Fixed combustible gas detection alarm

A fixed, alarm technology, applied in the directions of alarms, instruments, supporting machines, etc., can solve the problem that the alarm cannot be installed and fixed, and achieve the effect of convenient installation and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

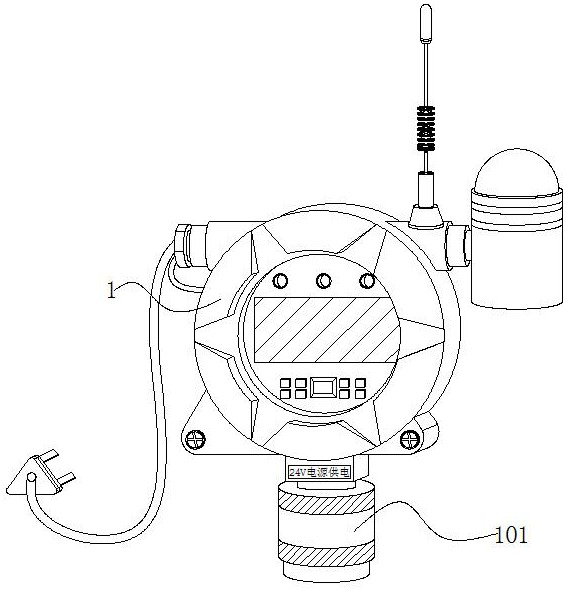

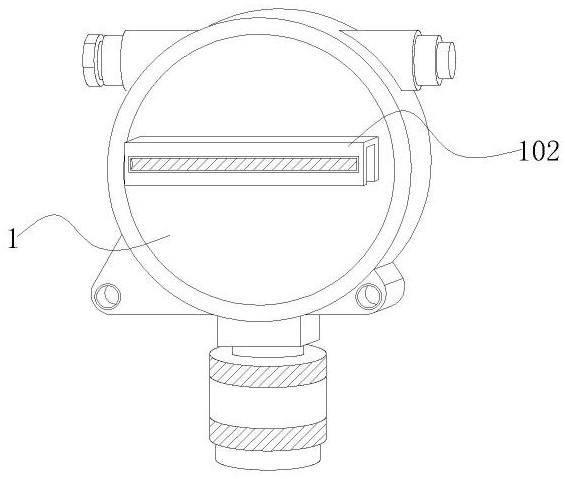

[0036] Embodiment 1: A fixed combustible gas detection alarm, including an alarm device 1, a sensor 101 is installed at the lower end of the alarm device 1, a bracket 102 is installed on the back of the alarm device 1, and the inside of the bracket 102 is provided with a negative pressure Quickly installed transmission mechanism;

[0037] A chip is installed inside the alarm device 1, and an information transmission device is installed inside the alarm device 1. The chip is connected to the receiving end of the cloud platform through the information transmission device. When the sensor 101 detects a combustible gas, the sensor 101 transmits the signal to the chip. Internally, the chip transmits the wireless signal to the receiving end of the cloud platform;

[0038] Once the fire information is detected, a signal transmitter is installed on the receiving end of the chip and the cloud platform. The chip is wirelessly connected to the cloud platform through the signal transmitte...

Embodiment 2

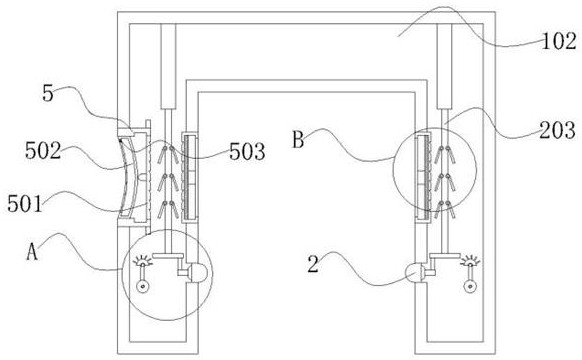

[0041] Example 2: Reference Manual Attached Figure 3-7It can be seen that the difference between Embodiment 2 and Embodiment 1 is that the transmission mechanism includes a slider 2, a shaft arm 201, a disk 202, a support column 203, a rotating disk 3, a convex strip 301, a rotating shaft 302, a swing arm 303, and a rotating bearing. 4 and the swash plate 401, the slider 2 slides on the inner wall of the bracket 102, the shaft arm 201 slides on one side of the slider 2, the disc 202 swings on the upper end of the shaft arm 201, the support column 203 swings on the upper end of the disc 202, and rotates The disk 3 swings on one side of the disk 202 , the protruding strips 301 are distributed on the outer side of the rotating disk 3 , the rotating shaft 302 is hinged to the lower end of the rotating disk 3 , the swing arm 303 swings on the lower end of the rotating shaft 302 , and the rotating bearing 4 is hinged to the lower end of the column 203 . On the outside, the swash pl...

Embodiment 3

[0050] Example 3: Reference Manual Attached image 3 , 4 , 7 and 8, it can be known that the difference between Embodiment 3 and Embodiments 1 and 2 is that the transmission mechanism includes a fixed frame 5, an extrusion frame 501, an adsorption layer 502, a negative pressure valve 503, a sleeve 6, a folding tube 601, The intake pipe 602 and the limiting frame 603, the fixing frame 5 is embedded on both sides of the bracket 102, the extrusion frame 501 slides on the inner wall of the fixing frame 5, the adsorption layer 502 is elastically stretched on the other side of the inner wall of the fixing frame 5, the negative pressure valve 503 runs through the inner wall of the adsorption layer 502, the sleeve 6 is installed on the other side of the bracket 102, the folding tube 601 is folded and retracted inside the sleeve 6, the air intake pipe 602 runs through one end of the folding tube 601, and the limiter 603 slides on one side of the folded tube 601;

[0051] Among them: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com