Automatic sleeve-loading and unloading and sleeve-transporting integrated device of cold-rolling mill

A technology for unloading sleeves and cold rolling mills, which is applied in the field of overall devices, can solve problems such as failure to meet the use requirements, occupy a large space, and cumbersome operations, and achieve reduced production auxiliary preparation time, uniform clamping force, and easy handling of sleeves. barrel smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

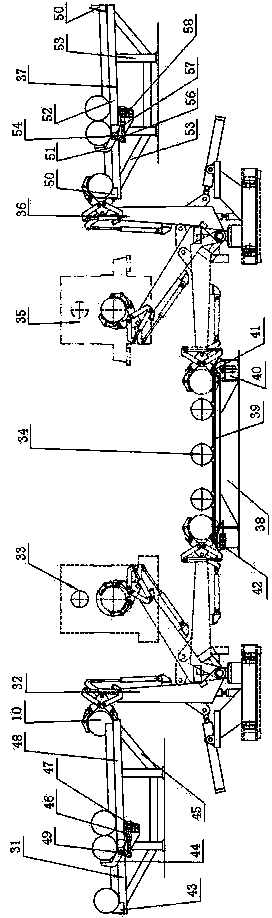

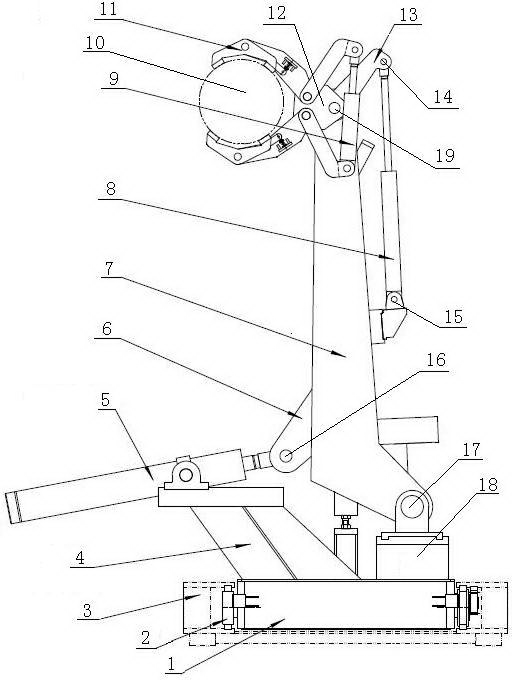

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, this embodiment includes an entry-side sleeve manipulator 32, a sleeve transporter 34, an exit-side sleeve manipulator 36, an entry-side sleeve storage platform 31, an exit-side sleeve storage platform 37, and car body rails fixed on the ground . 33 is an uncoiler, and 35 is a coiler.

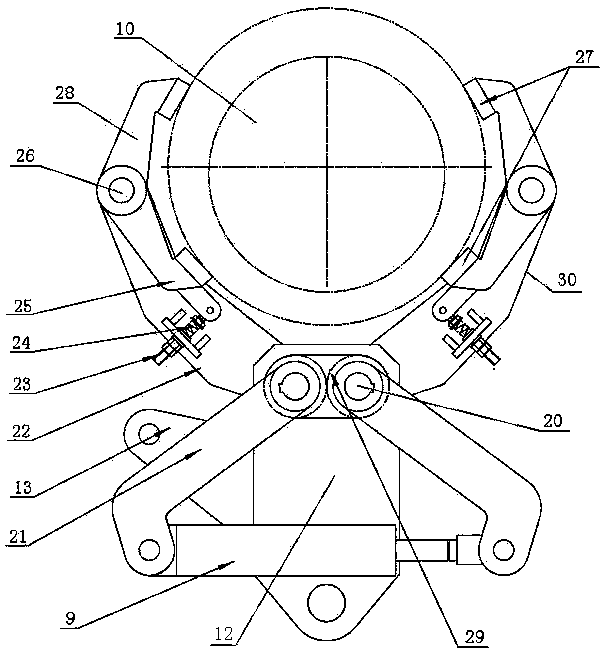

[0021] Described entry side sleeve manipulator 32 or out side sleeve manipulator 36 comprise chassis 1, the wheel 2 that is fixed on chassis 1 lower end, the wheel drive motor that is fixed on chassis 1, vehicle frame 4, swing arm oil cylinder 5, swing arm 7. Fixture swing cylinder 8, sleeve fixture 11 and clamping cylinder 9. The wheels 2 are clamped in the rails 3 of the vehicle body. The lower end of the swing arm 7 is hinged on the chassis bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com