Pick-and-place mechanism for circular combing link of silk spinning production line

A production line and circular comb technology, applied in textiles and papermaking, deburring devices, fiber processing, etc., can solve the problems of high work intensity, low safety, and manual processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

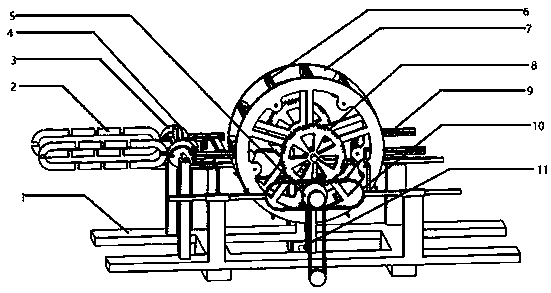

[0020] The invention provides a pick-and-place mechanism for a circular comb link in a silk spinning production line. The invention is mainly aimed at redesigning and optimizing the sub-splint. Based on the existing circular comb machine, it is designed to be automatically taken out from the cylinder skeleton of the circular comb machine. Put it into the device of the auxiliary splint and connect it with the front and rear conveyor belts.

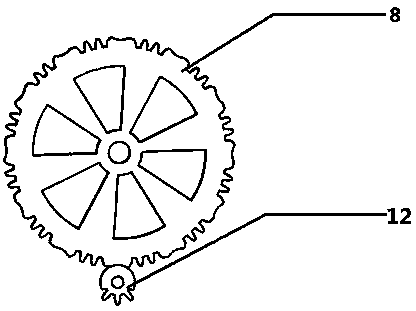

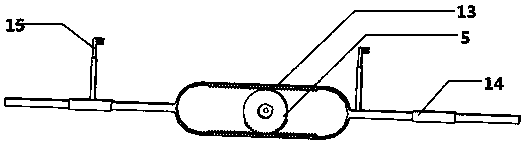

[0021] As an embodiment of the structure of the present invention, the present invention provides a pick-and-place mechanism for a circular comb link in a silk spinning production line, including a frame 1, a turning mechanism 3, an incomplete gear 5, a circular comb cylinder 7, and an irregular gear 8. Limiting guide rail 9, rack push rod 10, motor 11, incomplete gear 2 12, rack 13, guide rail frame 14 and L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com