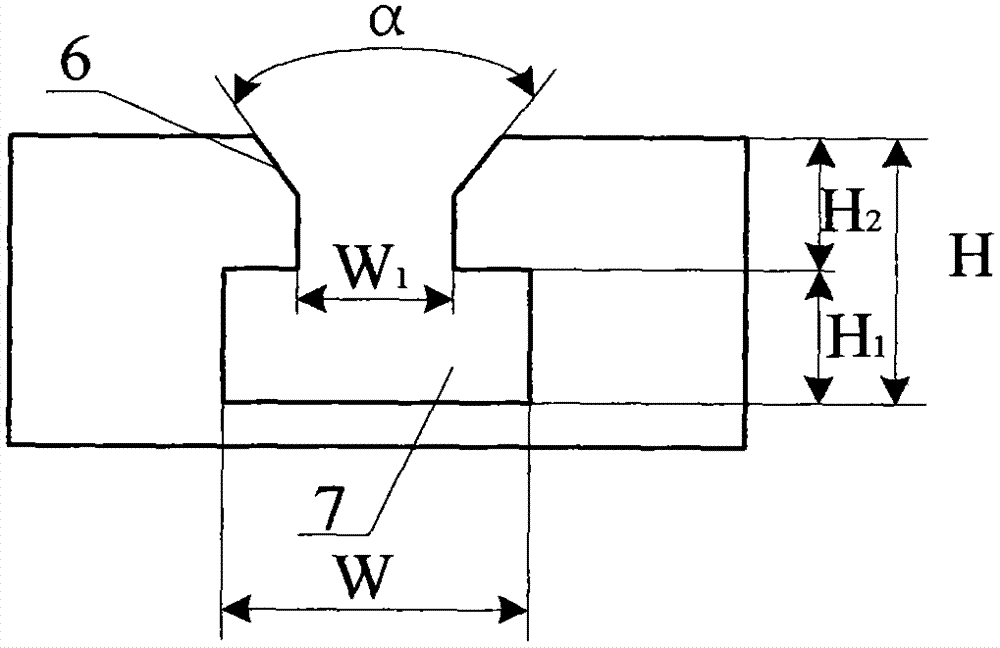

[0028] The invention adopts the design idea of realizing simultaneous vibration of multiple vibration tables in different combinations, and provides a moving mechanism for realizing six vibration functions of three vibration tables. The six vibration functions require high connection and installation accuracy, movement accuracy and fixing accuracy. Therefore, how to realize the movement and fixation of the vibration table becomes an important factor in realizing the vibration function. The design of the present invention adopts the pre-embedded steel plate foundation, the inverted "T" groove guide rail with "V" opening is pre-buried in the foundation steel plate, and the moving wheel is used to drive the vibrating table on the "T" groove pre-embedded guide rail. Moving, there is a "V" structure between the "T" groove guide rail and the moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com