Patents

Literature

62results about How to "Stable pick and place" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

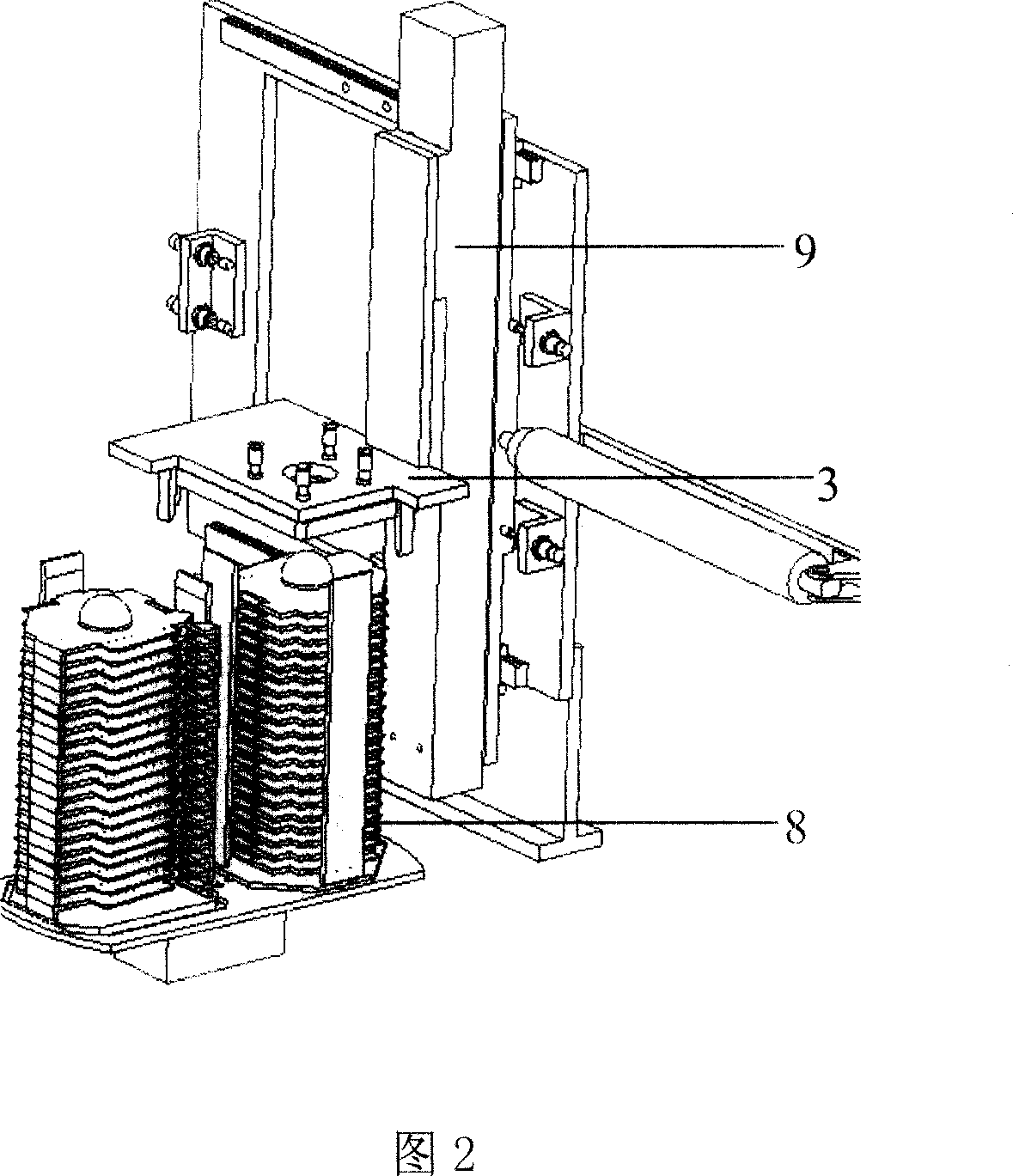

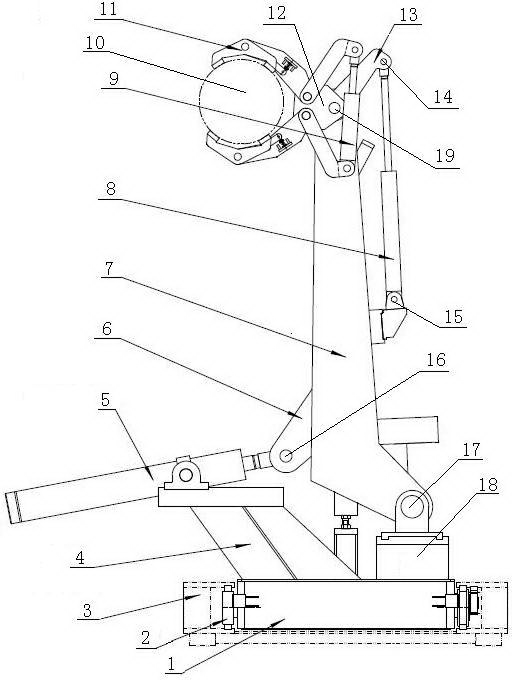

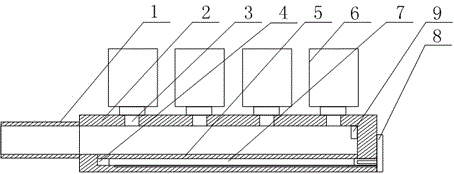

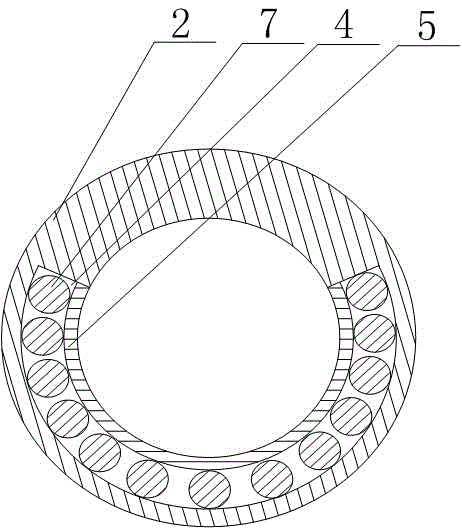

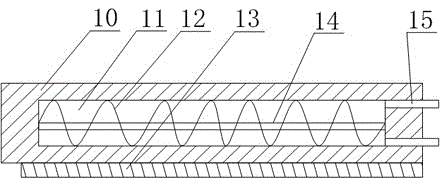

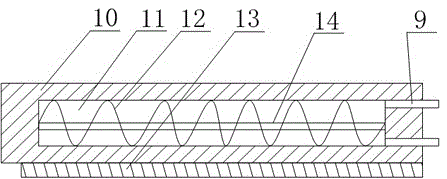

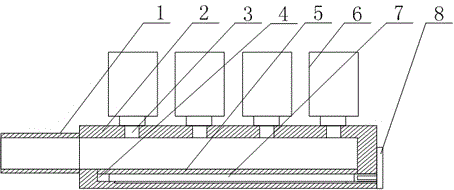

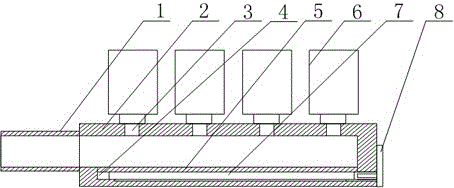

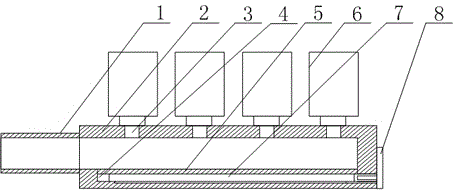

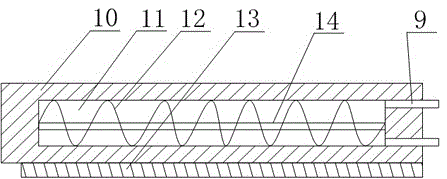

Cantilever-type push-pull boat system for plasma enhanced chemical vapor deposition (PECVD) device

InactiveCN102061456AImprove stabilityAvoid affecting normal movementChemical vapor deposition coatingConveyor partsHorizontal transmissionPush pull

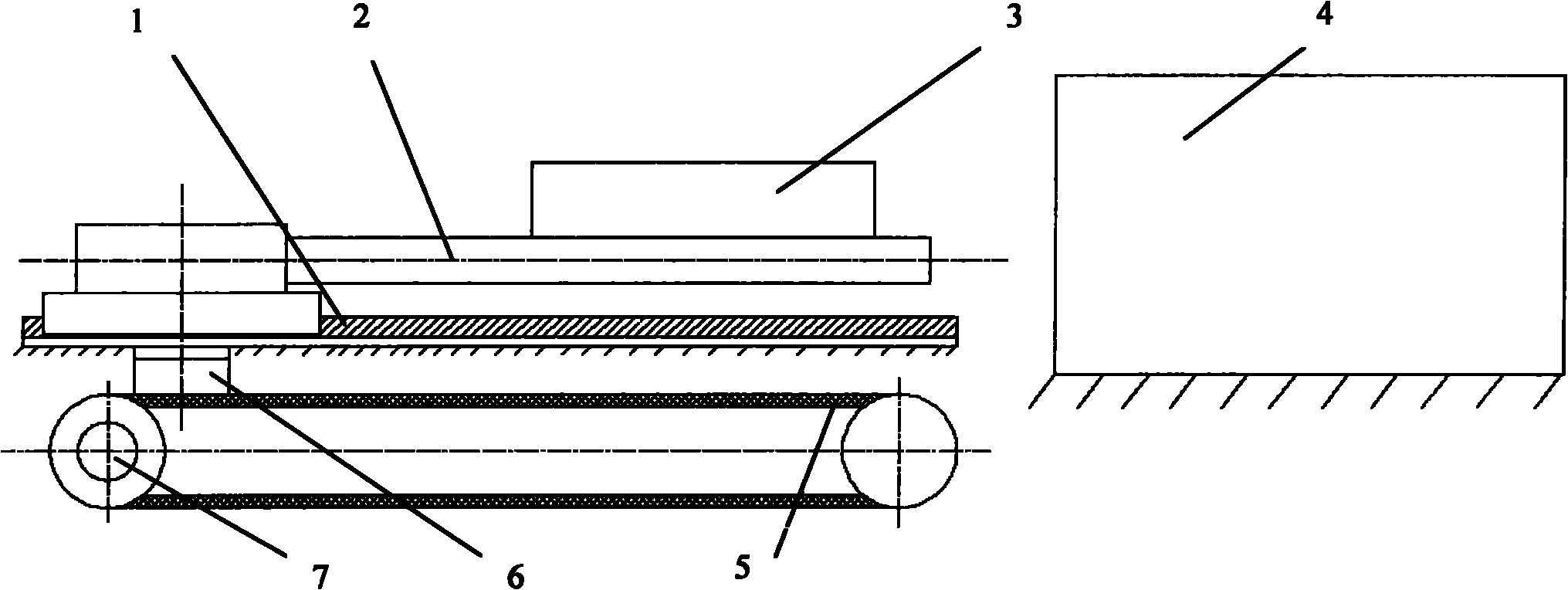

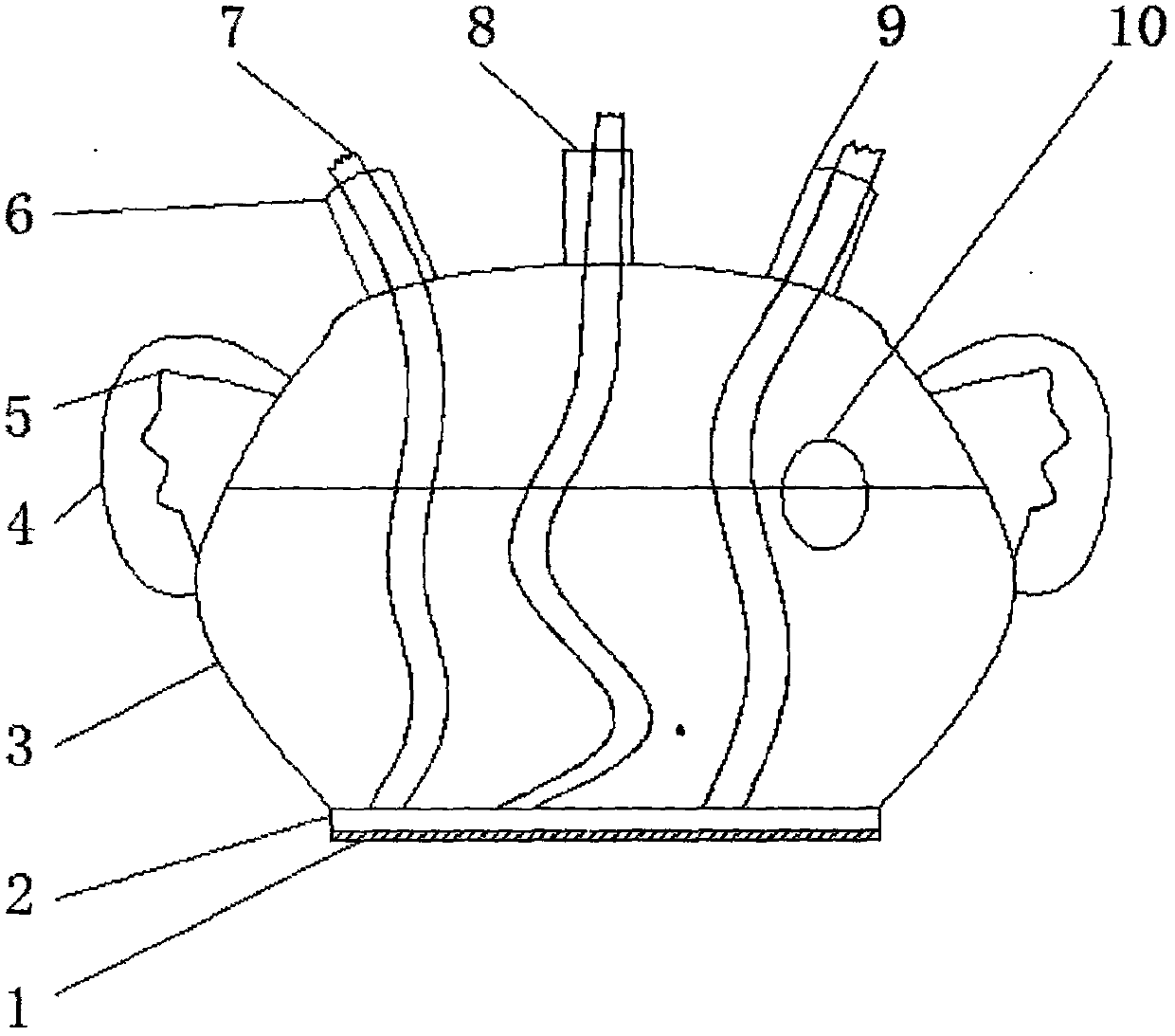

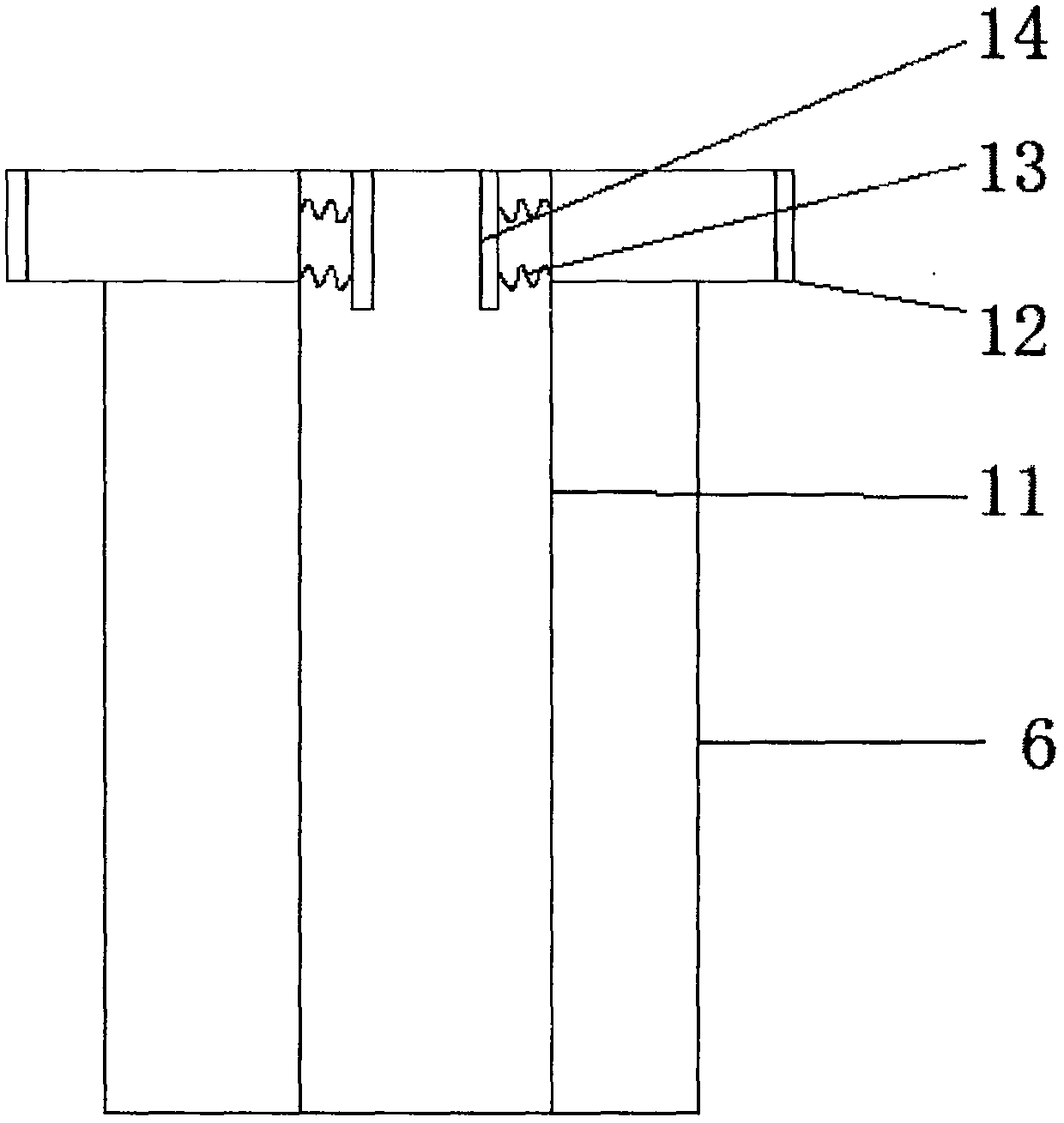

The invention discloses a cantilever-type push-pull boat system for a plasma enhanced chemical vapor deposition (PECVD) device, comprising a cantilever pole mechanism, a side bindiny mechanism and a rolling linear guide sleeve assistant mechanism, wherein the rolling linear guide sleeve assistant mechanism which is used for guiding the horizontal movement and vertical movement of the cantilever pole mechanism is arranged on the rack of the PECVD device; the cantilever pole mechanism is fixed on the side bindiny mechanism; the side bindiny mechanism is connected with the rolling linear guide sleeve assistant mechanism; the rolling linear guide sleeve assistant mechanism comprises a fixed plate, a horizontal transmission assembly and a vertical transmission assembly; and the horizontal transmission assembly and the vertical transmission assembly respectively control the cantilever pole mechanism to drive raw materials to move horizontally and vertically. The cantilever-type push-pull boat system has the following advantages: a mode that an antilever pole extends into a reaction cavity to take and put a graphite boat is adopted, thus a transmission system is simplified, and the transmission efficiency is improved; a side fixing mode is adopted, thus silicon wafer fragments on the graphite boat can be prevented from falling on the system so as to prevent influence on the normal action of the system; and in addition, the space is saved, and a plurality of push-pull boats can simultaneously move.

Owner:SOUTH CHINA UNIV OF TECH

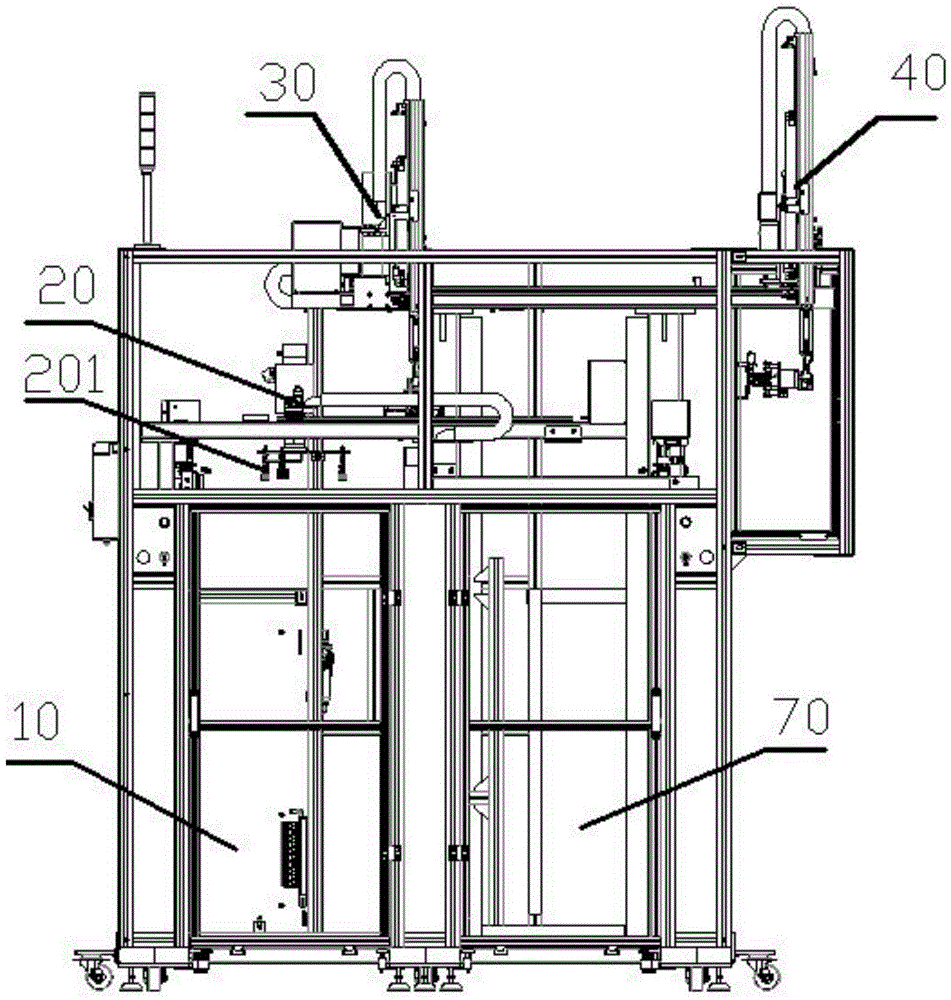

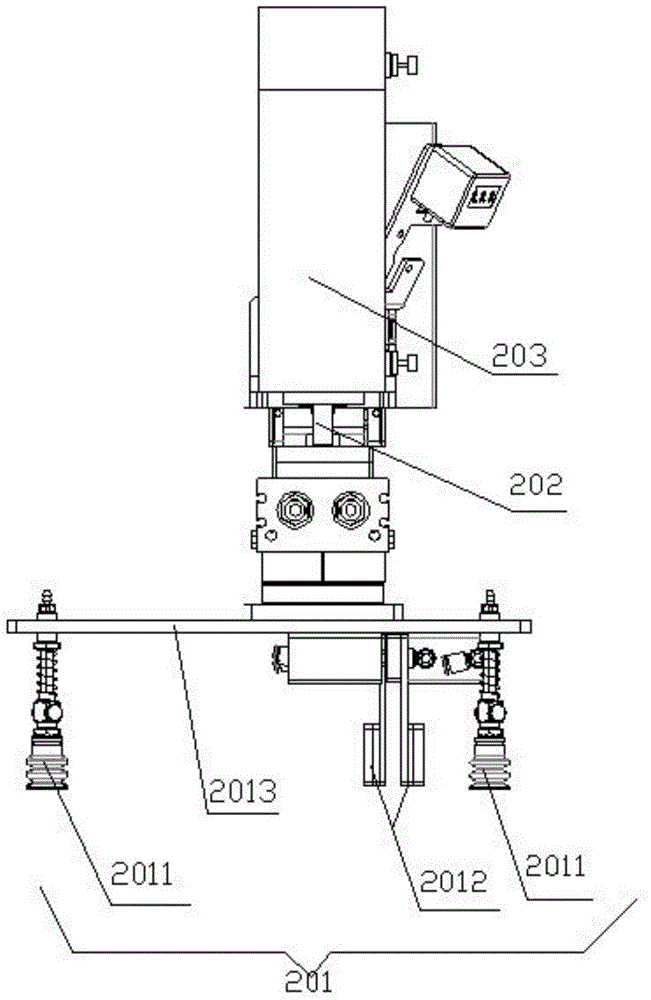

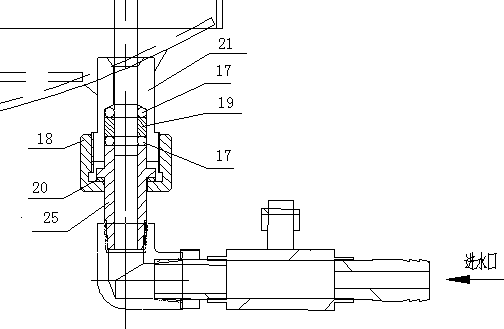

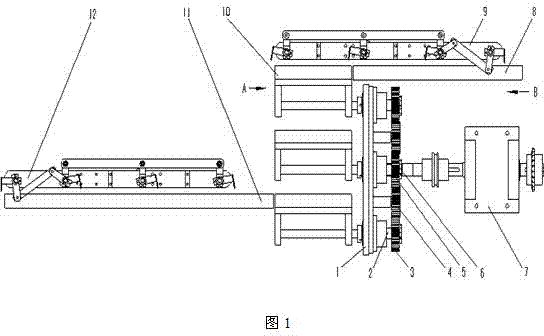

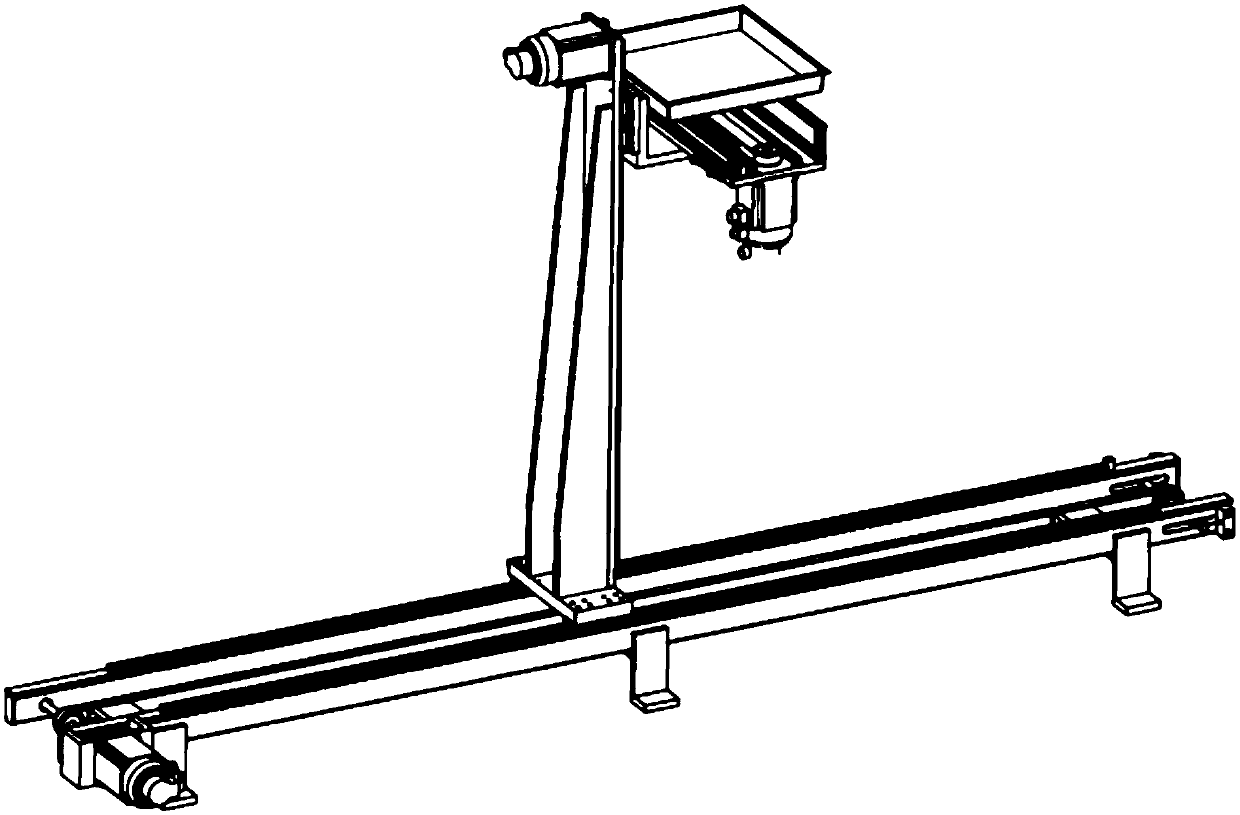

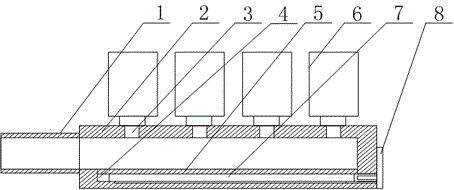

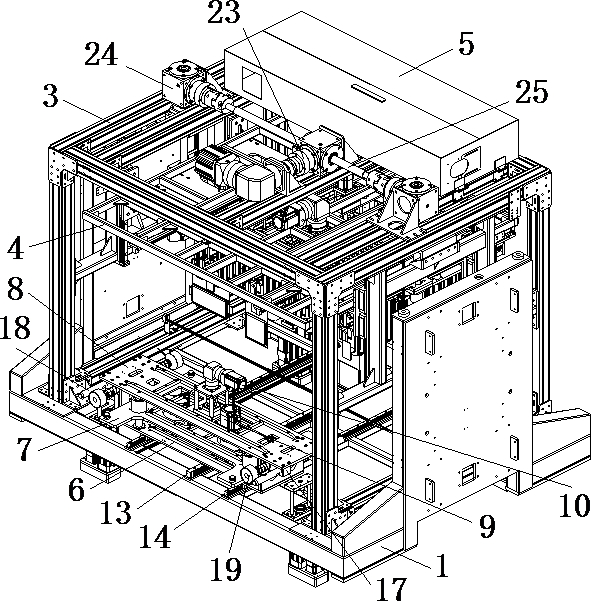

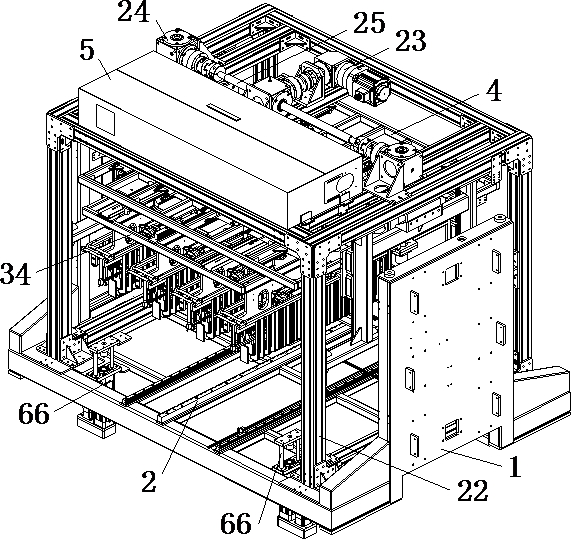

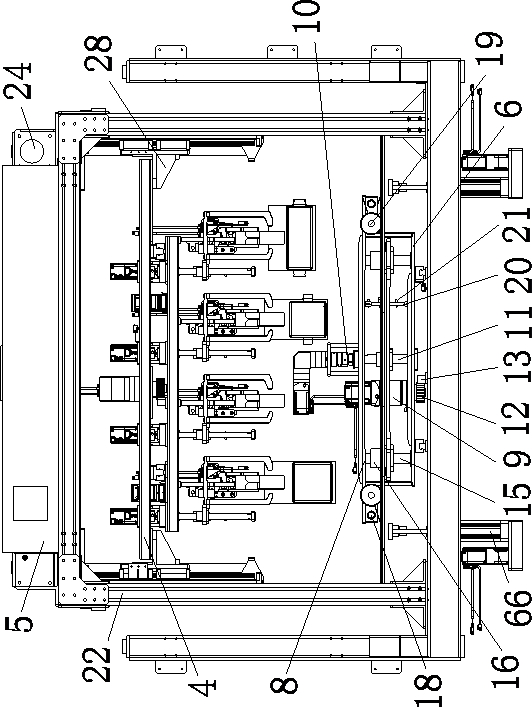

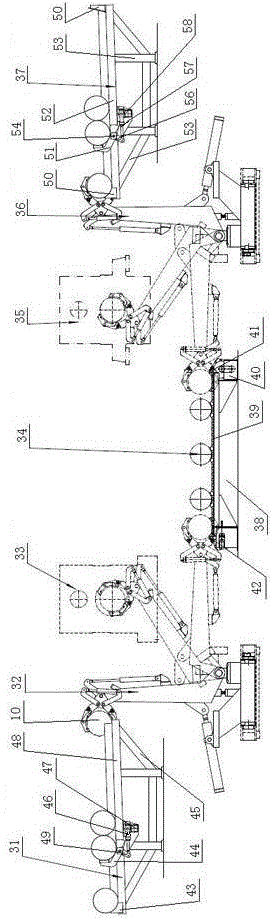

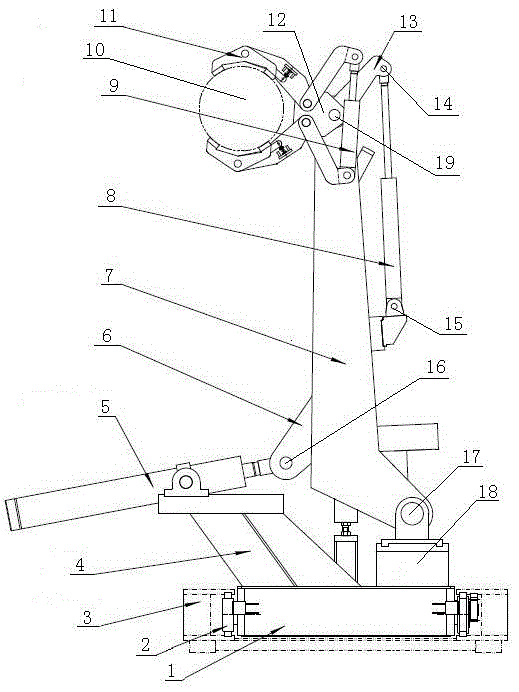

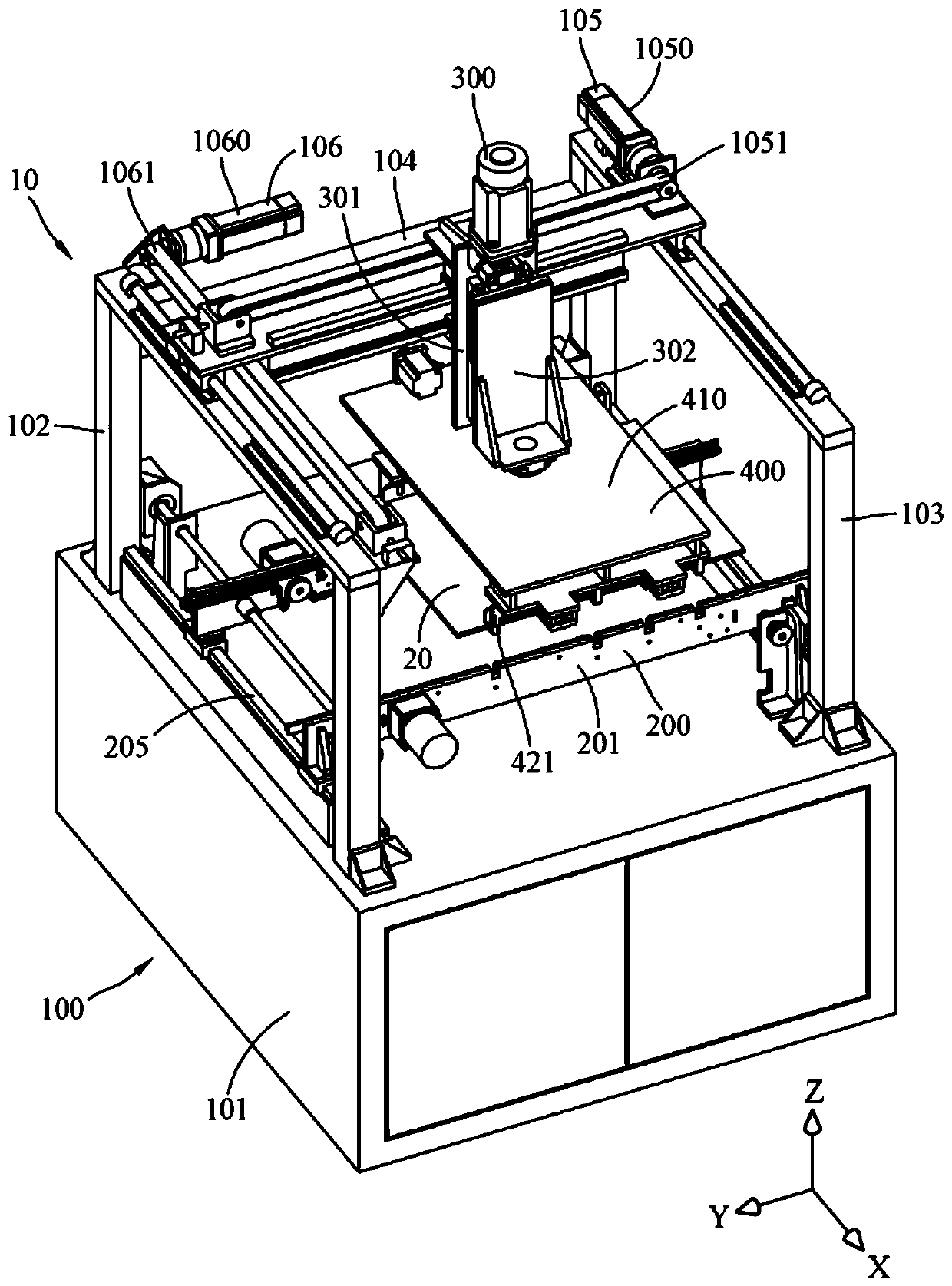

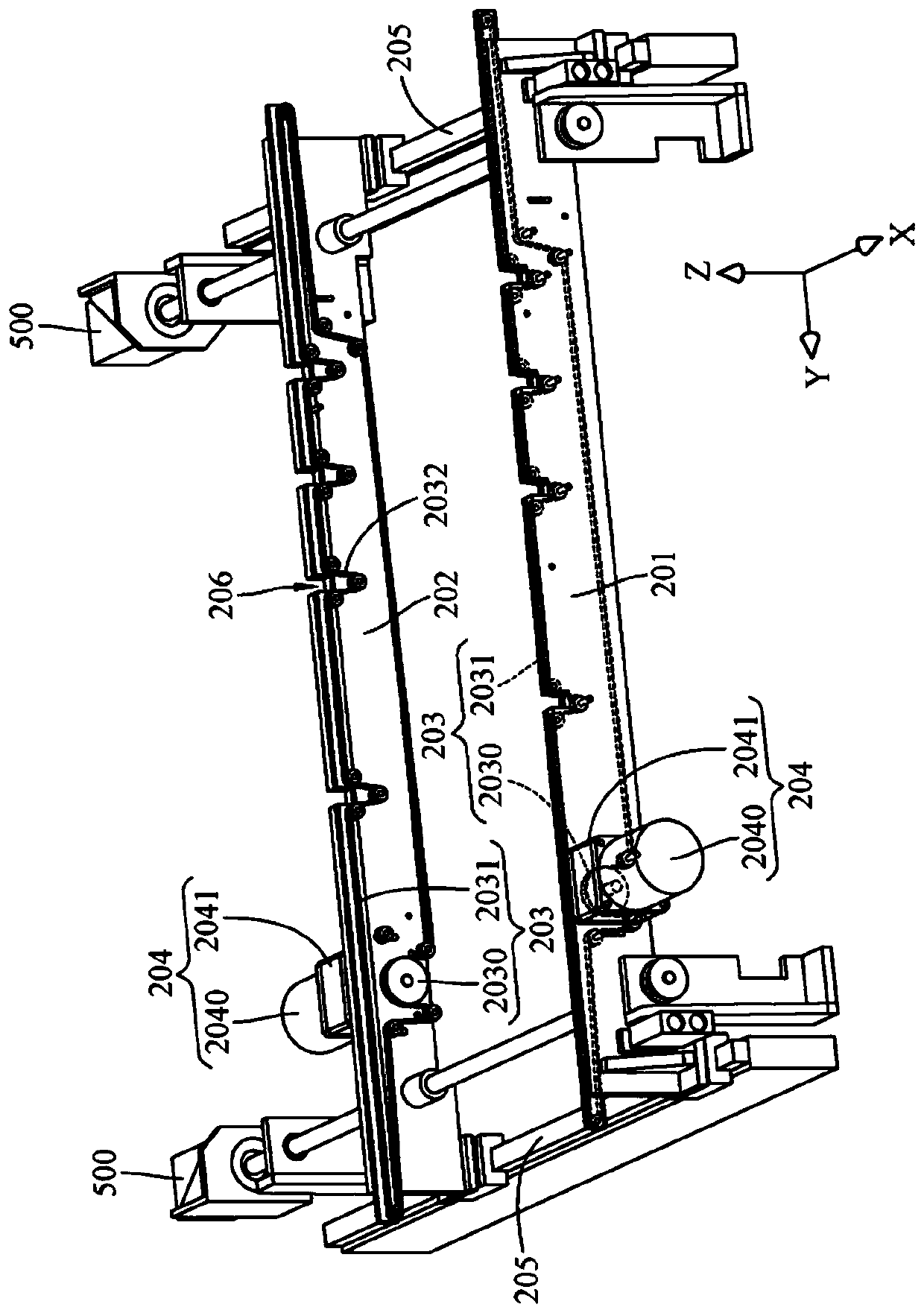

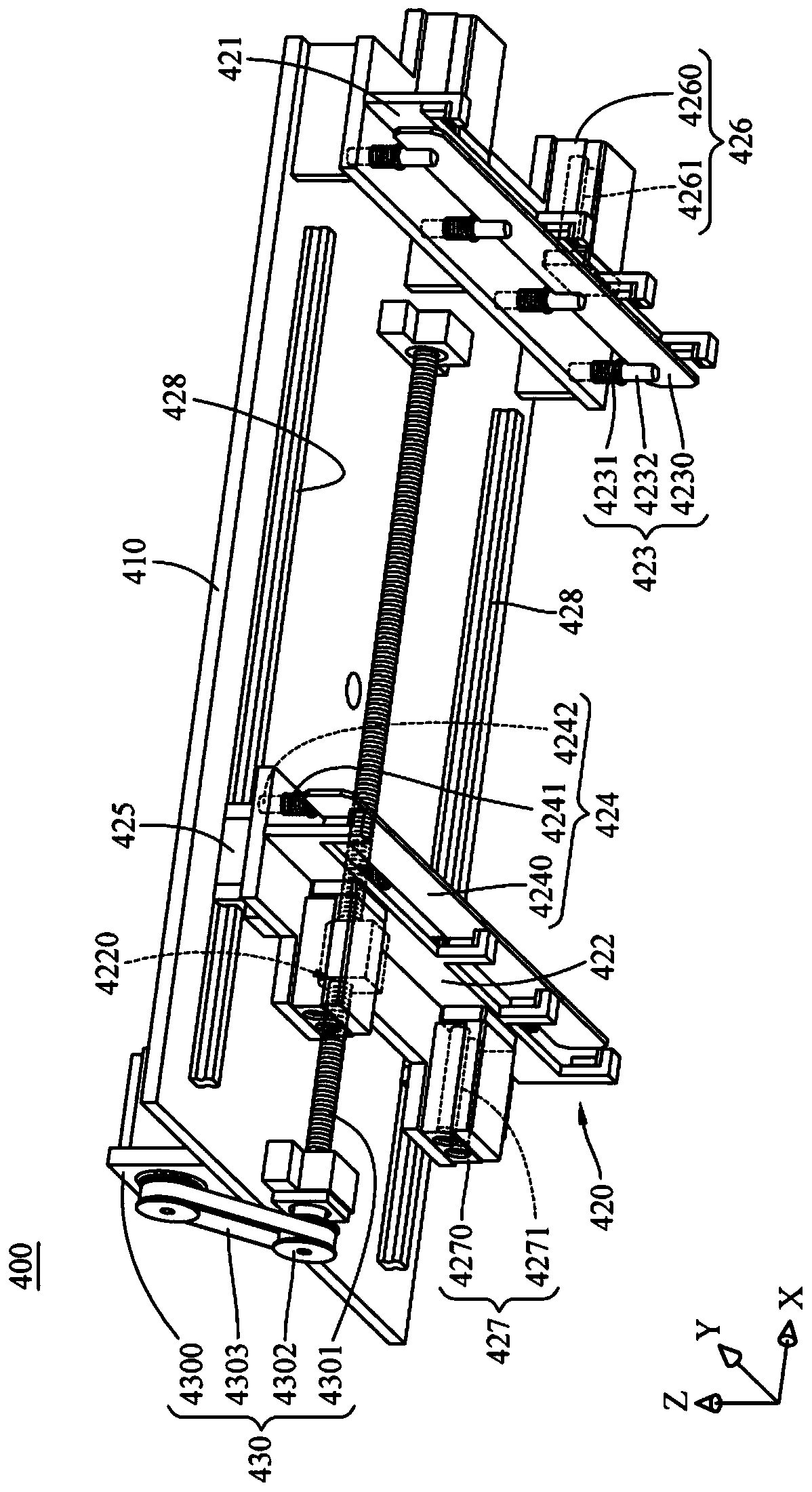

High-speed feeding machine

InactiveCN104555350AQuick and easy tray accessStable pick and placeConveyor partsTransfer mechanismManipulator

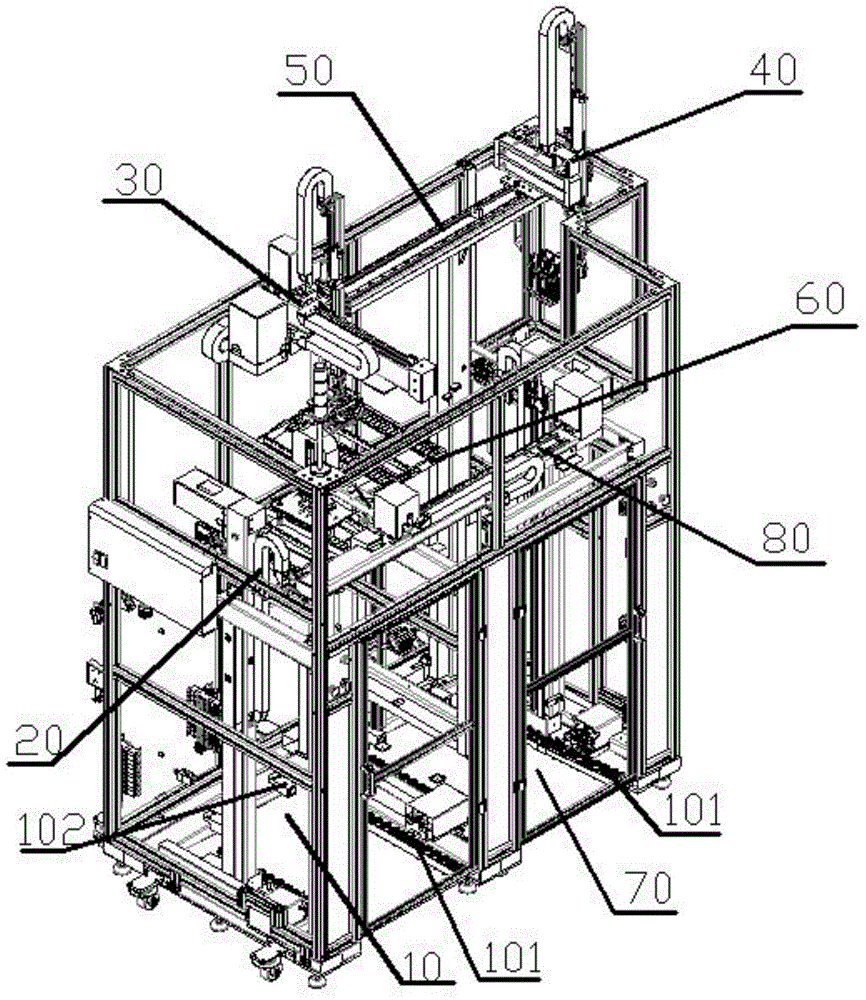

The invention discloses a high-speed feeding machine; based on the procedures, the high-speed feeding machine sequentially comprises a feed bin, a tray transferring mechanism, a high-speed material fetching manipulator, a high-speed shifting mechanism, a feeding manipulator, and a tray recycle bin; the feed bin and the tray recycle bin are arranged in positions at the bottom layer of the high-speed feeding machine; the tray transferring mechanism, the high-speed material fetching manipulator, the high-speed shifting mechanism and the feeding manipulator are arranged in positions at the upper layer of the high-speed feeding machine; the high-speed shifting mechanism is arranged between the high-speed material fetching manipulator and the feeding manipulator; the feeding manipulator is shifted beside the high-speed material fetching manipulator by the high-speed shifting mechanism; the high-speed material fetching mechanism hands over the fetched material into the feeding manipulator. Each portion of the disclosed high-speed feeding machine is in high-speed engagement, intelligently controlled, and is able to achieve high-speed feeding of toothbrush handles.

Owner:SUZHOU IND PARK CHAOQUN AUTOMATION EQUIP

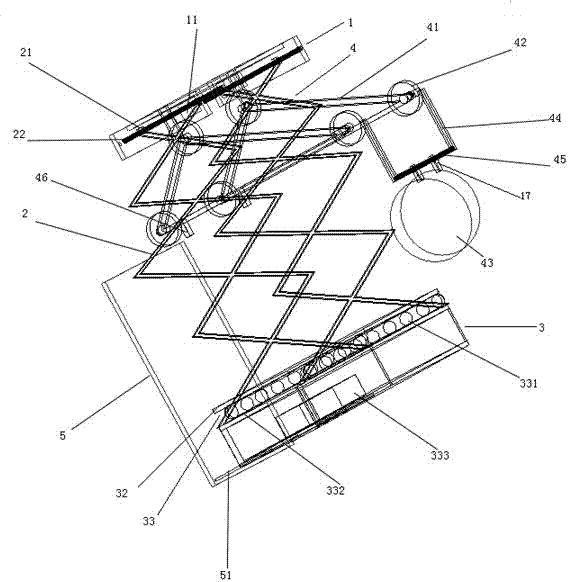

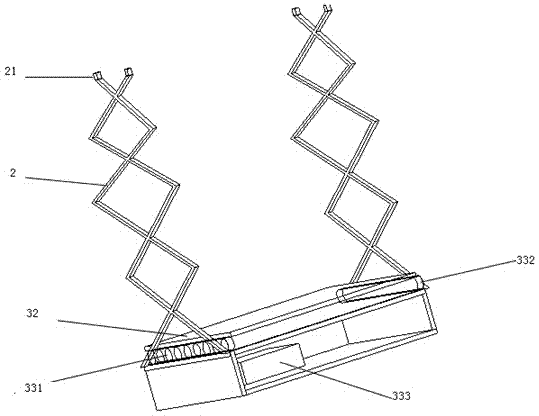

Luggage taking and placing device

The invention discloses a luggage taking and placing device, which comprises an installing plate, a folding frame, a transmission device and an extraction device, wherein lead screws with opposite screw threads are arranged at the two sides of the bottom of the installing plate, and connecting screw nuts are respectively arranged on the lead screws arranged at the two sides in a sleeving way; the lead screws are connected with a first motor; the top ends of the folding frame are respectively arranged on the connecting screw nuts arranged at the two sides, and the bottom end of the folding frame is connected with a transmission device; the transmission device comprises a bottom box and a transmission plate, a group of mutually matched gears and racks is arranged between the bottom box and the transmission plate, and the racks are connected with a second motor; the extraction device comprises a support frame, a pulley and a suction disc; the top end of support frame is arranged on the installing plate, the pulley is arranged on the support frame, a rope connected with the third motor is arranged on the pulley, the rope is connected with a screw nut lead screw, a screw nut is arranged on the screw nut lead screw in a sleeving way, and the suction disc is arranged on the screw nut. The luggage taking and placing device has the advantages that the labor work is reduced, the inconvenience in a compartment due to luggage taking and placing is reduced, the stable luggage taking and placing is realized, and the luggage can be reasonably ranged.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

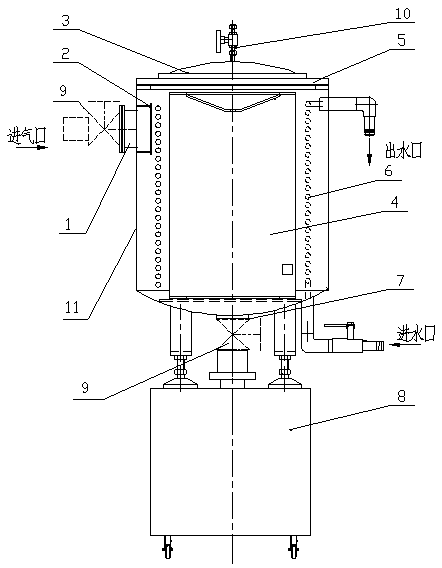

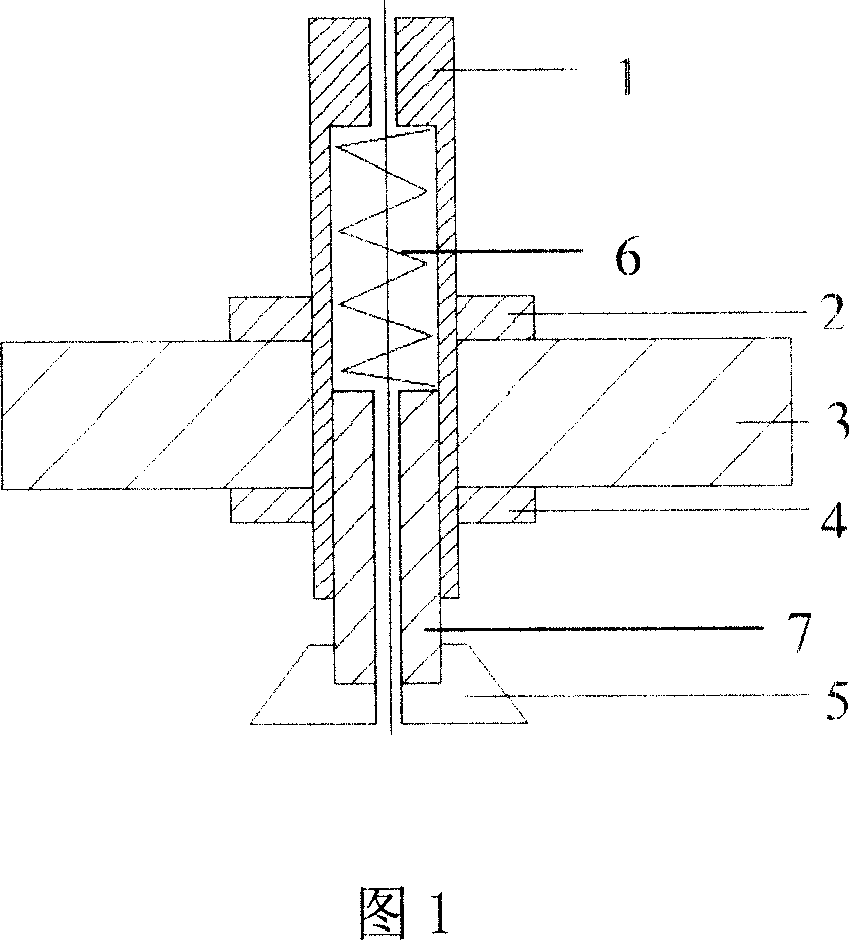

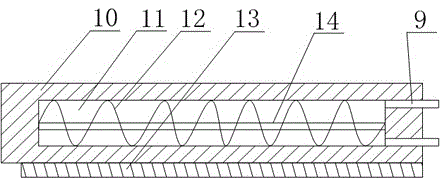

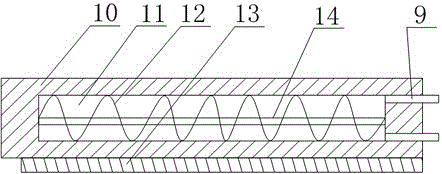

Vacuum filter

InactiveCN105498380AOptimize the installation structureQuick and easy installationHuman health protectionDispersed particle filtrationFiltrationUpstream downstream

The invention discloses a vacuum filter, and belongs to the field of filtration, which is used for solving the problems of cooling and dedusting of high-temperature and dust-contained gas in a vacuum working system. The vacuum filter comprises a cavity body, a diffuser and a filter element, wherein the cavity body is provided with a gas inlet connected with a specific gas pipeline and a gas outlet connected with a vacuum pump; the top end of the cavity body is provided with a top cover connected with the cavity body in a sealed mode; the cavity body is internally provided with the diffuser at the gas inlet; the filter element is installed at the center in the cavity body; the side wall of the filter element is provided with filter holes; the bottom surface of the filter element is provided with an opening leading to the gas outlet of the cavity body, thereby preventing the vacuum pump and an upstream-downstream system from being damaged by high-temperature, corrosive and dangerous dust particles, and solving the problem of too complex and frequent maintaining frequency of the vacuum pump of the vacuum filtration system. From the aspect of environment protection, gas in pipelines can be further cooled down and purified, and air pollution can be reduced.

Owner:青岛赛瑞达电子科技有限公司

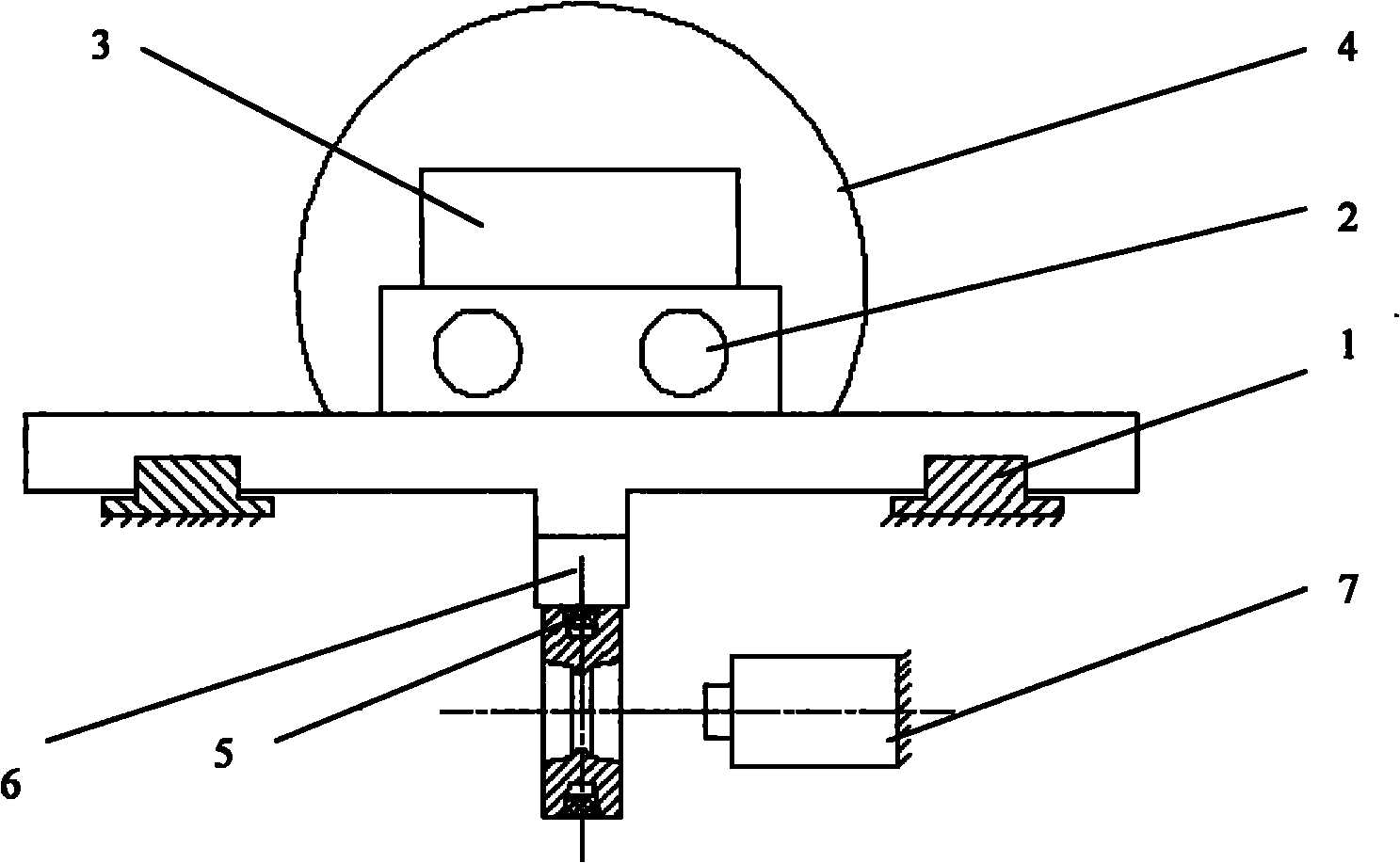

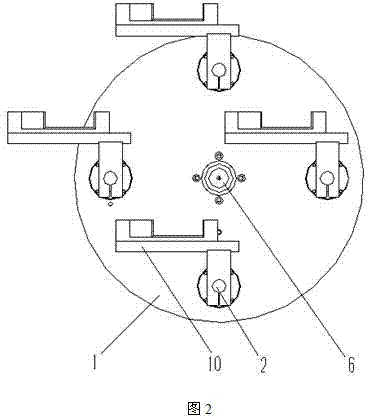

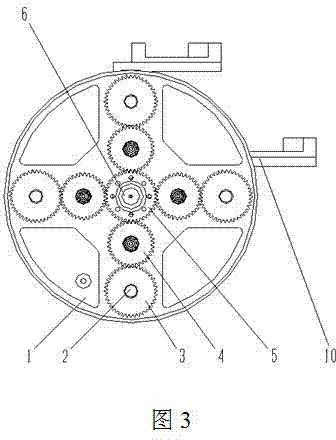

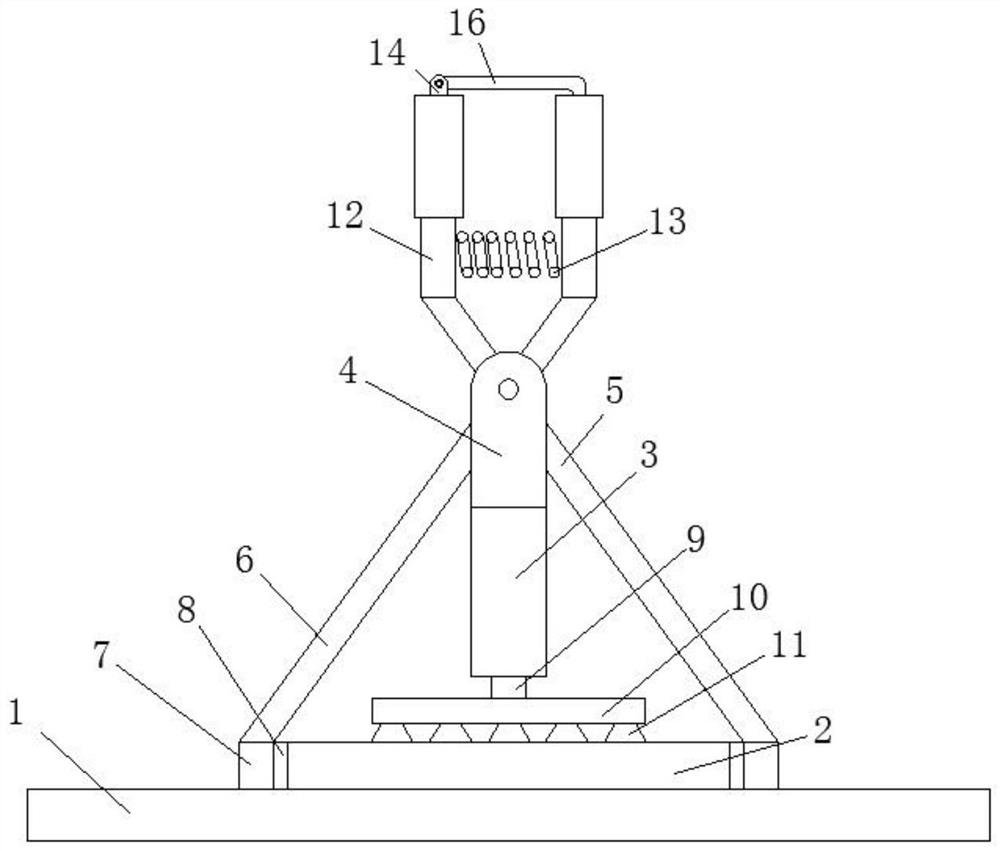

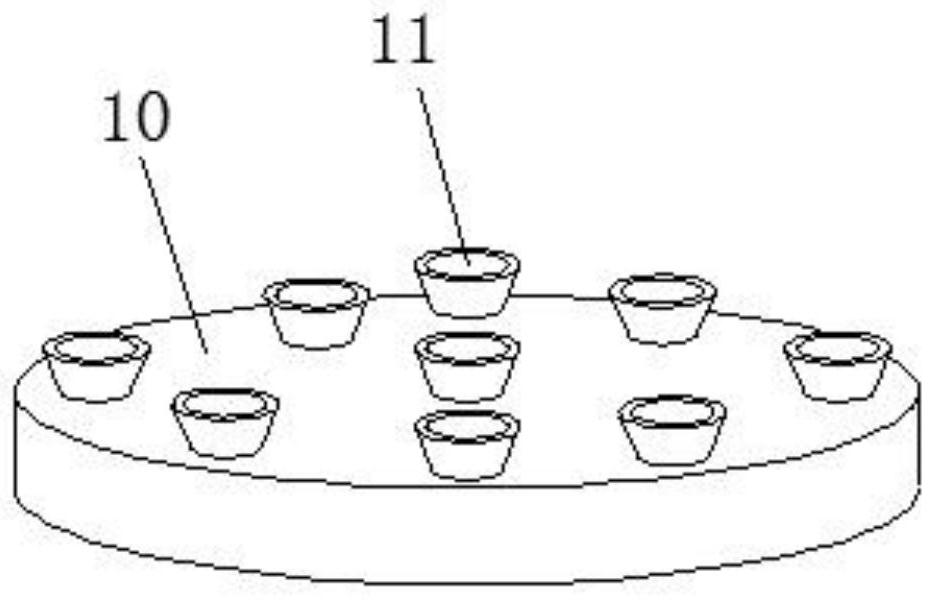

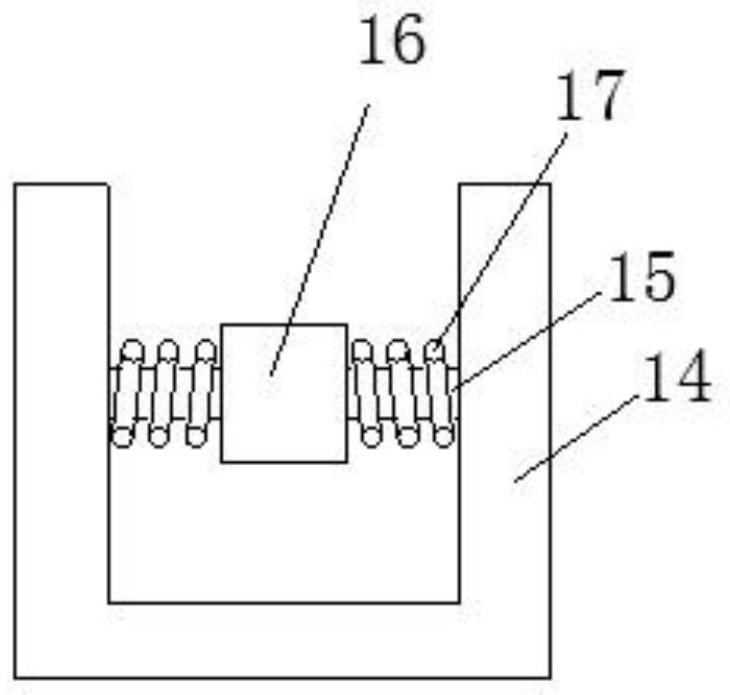

Rotary lifting device

The invention discloses a rotary lifting device. The rotary lifting device comprises a stand, a planetary wheel mechanism and an object table (10), the planetary wheel mechanism is composed of a central shaft (6), a rotary plate (1), a sun wheel (5), an intermediate wheel (4), a planetary wheel (3) and a rotating shaft (2), the central shaft (6) is arranged on the stand, the rotary plate (1) is provided with a central bearing, a planetary bearing and a support shaft, wherein the central shaft (6) drives the object table (10) on the rotating shaft (2) to rotate up and down, the table surface of the object table (10) always keeps the initial horizontal state, and an object on the object table (10) is conveyed to the next station through a rotary lifting mode. The rotary lifting device is novel and reasonable in design, the object is conveyed through using the planetary wheel mechanism to rotate continuously and circularly, and the object table can always keep the horizontal state so as to facilitate the stable object lifting and taking; the equipment runs stably, the automatic degree is high, the rotary lifting device can be matched with the production line, the production efficiency is high, and the use is safe and reliable.

Owner:JOYEA CORP

Hard disk protective cover fetching device

InactiveCN101067962AAccurate pick and place positioningShock mitigationGripping headsRecord information storageEngineeringNozzle

This invention discloses a taking and placing device for disc protection covers including: an assembling board, at least one absorbing nozzle, at least one fixed rod, in which, the absorbing nozzle is seal-connected at the end of the fixed rod, a through cavity is set in the fixed rod, the installation board is clamped at the middle of the rod and the cavity and the absorbing nozzle in the fixed rod form a gas channel for absorbing and placing protection covers.

Owner:YITUO SCI & TECH CO LTD SHENZHEN

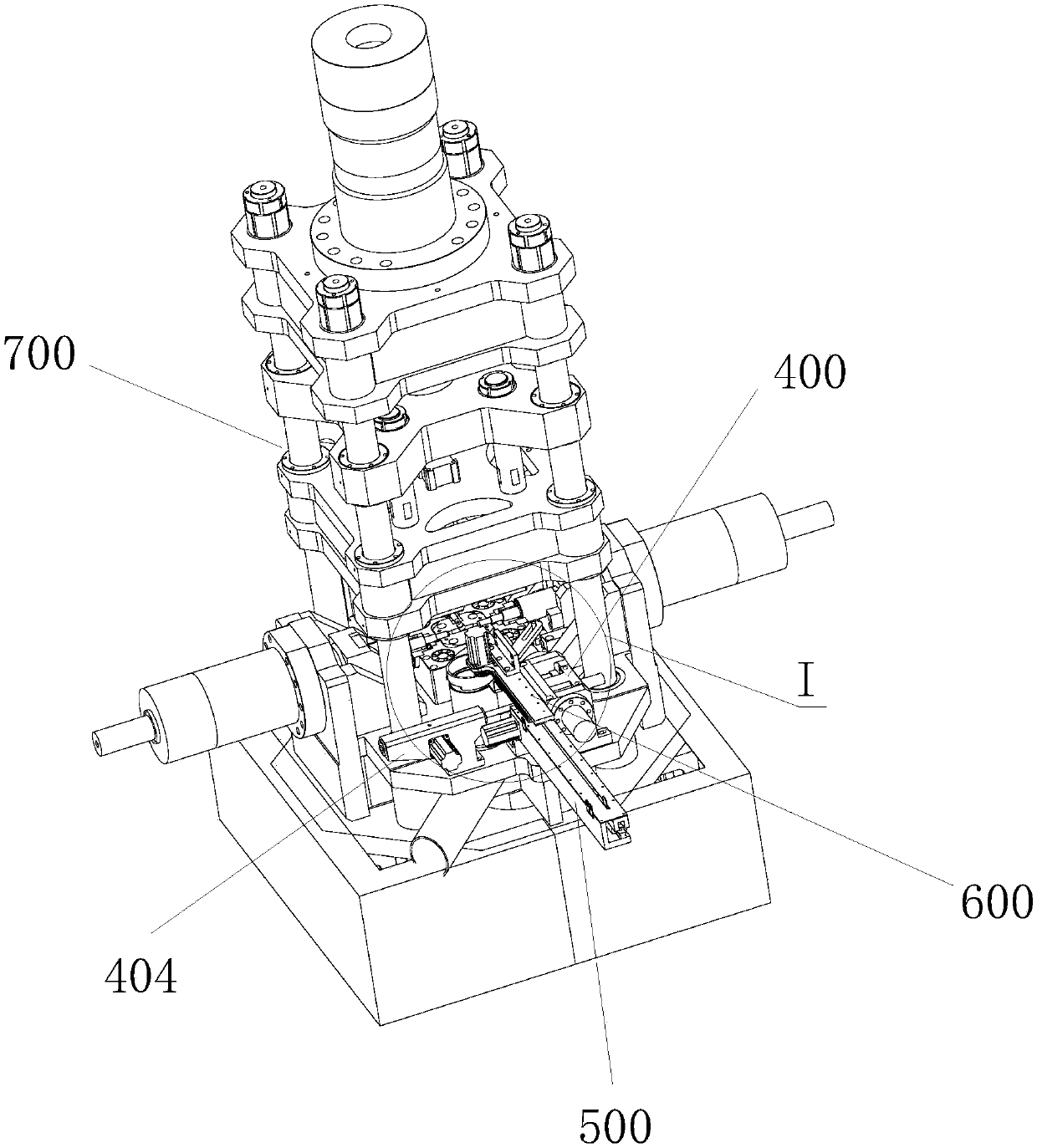

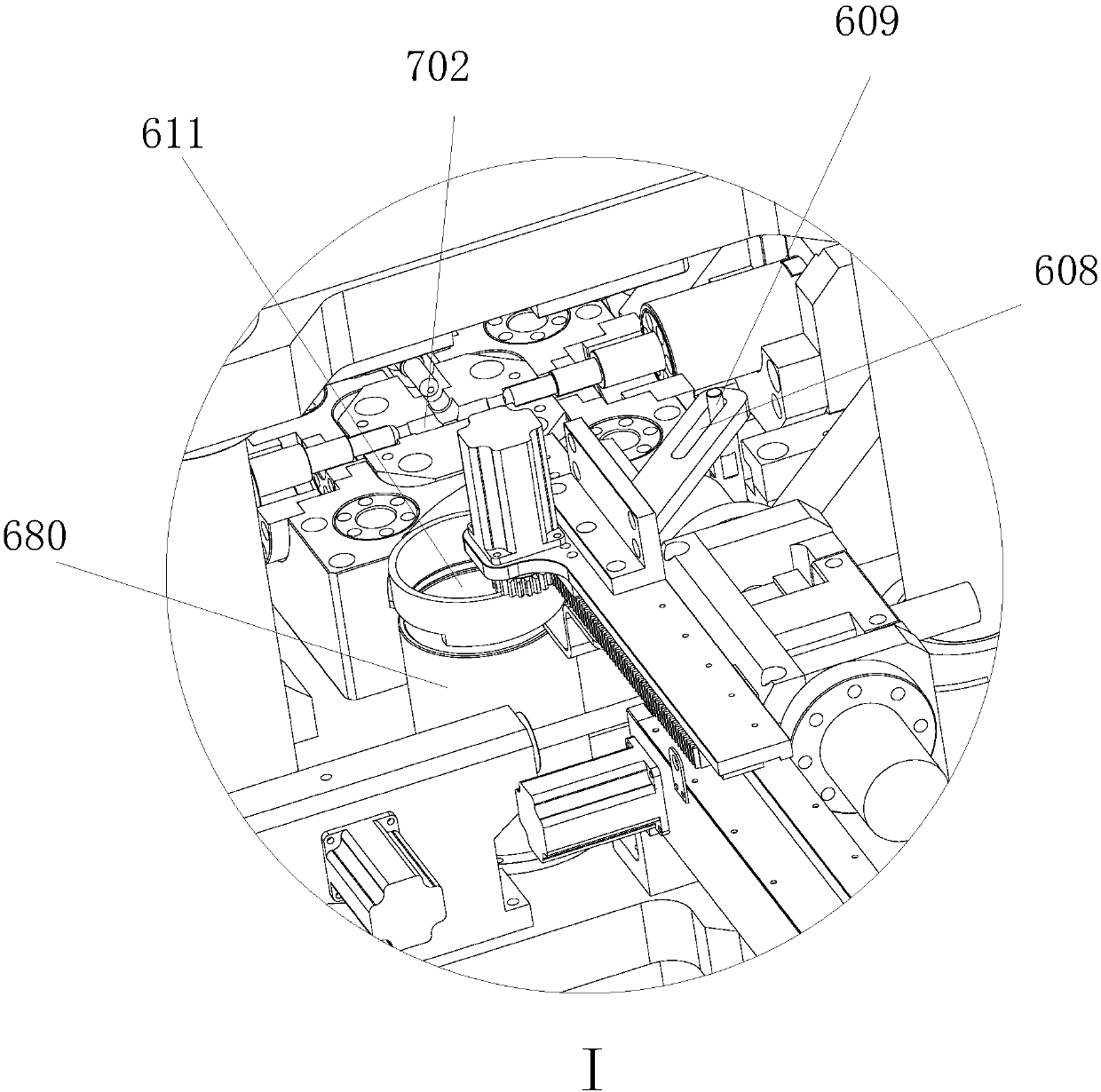

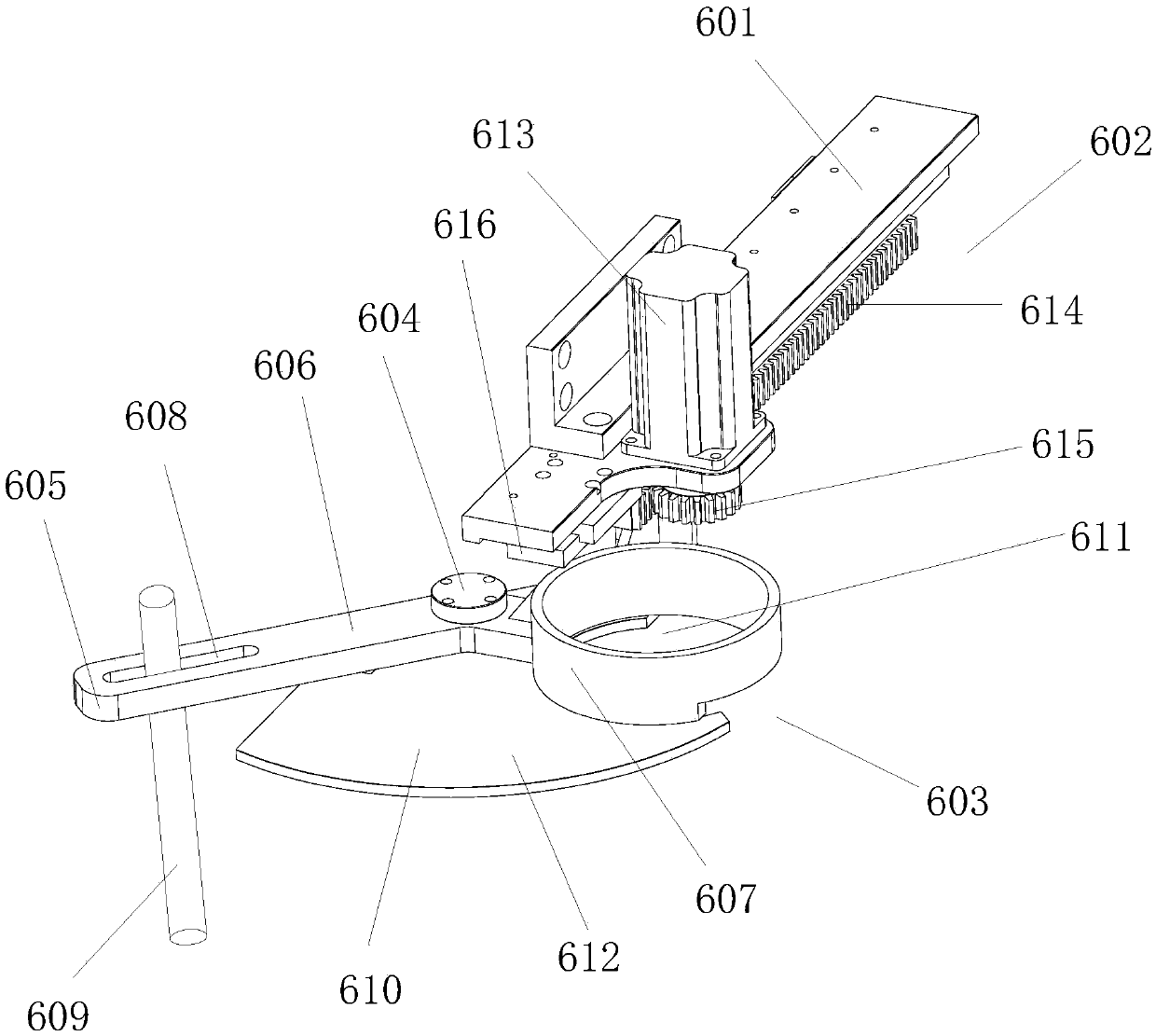

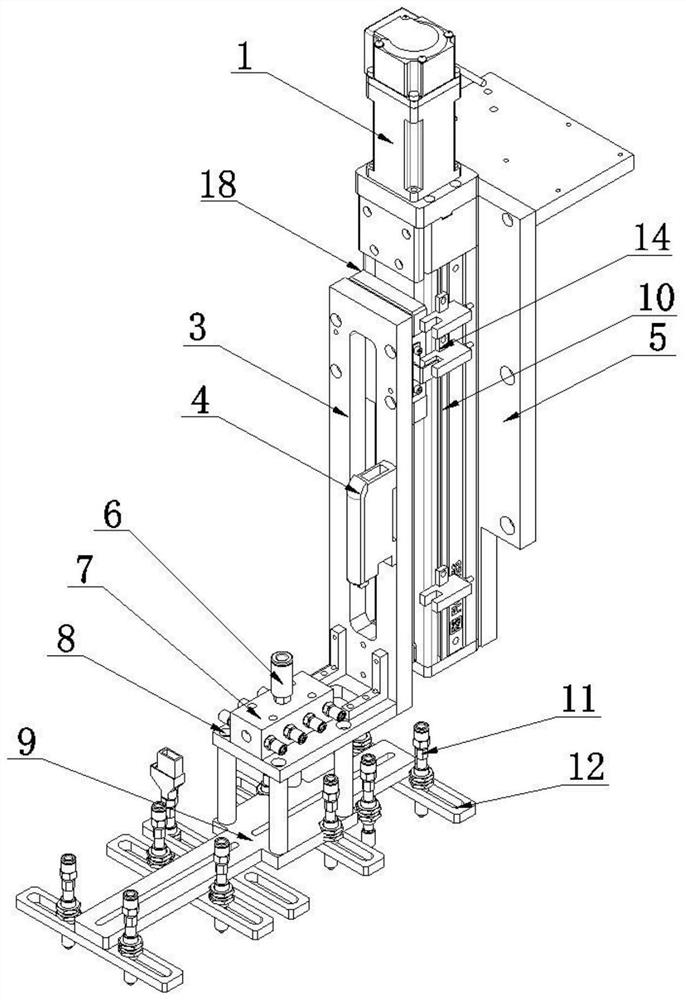

Workpiece machining device

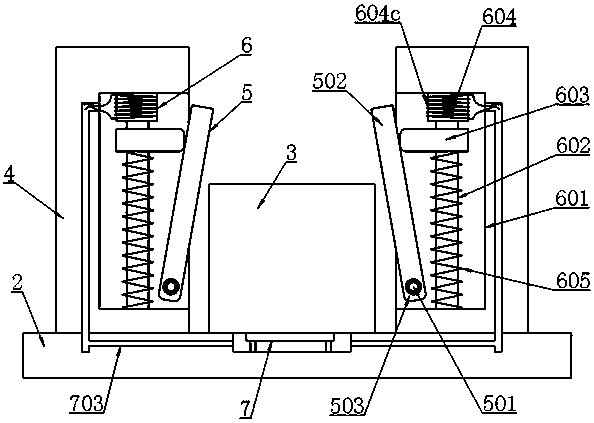

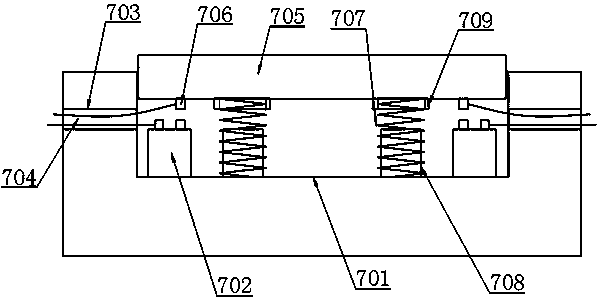

ActiveCN107891117AHigh degree of automationReasonable structureForging/hammering/pressing machinesHandling devicesLinear motionManipulator

The invention relates to the field of molds and discloses a workpiece machining device. According to the workpiece machining device, a material taking manipulator (600) comprises a mounting frame (601); a moving assembly (602) which moves along the mounting frame (601) is arranged on the mounting frame (601); a material taking assembly (603) is arranged on the moving assembly (602); the material taking assembly (603) comprises a rotating shaft (604) and a rotating rod (605); the rotating rod (605) rotates around the rotating shaft (604); the rotating rod (605) comprises a driving rod (606) positioned on one side of the rotating shaft (604) and a material receiving disc (607) positioned on the other side of the rotating shaft; a sliding groove (608) is formed in the rotating rod (605); a stop rod (609) inserted into the sliding groove (608) is arranged on a workbench (725); and during the linear motion, the rotating rod (605) rotates around the rotating shaft (604) in such a manner thatthe stop rod (609) is pushed by the sliding groove (608) to slide. The workpiece machining device has the advantages that the automatic material loading operation, the automatic material taking operation and the automatic machining operation can be achieved. Furthermore, both the material loading operation and the material taking operation are accurate.

Owner:叶腾斌

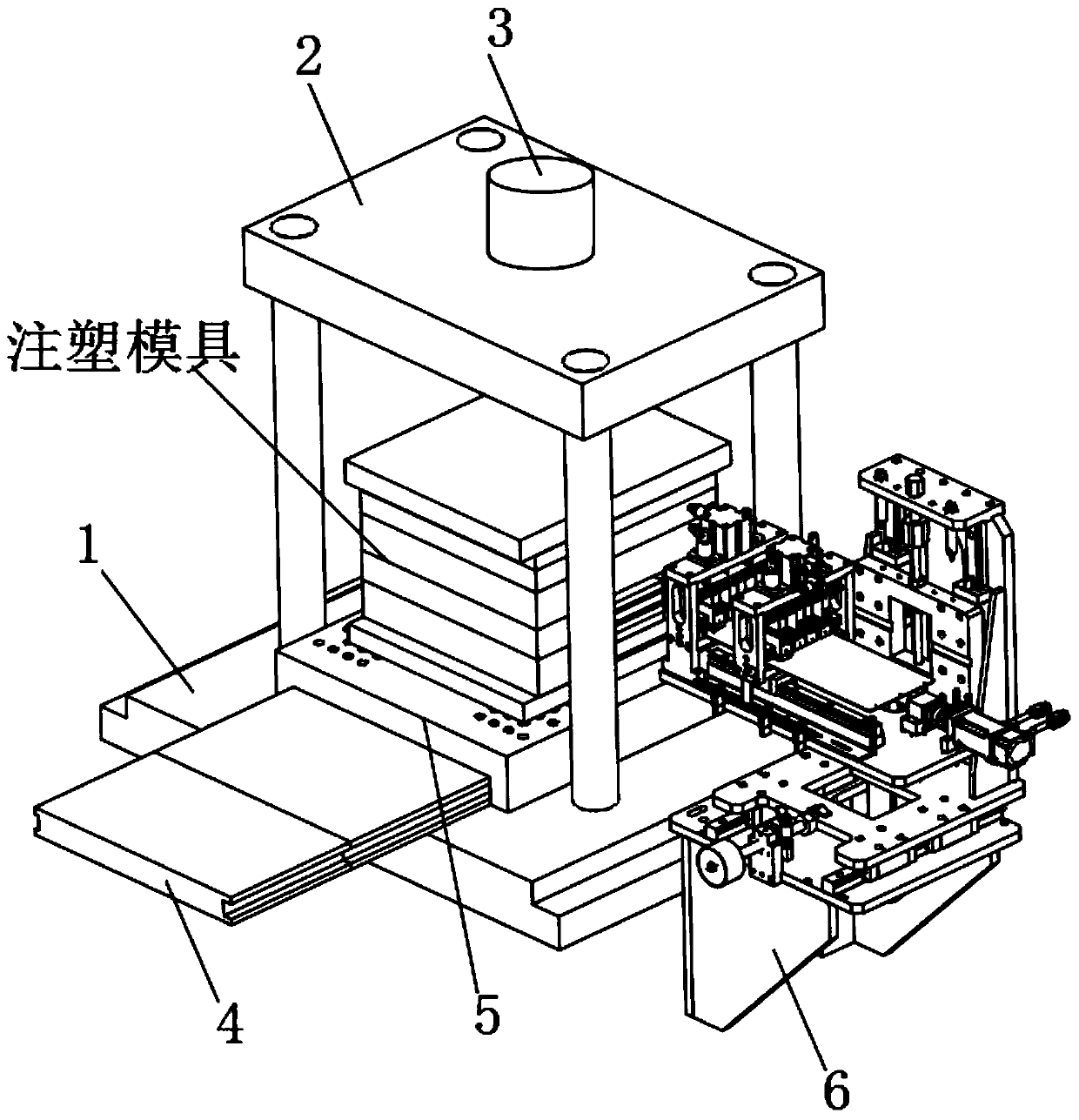

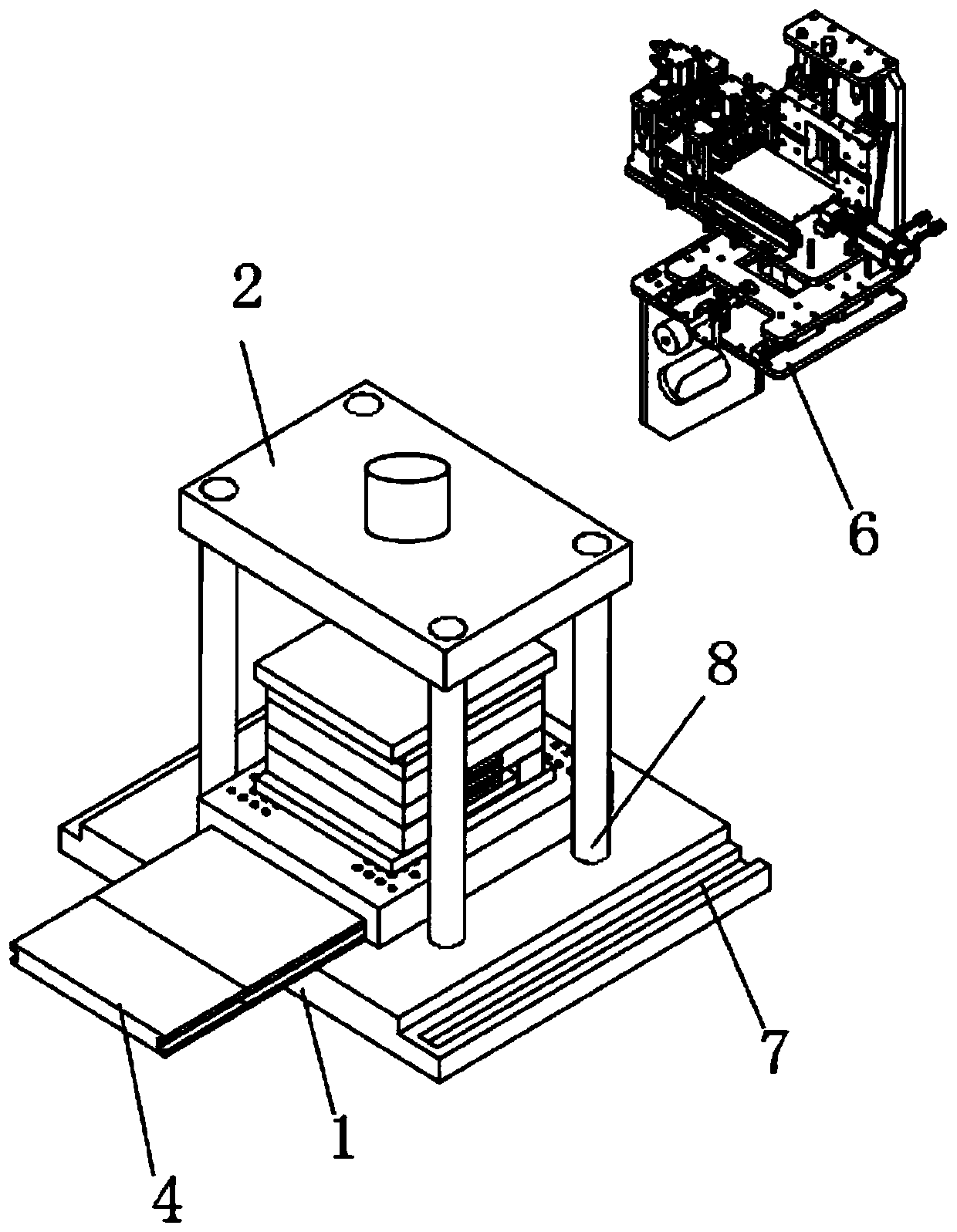

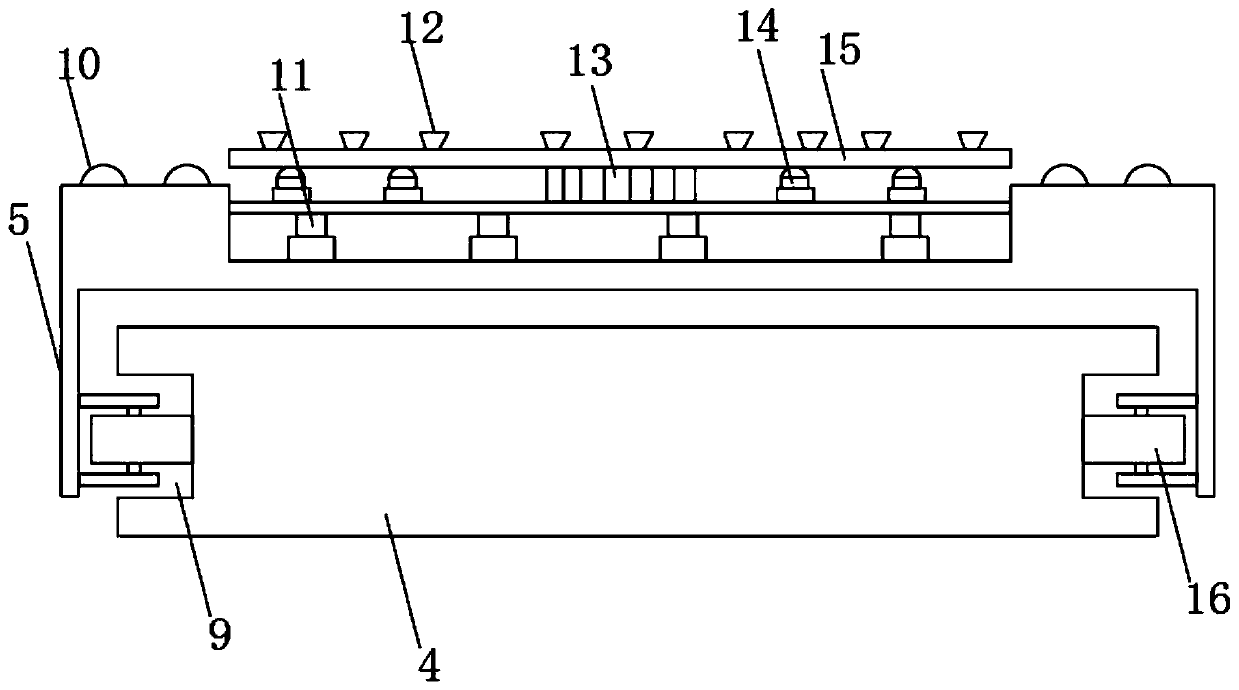

Turnable mold closing device and for injection molding machine and mold closing method of device

ActiveCN110936556AEasy to install and disassembleInstalled and disassembledEngineeringInjection molding machine

The invention discloses a turnable mold closing device and for an injection molding machine. The device comprises a base, a bearing plate is installed at the top of the base, a load-bearing plate is installed in the upper portion of the bearing plate in a sliding mode, and a detachable turning mechanism is installed at one side of the top of the base. When an upper mold and a lower mold need to beclosed, the upper mold is installed under a first hydraulic column or at one side of the turning mechanism, and a clamping mechanism drives the upper mold to move. The position of the upper mold is convenient and fast to adjust, the upper mold can fall into the upper portion of the lower mold after long-time adjustment, mold closing is more accurate, and collision damage is not likely to happen in the mold closing process. The problems that the position between the upper and lower molds is not accurate enough and the interior of a mold cavity is easy to collide and damage during manual mold closing are avoided.

Owner:东莞佳旭电子制品有限公司

Unmanned catering system

The invention discloses an unmanned catering system, which comprises a cooking device, a taking and placing device and a meal discharging device, wherein the position of the cooking device, the takingand placing device and the meal discharging device are sequentially arranged from inside to outside; the meal discharging device has an open one-sided or open two-sided structure or a closed annularstructure; the cooking device and the taking and placing device are electrically connected with a controller; the controller can send a cooking instruction to the cooking device, and the cooking device automatically completes a corresponding cooking program according to the cooking instruction; and the controller can further send a taking and placing instruction to the taking and placing device, and the taking and placing device takes out food from the cooking device and places the food on the meal discharging device according to the taking and placing instruction. According to the technical scheme, the occupied area of unmanned catering system equipment can be reduced, the space is saved, the meal delivery efficiency can be improved, and the meal delivery quality can be improved.

Owner:深圳市蒸滋味智能餐饮有限公司

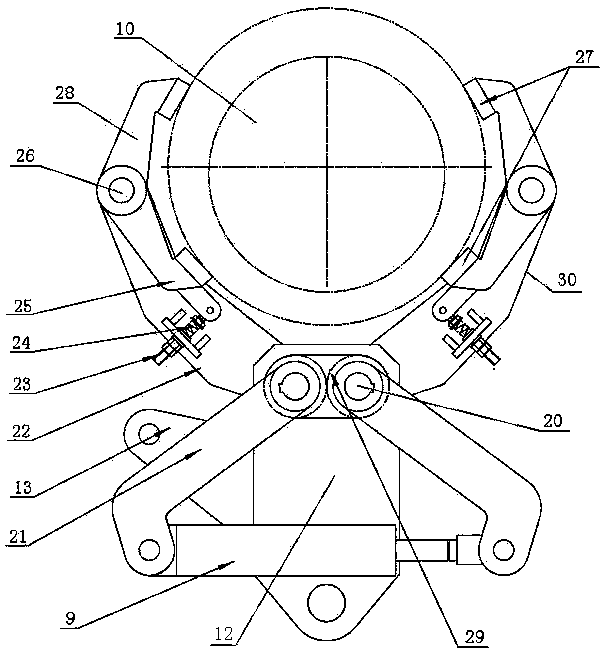

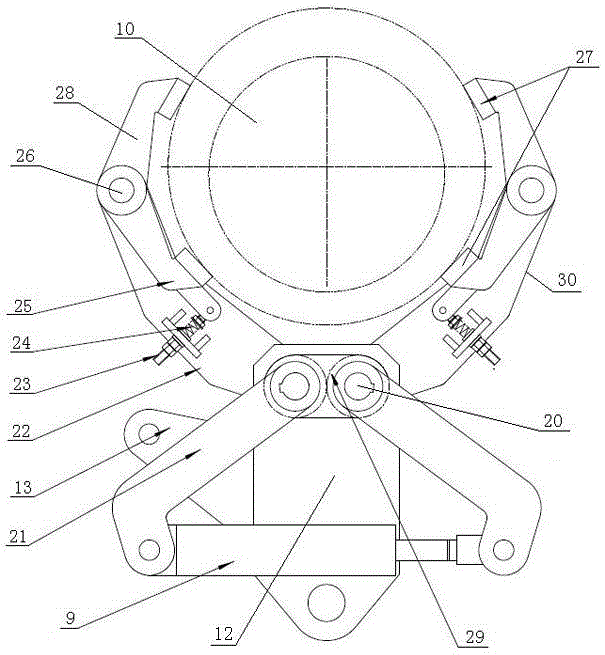

Automatic sleeve-loading and unloading and sleeve-transporting integrated device of cold-rolling mill

The invention discloses an automatic sleeve-loading and unloading and sleeve-transporting integrated device of a cold-rolling mill. The automatic sleeve-loading and unloading and sleeve-transporting integrated device comprises an inlet side sleeve manipulator, an outlet side sleeve manipulator, a sleeve transporting machine, an inlet side sleeve storing platform, an outlet side sleeve storing platform, wherein the lower end of a swinging arm of the inlet side sleeve manipulator or the outlet side sleeve manipulator is hinged on the upper end face of a chassis; a cylinder body of a swinging arm hydraulic cylinder is hinged at the upper end of a frame, the end part of a piston rod of the swinging arm hydraulic cylinder is hinged on a connecting plate I of the swinging arm; a sleeve clamp comprises two groups of synchronously-operating clamps which are hinged in the middle together and are hinged on a support block; the support block is hinged at the upper end of the swinging arm, a connecting plate II extends out of the support block, the end part of the connecting plate II is hinged at the end part of a piston rod of a fixture swinging hydraulic cylinder; a cylinder body of the fixture swinging hydraulic cylinder is hinged at the lower part of the swinging arm; a motor of the sleeve transporting machine drives a transporting chain to transport a sleeve from an uncoiling machine to a coiling machine. The automatic sleeve-loading and unloading and sleeve-transporting integrated device can complete a complete set of unloading, transporting, feeding and the like of an empty sleeve within a short time, and is high in working efficiency, stable and reliable to take or place the sleeve, free from damaging the sleeve, and low in energy consumption.

Owner:涿神有色金属加工专用设备有限公司

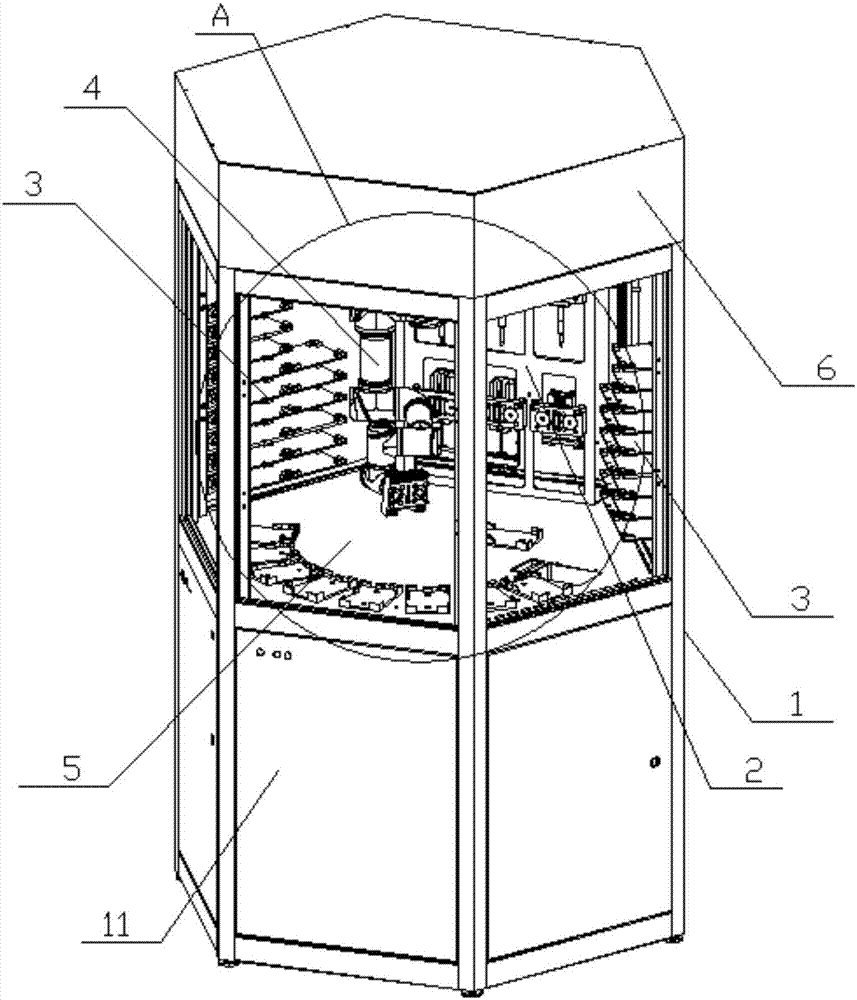

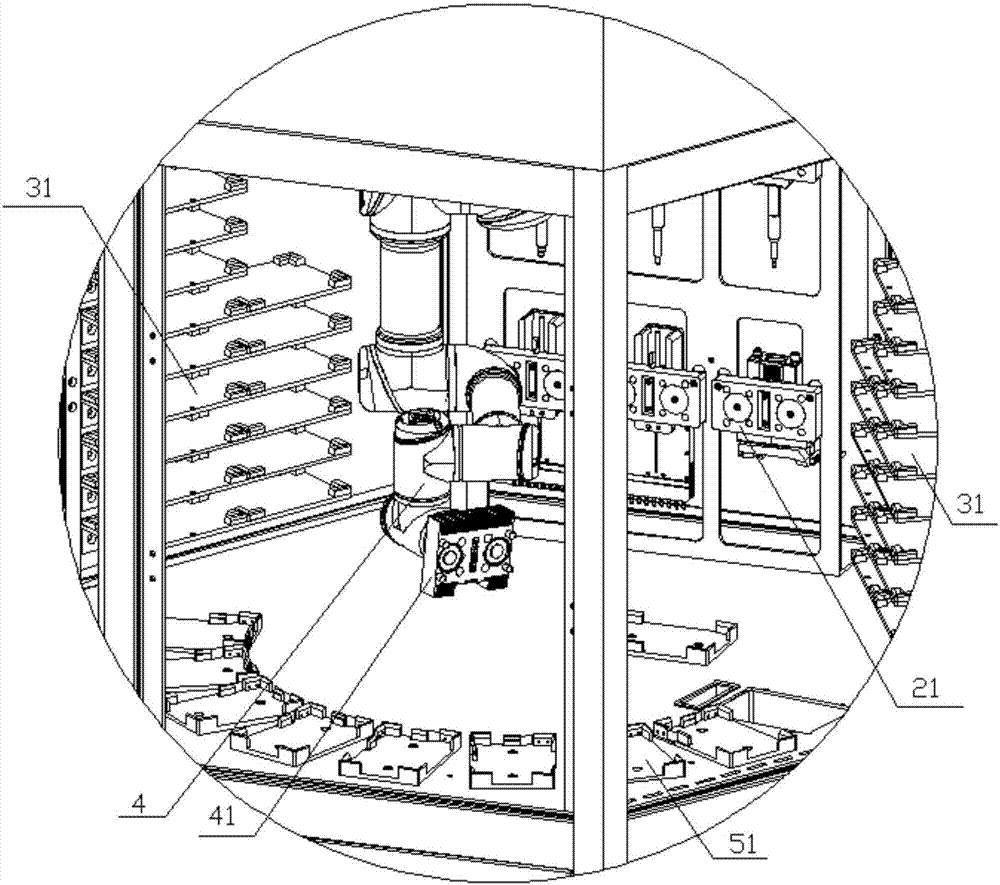

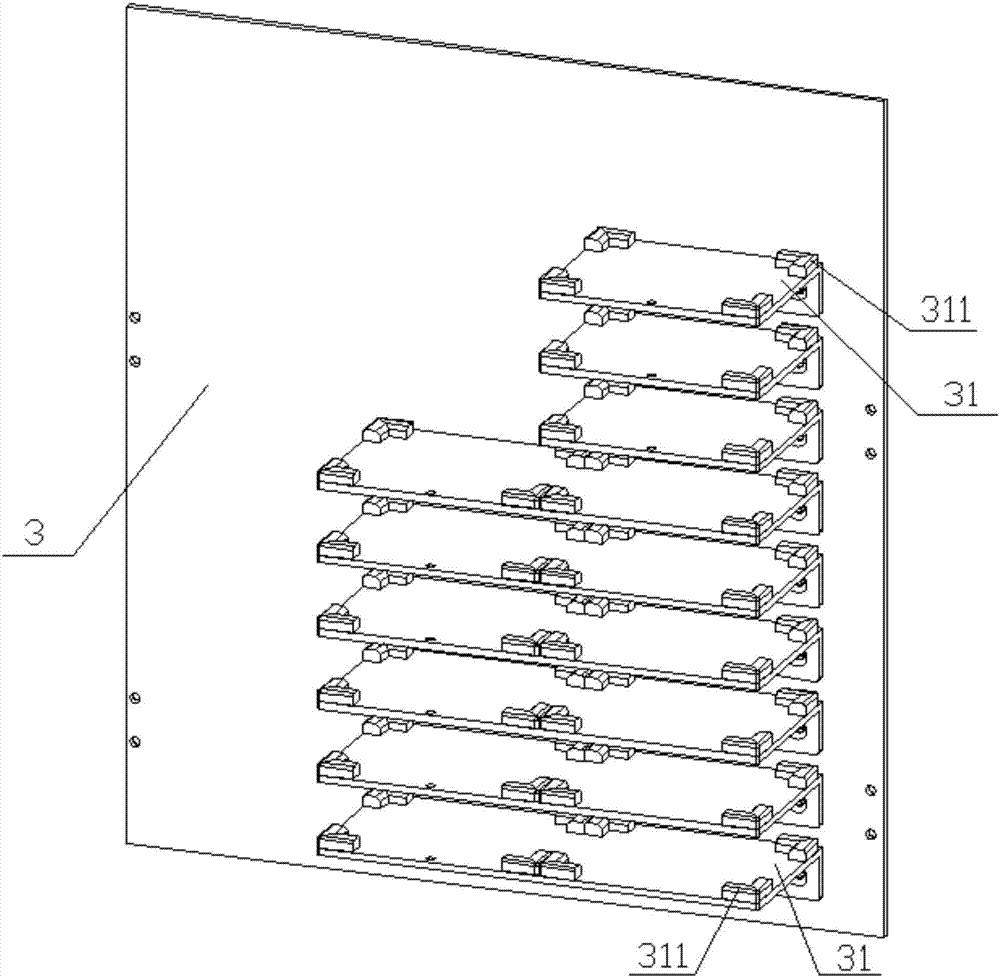

Biological experiment workstation

ActiveCN107377034ACompact structureImprove space utilizationProgramme-controlled manipulatorEnclosures/chambersInterior spaceMedicine

The invention relates to the technical field of biological medicine test equipment and particularly relates to a biological experiment workstation. The biological experiment workstation comprises a cabin and a mechanical arm arranged in the cabin, wherein a workbench panel which is used for separating the inner space of the cabin into upper and lower parts is arranged in the cabin; a detachable upper lateral plate component is arranged on the upper part of the cabin in an encircling manner; a working chamber is formed by the upper lateral plate component and the space above the workbench panel; a lower lateral plate component is arranged on the lower part of the cabin in an encircling manner; a storage chamber is formed by the lower lateral plate component and the space under the workbench panel. The workstation has the beneficial effects that the structure layout is compact, the space utility rate is increased, the motion of the mechanical arm along various directions is beneficial to the flexible application of various test operations, the operation is more convenient, the time and the labor are saved, the labor intensity is reduced and the working efficiency is improved.

Owner:CHONGQING WAVELET BIOLOGICAL TECH CO LTD

Gas injection device for automobile

InactiveCN105604743AAffect flow rateGuaranteed circulationInternal combustion piston enginesFuel supply apparatusElectricityHeat conducting

The invention discloses a gas injection device for an automobile. The gas injection device comprises a gas inlet pipe and a hollow pipe, wherein a groove of which the section is a major arc is formed in the inner wall of the hollow pipe; injection holes are just opposite to the arc bottom of the groove; a plurality of electric heating tubes are arranged in the groove; a guide block is arranged at the bottoms of the electric heating tubes; a guide groove matched with the guide block is formed in the bottom of the groove; each electric heating tube comprises a tube body, an insulated material filling the inside of the tube body and an electric heating wire arranged inside the tube body; a binding post is connected to the tail end of each electric heating wire, penetrates through a small hole and is connected with a wiring plug board; a heat conducting board covers the opening end of the groove. The plurality of electric heating tubes are arranged in the arc groove; the side end of the groove is sealed by the wiring plug board, so that the heat dissipation can be reduced; meanwhile, the electric hating tubes are favorably taken and placed, i.e., a user can determine the number of the electric heating tubes in real time according to the supply amount of gas, so that stable operation for gas output flow is finished at the minimum heating cost.

Owner:CHENGDU DUJIA ELECTRICAL

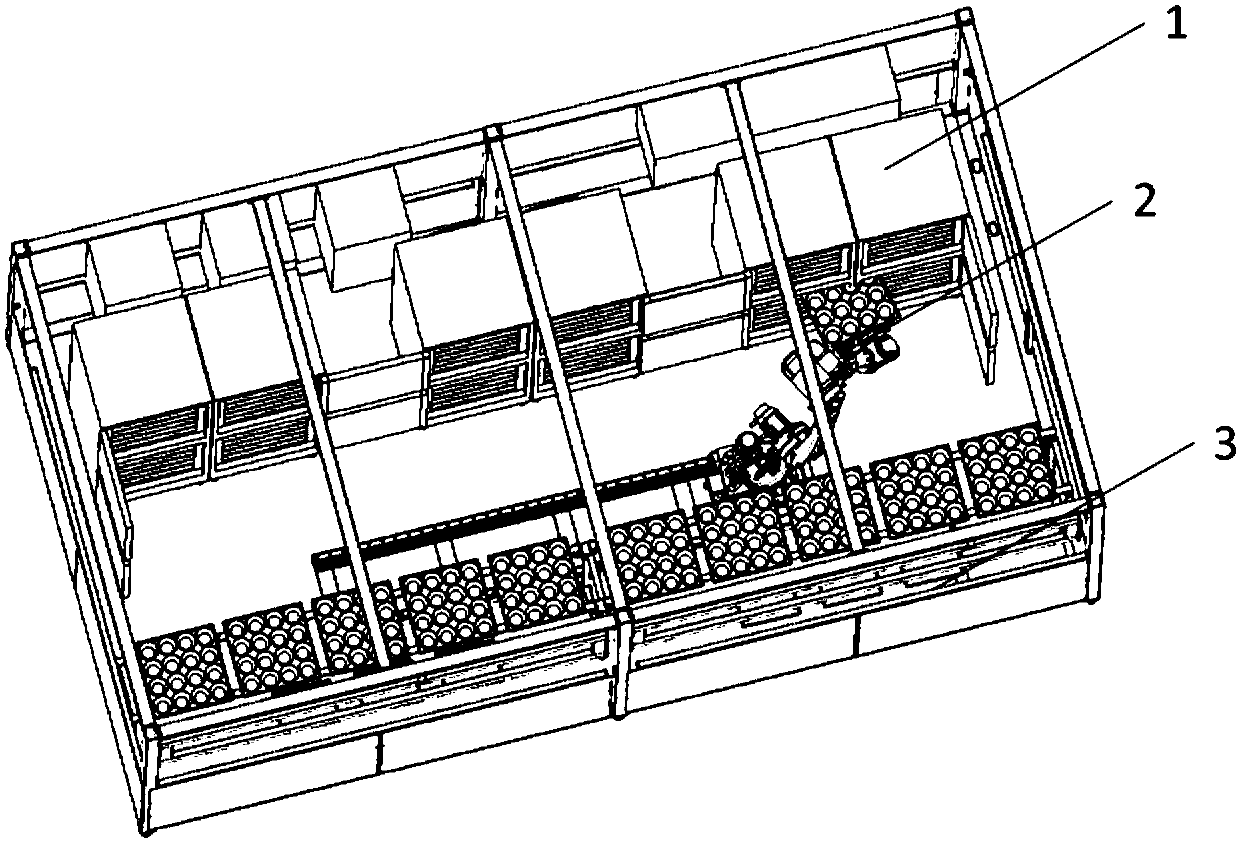

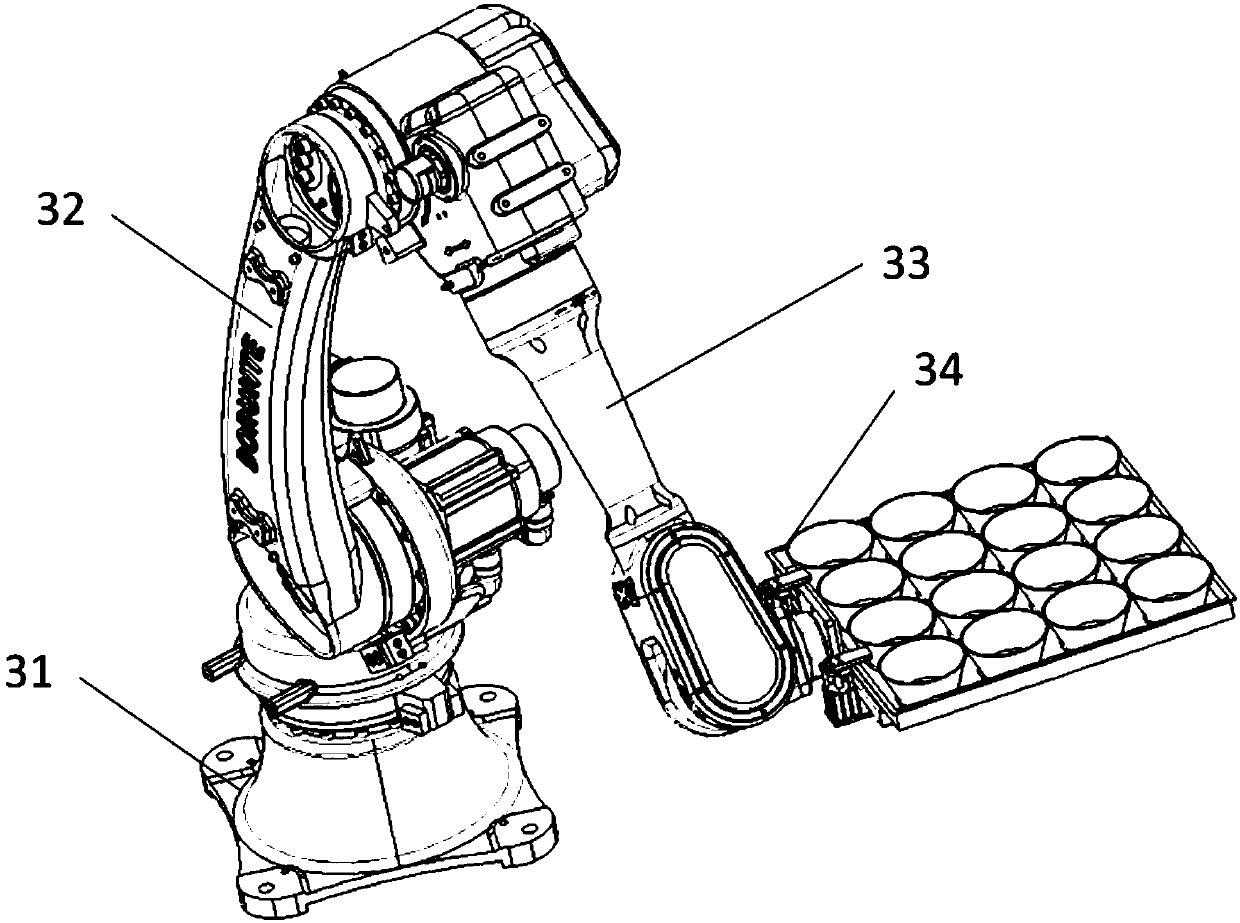

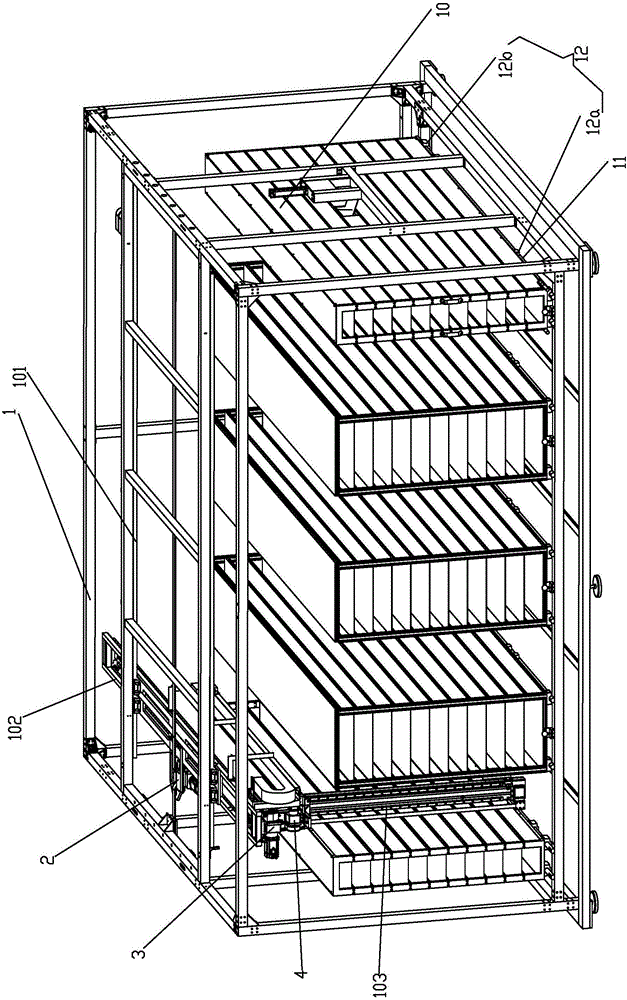

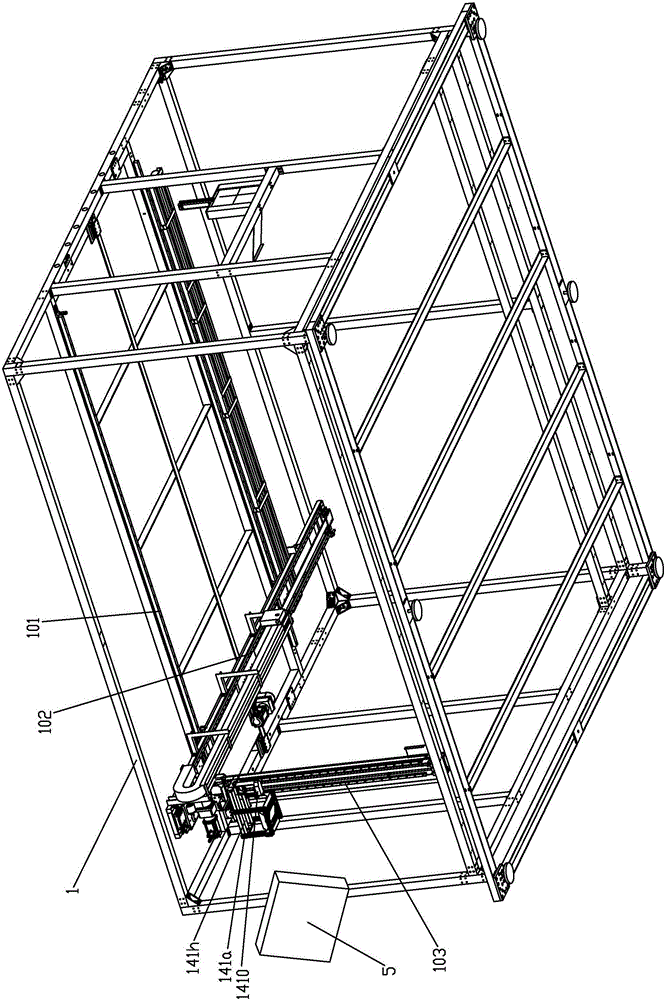

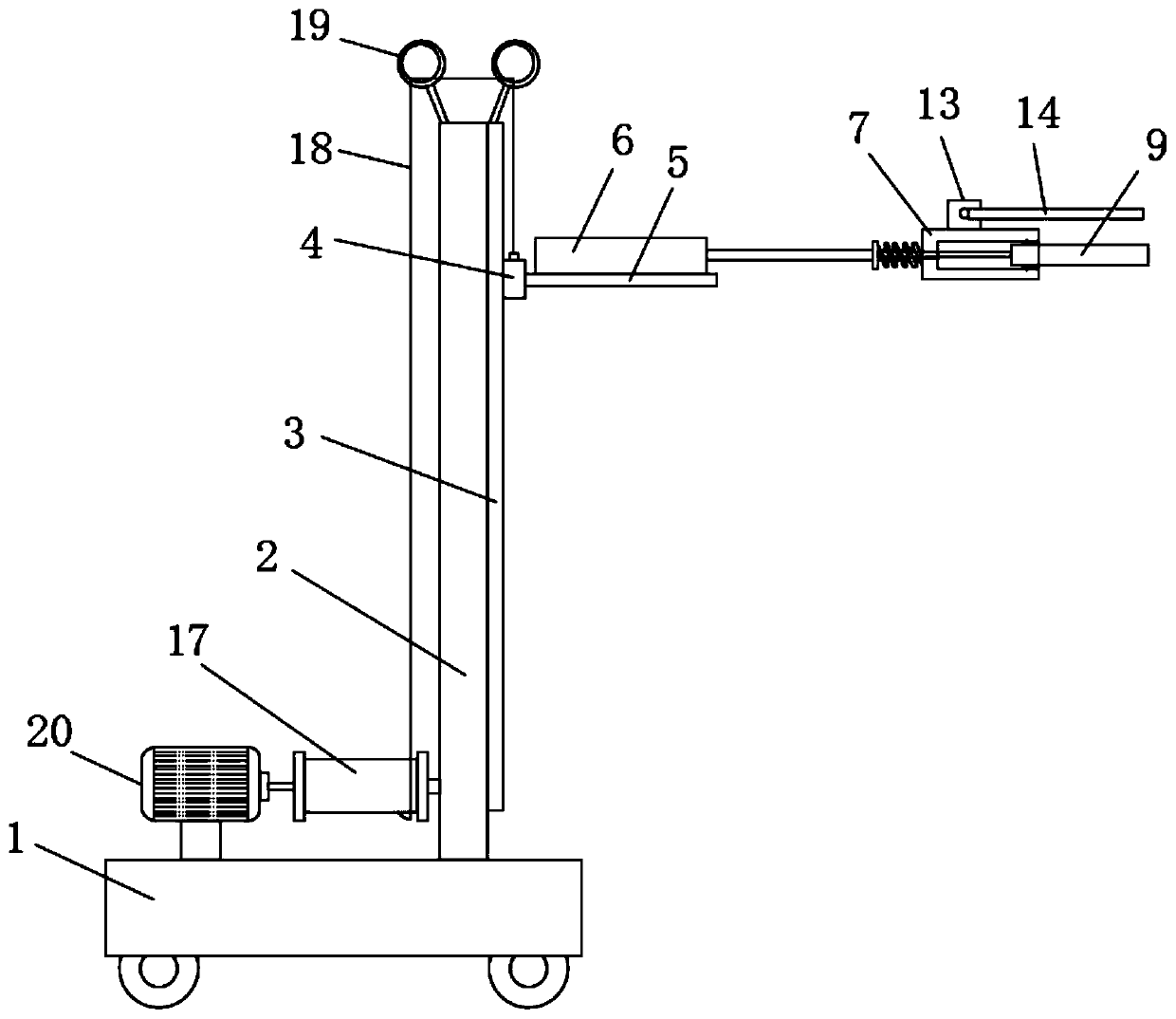

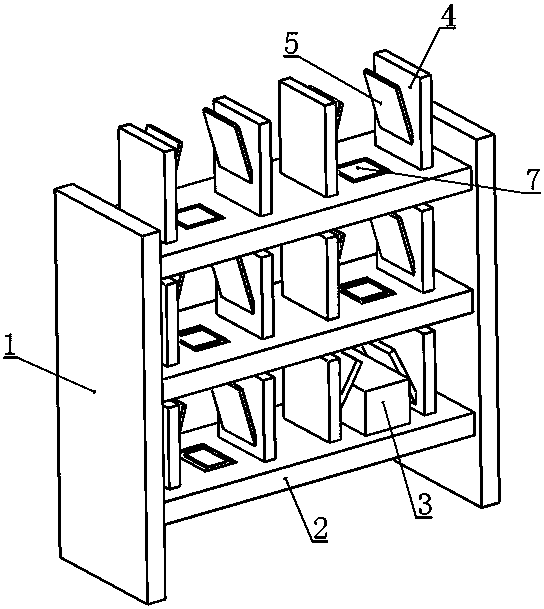

Intelligent robot capable of automatically taking material

ActiveCN105108736AEasy to useImprove storage effectProgramme-controlled manipulatorEngineeringMaterial storage

The invention discloses an intelligent robot capable of automatically taking material, which comprises a rack, wherein the a material storage frame is set inside the rack; the intelligent robot is characterized in that the rack is provided with a horizontal guide rail; the horizontal guide rail is provided with a longitudinal guide rail capable of horizontally sliding and walking along the horizontal guide rail; the rack is provided with a horizontal driving apparatus for driving the longitudinal guide rail to horizontally slide; the longitudinal guide rail is provided with a vertical guide rail capable of vertically sliding and walking along the longitudinal guide rail; the longitudinal guide rail is provided with a vertical driving apparatus for driving the vertical guide rail to vertically slide; the vertical guide rail is provided with an automatic material-taking apparatus capable of vertically slide along the vertical guide rail and automatically taking material from the material storage frame; the vertical guide rail is provided with a vertical driving apparatus for driving the automatic material-taking apparatus to vertically slide; and the rack is provided with a control apparatus for controlling the movements of the horizontal driving apparatus, the longitudinal driving apparatus, the vertical driving apparatus and the automatic material-taking apparatus.

Owner:GUANGDONG CLAW ROBOT CO LTD

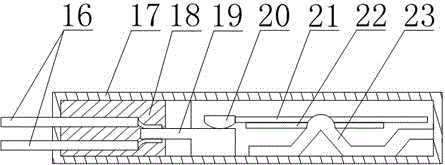

CNG (Compressed Natural Gas) injection system for automobile

InactiveCN105604740AAffect flow rateGuaranteed circulationInternal combustion piston enginesFuel supply apparatusElectricityCompressed natural gas

The invention discloses a CNG (Compressed Natural Gas) injection system for an automobile. The CNG injection system comprises a gas inlet pipe and a hollow pipe, wherein a plurality of injection holes are formed in the upper end of the hollow pipe; electromagnetic valves are correspondingly arranged on the injection holes; a groove is formed in the inner wall of the hollow pipe; the injection holes are just opposite to the groove; a plurality of electric heating tubes are arranged in the groove side by side; a guiding block is arranged at the bottom of each electric heating tube; a guiding groove matched with the guiding blocks is formed in the bottom of the groove; each electric heating tube comprises a tube body, an insulated material filling the inside of each tube body and an electric heating wire arranged inside each tube body; a binding post is connected to the tail end of each electric heating wire; a small hole communicating with the outside is formed in one end, away from the air inlet pipe, of the groove; each binding post penetrates through the corresponding small hole and is connected with a wiring plug board; a heat conducting plate covers an open end of the groove. The guiding block is arranged at the lower part of the tube bodies of the electric heating tubes and is matched with the guiding groove, so that the placement of the tube bodies is more stable, i.e., the electric heating tubes can be fastened without adding a new fixing structure, and further the aim of optimizing an internal structure of an injection rail is achieved.

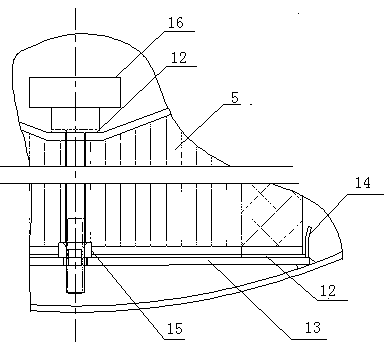

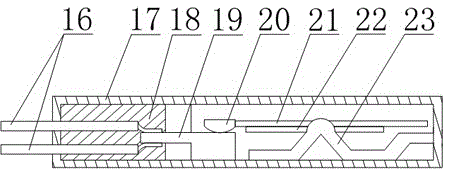

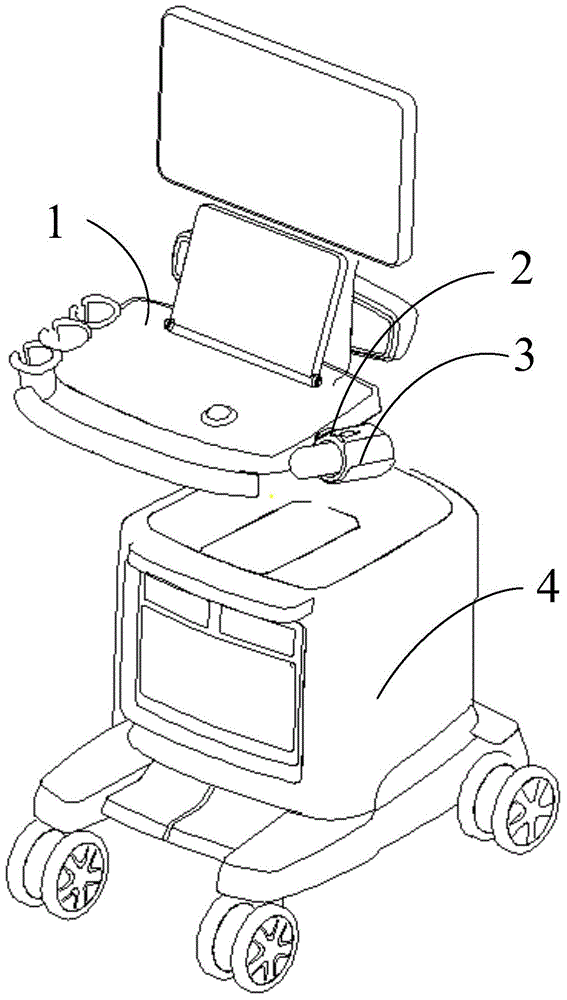

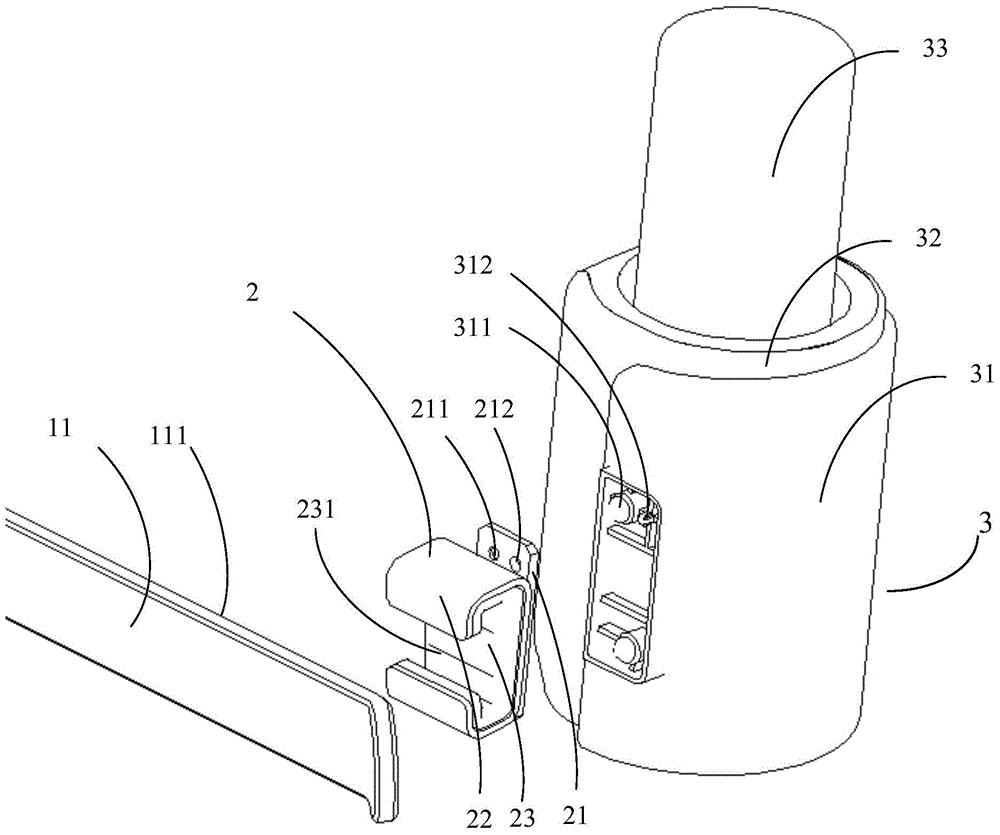

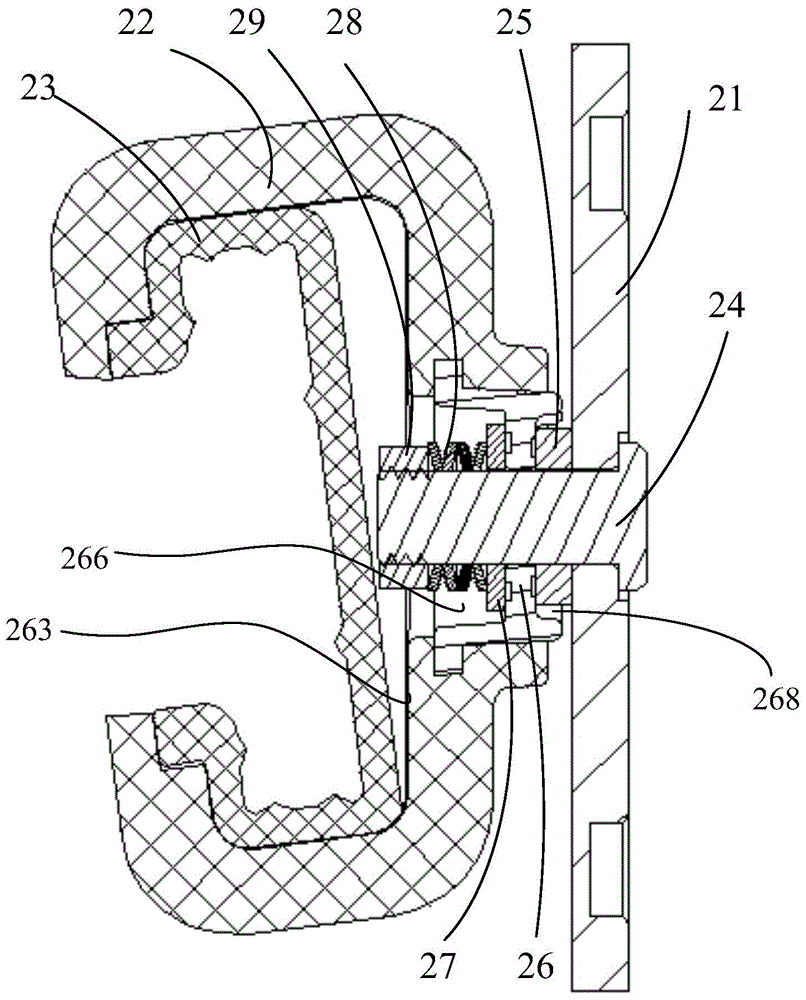

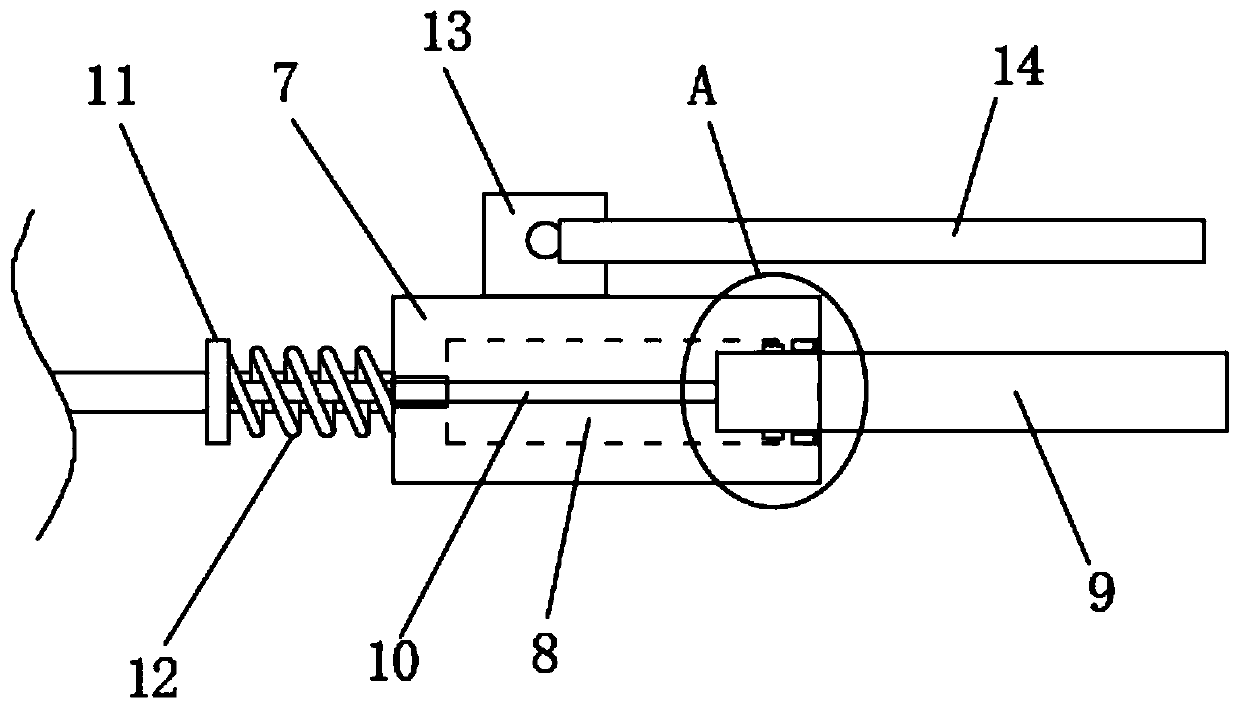

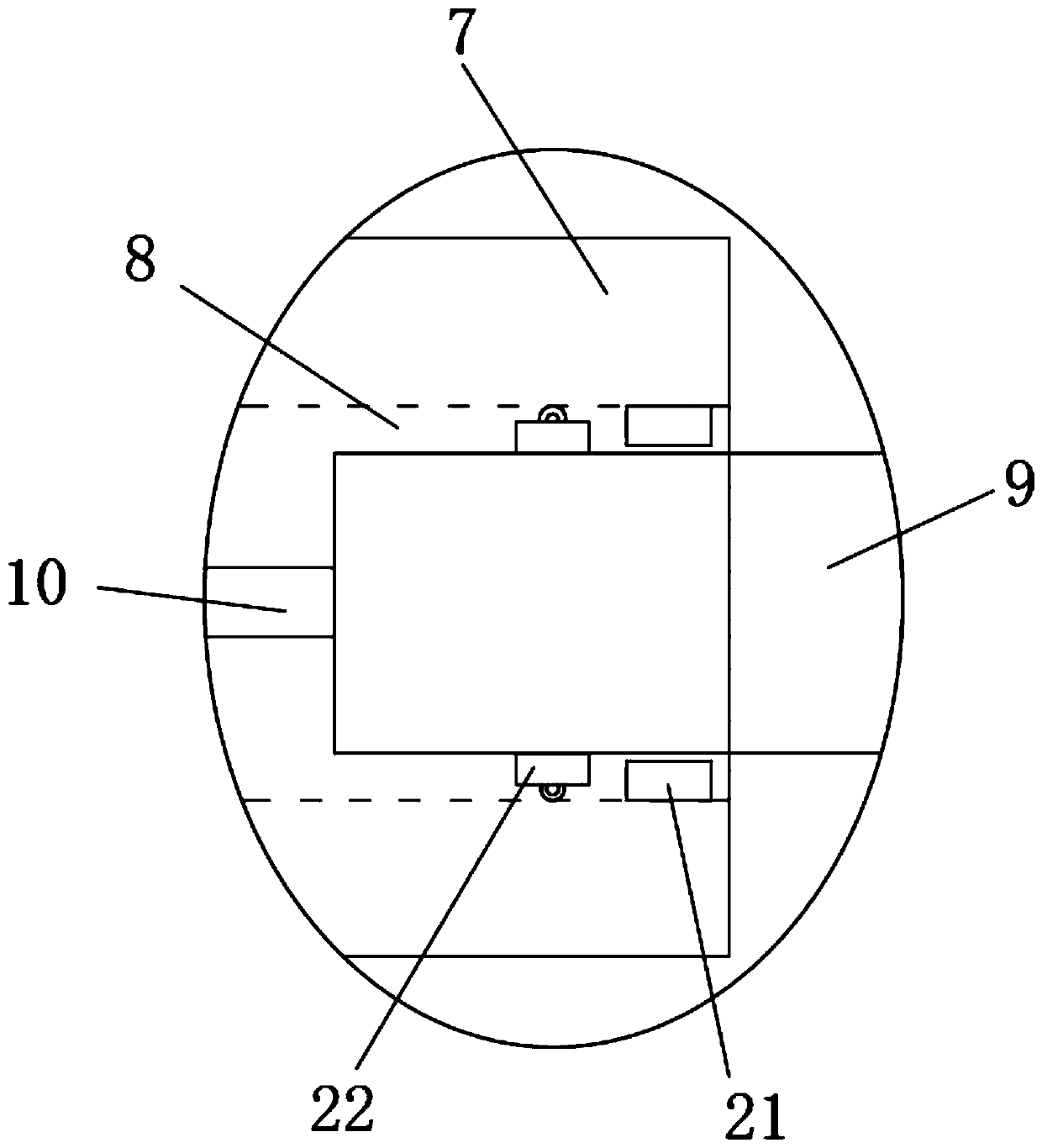

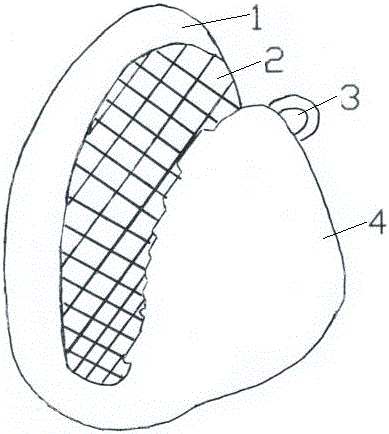

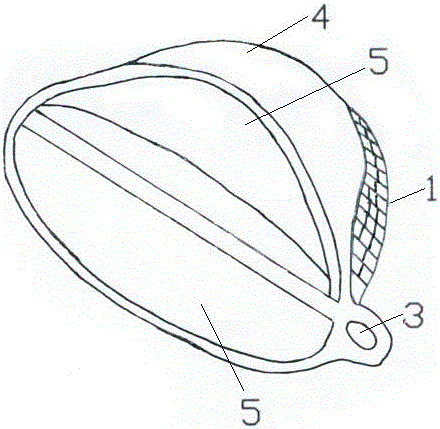

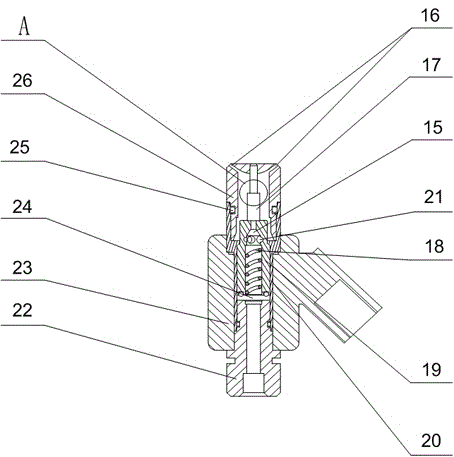

Angle adjustment mechanism, ultrasonic imaging system thereof and trolley

ActiveCN106175824AEasy accessStable pick and placeUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsUltrasound imagingEngineering

The invention discloses an angle adjustment mechanism and an ultrasonic imaging system. The angle adjustment mechanism can be coupled with a coupling agent heater and comprises a mandrel, a fixing support, an adjusting part and an elastic part which are connected integrally, wherein the mandrel and the fixing support form a rotating pair, the adjusting part and the mandrel perform synchronous rotation, a gear block is arranged in one of the adjusting part and the fixing support, the other one of the adjusting part and the fixing support is provided with a gear adjusting face, the gear adjusting face is provided with a circle of gear grooves in a concave mode, the part, located between every two adjacent gear grooves of the gear adjusting face is a transition face, and the elastic part makes the gear block and the gear adjusting face matched in a frictional mode. The angle adjustment mechanism facilitates any coupling agent heater angle adjustment performed by a user according to different usage habits of operation, diagnosis and treatment, further can adjust the taking and putdown angle of the coupling agent heater, provides rotation damping through the elastic part, makes the coupling agent heater stably stop at different angles, accordingly facilitates free taking and putdown and is stable to take and put down.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

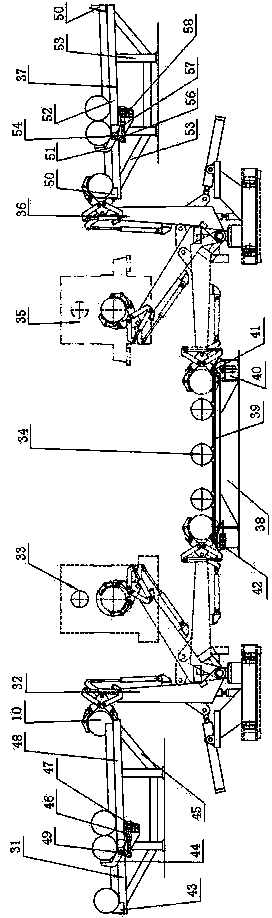

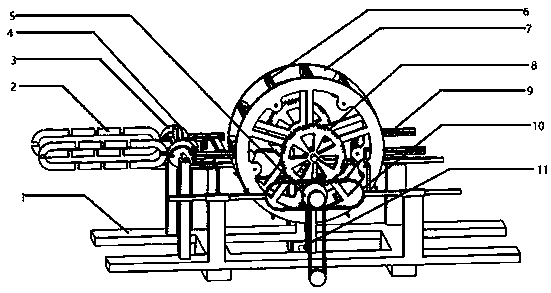

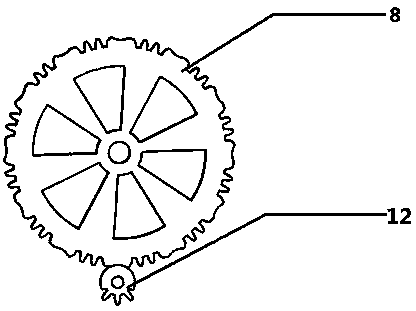

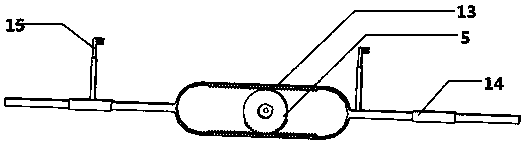

Pick-and-place mechanism for circular combing link of silk spinning production line

The invention relates to a pick-and-place mechanism for a circular combing link of a silk spinning production line. Circular comb cylinders are mounted on a machine frame, limiting guide rails are arranged at the front and rear ends of the circular comb cylinders, a pair of limiting guide rails are located between the circular comb cylinders and a turning mechanism, embedded cotton plates for turning over are fixed between two cam grooved frames, four-blade grabbing plates are arranged between the embedded cotton plates for turning over and the cam grooved frames, embedded cotton plates for circular combing are arranged on the inner walls of the two circular comb cylinders, irregular gears are arranged at both ends of the circular comb cylinders, second incomplete gears are arranged belowthe irregular gears, first incomplete gears are arranged at the outer sides of the second incomplete gears, racks are arranged on the upper and lower portions of the first incomplete gears, the racksare fixed on rack push rods, the rack push rods at the upper and lower ends are connected through an arc connecting bracket, the arc connecting bracket is connected with movable guide rail ends of guide rail frames, and movable guide rails of each of the movable guide rail frames are connected with a pair of L-shaped push rods. According to the pick-and-place mechanism, a device for automaticallytaking out and placing auxiliary clamping plates from circular comb cylinder skeletons is designed and is connected with front and rear conveyor belts.

Owner:JINLING INST OF TECH

Pick-and-place method special for box-type objects

InactiveCN111421520AStable pick and placeReduce occupancyGripping headsElectric machineryMobile device

Owner:FUYANG SHENGDONG INTELLIGENT MFG TECH DEV CO LTD

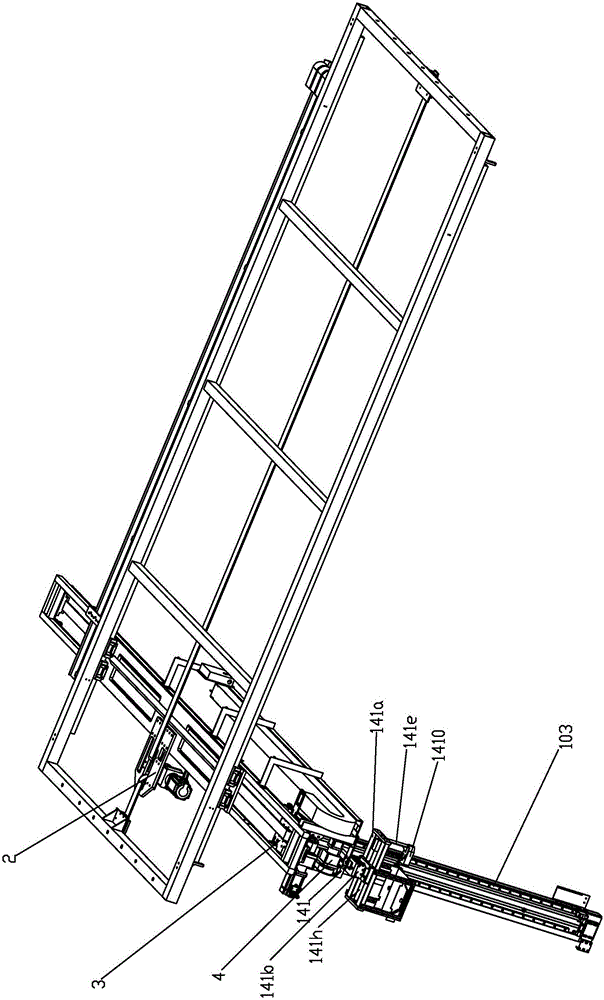

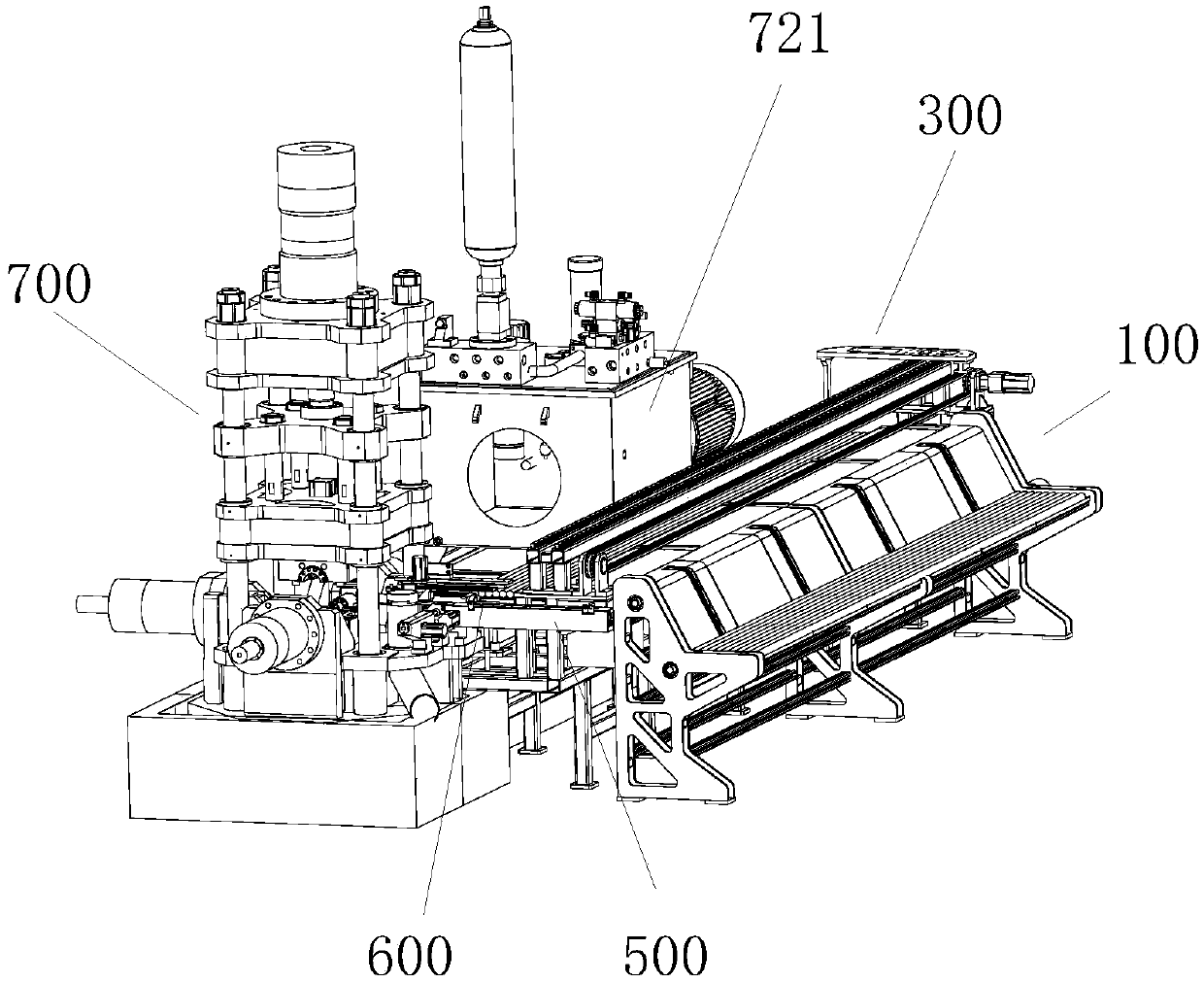

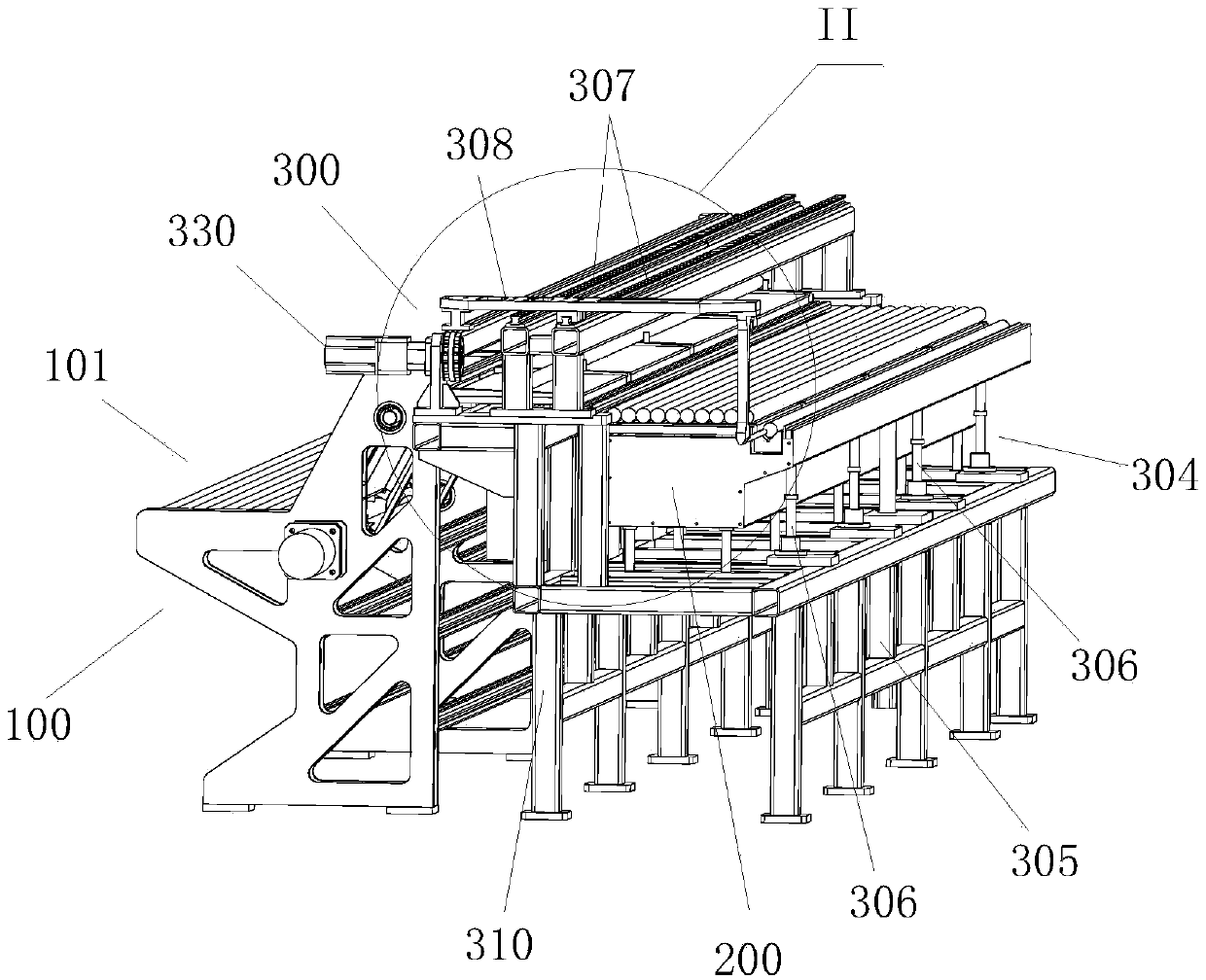

A bar processing control system

ActiveCN107983894BSmooth feedingPrecise feedingForging/hammering/pressing machinesHandling devicesMachine controlControl system

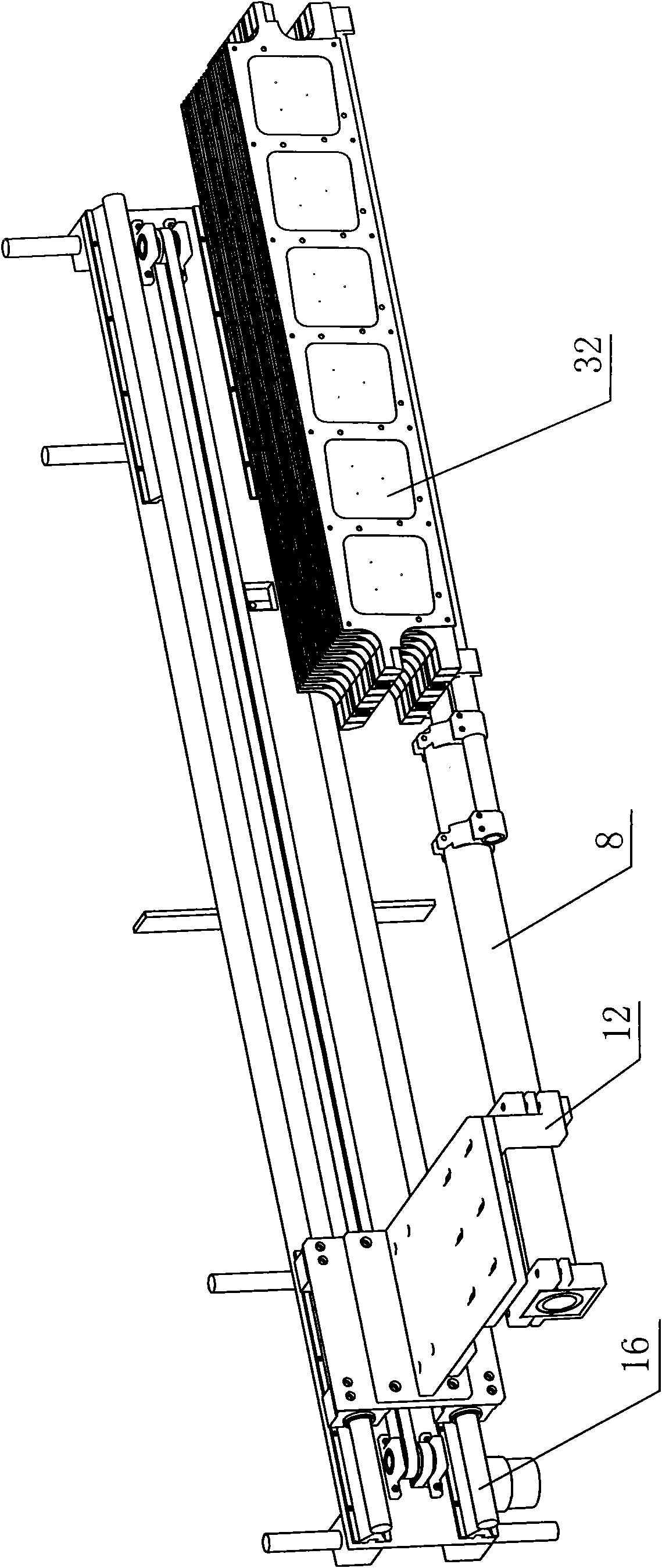

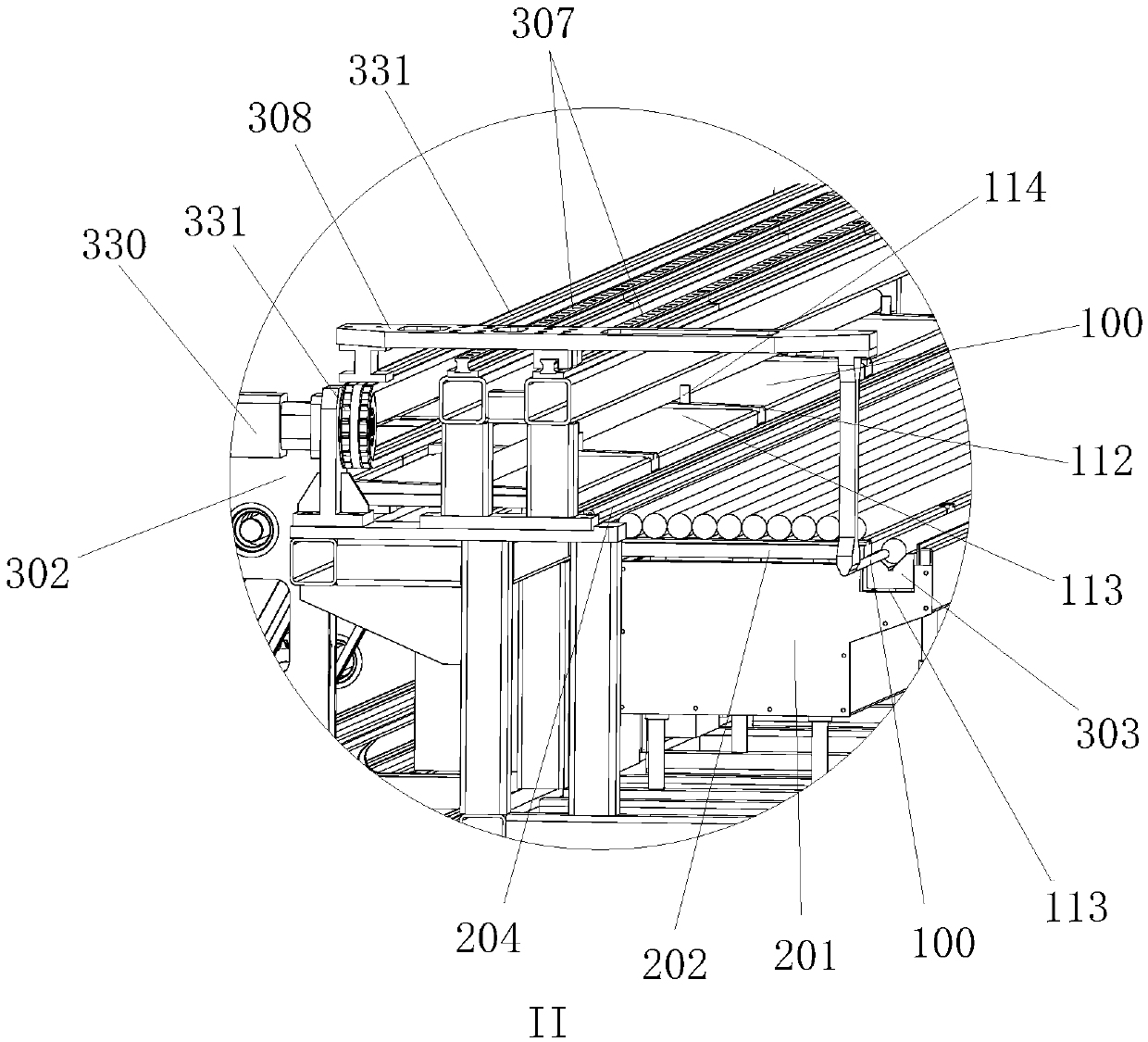

The invention relates to the field of rod automatic machining, and discloses a rod machining control system. The rod machining control system comprises a rod transportation system and a rod machiningsystem; the rod transportation system comprises a transportation device (100), a heating device (200), a feeding device (300) and a cutting device (400); copper rods are transported to the heating device (200) for heating through the transportation device (100), and them, are fed in the feeding device (300) for feeding; the transportation device (100) comprises a transportation platform (101) anda transportation mechanism; a transportation block (150) is driven through a transportation chain (106) to feed the copper rods from a lower support table (102) to an upper support table (103); the copper rods are fed in the rod machining system after passing through the heating device (200), the feeding device (300) and the cutting device (400); and workpiece manufacturing and automatic withdrawal are finished by a feeding manipulator (500), a machining mold (700) and a taking manipulator (600). The device is high in automation degree, stable in loading and machining and high in production efficiency.

Owner:叶腾斌

CPU clamping device for CPU taking and placing module

Owner:江苏汤谷智能科技有限公司

Novel anti-scalding clamp

The invention discloses a novel anti-scalding clip, which comprises an upper rubber pad and a lower rubber pad, the upper rubber pad and the lower rubber pad have hollow cavities, the upper rubber pad and the lower rubber pad are connected as one, and the upper rubber pad and the lower rubber pad are connected together. One side of the joint of the rubber pad is provided with a hanging hole. The inner sides of the upper rubber pad and the lower rubber pad are provided with non-slip square protrusions. The area of the lower rubber pad accounts for one-third of the area of the upper rubber pad. The width of the lower rubber pad is greater than the width of the upper rubber pad. Its advantages are: it is convenient to pick and place tableware, avoid scalding hands by high-temperature dishes, and it is more stable to take and place tableware.

Owner:唐婷婷

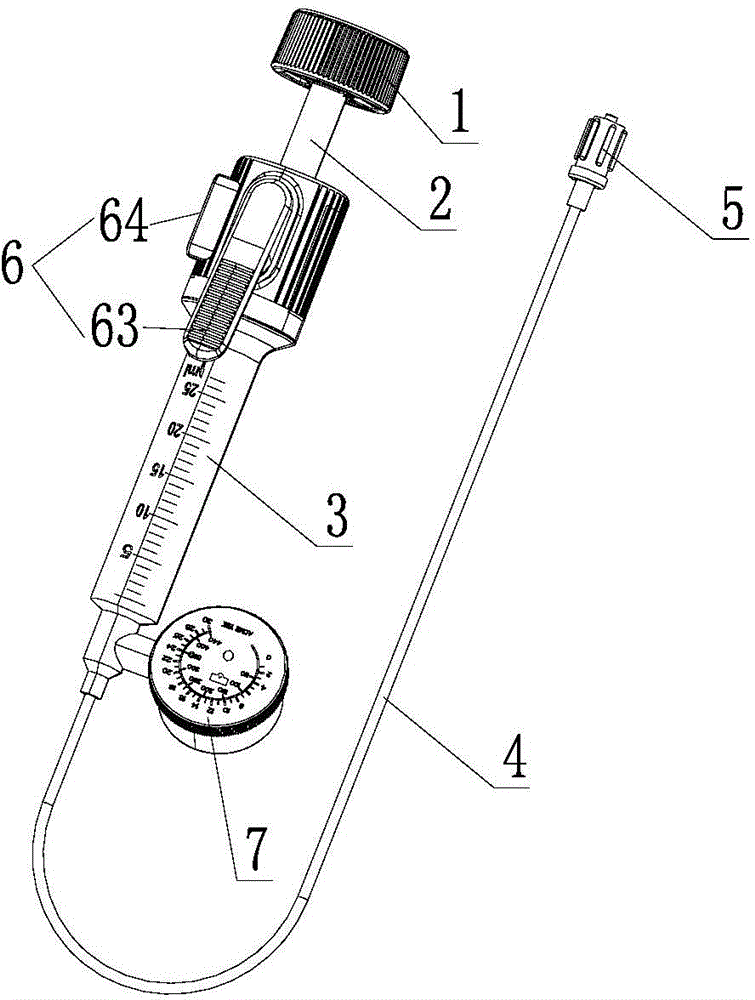

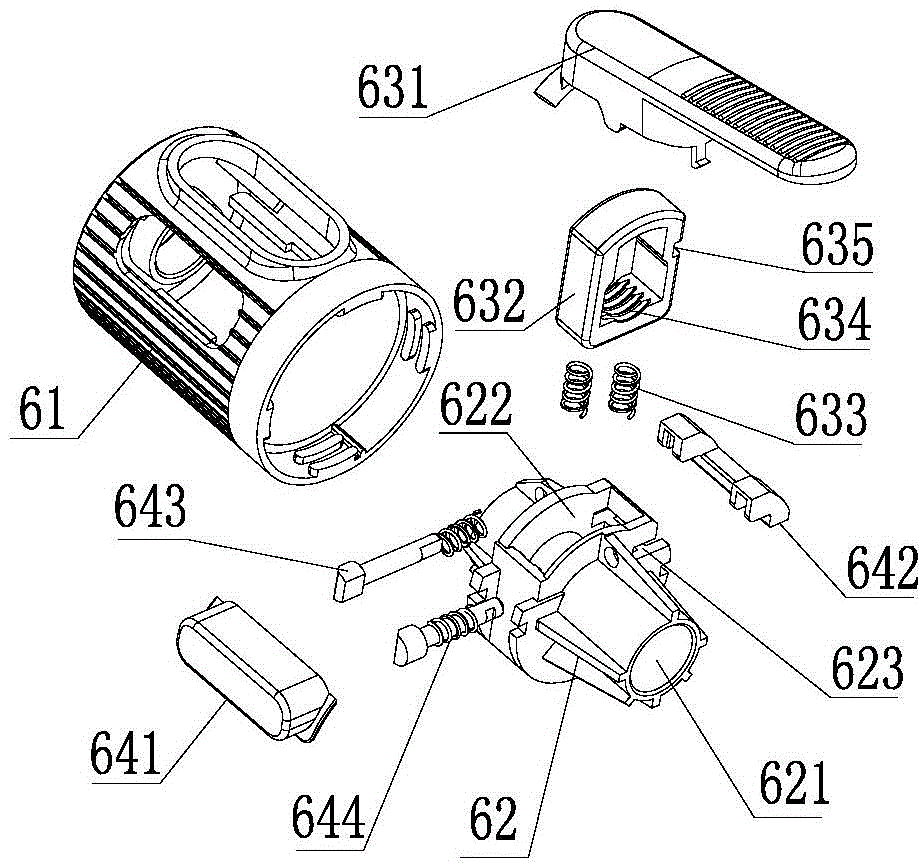

Quick air inflation, discharge and control device for expanding balloon

The invention discloses a quick air inflation, discharge and control device for expanding a balloon. The quick air inflation, discharge and control device for expanding the balloon comprises a handle body, a push handle, a pump body and a connecting piece, the pump body is provided with a pressure releasing component capable of realizing self-locking, the pressure releasing component comprises a grip, a cover body arranged in the grip, a releasing mechanism arranged on the cover body, and a self-locking mechanism capable of locking the releasing mechanism, a shaft hole is formed in the cover body, and a push rod is arranged in the shaft hole and capable of reciprocating along the axial line thereof. The quick air inflation, discharge and control device for expanding the balloon is novel in structure, and the grip is provided with the pressure releasing component capable of realizing self-locking; the quick air inflation, discharge and control device for expanding the balloon conforms to the human engineering, the operation is facilitated, the safety performance is high, and misoperation is avoided; a pressure display component is arranged at one side of the pump body, and the pressure display component is convenient for examining the numbers on the pump body and placing.

Owner:蔡静君

Combustible gas injection system for dual-fuel locomotive

InactiveCN105604742AAffect flow rateGuaranteed circulationInternal combustion piston enginesFuel supply apparatusElectricityHeat conducting

The invention discloses a combustible gas injection system for a dual fuel locomotive. The combustible gas injection system comprises a gas inlet pipe and a hollow pipe, wherein the upper end of the hollow pipe is provided with a plurality of injection holes which are correspondingly provided with solenoid valves; the inner wall of the hollow pipe is provided with grooves; the injection holes are over against the grooves; a plurality of electric heating tubes are arranged in the grooves side by side; the bottom of each electric heating tube is provided with a guide block; the bottom of each groove is provided with a guide groove matched with the guide block; each electric heating tube comprises a tube body, an electric insulating material filled in the tube body and an electric heating wire arranged inside the tube body; the tail end of the electric heating wire is connected with a wiring terminal; one end of the groove far from the gas inlet pipe is provided with a pinhole communicating with the outside; the wiring terminal penetrates through the pinhole and is connected with a wiring plugboard; and a heat conducting board is covered on the open end of each groove. The lower part of the tube body of each electric heating tube is provided with the guide block which is matched with the guide groove, so that the tube body can be mounted more stably; and thus, the electric heating tubes can be fastened without adding any new fixing structure, thereby achieving the goal of optimizing the injection rail internal structure.

Owner:CHENGDU KELIFU SCI & TECH

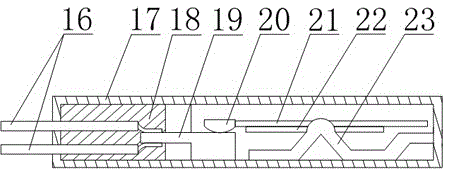

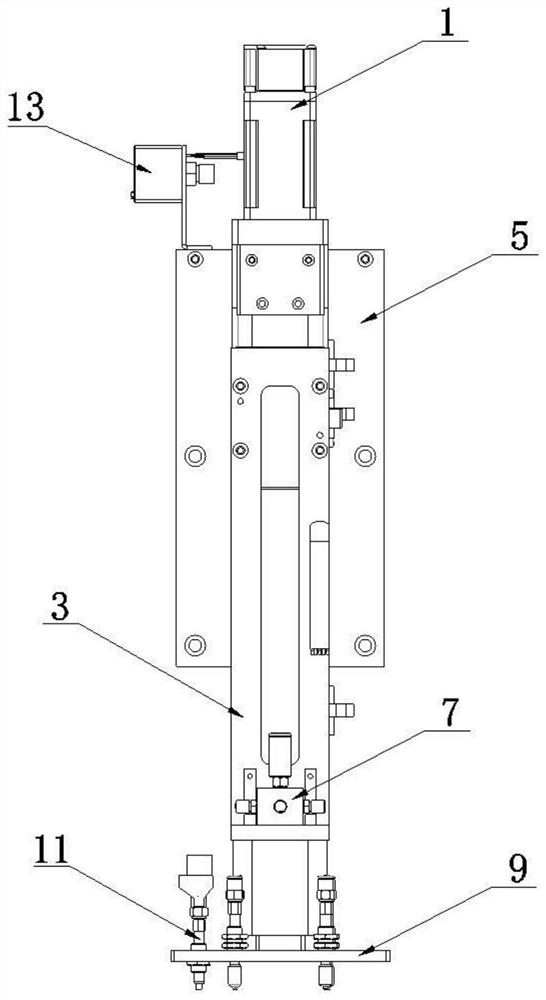

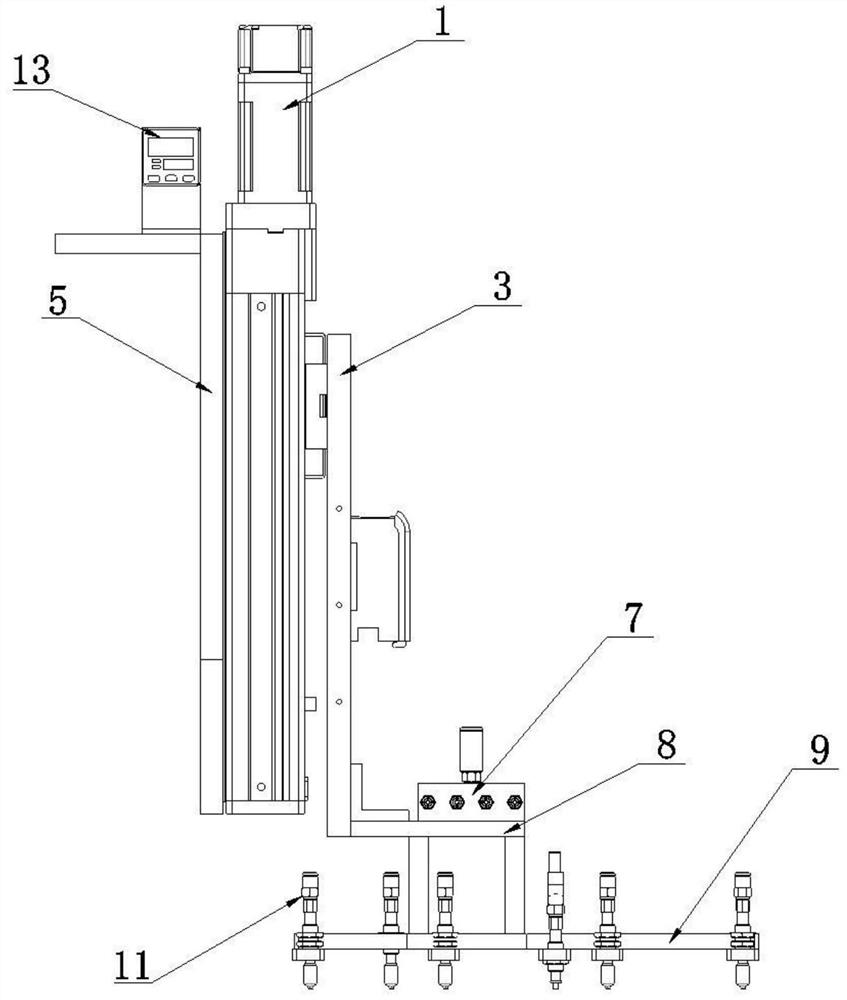

Loading suction cup assembly device

InactiveCN111807051AEasy to adjustEfficient pick and placeConveyor partsClassical mechanicsElectric machinery

The invention discloses a loading suction cup assembly device. The device comprises the loading suction cup assembly device which is provided with a Z-axis motor fixing plate, wherein the center of the front side of the Z-axis motor fixing plate is provided with a support column, the top of the support column is equipped with a Z-axis electric cylinder, the outer side of the support column is equipped with a suction cup support column mounting plate, a substrate loading suction arm drag chain rack is provided between the suction cup support column mounting plate and the support column, one side of the substrate loading suction arm drag chain rack is fixedly connected to the side of the suction cup support column mounting plate, the clip on the substrate loading suction arm drag chain rackis set in a chute on the side of the support column, the front side of the bottom end of the suction cup support column mounting plate is provided with a suction cup bracket mounting plate, and suction cups are arranged on the suction cup brackets on both sides of the suction cup bracket mounting plate. The loading suction cup assembly device has a reasonable design and can realize efficient and stable picking and placing of the suction cups.

Owner:南通金泰科技有限公司

Lithium battery carrying structure suitable for stacking machine

PendingCN114044371AAchieve positioningAchieve fixationFinal product manufactureNon-aqueous electrolyte cellsElectrical batteryEngineering

The invention discloses a lithium battery carrying structure suitable for a stacking machine. The invention comprises a base arranged on a stacking machine, a tray taking mechanism arranged on the base, a lifting mechanism arranged above the tray taking mechanism and arranged on the base, a battery carrying mechanism arranged above the tray taking mechanism and connected to the lower portion of the lifting mechanism, a battery conveying mechanism arranged on the top of the lifting mechanism and connected with the tray taking mechanism and the tray taking mechanism, and an electric cabinet electrically connected with the lifting mechanism and the battery carrying mechanism. during working, the stacking machine drives the base to move, the tray taking mechanism takes or sends back the feeding tray or the battery tray or the battery clamp and drives the feeding tray or the battery tray or the battery clamp to move, and the battery carrying mechanism clamps and carries lithium batteries under the cooperation of the tray taking mechanism and the lifting mechanism. Automatic carrying of lithium batteries is achieved, the carrying mode of manual grabbing and mechanical arm grabbing is replaced, taking and placing are more stable, falling accidents are not likely to happen, efficiency is high, compatibility is high, and control and maintenance are more convenient.

Owner:深圳力生物流仓储科技有限公司

Automotive fuel gas supply device

The invention discloses an automotive fuel gas supply device which comprises a gas inlet pipe and a hollow pipe. A plurality of spray holes are formed in the upper end of the hollow pipe. Electromagnetic valves are correspondingly mounted on the spray holes. A groove is formed in the inner wall of the hollow pipe, and the spray holes exactly face the groove. A plurality of electric heating pipes are arranged in the groove side by side. A guide block is mounted at the bottom of each electric heating pipe. Guide grooves matched with the guide blocks are formed in the bottom of the groove. Each electric heating pipe comprises a pipe body, an insulation material with which the pipe body is filled and an electric heating wire arranged in the pipe body. The tail ends of the electric heating wires are connected with binding posts. Small holes communicating with the outside are formed in the end, far away from the gas inlet pipe, of the groove. The binding posts penetrate the small holes to be connected with a wiring plug board. The open end of the groove is covered with a heat conduction plate. The guide blocks are mounted on the lower portions of the pipe bodies of the electric heating pipes and matched with the guide grooves, and therefore the pipe bodies can be mounted more stably, in other words, the electric heating pipes can be fastened without additionally arranging a new fixing structure, and the aim of optimizing an internal structure of a spray rail is achieved.

Owner:四川省诚德蓝天环保科技有限公司

Anti-freezing CNG air feeder

InactiveCN105626314AAffect flow rateGuaranteed circulationInternal combustion piston enginesFuel supply apparatusAnti freezingHeat conducting

The invention discloses an anti-freezing CNG air feeder. The anti-freezing CNG air feeder comprises an air inlet pipe and a hollow pipe. A plurality of injection holes are formed in the upper end of the hollow pipe. An electromagnetic valve is correspondingly installed at each injection hole. A groove is formed in the inner wall of the hollow pipe. The injection holes right face the groove. A plurality of electric heat pipes are arranged inside the groove side by side. Guide blocks are installed at the bottom of each electric heat pipe. A guide groove matched with each guide block is formed in the bottom of the groove. Each electric heat pipe comprises a pipe body, an insulating material and an electric heat wire, wherein each insulating material is filled in the corresponding pipe body, and each electric heat wire is arranged in the corresponding pipe body. Wiring posts are connected to the tail end of each electric heat wire. A small hole communicating with the outside is formed in the end, away from the air inlet pipe, of the groove. The wiring posts penetrate through the small hole and are connected with a wiring plug board. The open end of the groove is covered with a heat-conducting plate. The guide blocks are installed on the lower portion of the pipe body of each electric heat pipe, each guide block is matched with the corresponding guide groove, placing of the pipe bodies is made to be more stable, and the electric heat pipes can be fastened without adding new fixing structures, so that the purpose of optimizing the internal structure of an injection rail is achieved.

Owner:CHENGDU DUJIA ELECTRICAL

Express box shelf

The invention belongs to the technical field of the shelf structure, and particularly relates to an express box shelf which comprises stand columns and shelf body plates and further comprises verticalplates arranged on the shelf body plates and located on the two sides of an express box, inclined pressing units arranged on the side faces of the vertical plates, electromagnetic pushing units arranged on the side faces of the vertical plates and used for outward pushing through a magnetism repelling mode to open the inclined pressing units, and a gravity triggering unit arranged on the shelf body plates, located between the two vertical plates and used for conductively triggering the electromagnetic pushing units through an express box gravity pressing mode. By arranging the vertical plates, the inclined pressing units, the electromagnetic pushing units and the gravity triggering unit on the shelf body plates, the aim of stably placing the express box is achieved. The express box shelfhas the advantages that pressing and fixing operation is flexible and convenient and the express box is high in placement stability and convenient to deposit and pick up.

Owner:长汀县屿晨电子商务有限公司

The overall device for automatic loading and unloading of sleeves and sleeve transportation for cold rolling mills

The invention discloses an automatic sleeve-loading and unloading and sleeve-transporting integrated device of a cold-rolling mill. The automatic sleeve-loading and unloading and sleeve-transporting integrated device comprises an inlet side sleeve manipulator, an outlet side sleeve manipulator, a sleeve transporting machine, an inlet side sleeve storing platform, an outlet side sleeve storing platform, wherein the lower end of a swinging arm of the inlet side sleeve manipulator or the outlet side sleeve manipulator is hinged on the upper end face of a chassis; a cylinder body of a swinging arm hydraulic cylinder is hinged at the upper end of a frame, the end part of a piston rod of the swinging arm hydraulic cylinder is hinged on a connecting plate I of the swinging arm; a sleeve clamp comprises two groups of synchronously-operating clamps which are hinged in the middle together and are hinged on a support block; the support block is hinged at the upper end of the swinging arm, a connecting plate II extends out of the support block, the end part of the connecting plate II is hinged at the end part of a piston rod of a fixture swinging hydraulic cylinder; a cylinder body of the fixture swinging hydraulic cylinder is hinged at the lower part of the swinging arm; a motor of the sleeve transporting machine drives a transporting chain to transport a sleeve from an uncoiling machine to a coiling machine. The automatic sleeve-loading and unloading and sleeve-transporting integrated device can complete a complete set of unloading, transporting, feeding and the like of an empty sleeve within a short time, and is high in working efficiency, stable and reliable to take or place the sleeve, free from damaging the sleeve, and low in energy consumption.

Owner:涿神有色金属加工专用设备有限公司

Taking and putting device

InactiveCN110282341AStable pick and placeIncrease flexibilityConveyorsClamping/extracting meansEngineeringMechanical engineering

The invention provides a taking and putting device. The device is suitable for a circuit board and comprises a base, a conveying mechanism, a movable mechanism and a clamping mechanism. The conveying mechanism comprises a first side, a second side, two conveying assemblies and two first driving assemblies. The first side is arranged on the base, the second side is opposite to the first side, the conveying assemblies are arranged on the first side and the second side and are used for conveying the circuit board, the two first driving assemblies are connected to the two conveying assemblies, the movable mechanism is arranged on the base, the clamping mechanism comprises a body, a clamping module and a second driving assembly, the body is movably arranged on the base through the movable mechanism, a first clamping jaw and a second clamping jaw of the clamping module are used for clamping the circuit board, and the second driving assembly is arranged on the body and is connected to the clamping module and enables the first clamping jaw and the second clamping jaw to get close to or away from each other.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

Students' multifunctional three-head alcohol lamp for chemical experiments

The invention discloses a students' multifunctional three-head alcohol lamp for chemical experiments. The students' multifunctional three-head alcohol lamp comprises a base, a tray, a base disc, a rotating disc and a mounting frame. The students' multifunctional three-head alcohol lamp comprises the base, an alcohol lamp body and a first alcohol lamp cap. An anti-sliding layer is mounted below thebase, the alcohol lamp body is mounted above the base, a handle is mounted on the right side surface of the alcohol lamp body, and a floating ball is mounted in the alcohol lamp body. The first alcohol lamp cap, a second alcohol lamp cap and a third alcohol lamp cap are sequentially mounted above the alcohol lamp body from left to right in the horizontal direction. A lampwick tube is mounted in the first alcohol lamp cap and fixed through a spring and a lampwick fixing clamping plate, a sealing plug is mounted on the surface of the right side of the lampwick tube, and a lamp cap is mounted above the first alcohol lamp cap. By arrangement of the first alcohol lamp cap, the second alcohol lamp cap and the third alcohol lamp cap, different alcohol lamp caps can be ignited according to the use requirements, the heating area is larger, the heating speed is quick, and the effect is also good.

Owner:上海坤赟供应链管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com