Cantilever-type push-pull boat system for plasma enhanced chemical vapor deposition (PECVD) device

A cantilever type, push-pull boat technology, applied in the direction of transportation and packaging, gaseous chemical plating, metal material coating technology, etc., can solve the problems of affecting the reaction efficiency, affecting the service life of the device, and inaccurate positioning, so as to simplify the conveying system , Improving the conveying efficiency and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

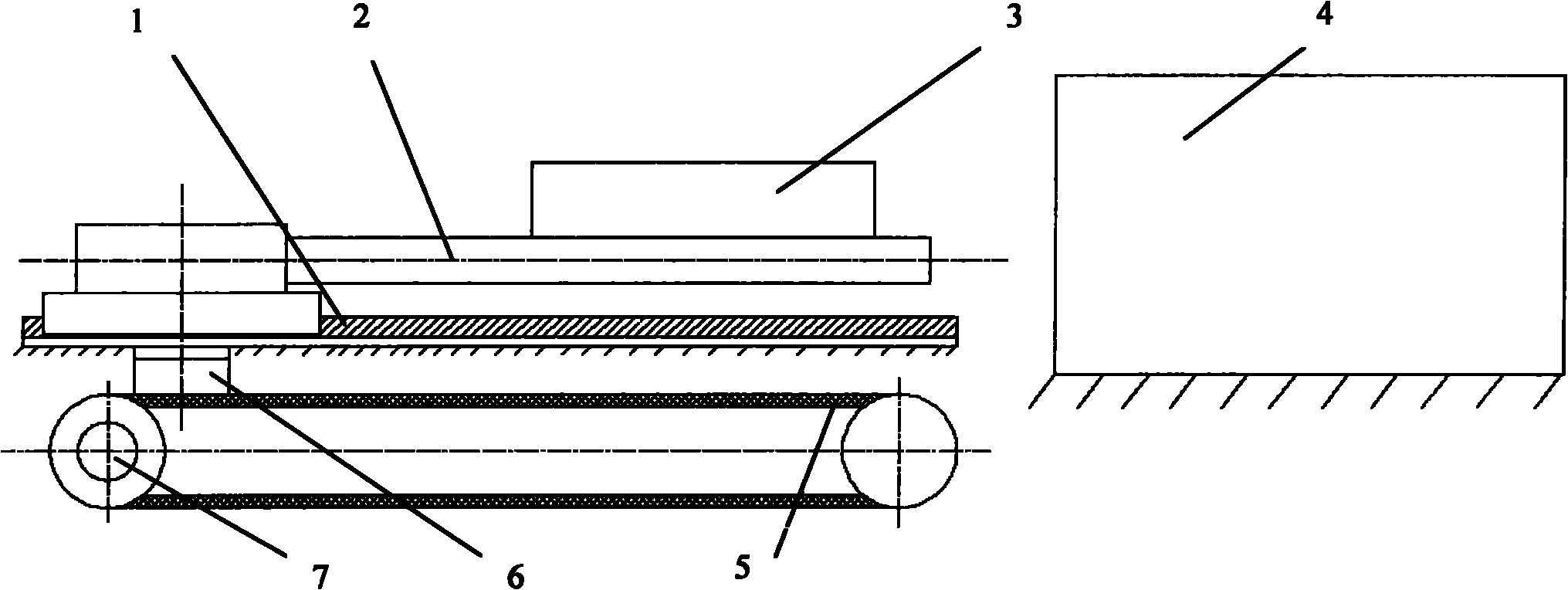

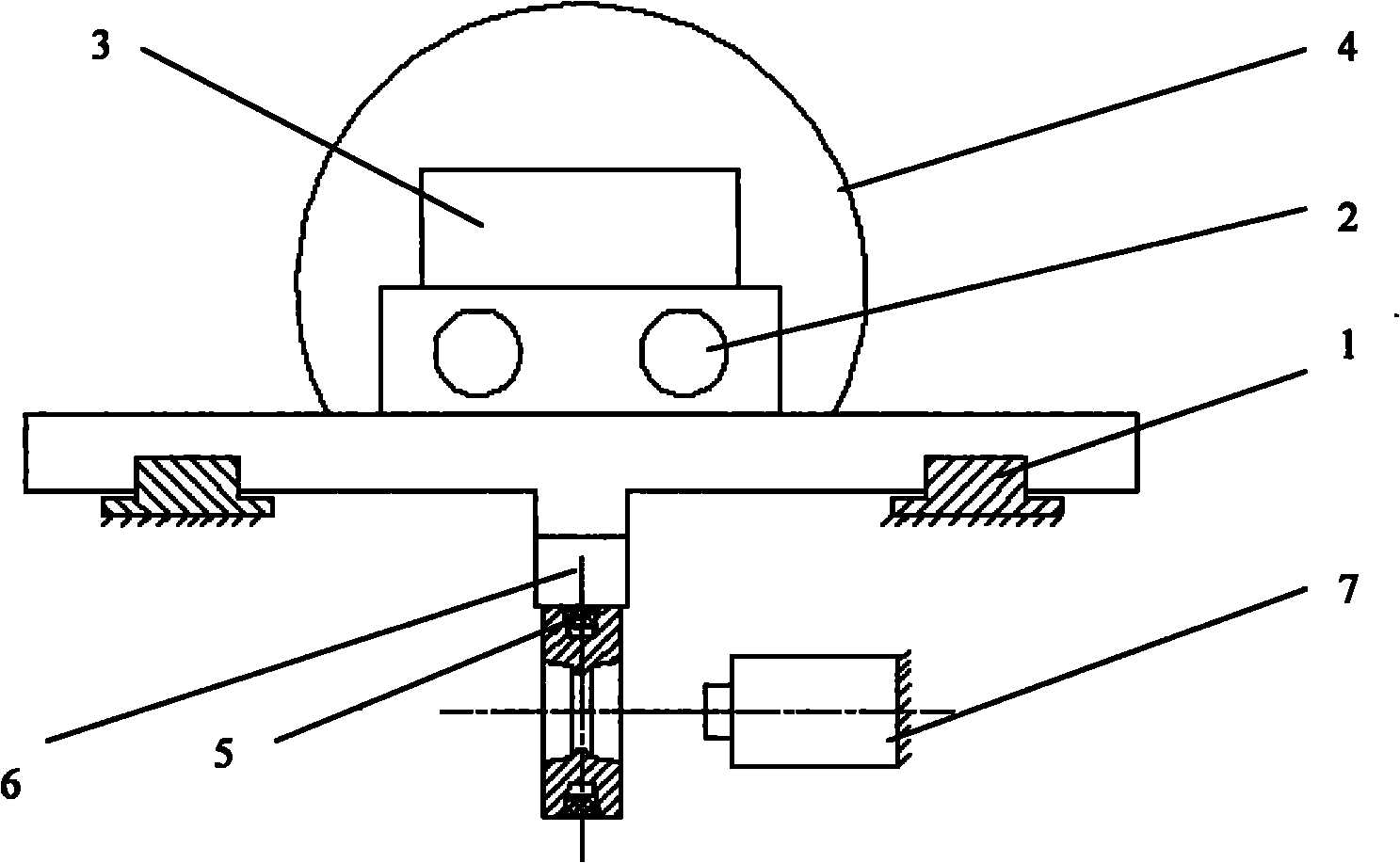

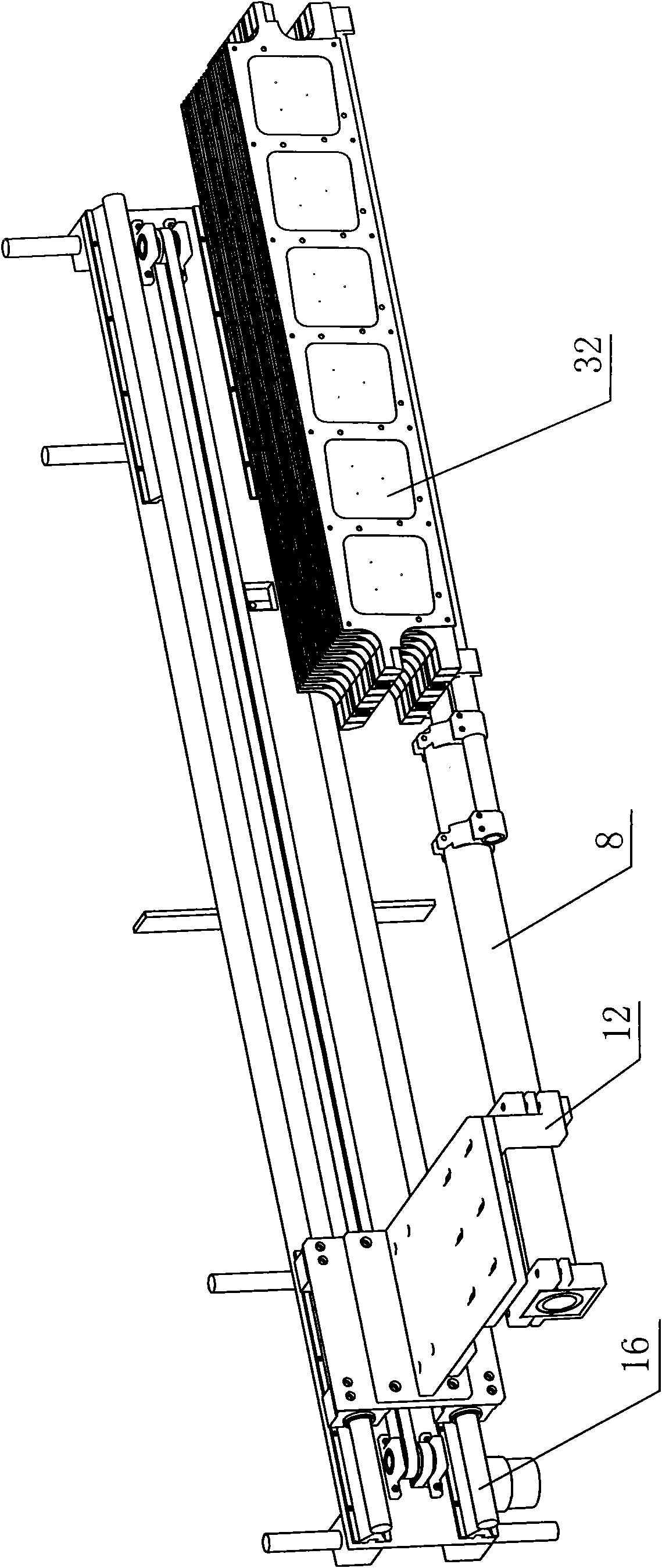

[0031] A kind of cantilevered push-pull boat system used for PECVD equipment in this embodiment, its structure is as follows image 3 As shown, it includes a cantilever rod mechanism, a side connection mechanism and a rolling linear guide bushing auxiliary mechanism. The rolling linear guide bushing auxiliary mechanism used as a cantilever rod mechanism for horizontal movement and vertical motion guidance is set on the frame of the PECVD equipment. The cantilever rod mechanism It is fixed on the side connecting mechanism, which is connected with the auxiliary mechanism of the rolling linear guide bush;

[0032] The specific structure of the cantilever mechanism is as follows: Figure 4As shown, it includes a thick tube 8 and two thin tubes 9, the two thin tubes 9 are arranged side by side, and are connected to one end of the thick tube 8 through the rear connection block 10, and the other end of the thick tube 8 is provided with a thick tube connection Seat 11 and thick tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com