A bar processing control system

A control system and processing system technology, applied in metal processing equipment, manufacturing tools, heating/cooling equipment, etc., can solve the problems of unstable mold clamping process, unreplaceable mold, inconvenient workpiece removal, etc., to achieve compact and accurate structure. High height and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

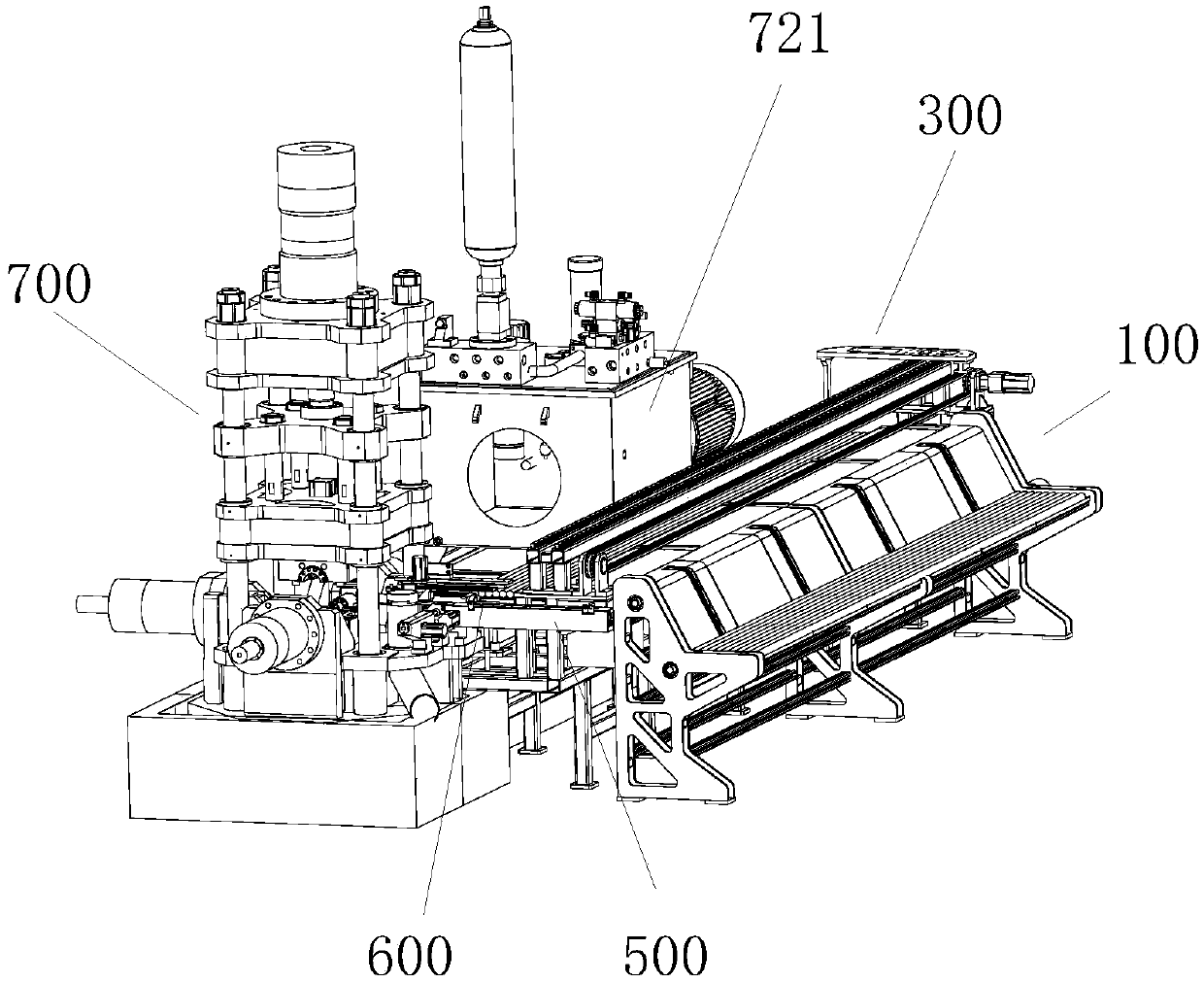

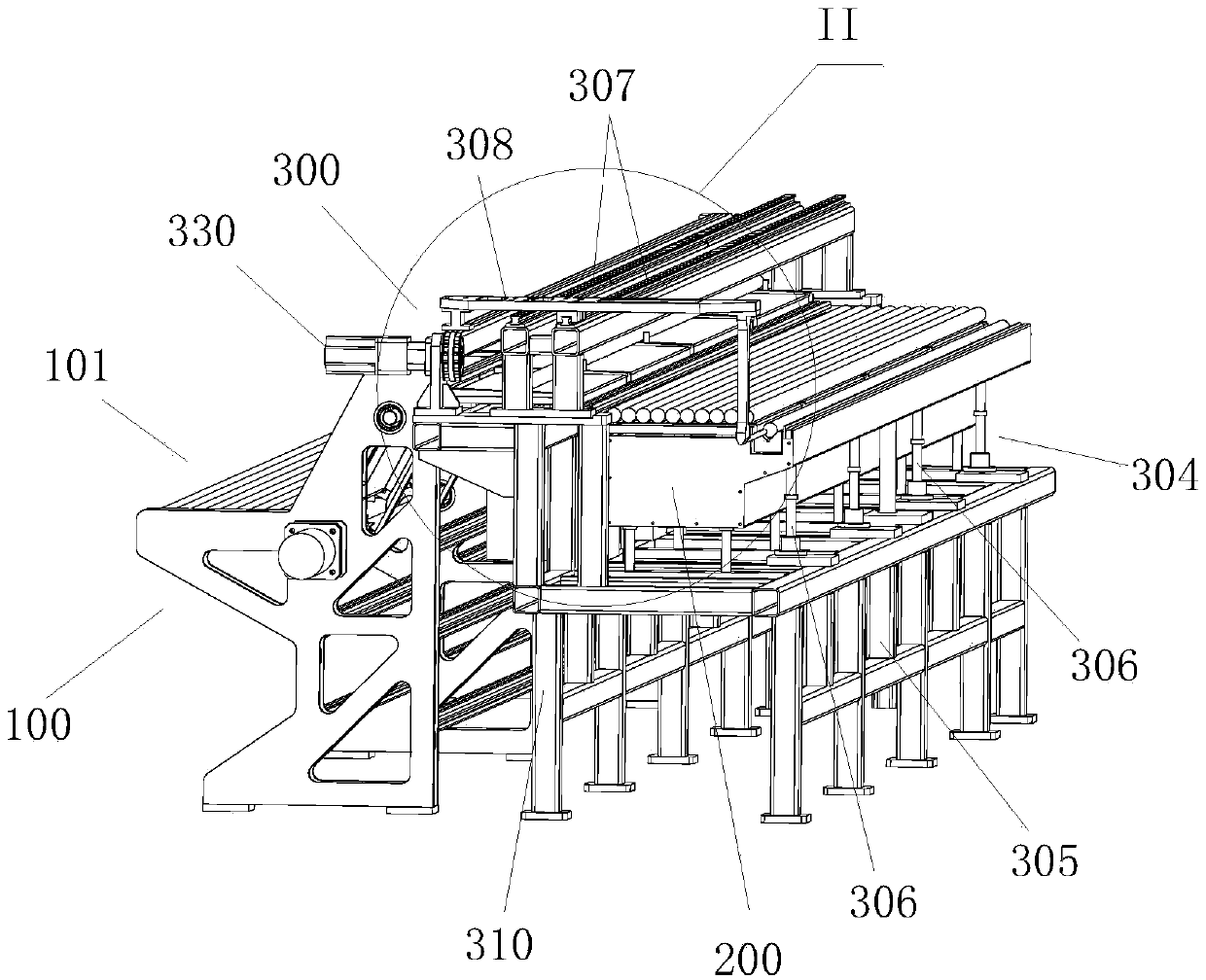

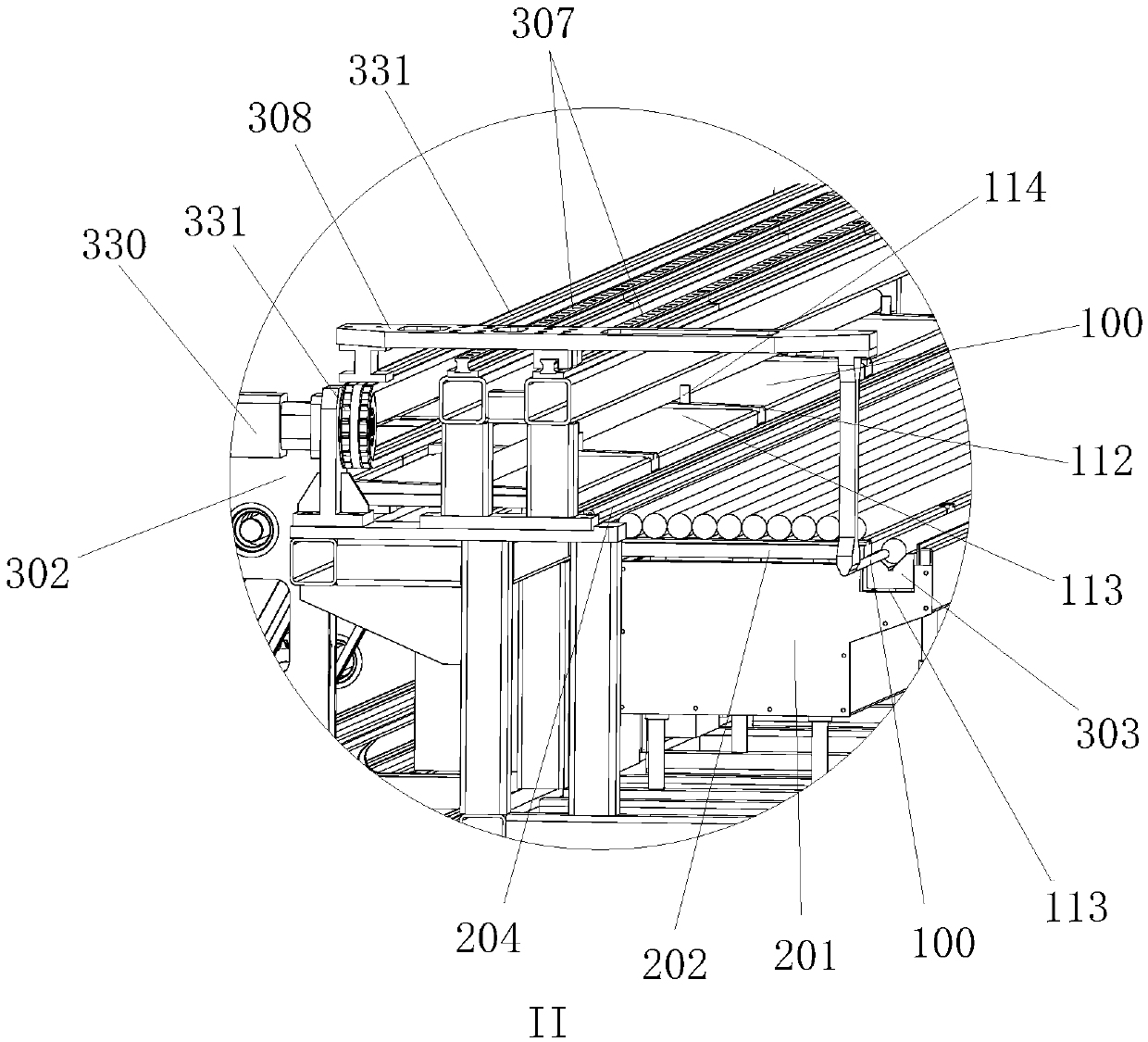

[0045] Such as Figure 1 to Figure 22 As shown, a bar processing control system includes a bar transportation system and a bar processing system, which is characterized in that: the bar transportation system includes a transportation device 100, a heating device 200, a feeding device 300 and a cutting device 400, and the copper rod passes through The transportation device 100 is transported to the heating device 200 for heating and then enters the feeding device 300 for feeding; the transportation device 100 includes a transportation platform 101 and a transportation mechanism, and the transportation platform 101 includes a lower support platform 102 on the left side and an upper support platform 103 on the right side; the transportation mechanism includes Drive shaft 104, driven shaft 105 and the transport chain 106 that connects drive shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com