Integrated cell laminating machine and cell laminating method

A lamination machine, lamination technology, applied in the direction of assembling battery machines, circuits, electrical components, etc., can solve the problems of low lamination accuracy, low work efficiency, poor alignment of positive and negative plates, etc., to improve lamination. Accuracy, the effect of improving lamination quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

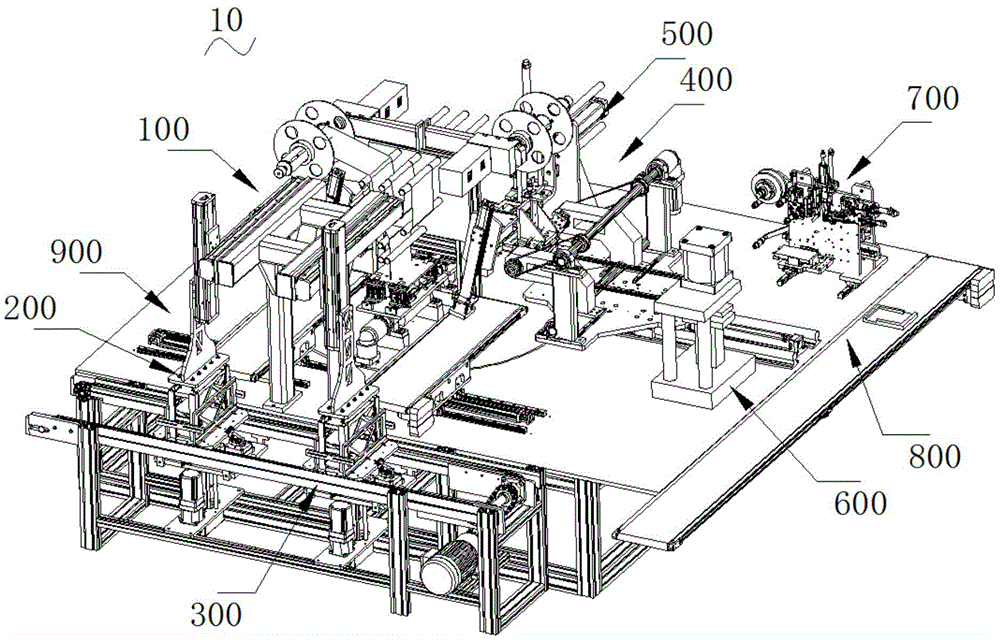

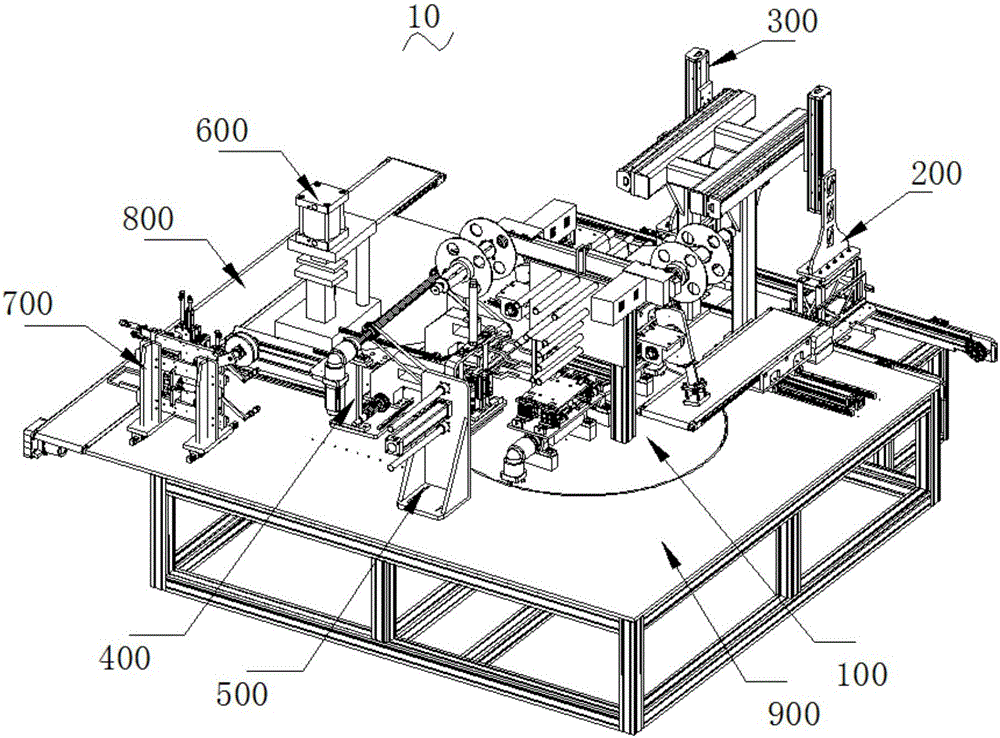

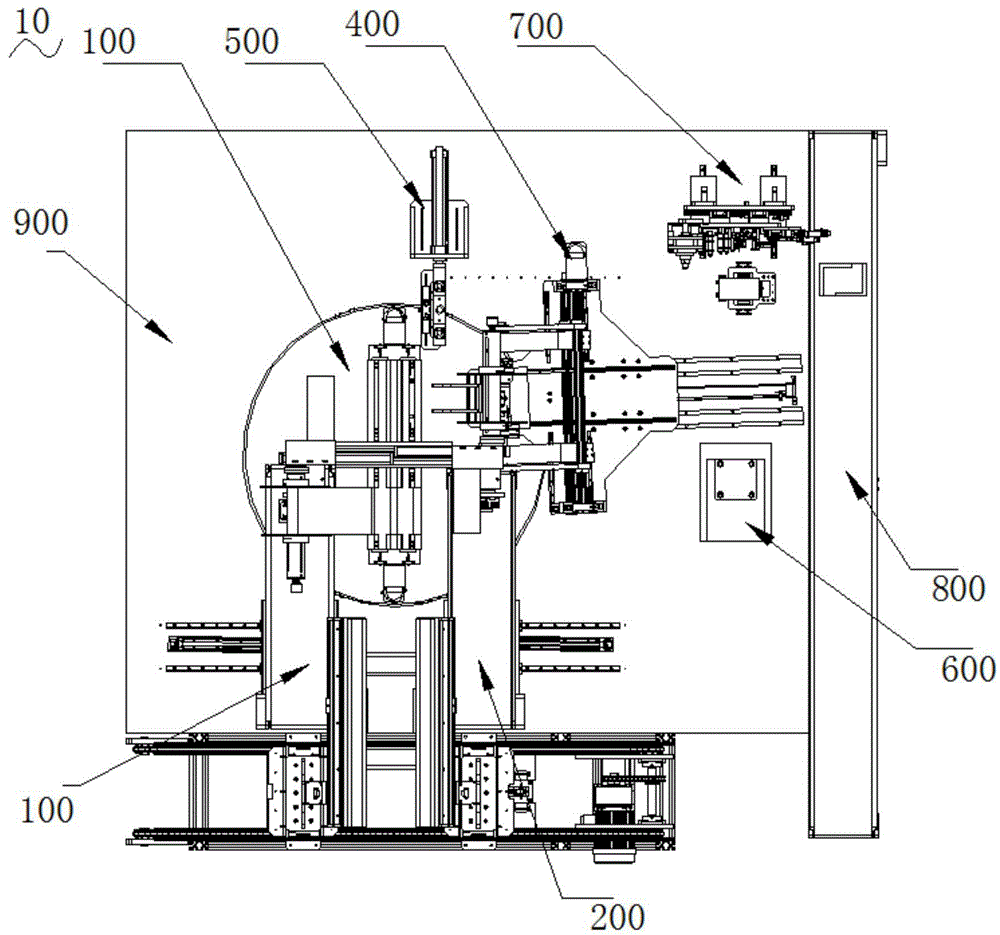

[0047] Such as Figure 1 ~ Figure 3 As shown, they are respectively different perspective views and front views of the present invention.

[0048] The integrated cell stacking machine 10 includes a stacking station 100, and also includes a first loading station 200 for positive electrode sheet loading, a second loading station 300 for negative electrode sheet loading, and a The winding station 400 for winding, the cutting station 500 for cutting the diaphragm, the stamping station 600 for pressing the battery core, the adhesive paper station 700 for attaching the adhesive paper on the surface of the battery core, and The blanking station 800 for cell blanking also includes a platform 900 for installing the stacking station 100, winding station 400, cutting station 500, stamping station 600, and adhesive paper station 700 , Each station moves in turn without manual in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com